3

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

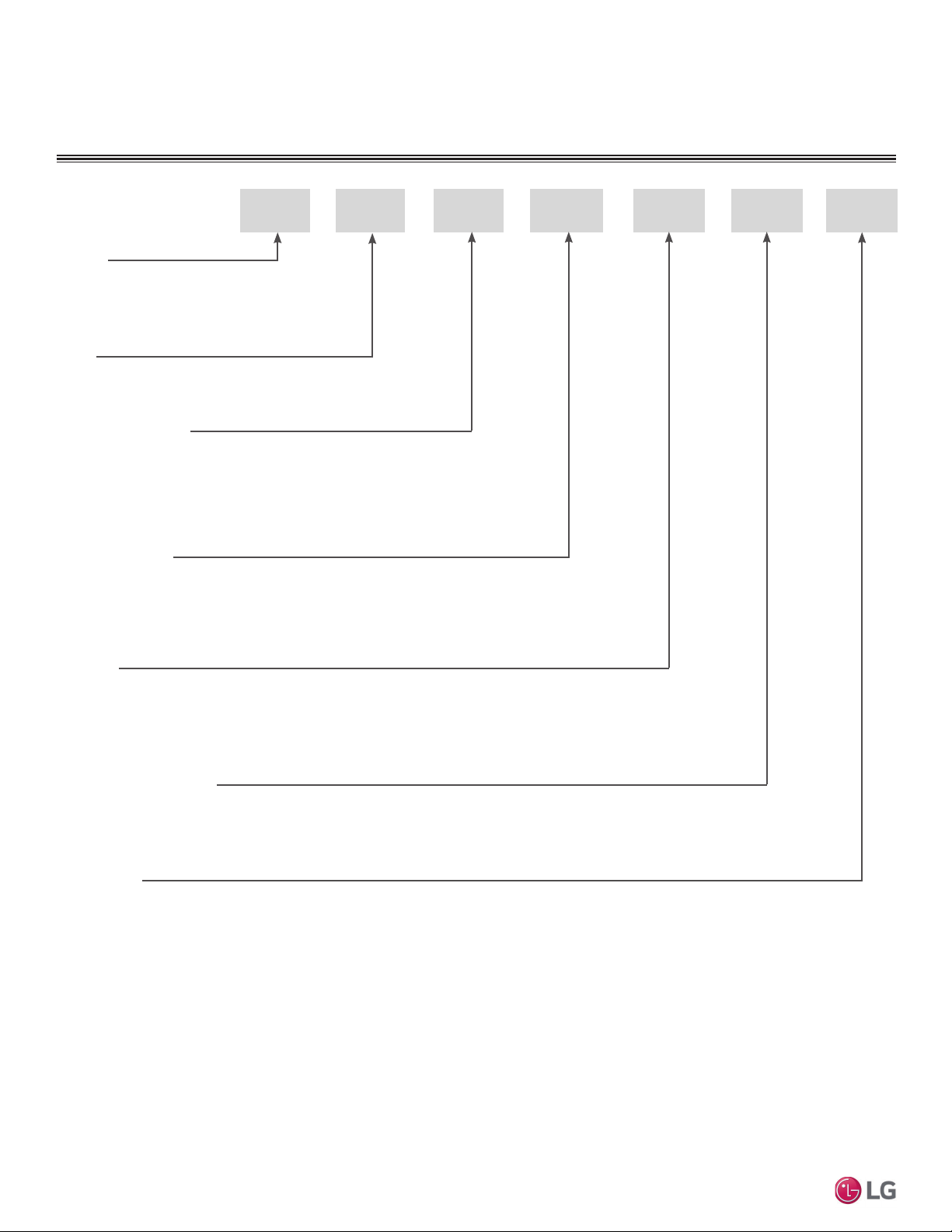

TABLE OF CONTENTS

Safety Precautions .............................................................................4-7

Unit Nomenclature................................................................................. 8

