Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

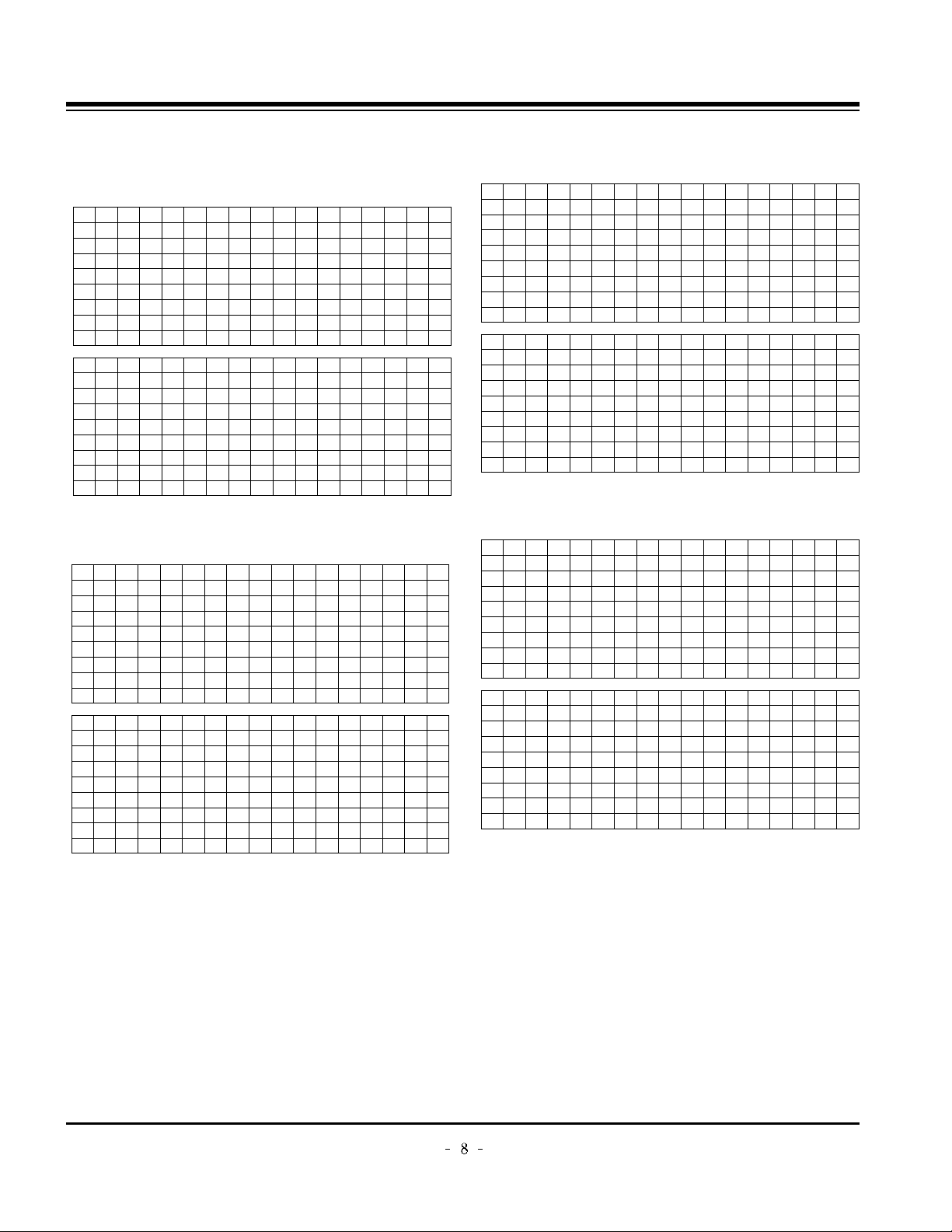

5-2. EDID DATA for PA75C

:EDID for HDMI-1 (DDC (Display Data Channel) Data)

EDID table =

:EDID for HDMI-2 (DDC (Display Data Channel) Data)

EDID table =

:EDID for HDMI-3 (DDC (Display Data Channel) Data)

