Ligoo EK-YT-21 User manual

EK-YT-21 BMS

- 0 -

Prominent Advantages

EK-YT-21 BMS

- 1 -

Foreword

Foreword

Thank you very much for choosing our EK-YT-21 BMS (BMS: Battery Management System). In order to help you install,

use and maintain the product better, please read our user manual (hereinafter referred to as manual) carefully before installing

and using it.

EK-YT-21 BMS is a new generation of BMS specially developed for light cars, mini-cars, space vehicles and electric

motorcycles. Because of the low working voltage of light cars, mini-cars, space vehicles system, less strings of battery pack

can meet the requirement of the system. Due to limited total volume, the electric motorcycles require a kind of BMS with

smaller volume, more functions and more stable performance.

EK-YT-21 BMS can also be applied to forklift trucks, road sweepers and other special vehicle as emergency power supply

for communication base station BMS etc.

With unique design structure of collection and control in collection, EK-YT-21 BMS reduced its volume greatly, lower the

requirement for installation space; its high integration degree of the system makes wiring installation more concise .

EK-YT-21 BMS also provides communication mode of CAN Bus, RS485 Bus, and perfect balance failure protection and

balance control strategy.

1.1 Suggestion

This manual contains important information that the users must grasp, if customers are not in strictly with the manual

direction to install, use and maintain the product, our company would not take any relevant consequence and responsibility.

1.2 Qualifications and Relevant Certificates of Company

1.3 Statement

To ensure the accuracy, this manual has been validated and rechecked.The description and direction of EK-YT-21 BMS in

this manual is correct ,but because of technical improvements, the EK-YT-21 BMS and the manual may change without prior

notice.

EK-YT-21 BMS

- 2 -

Prominent Advantages

Prominent Advantages of EK-YT-21BMS

Power Function

System integration of voltage, current, temperature

and other battery information collection functions,

integrated SOC estimation, battery balance, data

storage and other ancillary functions, support CAN

Bus, 485 Bus communication, relay control, stem

node control and other management features,

function is powerful

High Reliability

Adopting multiple power isolation plans in order to

greatly increase reliability of the system sampling and

communication; high redundancy design of circuit

enhance the stability of system; unique balance

failure protection to ensure the balance function in

stable state; protection circuit design for each of the

power supply output interface, effectively improve

fault tolerance of the system; passed EMC test,

insulation resistance, pressure-proof, high and low

temperature aging, waterproof, dustproof and

vibration experiment to ensure the system is in

reliable operation.

Easy Installation

Unique integration design of detection and

management integrates the collection system and

control function in one module, only 4 interfaces

achieve a variety of collection, detection,

communication and control functions, greatly reduces

the complexity of system connection, improves

efficiency of the product installation, commissioning

and maintenance convenience.

Small Volume

Highly integrated automotive control chip, small

volume and excellent performance of automotive

components, realize three-dimensional narrowing of

length, width and height, greatly improve the product

adaptability to various models and equipment

High Accuracy

Adopting unique SOC estimation algorithm of battery

capacity-- Vmin-EKF algorithm (theory) estimation

accuracy is over 97%,being the first in this industry;

based on unique D–filter algorithm with high

accuracy collection system; system parameters

(dynamic battery voltage, current, etc) collection

errors are higher than this industry

Widely Application

High reliability, small volume, powerful function and

other features make the system can be widely

applied to various electric vehicles ( such as electric

motorcycle, light cars, mini-cars and the space

vehicles ), special vehicle and communication base

station BMS, especially suitable for a variety of small

volume, small capacity battery system.

EK-YT-21 BMS

- 2 -

Typical Application

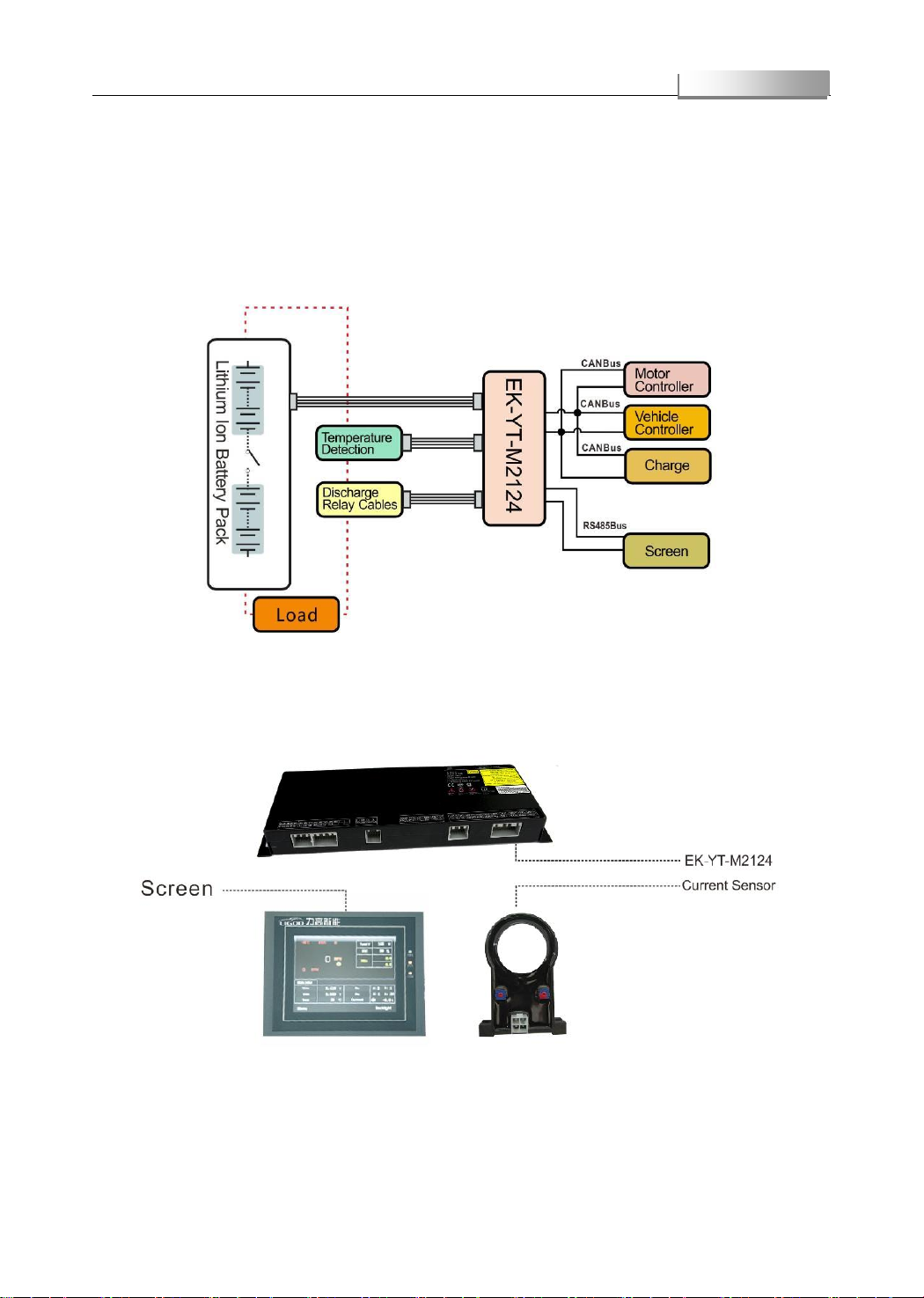

Typical Application of EK-YT-21 BMS

EK-YT-21 BMS can be widely used in a variety of less than 24 strings of battery system, from electric vehicles battery to

emergency power supply of communication base station, meet different customers' various requirements in a full range.

