Lewmar OCEAN & EVO® Electric/Hydraulic Winches ref B2303 Iss.14 | 9

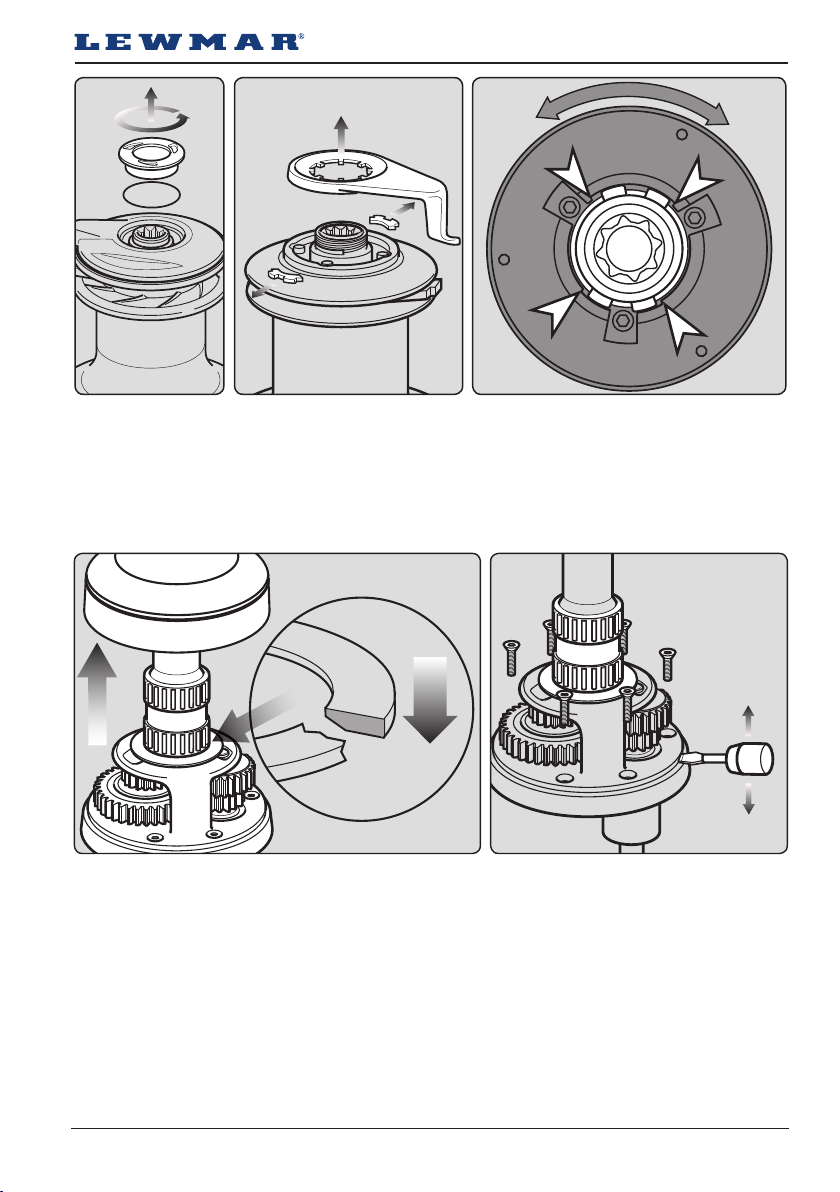

3.6-1

OCEAN EVO®

(x)

mm

(Min.)

(x)

