Table of Content

1SAFETY PRECAUTIONS ..........................................................................................................................................3

2SPECIFICATIONS .....................................................................................................................................................4

2.1 Specification of Components.............................................................................................................................4

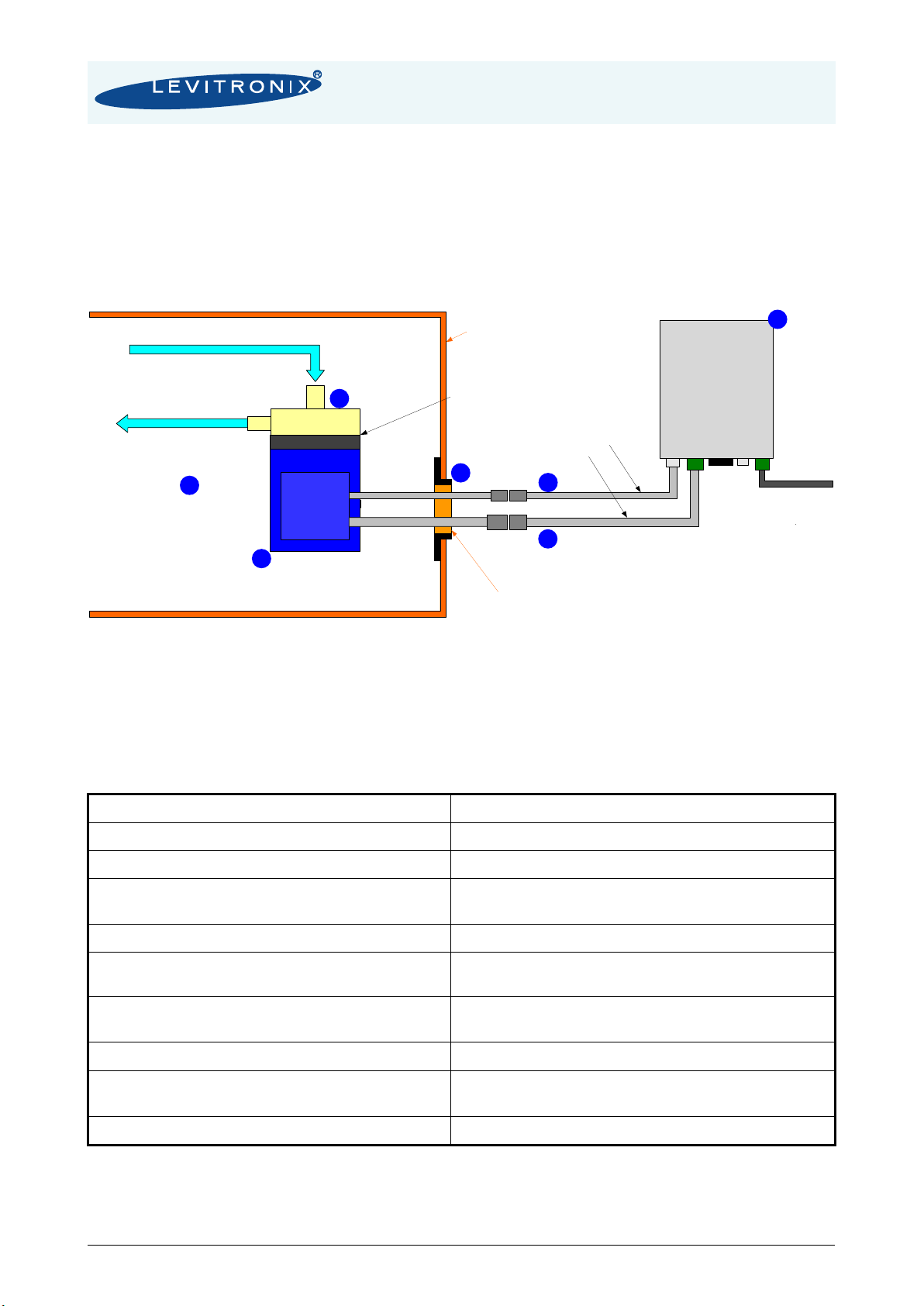

2.2 Standard System Configurations.......................................................................................................................6

2.3 General Environmental Conditions....................................................................................................................7