Application in Electronic Vehicle

BMS plays a very important part in the whole electric control system of the electronic vehicle. BMS manages the whole

system in a safe, reliable and high efficient way by communicating with MCU and intelligent charger.

Technical Features:

Strong communication function: Communicate with MCU and intelligent charger via CAN-Bus or RS485 to insure the

efficient of the vehicle. Communicate with monitor via RS485 to show real-time parameters of the vehicle;

Perfect system control : BMS set up a perfect system control strategy, the alarm and the corresponding control signals

would be sent out timely and accurately when the overcharge, under voltage, over discharge, over-current, over-heat

occurs ; including sound and light alarm, CAN communication, switch signal and the relay control.

Powerful environmental adaptability: the system through EMC testing, high and low temperature aging, waterproof and

dustproof, vibration and other simulation experiment, can be adapted to the actual use of electric transport processes in a

variety of harsh environment, ensure the reliable operation of system;

别说明)

Pic 1 Electric Transport System (uncertain)

EK-YT-21 BMS

- 3 -

Typical Application

The Application of Communication Base Station

Although communication base station environment is relatively stable, its working state need asks for an extremely stable

system if keeping working. Only more stable, more reliable management system can effectively ensure power supply to the

communication base station.

Technical Features:

Powerful Protection Function: Overcharge protection, under voltage protection, over discharge protection, over heat

protection, over current protection etc, and reasonable logical control, provide powerful protection for equipment

continuous and stable operation

The comprehensive early warning: LCD screen sound alarm, LCD screen icon warning, buzzer alarm management

system and other sound and light warning mode, improve the system of early warning ability, facilitate a timely processing

to equipment

Storage and analysis of data: Optional DSM to achieve real-time record and save every key data, then analyze and

reconstruct all the data to establish a best mode of charge and discharge;

Pic 2 Communication Base Station System

EK-YT-21 BMS

- 5 -

Security Guide

Security Guide

Security warning explanation:

Hazards: Hazards that may cause fire or serious personal injury or death due to the failure of following required

operations.

Attention: danger that maycause a slight or moderate injury or damage to the system due to the failure of following

required operations.

Please read this part carefully during installation, adjustment or repairing. The user must follow the security instructions of

this part. In case of any damage or loss caused by any irregularities, the manufacturer party won't take any responsibility for

the damage or loss.

Usage

Hazards

This series of BMS must be specified voltage of power supply, or the system will get damaged.

This series of BMS is applied for monitoring and management of battery pack. It can't be used for other

application, or it will cause system failure or fire.

Inspection of the

goods' arrival

Attention

If it is found the BMS is damaged or any parts are missing, don't install it .or accident may occur.

When the goods you receive doesn't match the Pack list ,please contact sales person soon before

installation.(see Part Eight of this manual: Service Direction)

Installation

Attention

Handling with care during moving, installation to avoid damage of the product or injury to the person.

Keep away from inflammable items and heats.

Never let debris come into the BMS, otherwise it will lead to system failure.

The shell of Insulation Test Module must have good connection with the body of the vehicles, or the module will

be ineffective.

Wiring

Hazards

Wiring should be operated by qualified electrical engineers. Otherwise, there will be risk of electric shock or

damaging the system.

Before wiring, make sure the power supply is cut off or it has risks of electric shock or fire.

Attention

Strictly follow the sequence of the address of the Data Collection Module during installation, or the data that

DCM has collected won't match with the data that the screen displays.

Make sure if the serial number of DCM is the same with the battery serial number, otherwise it leads to

incomplete data collection.

Make sure the sequence of wiring of voltage monitoring cables is right or not, or it will damage the system

Check the wiring of relay is correct or not, or it will cause system failure or battery pack damage.

Check the wiring of positive pole and negative pole of the power supply is correct or not, or it will cause system

failure.

Operation

Hazards

After all the modules and wirings are correctly connected, power on the system.

The parameter on the screen can't be changed at ease, or it might damage the battery pack.

Attention

Before running, make sure this system is used within the allowed conditions and applications, or it might cause

system failure.

Before running, make sure the control strategy is correct or not, or it might cause damage to the battery pack.

Maintenance And

check

Hazards

Cut off the power supply before removing the shell to avoid the risks of electric shock

Circuit board has a lot of chips. Don't touch it to prevent electrostatic damage to the circuit board.

Specify qualified electrical engineers for maintenance, inspection or replacement of parts.

Other

Hazards

Prohibit self-transformation of this system to avoid any serious accident.

EK-YT-21 BMS

- 6 -

Catalogue

Catalogue

Chapter 1 Introduction of EK-YT-21 Battery Management System................................................................... - 8 -

1.1 System Structure.................................................................................................................................- 8 -

1.2 System Configuration.........................................................................................................................- 8 -

1.3 Function of System.............................................................................................................................- 9 -

1.4 Technical Parameters.........................................................................................................................- 9 -

Chapter 2 EK-YT-M2124 Module in EK-YT-21 BMS......................................................................................... - 10 -

2.1 Function of EK-YT-M2124................................................................................................................- 10 -

2.2 Model of EK-YT-M2124 Module...................................................................................................... - 11 -

2.3 EK-YT-M2124 Module Basic Protection Parameters................................................................... - 11 -

2.4 EK-YT-M2124 Module Installation Size.......................................................................................... - 12 -

2.5 EK-YT-M2124 Module Interface......................................................................................................- 12 -

Chapter 3 Monitor on EK-YT-21 BMS ............................................................................................................ - 15 -

3.1 Screen Function ................................................................................................................................ - 15 -

3.2 Screen Selection...............................................................................................................................- 15 -

3.3 Screen Shape Size...........................................................................................................................- 16 -

3.4 Screen Interface................................................................................................................................- 17 -

3.5 Main Interface of Screen..................................................................................................................- 18 -

3.6 Display Configuration Parameter....................................................................................................- 18 -

3.7 Display Screen Parameter Configuration ......................................................................................- 19 -

3.8 Battery Cell Information Display......................................................................................................- 20 -

3.9 Charger Information Display............................................................................................................ - 21 -

3.10 Instruction of Charging Control .....................................................................................................- 21 -

Chapter 4 Current Sensor On EK-YT-21 BMS................................................................................................ - 23 -

4.1 Current Sensor Function..................................................................................................................- 23 -

4.2 Current Sensor Selection.................................................................................................................- 23 -

4.3 Current Sensor Size..........................................................................................................................- 24 -

4.4 Current Sensor Interface..................................................................................................................- 24 -

Chapter 5 Installation of EK-YT-21 BMS....................................................................................................... - 25 -

5.1 System Wiring Diagram....................................................................................................................- 25 -

5.2 Installation Environment and Requirement....................................................................................- 25 -

Chapter 6 System wiring for EK-YT-21 BMS....................................................................................................- 26 -

6.1 Type of Cables...................................................................................................................................- 26 -

6.2 Cables.................................................................................................................................................- 26 -

6.3 Cable Connect Mode........................................................................................................................- 28 -

Chapter 7 Malfunction Handling .................................................................................................................. - 32 -

7.1 Malfunction and Prompts .................................................................................................................- 32 -

7.2 Procedures of Diagnosis of Malfunction. ....................................................................................... - 34 -

Chapter 8 Regular Maintenance ................................................................................................................... - 35 -

Chapter 9 Service Direction.......................................................................................................................... - 36 -

EK-YT-21 BMS

- 7 -

Catalogue

9.1 Contact Information...........................................................................................................................- 36 -

Appendix A System List ..............................................................................................................................- 37 -

Appendix B Product Certificate ................................................................................................................. - 38 -

EK-YT-21 BMS

- 8 -

Introduction

Chapter 1 Introduction of EK-YT-21 Battery Management System

1.1 System Structure

EK-YT-21 BMS is composed of EK-YT-M2124 module which has functions of system management and information

monitoring, monitor(optional), current sensor and cables.