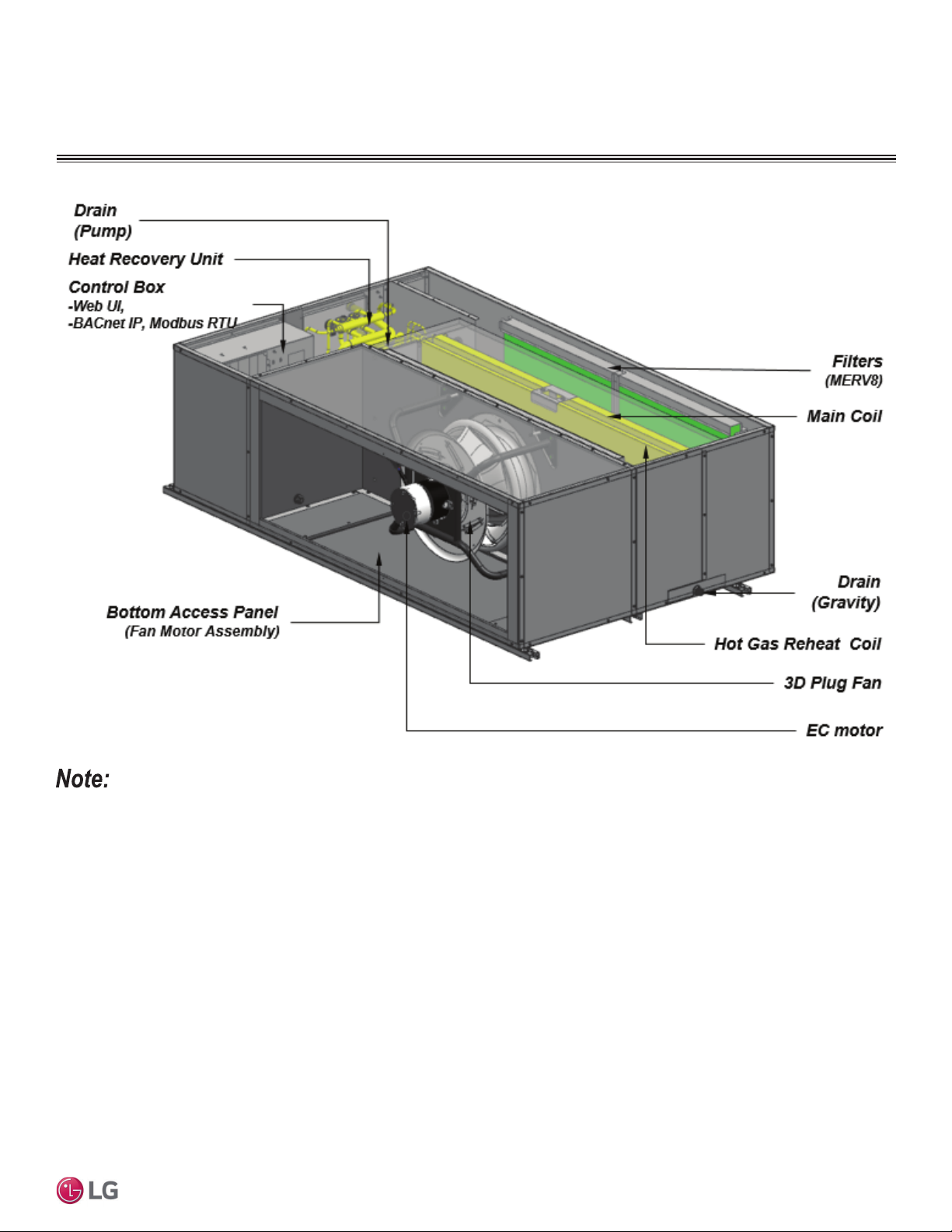

Product Overview.............................................................................9-10

Interior Components............................................................................ 9

Electrical Components....................................................................... 10

General Data ................................................................................... 11-20

6SHFL¿FDWLRQV .................................................................................... 11

Electrical............................................................................................ 12

