6 | EN Copyright © Liberty Pumps, Inc. 2020

All rights reserved. 5755000K

Do not use an extension cord to power the product.

Extension cords can overload both the product and extension

cord supply wires. Overloaded wires will get very hot and can

catch on fire.

Explosion hazard during installation. PVC cleaners, primers,

and cements can release explosive vapors. These

heavier-than-air vapors can accumulate in the tank. The heat

of soldering or sweating copper or other metal pipe can

ignite these vapors causing a violent explosion. If the unit is

to be connected to copper discharge or vent piping, all

solvent-welded PVC joints must be allowed to cure a

minimum of 24 hours. The access cover must be removed to

allow the tank to be thoroughly ventilated prior to sweating

copper pipe near the unit.

Do not modify the pump/pump system in any way.

Modifications may affect seals, change the electrical loading

of the pump, or damage the pump and its components.

All pump/pump system installations shall be in compliance

with all applicable Federal, State, and Local codes and

ordinances.

Macerating unit must be located on same floor as connecting

fixtures.

Layout: The bathroom layout should be designed prior to

installation. Make certain the power source (GFCI receptacle) is

within range of the macerator’s 8 ft power cord. The GFCI

receptacle shall be 40 inches away (in a straight line) from a

shower or bathtub. For basement installation, the receptacle shall

be 48 inches from the floor.

Power Cord: The power cord can be configured to exit the unit on

either the left or right side. If the power cord will exit the left side

of the macerator, the vent flange must be removed so the cord

can be routed between the positioning clips. Reinstall vent flange

after routing the cord. Do not use an extension cord. If the

electrical power receptacle (outlet) is in close proximity to the

macerator, any extra power cord can be coiled and tucked away in

the access cover located under the right decorative cover.

Easy Access: The unit should be accessible and removable in the

event of required maintenance. During installation, a full port ball

valve should be installed near the discharge flange to allow easy

service of the unit. If possible, the right side of the macerator

should remain unobstructed. The access cover allows access to

the internal mechanisms. In the event of a jam, the decorative

cover as well as the access cover will need to be removed from the

macerator and working room to do so would be beneficial.

Water Supply: The water supply line for the toilet tank is located

on the left side. When roughing in, allow for the macerator.

Discharge: Never discharge directly into an open drain, fixture,

manhole or rainwater drainpipe. It is illegal, as it constitutes a

health hazard. Only direct connections into sanitary waste systems

shall be acceptable.

Auxiliary Ports: Auxiliary inlet ports are located on either side

toward the back of the macerator tank. These ports can accept

waste from sink or tub/shower. A sink should be plumbed into

one of the auxiliary inlets and not the discharge line of the

macerator even if elevations would allow such an installation. The

discharge line is pressurized and the plumbing system needs to

accommodate this.

Freezing: Ensure all pipework susceptible to freezing is adequately

insulated or heated. In unheated buildings, the toilet, piping, and

macerating unit must be properly winterized. Use plumbing

antifreeze or drain completely. The battery should also be

disconnected.