Pic 1-1 System Structure

1.2 System Configuration

Pic 1-2 System Configuration

EK-YT-21 BMS

- 9 -

EK-YT-M2124

1.3 Function of System

The EK-YT-21 system adopts the design of detection and management in collection , with high precision, high accuracy

function of information collection, can collect voltage of single cell, battery voltage, battery box temperature and other data,

balance single cell ,analyze and processing the battery pack data; send alarm and control according to the battery status

The EK-YT-21 system through the current sensor to collect current data, determine the charging and discharging state,

complete working current measurement, charge and discharge control of the battery pack, comprehensive utilization of the

battery data to do SOC estimation and discrete evaluation.

The EK-YT-21 system can also real-time display the battery pack voltage, current, temperature, SOC etc. and convenient

setting by screen.

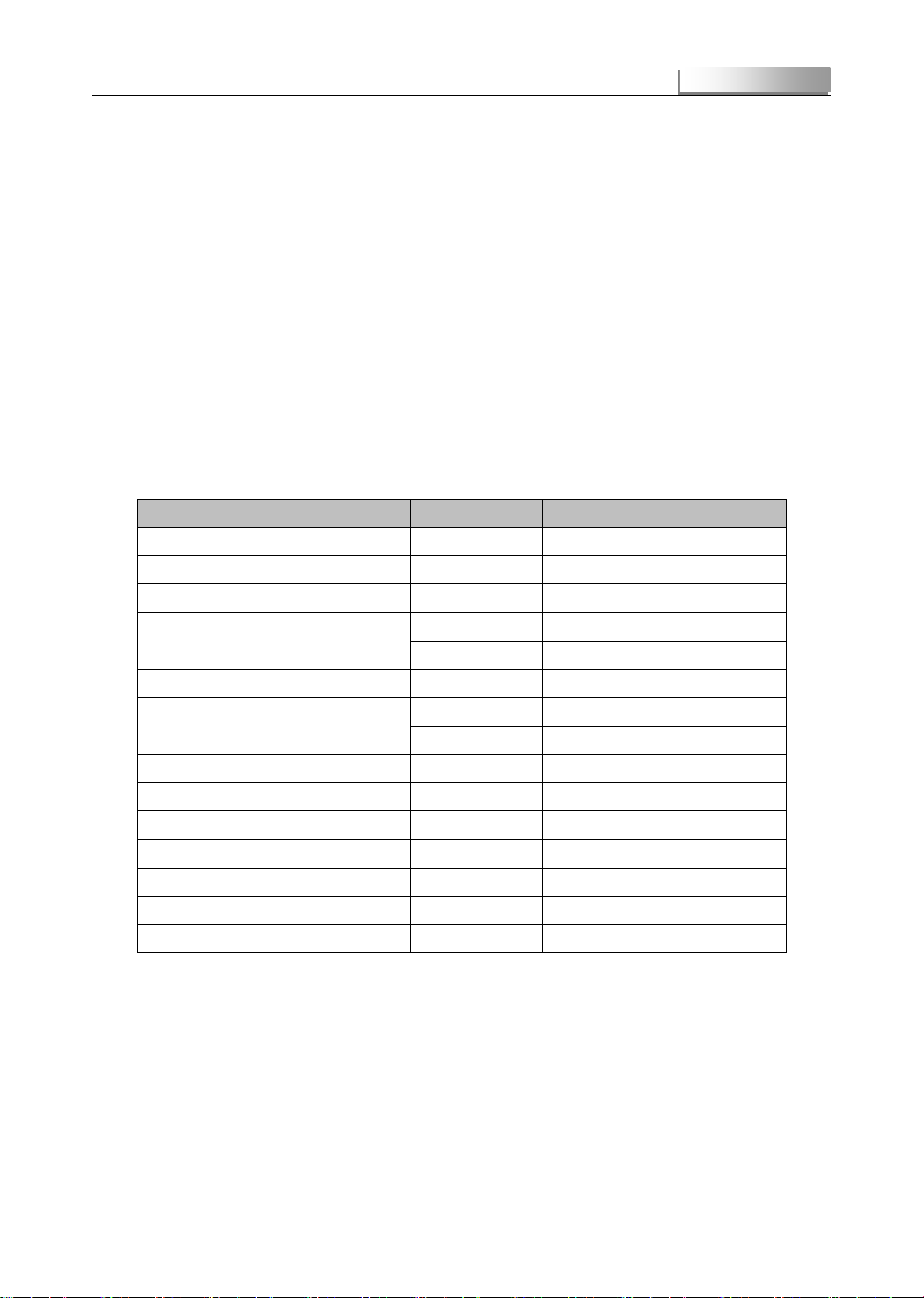

1.4 Technical Parameters

Table 1-1 Technical Parameters of BMS

Specification

Remarks

System Power Supply

DC12V/DC24

DC9~16V/DC16~32V

System Power

≤3W

Not Including Screen and other accessories.

Accuracy of Monomer Voltage Detection

±10mV

0~4.7V

Current Accuracy

±1%

±500A

±0.3A

≤30A

SOC Accuracy in theory

≥97%

Accuracy of Temperature Detection

±1℃

-40℃~85℃

±2℃

85~125℃

Rated Current of Relay

≤1A

Peak≤2A

Rated Current of Switching Signal

≤1A

Working Temperature Range

-20℃~70℃

Storage Temperature Range

-40℃~85℃

Balance Current

250mA/Circuit at most

Working Moisture Range

40%~90%

Anti-electromagnetic Interference Range

400MHZ~1000MHZ

Note)* Voltage of single cell only take Lithium iron phosphate battery for example, other types of batteries can be