External Dimensions.....................................................................13-14

Wiring ...........................................................................................15-16

Refrigerant Flow - Cooling................................................................. 17

5HIULJHUDQW)ORZ'HKXPLGL¿FDWLRQ .................................................. 18

Refrigerant Flow - Heating................................................................. 19

Sound Power Levels.......................................................................... 20

Installation.......................................................................................21-25

Receiving........................................................................................... 21

Handling ............................................................................................ 21

Storage / Removing........................................................................... 21

Assemblies ........................................................................................ 21

$LUÀRZ$UUDQJHPHQW .......................................................................... 21

Location Selection ............................................................................. 22

Roughing In ....................................................................................... 22

Mounting Dimensions........................................................................ 23

'XFWZRUN&RQ¿JXUDWLRQ ..................................................................... 23

Service Clearances ........................................................................... 24

Piping Connections............................................................................ 24

Field-Installed Outdoor Air (OA) Filter ............................................... 25

Unit Piping.......................................................................................26-31

Refrigerant Safety ............................................................................. 26

Piping Handling ................................................................................. 26

Brazing Procedure............................................................................. 27

Pipe Support Location ...................................................................... 27

Insulate.............................................................................................. 27

Condensate Drain Connections......................................................... 28

Condensate Pump Connection.......................................................... 28

Unit Drain Information........................................................................ 28

Gravity Condensate Pipe Connection ............................................... 29

Installing the Condensate Drain Pipe ................................................ 29

Refrigerant Piping Installation............................................................ 30

Refrigerant System Eng., Allowable Pipe Length.............................. 30

Sample Layout................................................................................... 31

Conditional Applications .................................................................... 31

Electrical Information.....................................................................32-39

General Information........................................................................... 32

Separating Power Wiring and Communication Cables...................... 32

Power Wiring ..................................................................................... 33

Communication Cable Connections .................................................. 33

Terminal Connections ........................................................................ 33

3RZHU6XSSO\3RZHU:LULQJ6SHFL¿FDWLRQV..................................... 34

Communication Cable Specs. from ODU to DOAS........................... 35

Connection Procedure....................................................................... 36

Field Wiring........................................................................................ 37

Field-Mounted Sensors ................................................................38-39

Leak Pressure Check / Evacuation...............................................40-44

Leak / Pressure Check .................................................................40-41

Ambient Conditions ........................................................................... 41

Evacuation....................................................................................42-44

Charging Refrigerant........................................................................... 45

Refrigerant Charge Worksheet.......................................................... 45

6WDUWXS&RQÀJXUDWLRQ ......................................................................... 46

Checks Before Initial Startup............................................................. 46

Electric Preheater Accessory........................................................47-63

Safety Precautions .......................................................................47-49

Overview............................................................................................ 50

General Data ..................................................................................... 51

Dimensions...................................................................................52-53

Wiring Diagram.............................................................................54-55

Installation Procedure...................................................................56-58

Sequence Setting .........................................................................59-63

Controller ........................................................................................64-85

Overview............................................................................................ 64

(OHFWULFDO6SHFL¿FDWLRQV..................................................................... 64

Connecting to the Web UI ................................................................. 64

Service Password ............................................................................. 65

Startup Settings................................................................................. 65

IP Address ......................................................................................... 65

DOAS Unit Address Setting............................................................... 65

Central Controller Setting .................................................................. 66

AC Smart / ACP Controller Setup.................................................67-68

%06&RQ¿JXUDWLRQ ............................................................................ 69

Main Control Board Terminal Connections ....................................... 70

CAREL Control Board Terminal Connections .................................... 70

LG Control Board Layout................................................................... 71

UI Module .......................................................................................... 72

NTC Module ...................................................................................... 73

EEV Module....................................................................................... 74

Navigation.....................................................................................75-77

Software Update................................................................................ 78

BACnet / Modbus Object List .......................................................79-85

Installation Checklist......................................................................86-87