inch

(Min.) Nm

40 40 30 1¼ 5 x M6 (¼”) 9

46-48 45-50 33 1⁵/₁₆ 5 x M8 (⁵/₁₆”) 21

50/54 55 33 1⁵/₁₆ 6 x M8 (⁵/₁₆”) 21

58 - 36 1⁷/₁₆ 5 x M10 (⅜”) 43

65 65 38 1½ 5 x M10 (⅜”) 43

68-77-88 70-80-90 31 1¼ 8 x M10 (⅜”) 43

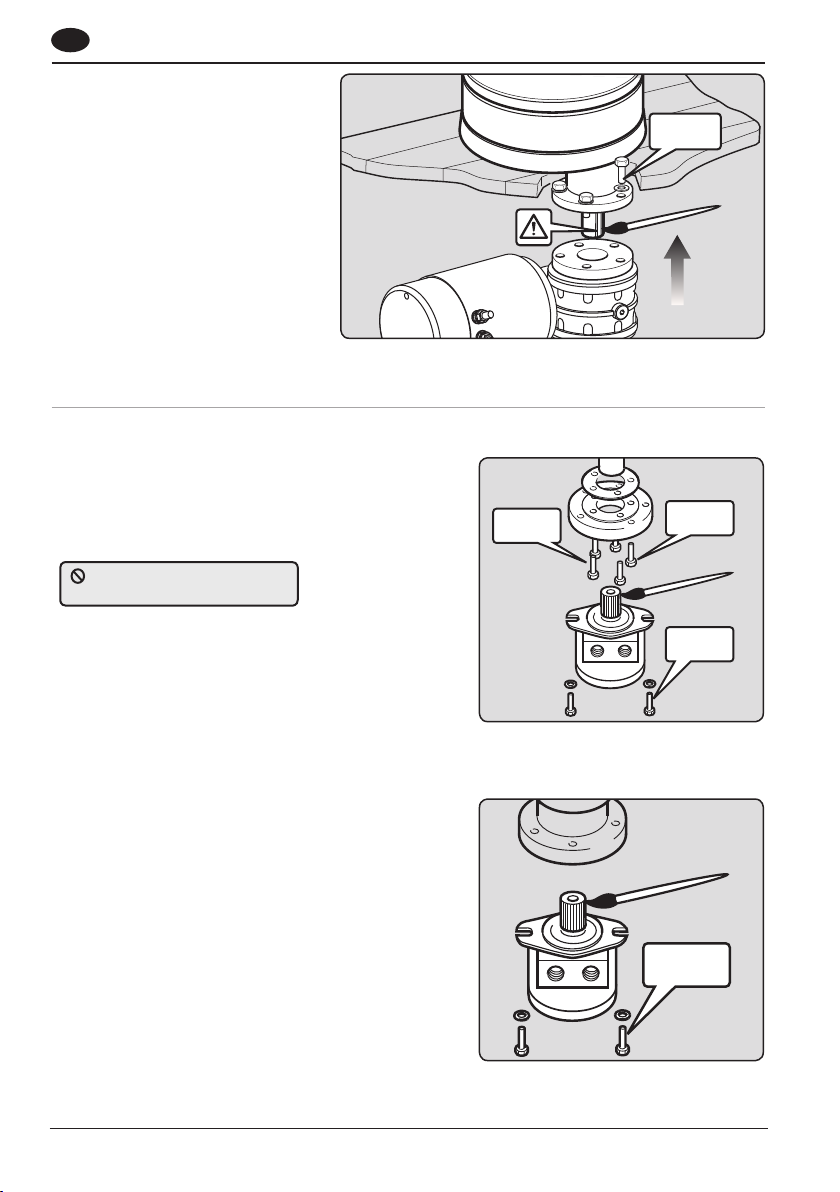

3.6-2

21 Nm

LOCTITE

®

#15

B0678 x 5

3.7-1

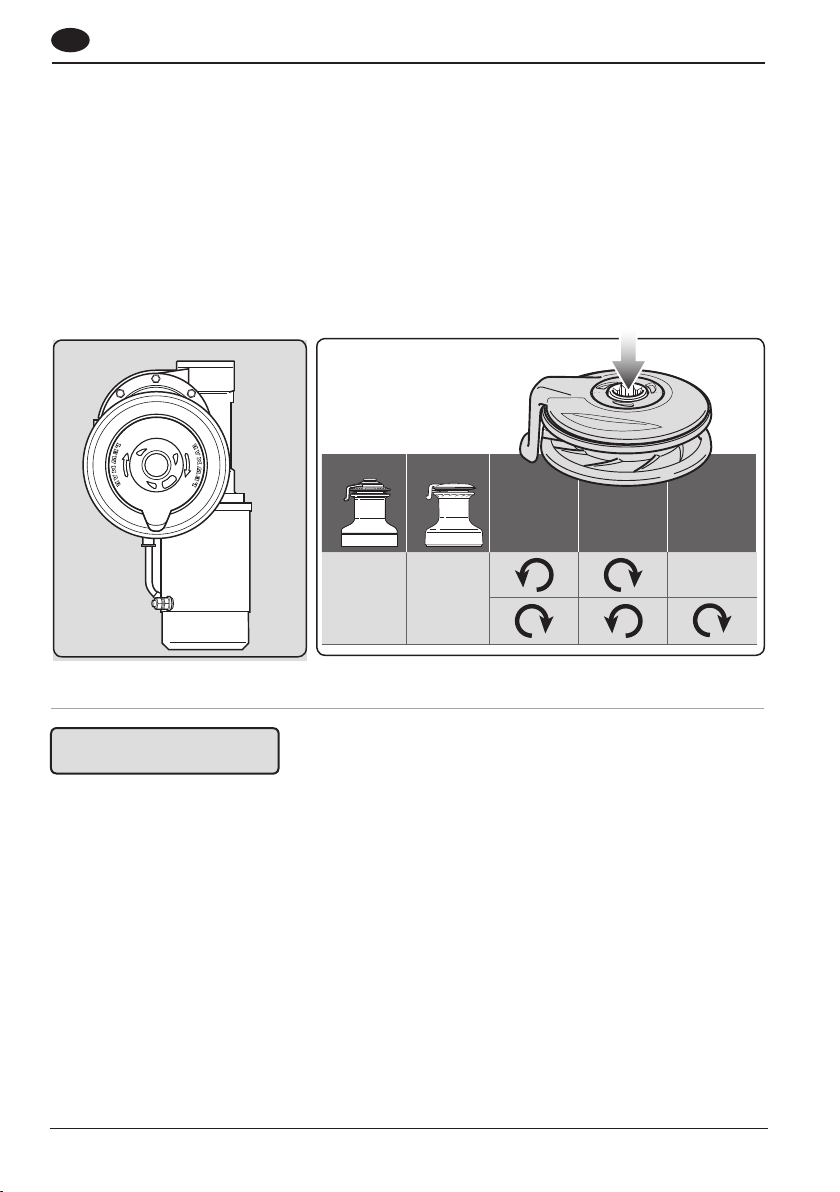

2. If a thick deck or increased motor/gearbox

distance from deck demands a greater ‘T’