EDID table =

:EDID DATA for RGB

EDID table =

ADJUSTMENT INSTRUCTIONS

0123456789ABCDEF

000FFFFFFFFFFFF001E6D010001010101

10 00 11 01 03 80 73 41 96 0A CF 74 A3 57 4C B0 23

20 09 48 4C AF CF 00 31 40 45 40 61 40 81 80 A9 40

30 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 36 00 C4 8E 21 00 00 1E 02 3A 80 18 71 38 2D 40

50 58 2C 45 00 C4 8E 21 00 00 1E 00 00 00 FD 00 30

60 58 1F 64 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 8A

0123456789ABCDEF

0020316F1478405030220221023150750

10 65 03 0C 00 10 00 01 1D 00 72 51 D0 1E 20 6E 28

20 55 00 C4 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20

30 58 2C 25 00 C4 8E 21 00 00 9E 8C 0A D0 8A 20 E0

40 2D 10 10 3E 96 00 C4 8E 21 00 00 18 8C 0A D0 8A

50 20 E0 2D 10 10 3E 96 00 13 8E 21 00 00 18 26 36

60 80 A0 70 38 1F 40 30 20 25 00 C4 8E 21 00 00 1A

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 10

0123456789ABCDEF

000FFFFFFFFFFFF001E6D010001010101

10 00 11 01 03 80 73 41 96 0A CF 74 A3 57 4C B0 23

20 09 48 4C AF CF 00 31 40 45 40 61 40 81 80 A9 40

30 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 36 00 C4 8E 21 00 00 1E 02 3A 80 18 71 38 2D 40

50 58 2C 45 00 C4 8E 21 00 00 1E 00 00 00 FD 00 30

60 58 1F 64 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 8A

0123456789ABCDEF

0020316F1478405030220221023150750

10 65 03 0C 00 20 00 01 1D 00 72 51 D0 1E 20 6E 28

20 55 00 C4 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20

30 58 2C 25 00 C4 8E 21 00 00 9E 8C 0A D0 8A 20 E0

40 2D 10 10 3E 96 00 C4 8E 21 00 00 18 8C 0A D0 8A

50 20 E0 2D 10 10 3E 96 00 13 8E 21 00 00 18 26 36

60 80 A0 70 38 1F 40 30 20 25 00 C4 8E 21 00 00 1A

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

0123456789ABCDEF

000FFFFFFFFFFFF001E6D010001010101

10 00 11 01 03 80 73 41 96 0A CF 74 A3 57 4C B0 23

20 09 48 4C AF CF 00 31 40 45 40 61 40 81 80 A9 40

30 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 36 00 C4 8E 21 00 00 1E 02 3A 80 18 71 38 2D 40

50 58 2C 45 00 C4 8E 21 00 00 1E 00 00 00 FD 00 30

60 58 1F 64 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 8A

0123456789ABCDEF

0020316F1478405030220221023150750

10 65 03 0C 00 30 00 01 1D 00 72 51 D0 1E 20 6E 28

20 55 00 C4 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20

30 58 2C 25 00 C4 8E 21 00 00 9E 8C 0A D0 8A 20 E0

40 2D 10 10 3E 96 00 C4 8E 21 00 00 18 8C 0A D0 8A

50 20 E0 2D 10 10 3E 96 00 13 8E 21 00 00 18 26 36

60 80 A0 70 38 1F 40 30 20 25 00 C4 8E 21 00 00 1A

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 F0

0123456789ABCDEF

000FFFFFFFFFFFF001E6D010001010101

10 00 11 01 03 18 73 41 96 0A CF 74 A3 57 4C B0 23

20 09 48 4C AF CF 00 31 40 45 40 61 40 81 80 A9 40

30 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 36 00 C4 8E 21 00 00 1A 02 3A 80 18 71 38 2D 40

50 58 2C 45 00 C4 8E 21 00 00 1E 00 00 00 FD 00 30

60 58 1F 64 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 F6

0123456789ABCDEF

0020304000E1F008051001E3040803700

10 C4 8E 21 00 00 1C F1 27 00 A0 51 00 25 30 50 80

20 37 00 C4 8E 21 00 00 1C 00 00 00 00 00 00 00 00

30 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

40 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

50 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

60 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 31