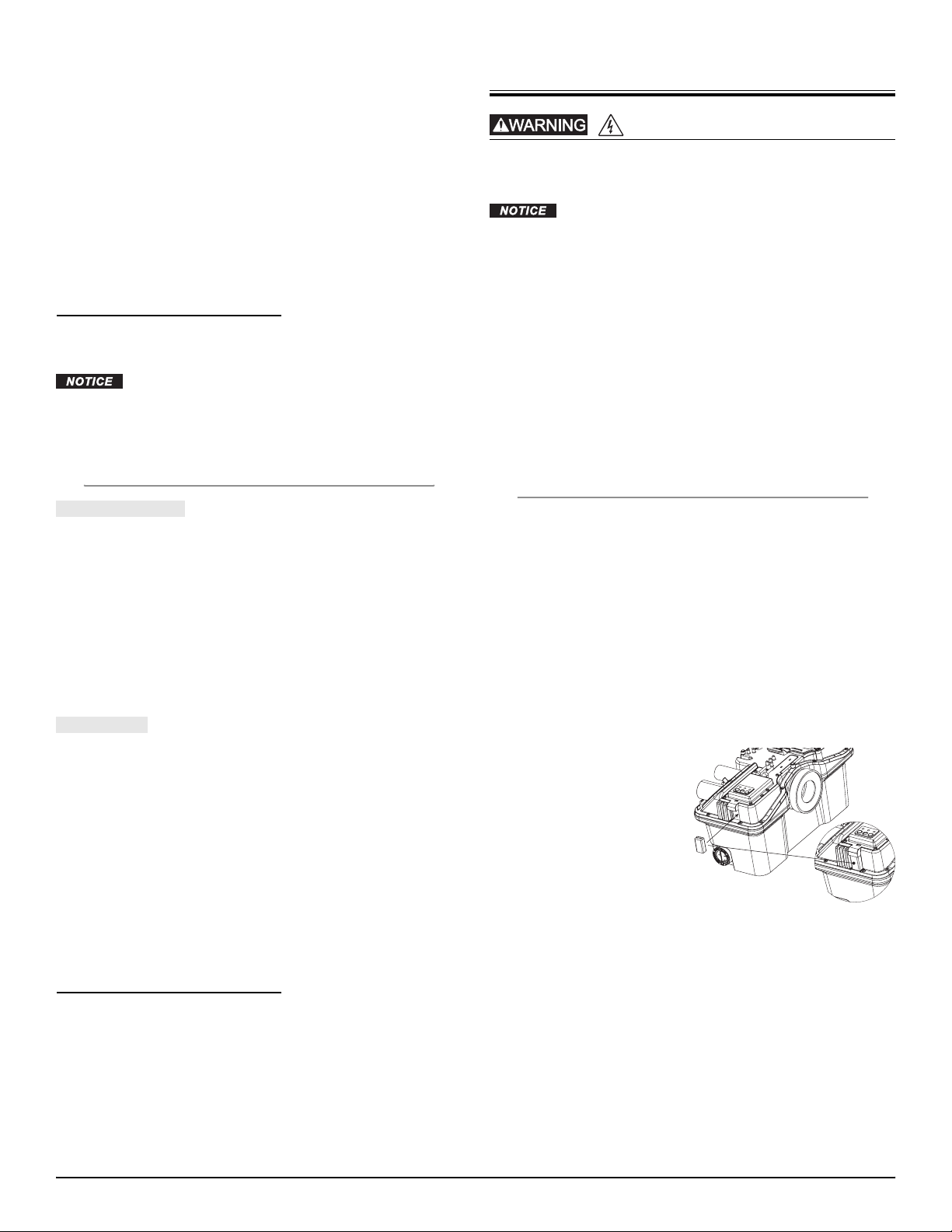

Discharge Extension: An optional discharge extension [P/N

K001184 sold separately] allows the macerator to be positioned

behind a wall. For example, the macerator could be positioned on

the floor of a linen closet or utility room. Do not fully frame unit

into a wall as access to macerator must be maintained.