dimension (see section 8). Optional extension

kits are available to special order, please

contact your nearest Lewmar office.

NOTE: Optional Lewmar “FAST FIT” studs screw

directly into the base of the winch without having to

remove the drum. Contact Lewmar for more details.

3.6 Fastenings

NOTE: Deck fastenings are not supplied.

1. Fix the winch to the deck using CSK Head, stainless steel washers and locknuts.

Use the table below to calculate the correct bolt length for your deck thickness.

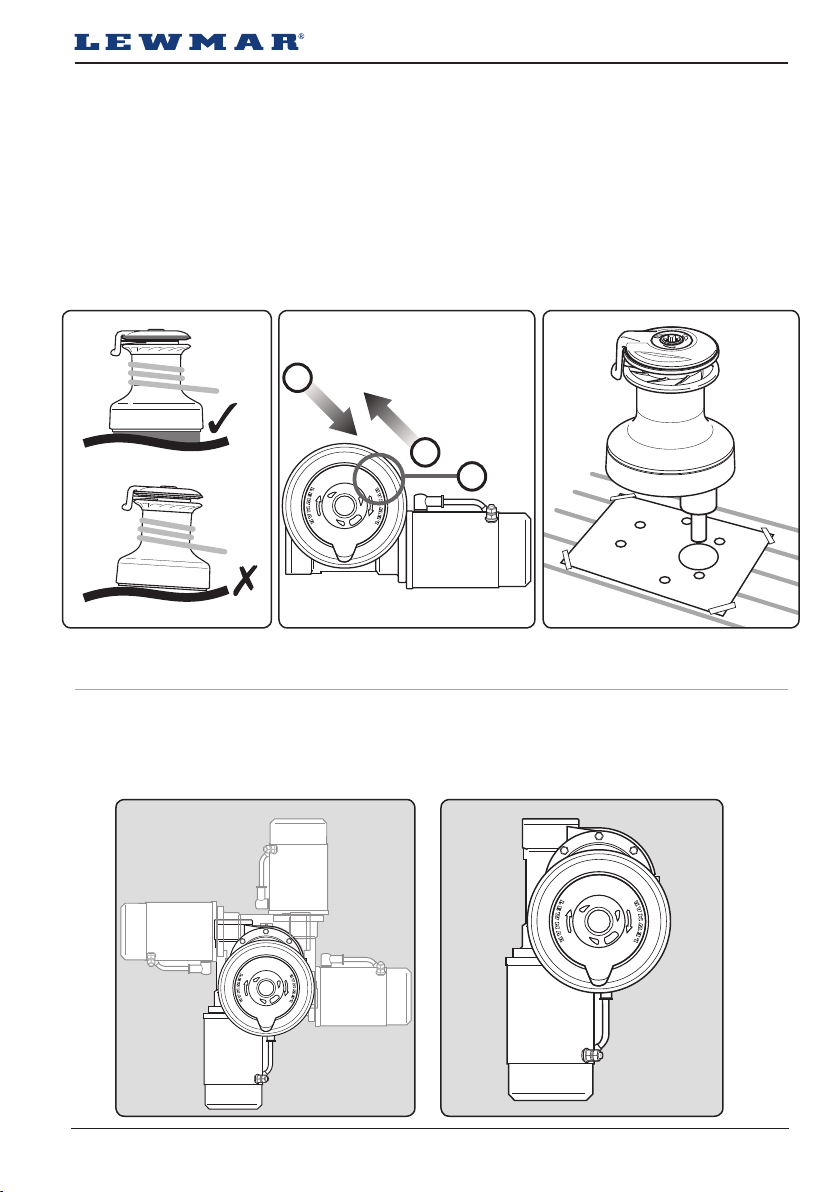

3.7 Electric winch motor/gearbox coupling

Winches 40-65

1. These winches require the base motor coupling

and shim to be fitted. Apply Loctite® threadlock

to coupling bolts (# 15), insert isolation shim and

secure to winch base plate. Assemble coupling

bolts and washers, apply Loctite® threadlock and

secure to 21Nm.

• Lightly coat the drive sha with grease. Ensure

the drive key is in place. Select the most suitable

position and slide motor/gearbox into position,

assemble bolts and washers, apply Loctite®

threadlock and secure to 43Nm.