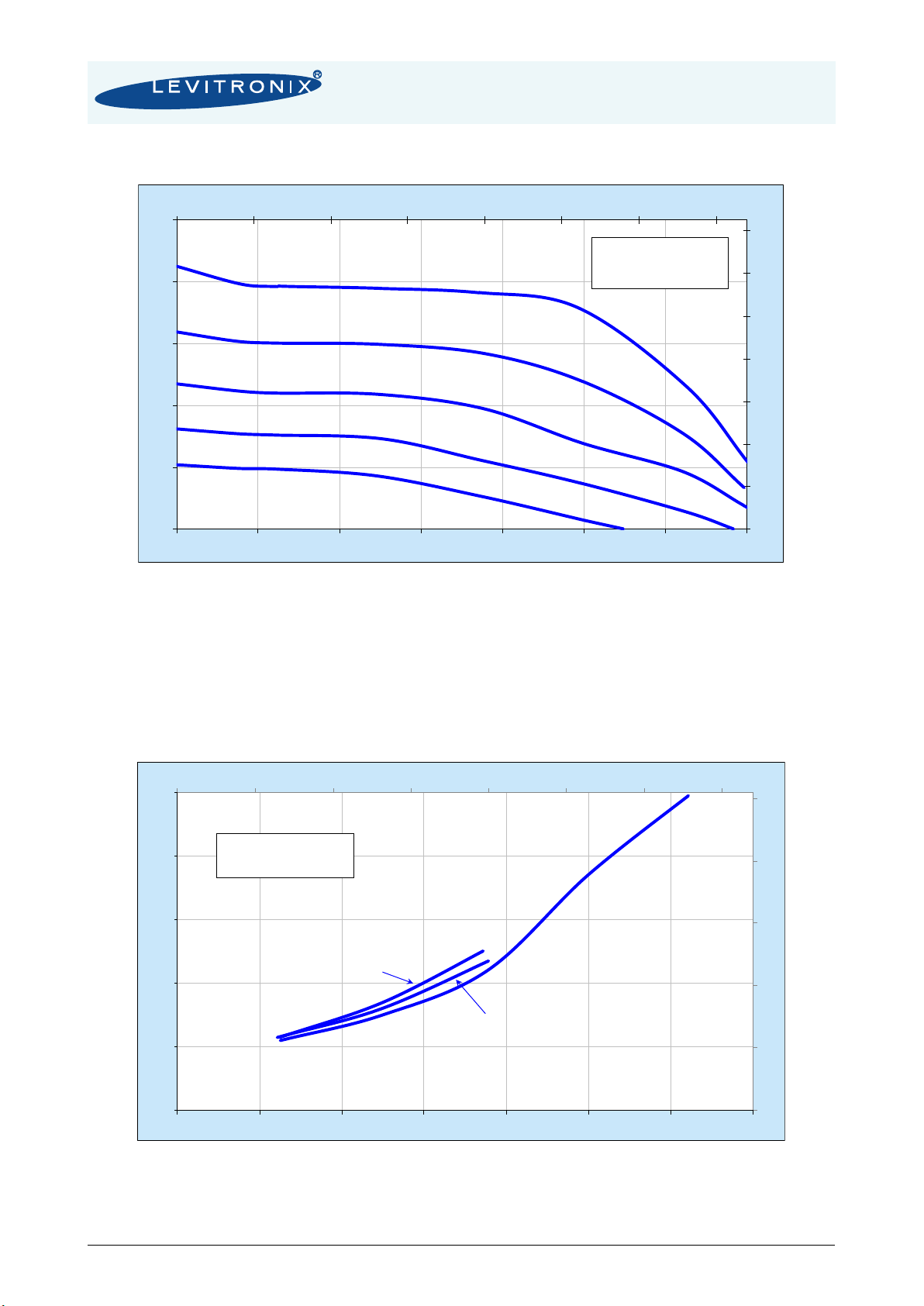

2.4 Pressure-Flow Curves.......................................................................................................................................8

2.5 NPSHr Curves...................................................................................................................................................8

