Actual product characteristics may vary

www.lightculture.com.au

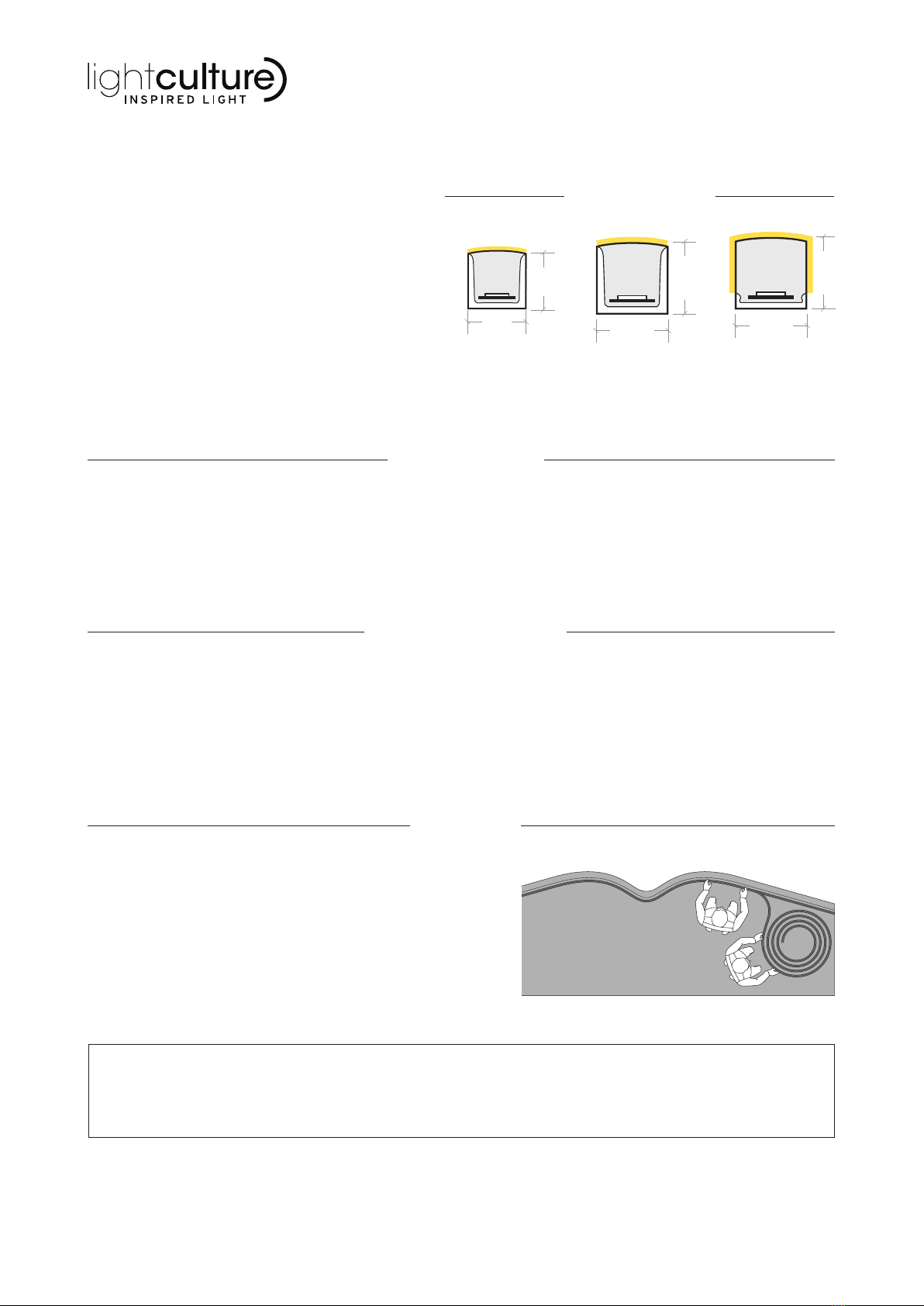

NEON MICRO Y NEON Y NEON Y3

HANDLING

GENERAL INFO

ELECTRICAL SAFETY

NEON Y MODELS

NEON Y | INSTALLATION INTRO

16.5

16.5

13.5

13.5

16.5

16.5

1/8

This installation guide is for Neon Y, Neon Micro Y &

Neon Y3. LED Neon Y is a vertical bending and highly

durable linear LED product suitable for both indoor and

outdoor applications. This installation guide is divided

into four sections:

-INTRO

- CORES & WIRE CONNECTION REFERENCE

(wiring diagrams on specication sheets)

- PRODUCT PHYSICAL PARAMETERS

- INSTALLATION & MOUNTING

This user manual is intended to cover as much detail as possible for this product, and great care has been taken to ensure this and the accuracy of

the information contained within, however should additional information or clarication be required that is not covered within this manual or associated

data sheets, or if there are any uncertainties regarding the installation and operation of this product, Distributor MUST be contacted before any work is

carried out on the xture or associated products.