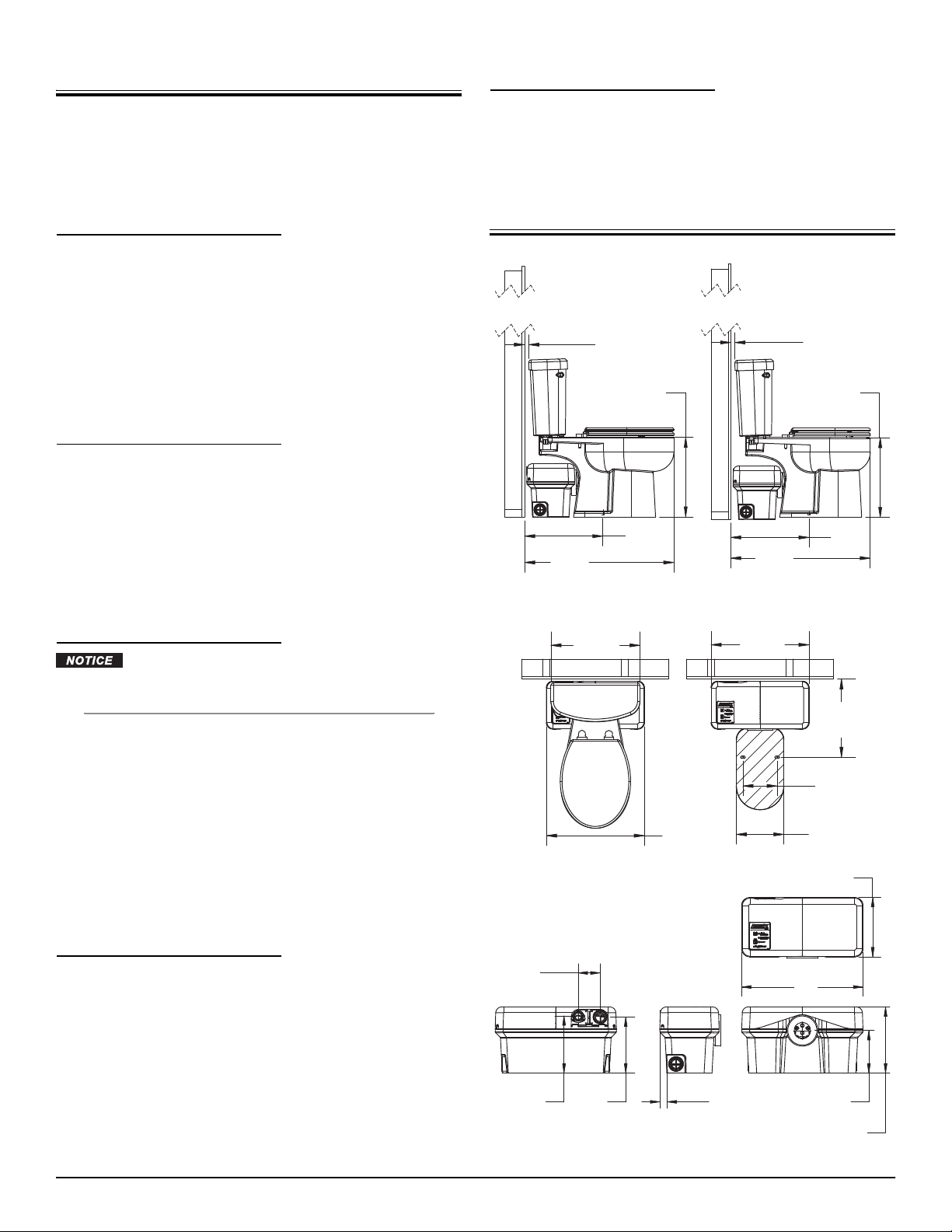

Toilet Placement: The toilet hold down fasteners should be

located 16 inches from the wall and spaced 7 inches apart. This

assumes a typical baseboard of 3/4” x 5-1/2” with 3/4” quarter

round. Actual baseboard dimensions must be taken into account

during the installation and thus rough-in dimensions may change.

Tub/Shower: Water height will be 4½ inches in the macerator

tank before the unit starts pumping. A shower stall floor must be

well above this level. Liberty Pumps recommends at least 6–8

inches to ensure proper shower drainage and prevent any

backflow.