customized based on customer requirements

Introduction

EK-YT-21 BMS

- 10 -

EK-YT-M2124

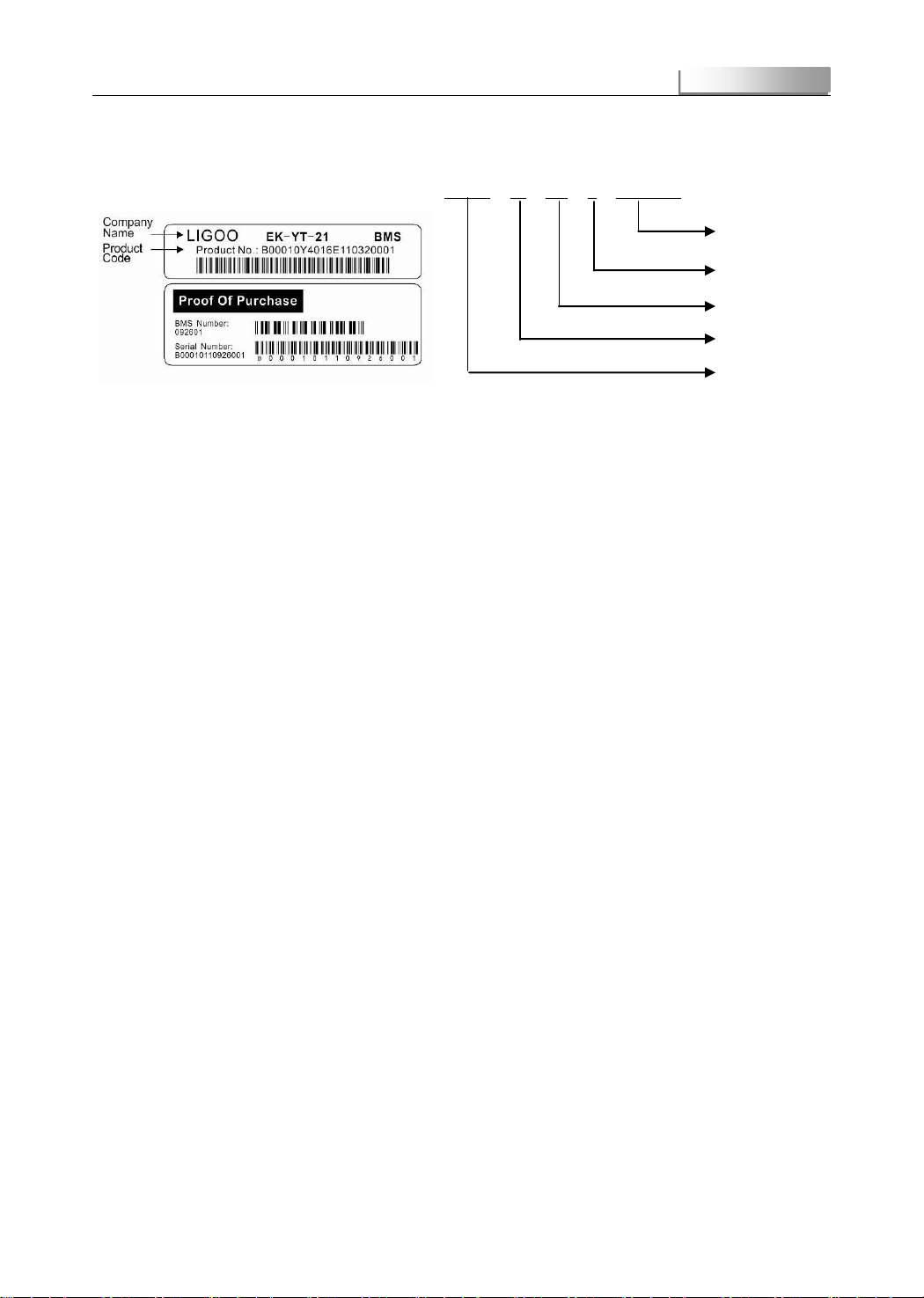

1.5 Product Code

B00010 Y4 016 E110320001

Production code

Type of balance

Total number of series

Type of system code

Custom code

Pic 1-3 Product System Code

Chapter 2 EK-YT-M2124 Module in EK-YT-21 BMS

2.1 Function of EK-YT-M2124

EK-YT-M2124 is the core equipment in EK-YT-21 for collect, process and control of system data. The main functions are

as follow:

Information Collecting Function

Max.24 of single cell voltage real time high precision data collection and wave filtering processing

Max. 4 of real time acquisition and processing to temperature sensor signal

Collection and processing to charging and discharging current

Communication and Control Mode

1 CAN-bus communication

1 communication mode of display screen LCD_485

1 RS485 communication mode to realize customers’requirement

2 relay control modes (charge and discharge)

