ATTENTION

• Please read and understand entire manual,

including all safety information, before using

torque wrench. This tool is a precision

measuring instrument. Handle with care

and store properly. Do not attempt to

increase the leverage of this wrench with

any other device. Failure to follow all the

instructions could result in damage to

torque wrench, property damage, or

physical injury.

• At low torque settings, click might be

subtle; pull wrench slowly to observe click -

Learn to hear and feel the click.

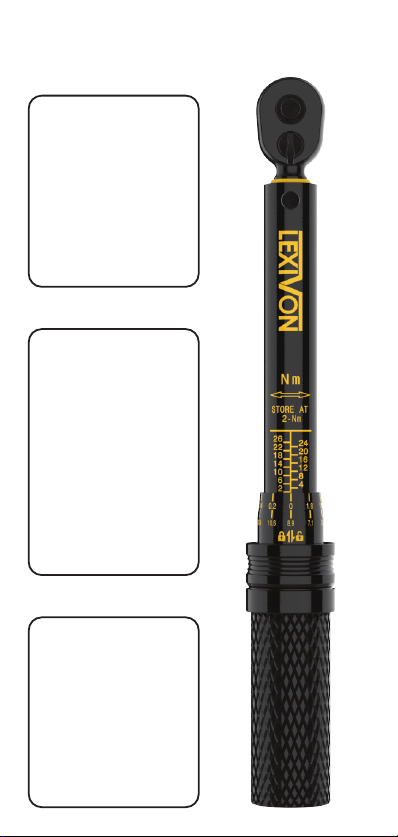

• Wrench is shipped ready to use, calibrated

and tested to an accuracy of +/- 4% in

CLOCKWISE direction and +/- 6% in

COUNTERCLOCKWISE direction. To

maintain this accuracy, it is crucial that the

wrench is stored at the lowest torque

setting, 2 Nm (17.7 in.-lb.). This setting

relieves extra tension on the internal spring,

reducing fatigue that can adversely affect

accuracy.