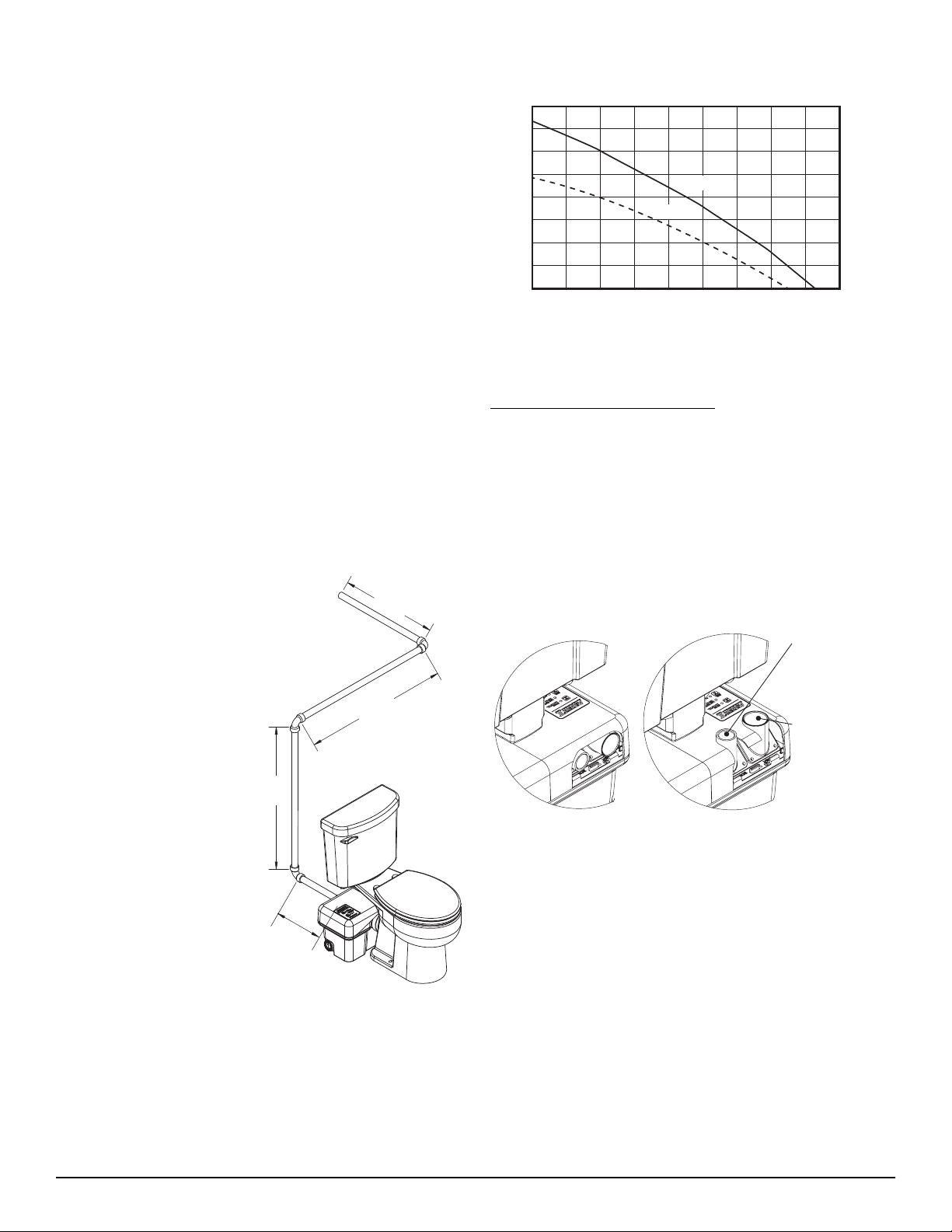

Figure 1. Typical Applications

Pipework: All pipework should be copper, PVC, or CPVC. Do not

use flexible piping. Support hangers should not be less than 4 ft

apart to prevent pipe rattling.

Pipe Supports: All sanitary pipework must be supported in

accordance with the pipe manufacturer’s recommendations.

Avoid dipping or trapping, which may cause the buildup of

residual solids and subsequent blockage.

Bends: Wherever possible, long sweeping bends should be used.

Do not use short elbows. If sweeping 90° elbows are not available,

use two 45° elbows to make a 90° turn.

Shut-off Head: The macerator has a shut-off head of 36 ft. All

frictional losses from horizontal runs and elbows need to be

accounted for. The minimum flow rate for 1” PVC Schedule 40

pipe is 5 gal/min compared to 3 gal/min for 3/4” PVC pipe.

RISK OF FIRE

RISK OF SERIOUS INJURY OR DEATH

Tub/shower should be installed on

a riser to accommodate the p-trap.

All fixtures must be properly vented per applicable local plumbing code.