CONTENT

1 Precautions............................................................................................. 1

2 Product Introduction.............................................................................. 3

2.1 Overview...................................................................................... 3

2.2 Technical Parameter................................................................4

2.2.1 General Parameter......................................................... 4

2.2.2 Performance Parameter.................................................5

2.2.3 Installation Drawing.........................................................5

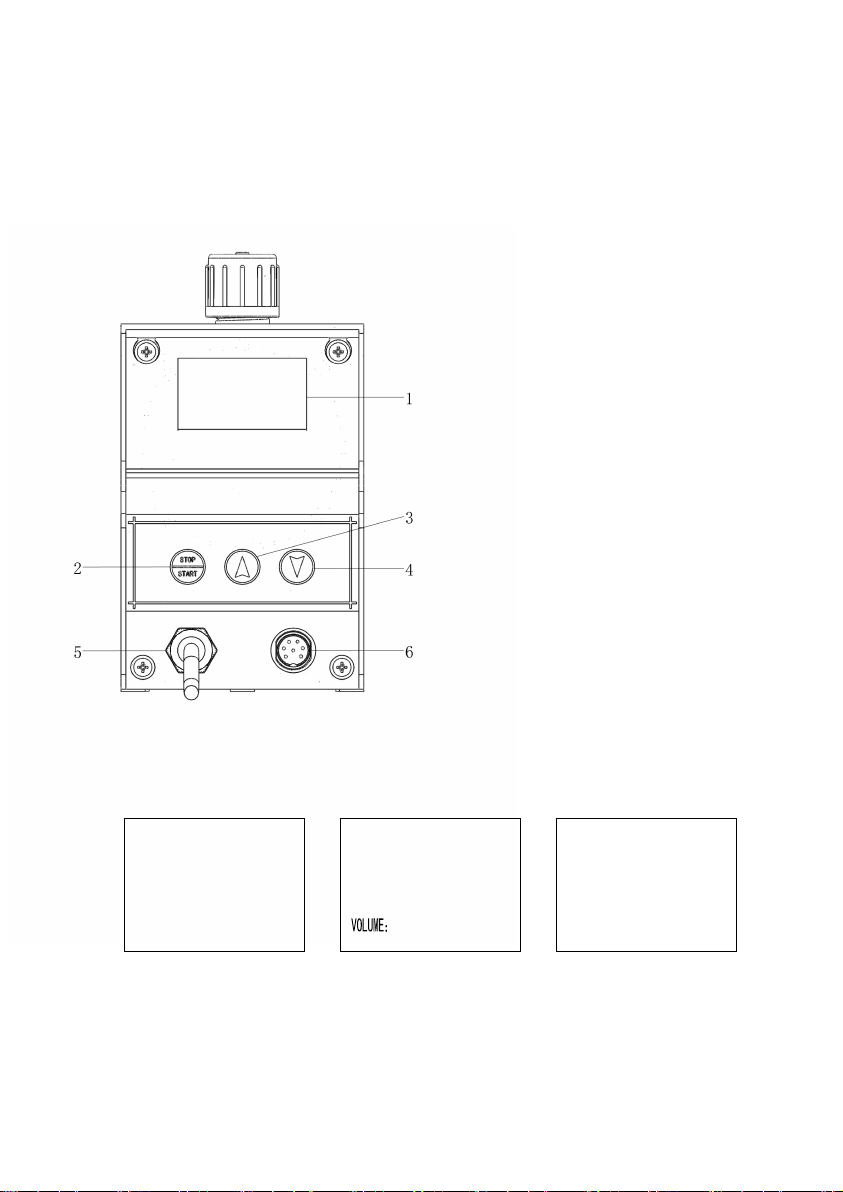

2.3 Operation Instruction..................................................................6

2.4 Unpacking Check List........................................................................ 7

3 Installation............................................................................................... 8

3.1 Pump Installation........................................................................ 9

3.2 Tubing Connections................................................................. 14

3.3 Food Valve and Suction Tubing Installation......................... 14

3.4 Injection Valve and Discharge Tubing Installation.............. 15

3.5 Air Release Valve Installation................................................. 16

4 Operation and Setting......................................................................... 17

4.1 Start-Up and Priming............................................................... 17

4.2 Setting.........................................................................................18

4.3 Signal Connector Description......................................................... 27

4.4 Calibration..................................................................................27

5 Maintenance and Repair.....................................................................29

5.1 Maintenance.............................................................................. 29

5.2 Diaphragm Replacement........................................................ 30

5.3 Check Valves Replacement....................................................33

6 Troubleshooting.................................................................................... 34

7 Main Parts List...................................................................................... 36

Appendix................................................................................................... 39