2 switch signal control modes

Battery equilibrium strategies

The battery voltage real-time detection of consistency

The 250mA charging balance

The balanced failure protection function

System Management Function

SOC high precision estimation

The battery failure alarm

EK-YT-21 BMS

- 11 -

EK-YT-M2124

Real time processing and distribution of battery pack and system information

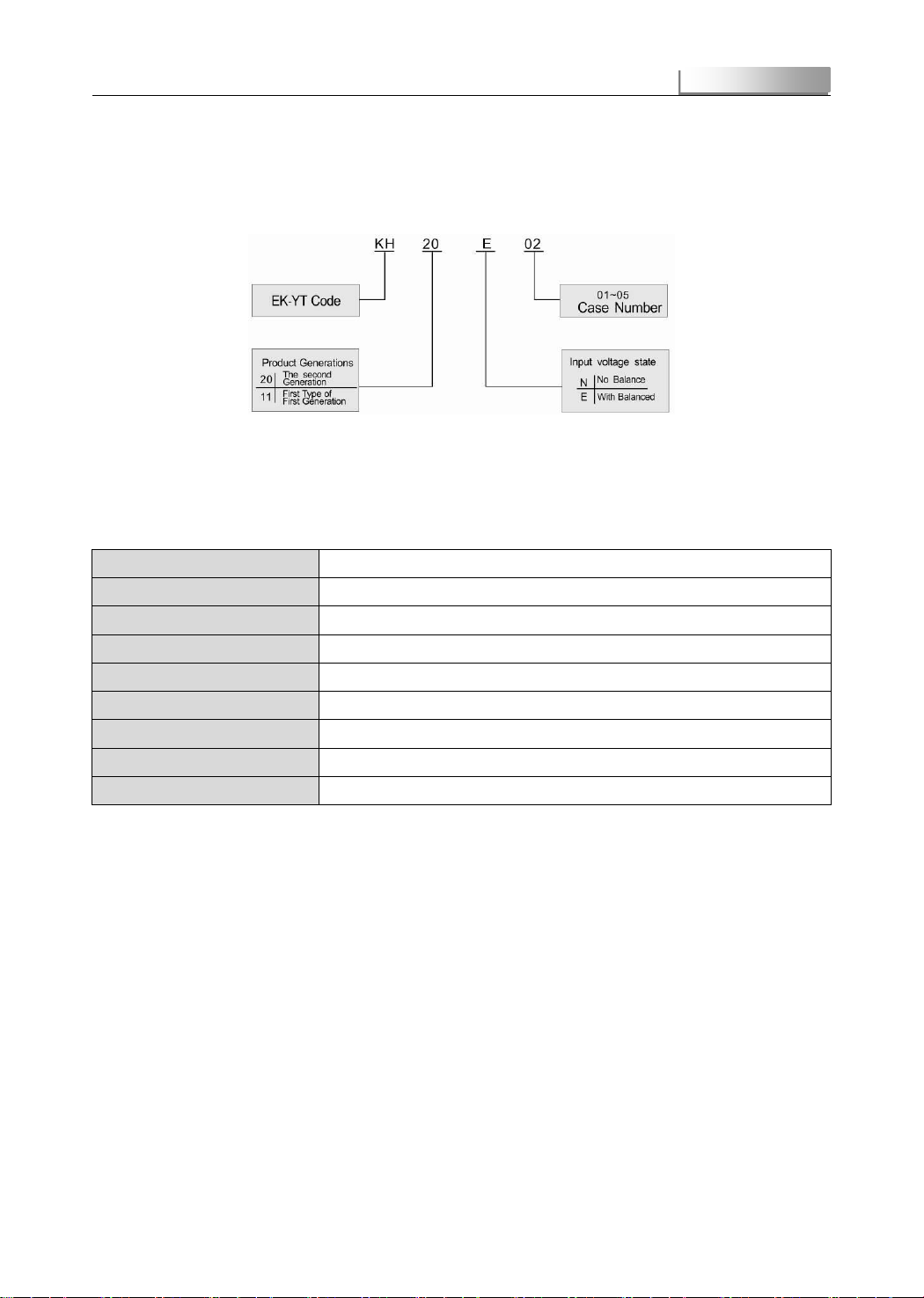

2.2 Model of EK-YT-M2124 Module

Pic 2-1 EK-YT-M2124 Module Mode

2.3 EK-YT-M2124 Module Basic Protection Parameters

Table 2-1 EK-YT-M2124 Module basic protection parameters (uncertain)

Name

Value

Overcharging protection voltage

3.70V

Overcharging release voltage

3.60V

Under Voltage alarm voltage

3.15V

Under Voltage release voltage

3.20V

Over discharging protection voltage

2.60V

Over discharging release voltage

2.8V

Over heat protection temperature

55℃

Over heat release temperature

40℃

Note)* The above parameters are basic protection parameters, they can be configured according to customer demand.

EK-YT-21 BMS

- 12 -

EK-YT-M2124

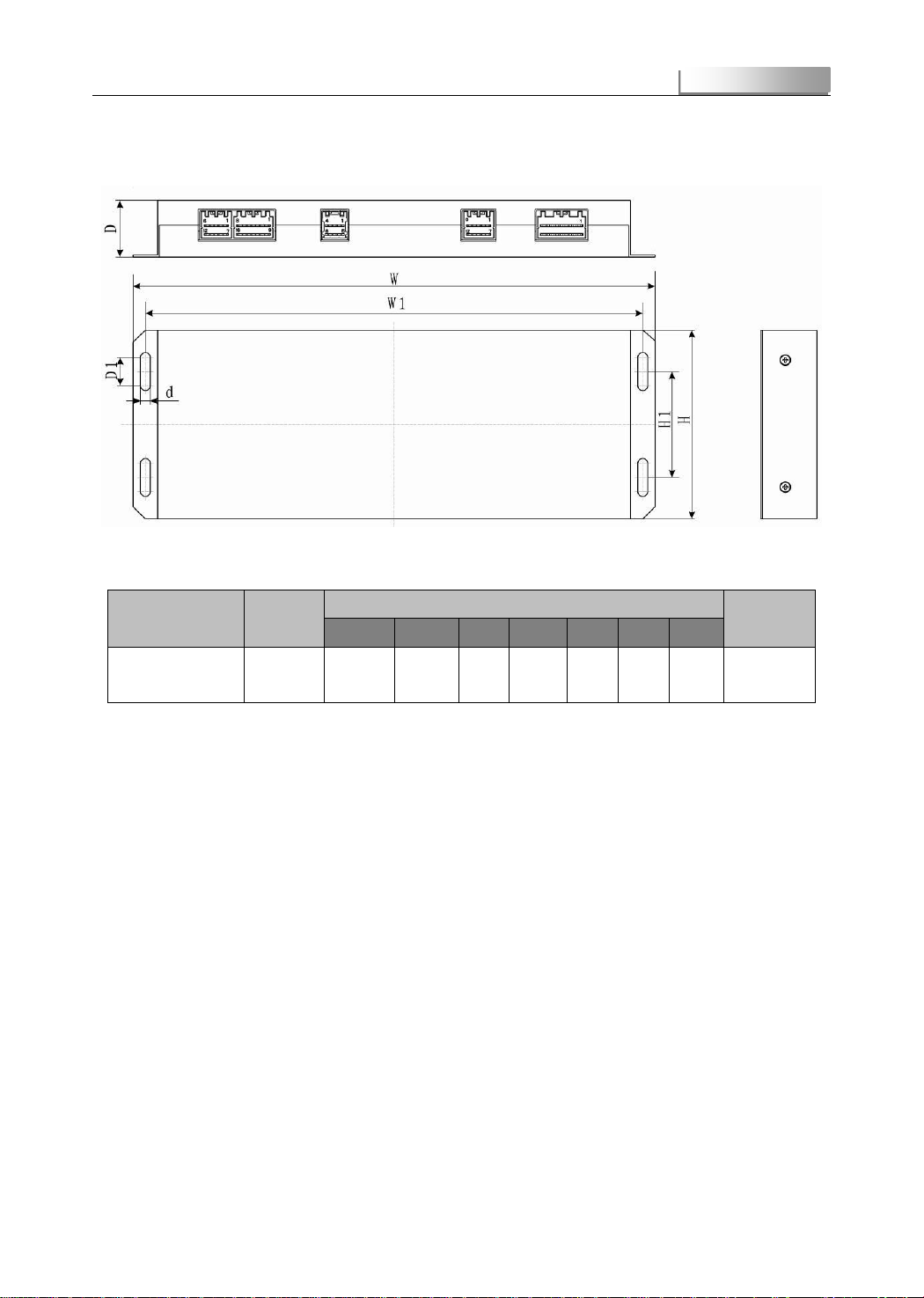

2.4 EK-YT-M2124 Module Installation Size

Pic 2-2 EK-YT-M2124 Module Installation Size Diagram

Table 2-2 Size of EK-YT-M2124 Module

Product Name

Product

Model

Shape and Installation Size

(

Unit

:

mm

)

Weight(KG)

W

H

D

W1

H1

D1

d

EK-YT-M2124

Module

KH20E02

296

107

31

283

60

12

4.5

0.89

Note)* W, H, D as the external structure size, W1, H1, D1 as the installation size of internal structure , D is width of

installation hole

2.5 EK-YT-M2124 Module Interface

2.5.1 EK-YT-M2124 Module Interface Distribution

EK-YT-21 BMS

- 13 -

EK-YT-M2124

Pic 2-3 EK-YT-M2124 Module Interface Distribution Picture

2.5.2 EK-YT-M2124 Module Interface Function

Table 2-3 EK-YT-M2124 Module Interface Function

Interface

Number

Interface Name

Interface Function

1

Voltage Detection Interface

Fulfill the voltage detection of a single battery

2

Temperature Detection Interface

Real time monitor of battery temperature

3

System Power and Current Sensor Interface

Supply the working voltage of EK-YT

Connect to current sensor to monitor real time working current.