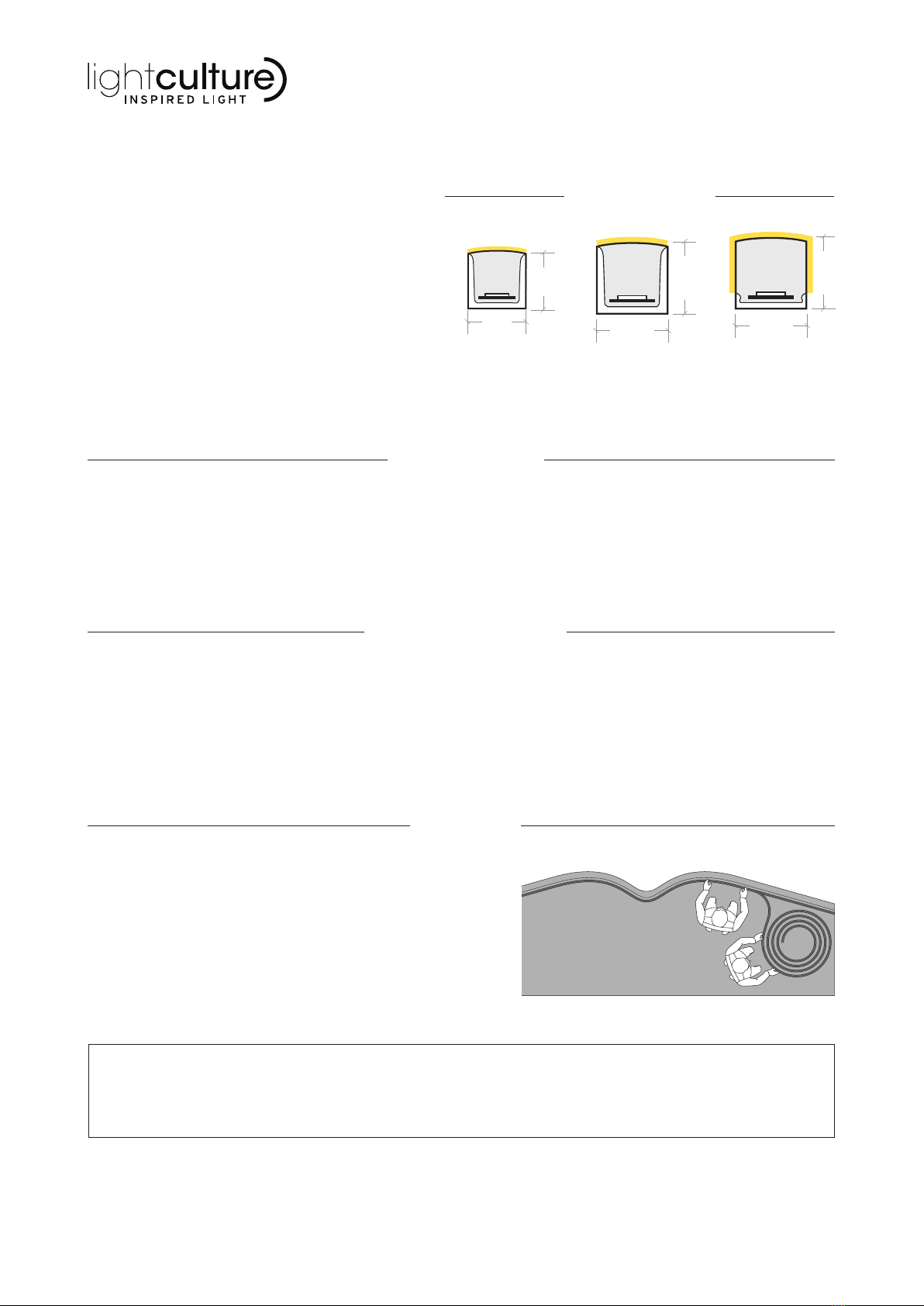

LED Neon must be installed by at least 2 people, who can support the

product in various locations as shown. During installation, care should

be taken to ensure the bending radius of is not exceeded.

When transporting the product, it is advisable to use the original

packaging in which the product left the factory.

Do not roll out the product onto rough surfaces or over sharp corners.

This will scratch the PVC optics and damage the finish of the product.

Do not power the product whilst in packaging.

Note: Other models may have different parameters,ensure

you have the correct installation guide for your model.

FAILURE TO COMPLY WITH THIS MANUAL AND LOCAL ELECTRICAL AND CONSTRUCTION REGULATIONS MAY RESULT IN SERIOUS INJURY

OR EVEN DEATH - ALWAYS ISOLATE POWER BEFORE WORKING ON ELECTRICAL PRODUCTS AND ENSURE ADEQUATE MEASURES ARE

TAKEN TO MECHANICALLY SUPPORT FIXTURES AT ALL TIMES.

- This product must be installed by a qualied

and competent professional.

- Always disconnect the power supply before

attempting to maintain or service the

equipment.

- Do not work on the product with wet hands.

- Make sure that all parts of the equipment are

kept clean and free of dust which should be

carried out as part of a maintenance cycle

that’s appropriate for the installation location

of the product.

- The lamp (LED) should be changed if it has

become damaged or thermally deformed.

- Do not power the product if :

- The outer PVC jacket is damaged

- There are loose electrical connections

- The wires are visible without insulation.

- Do not stare directly into the LED light

source.

- Always disconnect the power supply before

attempting to maintain or service the

equipment.

- The Earth wire MUST ALWAYS be

connected.

- Local electrical and building regulations must

be followed.

- Do not power the product whilst in

packaging.

- Always make sure that the power and data

connections are connected correctly and

securely.

- The power supply (PSU), DMX/RDM driver

and LED drivers should be changed if they

fail to operate.

- Do not cut while the LED ex neon is

connected to power.

- Do not reverse polarity when connecting

from both ends. This will damage the internal

PCB. Always test connections with a multi-

meter before applying power.

- Must always be used with an electrical

isolation transformer providing SELV (safety

extra low voltage).