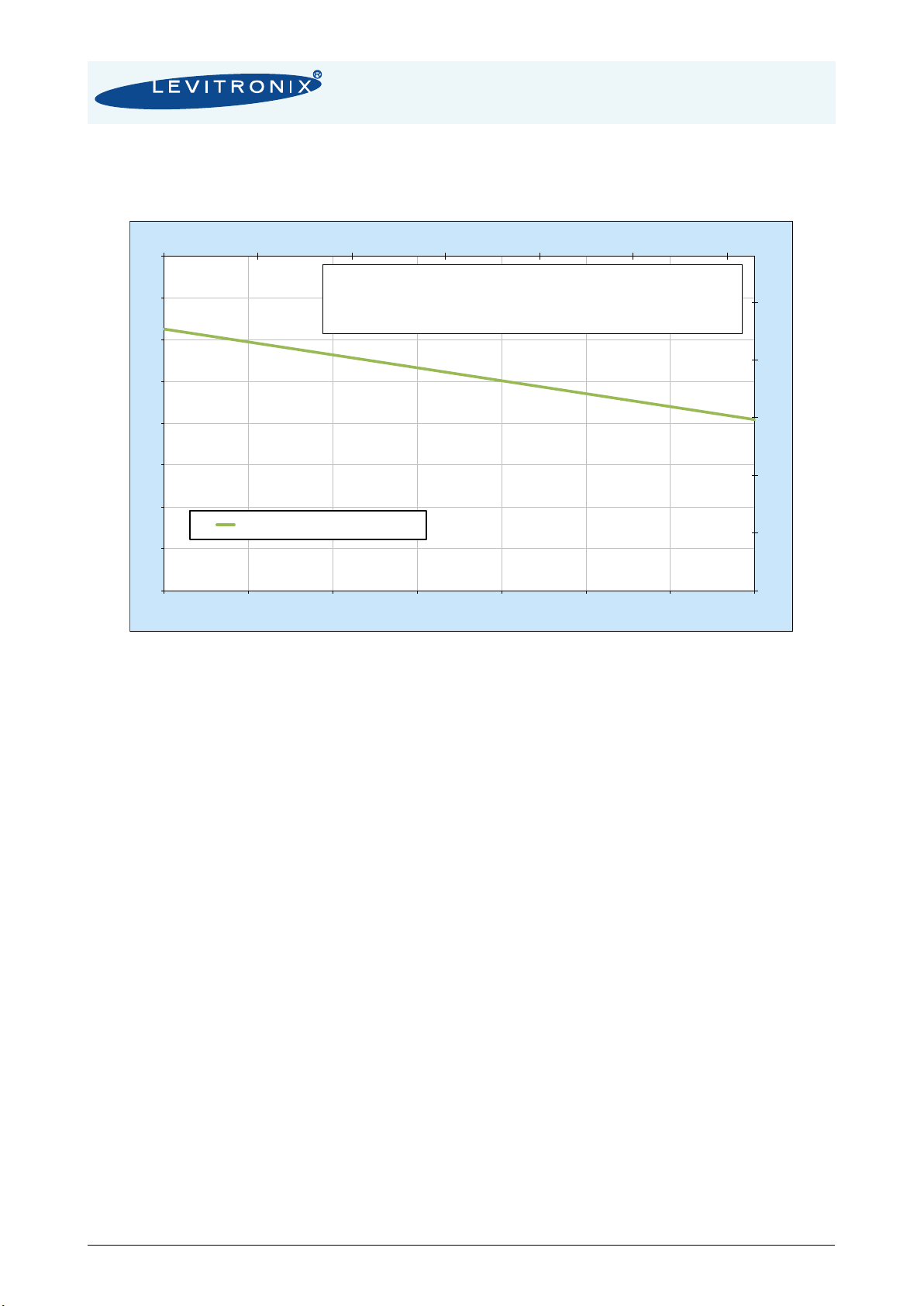

2.6 Maximum Static Pressure for Pump Heads.......................................................................................................9

2.7 Basic Dimensions of Main Components..........................................................................................................10

3ENGINEERING INFORMATION..............................................................................................................................12

3.1 Material and Sealing Concept..........................................................................................................................12

3.2 AC Supply and Power Consumption................................................................................................................13

3.3 Temperature Monitoring ..................................................................................................................................14

3.4 Thermal Management......................................................................................................................................15

3.5 Hydraulic Circuit Design ..................................................................................................................................19

4INSTALLATION.......................................................................................................................................................20

4.1 Electrical Installation of Controller....................................................................................................................20

4.2 Mechanical Installation of the Motor ................................................................................................................26

4.3 Mechanical Installation of the Controller..........................................................................................................28

4.4 Mechanical Installation of Adaptor/Extension Cables......................................................................................29

4.5 System Operation with LPC-2000.1 (Stand-Alone Version) ............................................................................30

4.6 System Operation with Controller LPC-2000.2 (PLC version) .........................................................................33

4.7 System Operation for ATEX / IECEx Applications...........................................................................................35

5INSTRUCTIONS FOR USE OF PUMP HEAD .........................................................................................................36

5.1 Description and Preparation ............................................................................................................................36

5.2 General Warnings and Cautions......................................................................................................................36

5.3 Mounting of Pump Head..................................................................................................................................37

5.4 Removal of Pump Head...................................................................................................................................37

5.5 Assembly into Circuit.......................................................................................................................................37

6TROUBLESHOOTING.............................................................................................................................................38

6.1 Troubleshooting for Operation with Controller LPC-2000.1.............................................................................38

6.2 Troubleshooting for Operation with Controller LPC-2000.2.............................................................................38

6.3 Troubleshooting with Levitronix®Service Software..........................................................................................38

7TECHNICAL SUPPORT ..........................................................................................................................................38

8APPENDIX...............................................................................................................................................................39

8.1 Regulatory Status............................................................................................................................................39

8.2 Symbols and Signal Words..............................................................................................................................42