Output control of discharge relay

4

Communication Interface

LCD display power output

LCD display 485-bus

CAN-bus to communicate with vehicle control system

CAN-bus to communicate with charge

485 to communicate with optional DSM

EK-YT-21 BMS

- 14 -

EK-YT-M2124

Reserve 2 switching signal control circuit to meet customer specified

Control charge relay

2.5.3 EK-YT-M2124 Module Interface Define

Table 2-4 EK-YT-M2124 Module Interface Define

接

口

Interface Exterior

Interface Line Order Define

1

1

2

3

……

25

26/27/28

B1+

B1-

B2-

……

B24-

空

2

1

3

5

7

2、4、6、8

Temperature Sensor

Signal 1

Temperature Sensor

Signal 2

Temperature Sensor

Signal 3

Temperature Sensor

Signal 4

GND

3

1

2

3

4

5

6

7

8

9、10、11、12

Discharge

Relay

Control+

Discharg

e Relay

Control-

System

Power

Input+

System

Power

Input-

Current

Sensor

Power

Output+

Current

Sensor

Power

Output -

Current

Sensor

Signal

Input

GND

空

4

1

2

3

4

5

LCD Power

Output+

LCD Power

Output-

LCD RS485+

LCD RS485-

GND

6

7

8

9

10

GND

RS485+

RS485-

GND

GND

11

12

13

14

15

CAN_H

CAN_L

CAN_H

CAN_L

External

Switching Signal

Control 1+

16

17

18

19

20

External Switching

Signal Control 1-

External Switching

Signal Control 2+

External Switching

Signal Control 2-

Charge Relay Control

+

Charge Relay

Control -

EK-YT-21 BMS

- 15 -

EK-YT-M2124

Chapter 3 Screen on EK-YT-21 BMS

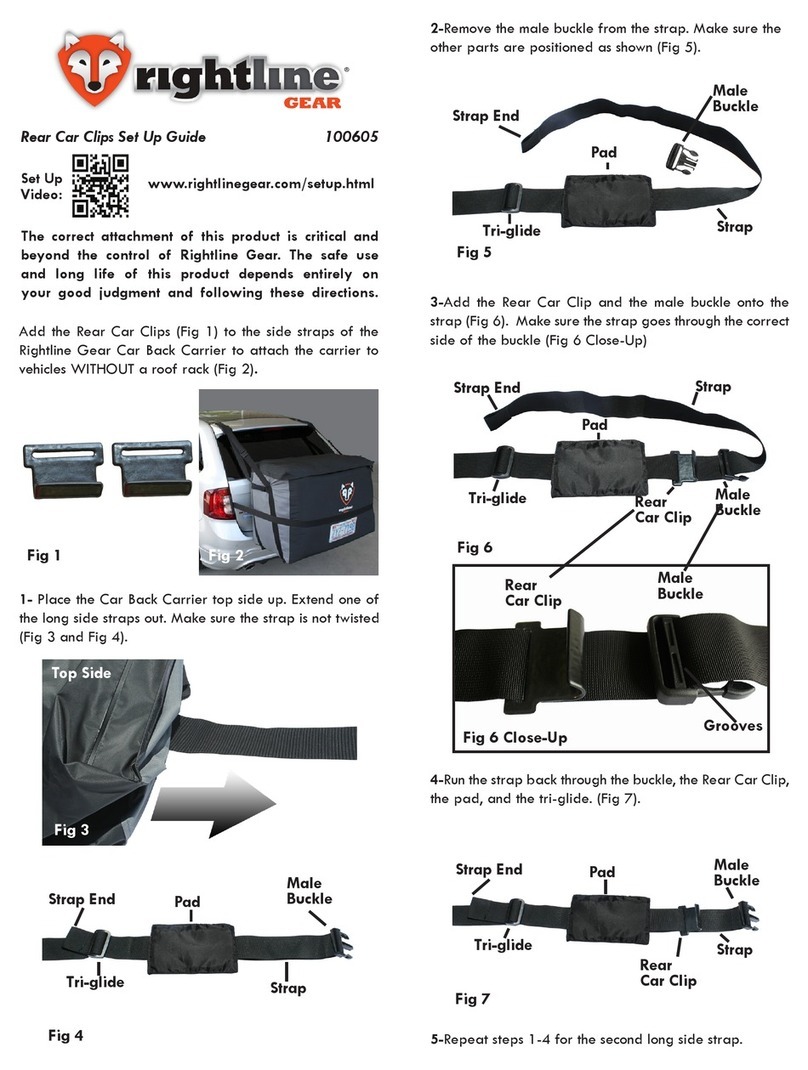

3.1 Screen Function

Screen is the User Interface of system running situation. All types are all designs by industry standard and suitable to

various environments. The display interface of screen can display all kinds of operation parameters of the system and fault

condition.

Description:

