- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

X-RAY Radiation

Warning:

To determine the presence of high voltage, use an accurate

high impedance HV meter.

Adjust brightness, color, contrast controls to minimum.

Measure the high voltage.

The meter reading should indicate

23.5 ±1.5KV: 14-19 inch, 26 ±1.5KV: 19-21 inch,

29.0 ±1.5KV: 25-29 inch, 30.0 ±1.5KV: 32 inch

If the meter indication is out of tolerance, immediate service

and correction is required to prevent the possibility of

premature component failure.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc.,

to be sure the set is safe to operate without damage of

electrical shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on position, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

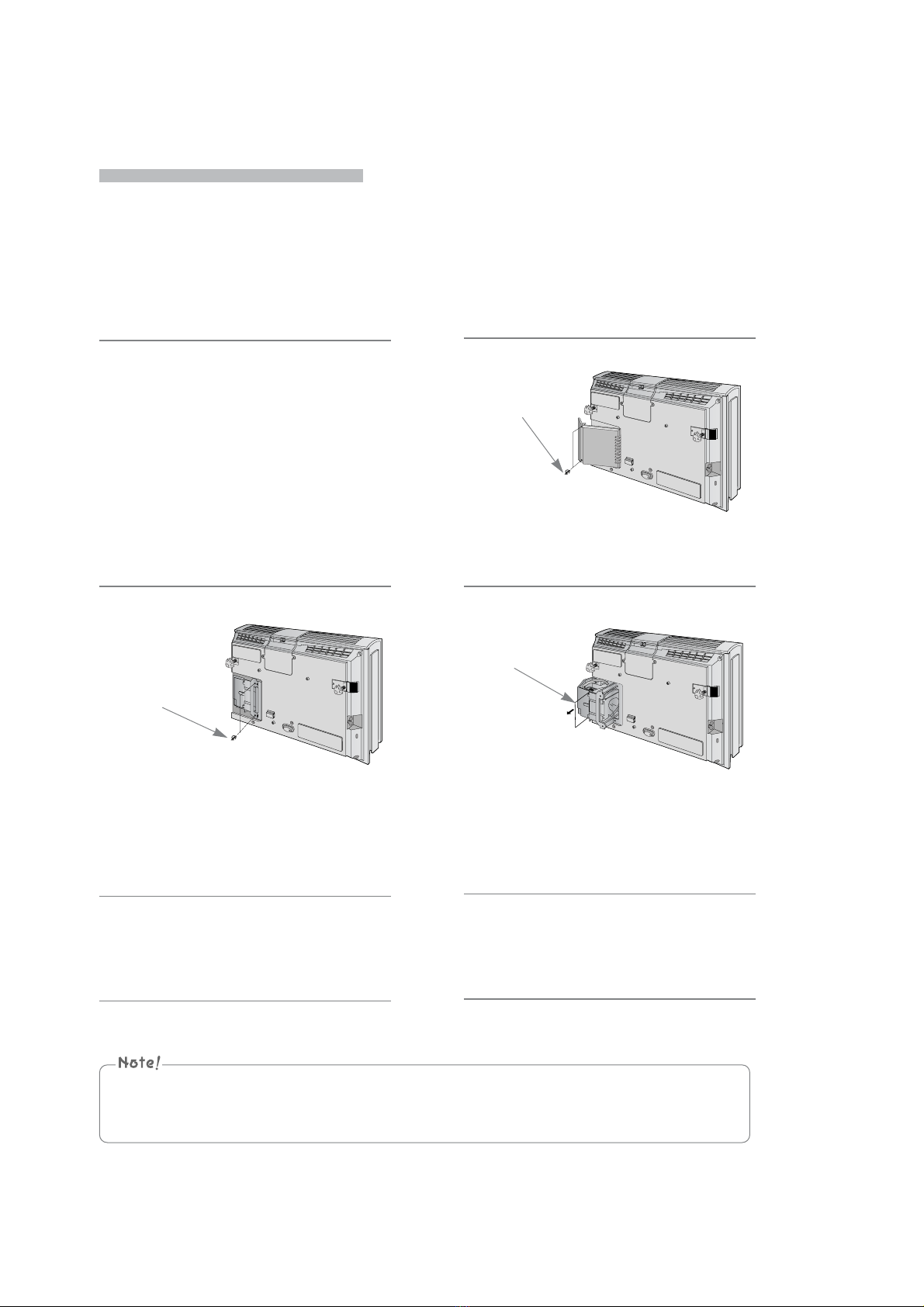

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each exposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

The source of X-RAY RADIATION in this TV receiver is the

High Voltage Section and the Picture Tube.

For continued X-RAY RADIATION protection, the

replacement tube must be the same type tube as specified in

the Replacement Parts List.