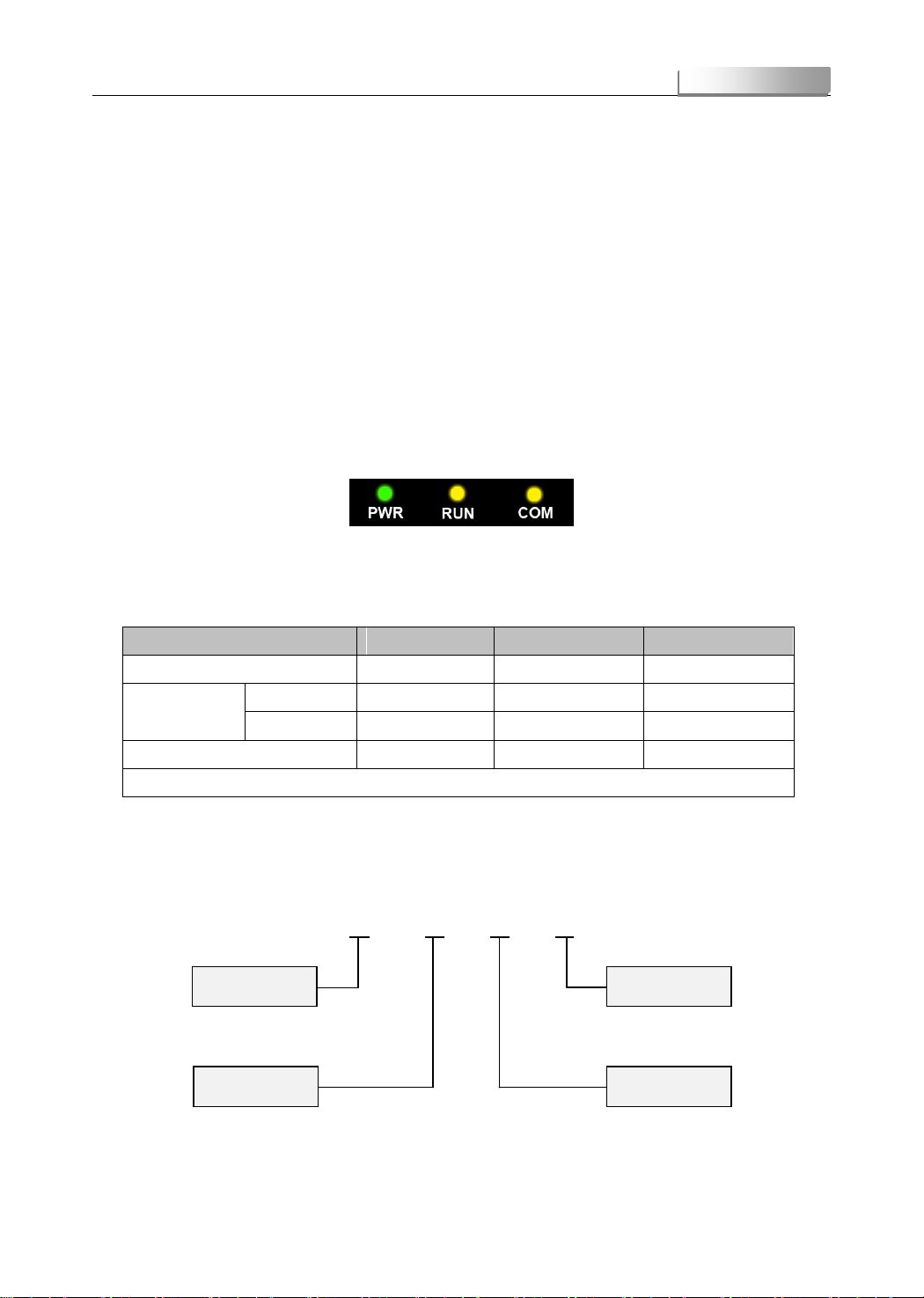

There are three lights on the screen that indicate the status of the operation of the system, including power light (PWR),

Running (RUN), communication (COM). When the screen is powered on, the PWR light will be always bright; if the RUN light

is always bright, it means the screen is running fine; if the RUN light is dark, it means the screen has something wrong; if the

EMS is connected, COM light is flash yellow.

Pic 3-1 Indicator Light in Operation Status

The following table shows indicator lights status in different state:

Table 3-1 Pilot Lamp Condition on Screen

Equipment Status

Green LED(PWR)

Yellow LED(RUN)

Yellow LED(COM)

No Power

○

○

○

Power on and no

communication

3.5 Inch Screen

●

●

●

5.7 Inch Screen

●

●

○

Communicate with equipment

●

●

※

○ LED Off ● LED On ※Flicker

3.2 Screen Selection

Pic 3-2 Screen Model

Screen Number

Screen Code

KX 01 00 01

Spare Code

Manufacturer Code

Screen

EK-YT-21 BMS

- 16 -

EK-YT-M2124

Table 3-2 Screen Selection Table

Product Name

Screen Model

3.5 Inch Screen

KX010001

5.7 Inch Screen

KX010002

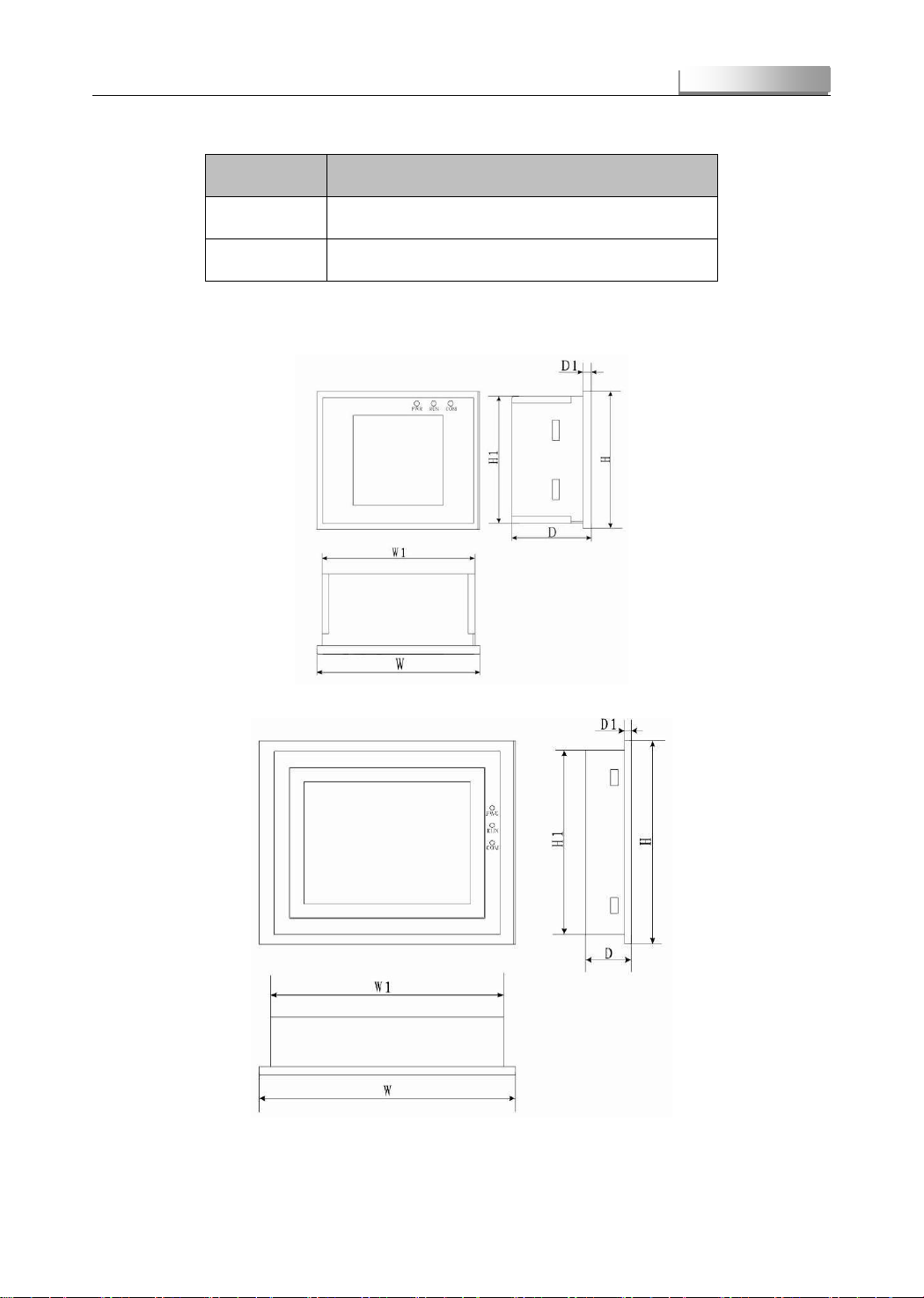

3.3 Screen Shape Size

Pic 3-3 3.5 Inch Screen Size

Pic 3-4 5.7 Inch Screen Size

Screen

EK-YT-21 BMS

- 17 -

EK-YT-M2124

Table 3-3 Screen Size

Product Name

Product

Type

Shape and Installation Size

(

Unit

:

mm

)

Weight(KG)

W

H

D

W1

H1

D1

d

3.5 Inch Screen

KX010001

96

81

46

90

73

4

4

0.186

5.7 Inch Screen

KX010002

177

140

40

161

130

6

4

0.5

Note)* W, H, D as the external structure size, W1, H1, D1 as the installation size of internal structure , d is width of

installation hole

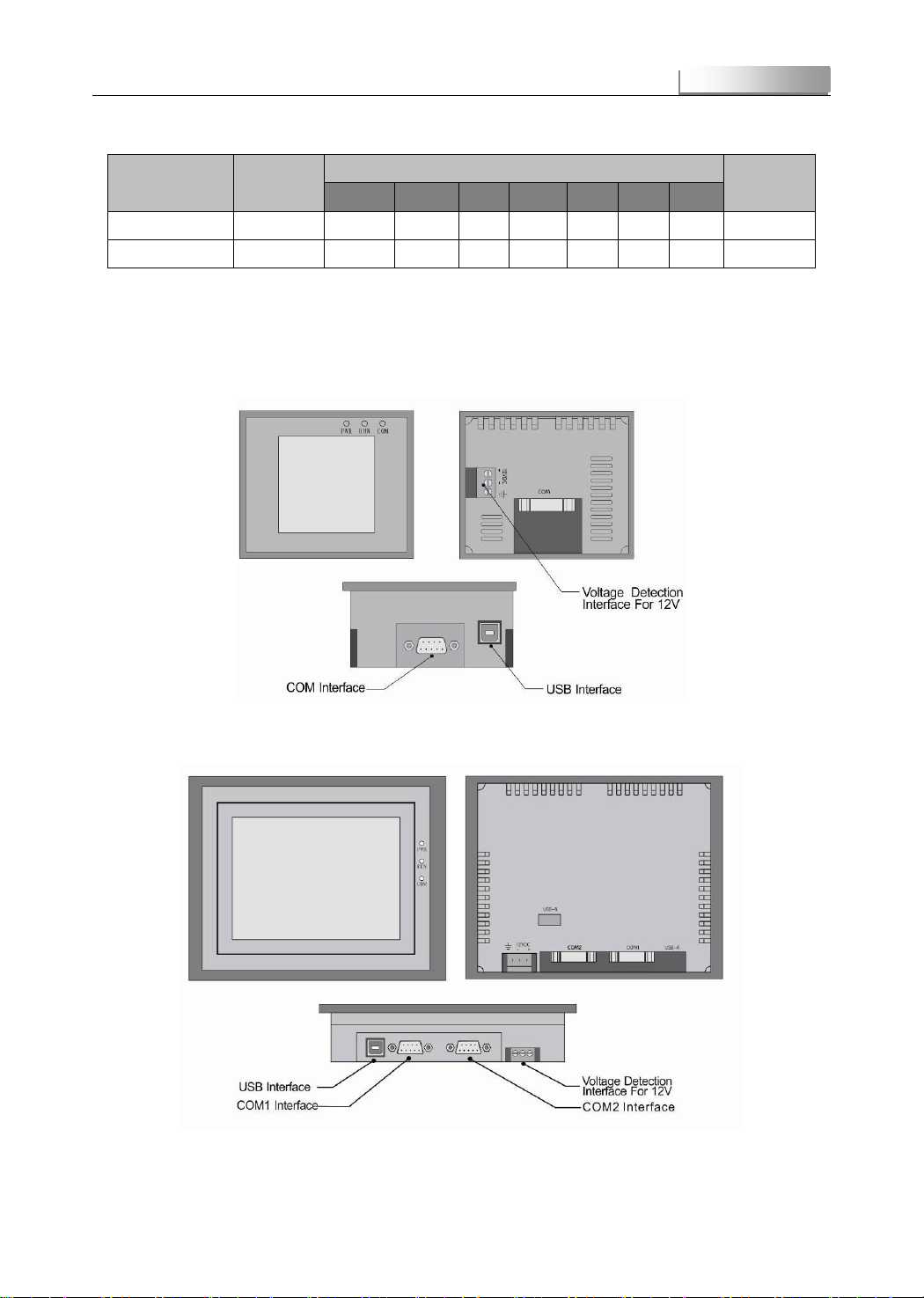

3.4 Screen Interface

Pic 3-5 3.5 Inch Screen Interface

Pic 3-6 5.7 Inch Screen Interface

Screen

EK-YT-21 BMS

- 18 -

EK-YT-M2124

3.5 Main Interface of Screen

When screen is working with system power, the main interface of screen will be as the following picture:

Pic 3-7 Screen Main Interface

Note)*1. The above 、 、 、 、 icon only displayed in failure state and not display in nornal

condition.

* 2 Both 1-30 seconds delay for all the protection and release

* 3 Display screen may change, please take the actual one as true.

3.6 Display Configuration Parameter

Total Capacity

Battery releases the maximum capacity when it completes charging. Generally batteries’ nominal capacity would be

used for initial configuration.

Remain Capacity

Current ampere value of battery, it is configured according to the parameters provided by the manufacturer.

Calibration of Current

Used for current zero point correction, current calibration values is 0.0A in default condition, if the system stops running

(no charge or discharge), the screen shows current is not 0, ―, the current can be calibrated to 0Aby setting the" Current

Cal. Calibration range from - 20.0A to 20.0A. For example: the screen shows current values for 0.6A when the system

Screen

EK-YT-21 BMS

- 19 -

EK-YT-M2124

stops," Current Cal by typing" 0.6A, and click the" Settings", current can be calibrated to 0Aby inputting 0.6Afor Current

Cal and click "setting".

Calibration of Voltage

Used for zero correction of voltage value, the calibration value of voltage is 000mV in default condition

Max Current of Charging

Defines CAN communication charger allowed maximum charging current.

Overcharging Protection Voltage

Defines the highest allowed rising voltage value during charging process of single cell, above this value it needs to

perform overcharging protection and alarm to the battery.

Overcharging Release Voltage

Canceling the protection voltage threshold, of overcharging i.e. when the max voltages value of single cell below this

value it cancels the overcharging protection and alarm.

Under voltage Protection Voltage

Define low voltage alarm threshold of single cell, for prompting the battery is not much.

Under voltage Release Voltage

Cancelling alarm voltage threshold when under voltage i.e. under voltage alarm is cancelled when the lowest voltage of

single voltage is higher than the parameter.

Over discharging Protection Voltage

Definition of lowest voltage allowed falling when battery discharges, discharge protection occurs when below this value.

Over discharging Release Voltage

Defines cancelling parameters of over discharging protection, i.e. when the lowest voltage is higher than the parameter

of single cell, it will cancel over discharging protection to battery

Over Heat Protection Threshold

Definition of battery maximum allowable working temperature, over-temperature protection and alarm to battery occurs

when higher than the temperature.

Over Heat Release Threshold

Definition of overheat alarm release temperature threshold, i.e. it cancels over-temperature protection and alarm when

the highest temperature of the battery is lower than this value.

3.7 Display Screen Parameter Configuration

In order to accurately estimate all parameters of batteries, BMS can be re-configured for the first time of running.

The parameters that can be reset includes: total capacity of the battery pack (nominalcapacity), SOC, current calibration,

over charge voltage of single cell, over charge release voltage of single cell, under-voltage protection voltage for single

cell, under-voltage release voltage for single cell, over discharge protection voltage, over discharge release voltage for

single cell, over heat protection temperature, overheat release temperature.

Step 1 Click the button ―Apply‖ and then input the password ―8888‖ to enter BMS configuration page.

Screen

Table of contents

Popular Automobile Accessories manuals by other brands

Slee

Slee MaxTrax SOK0054 Installation instruction

DECKED

DECKED DS1 installation instructions

Mont Blanc

Mont Blanc MB RoofBar ReadyFit RF 28 Fitting instructions

ULTIMATE SPEED

ULTIMATE SPEED 106321 Assembly and Safety Advice

Sony Ericsson

Sony Ericsson HBM-30 Disclaimer and safety guidelines

Panasonic

Panasonic CF-WEB184 Series operating instructions