IS 399 ECN 3607 Page 8 of 15

Turn on the power supply at the isolating switch; the green neon will illuminate

indicating power to the appliance.

Rotate the control knob to the desired setting –the amber neon will illuminate

indicating power to the element. There is a range of 1-6 settings, with constant power

position beyond the ‘6’ setting.

When the set temperature is reached, the element will cycle on and off to maintain

temperature.

Introduce baskets of pasta, positioning onto basket support, and cook as per

manufacturer’s instructions. Note that overloading the baskets reduces the appliances

recovery times and output, and will result in uneven cooking. It also increases the risk

of surge boiling –the water may suddenly boil over when the basket is placed into the

tank.

During cooking, scoop starch from the surface of the water and pour into the

overflow/starch removal trough in front of the tank.

If the water falls below the level of the basket plate, the pressure switch will operate

and cut off power to the elements.

Bains marie operation (OE7702 only)

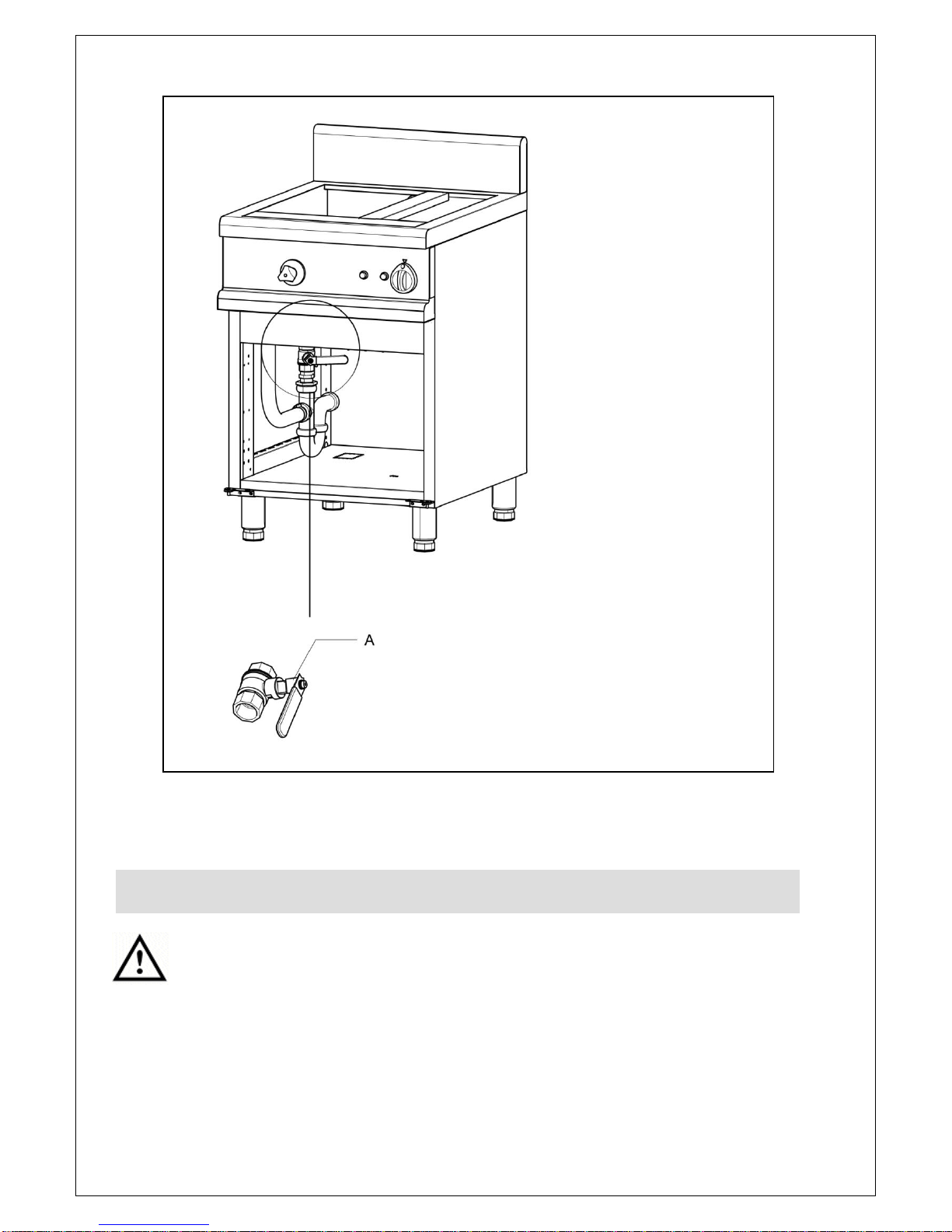

Fit gastronorm pan support, slotting it into the overflow cover (Fig 3).

Position gastronorm pans onto top of tank, cover produce with lids.

For steaming operations, use perforated gastronorm pans and lids (see Accessories).

Safety cutout

This appliance is fitted with safety cutout thermostats which will shut the appliance

down in the event of a fault. If the appliance fails to heat when the control knob is set

to a heating position, the safety cut-outs may require resetting. Disconnect the

appliance from the supply, allow to cool for at least 20 minutes and then reset the

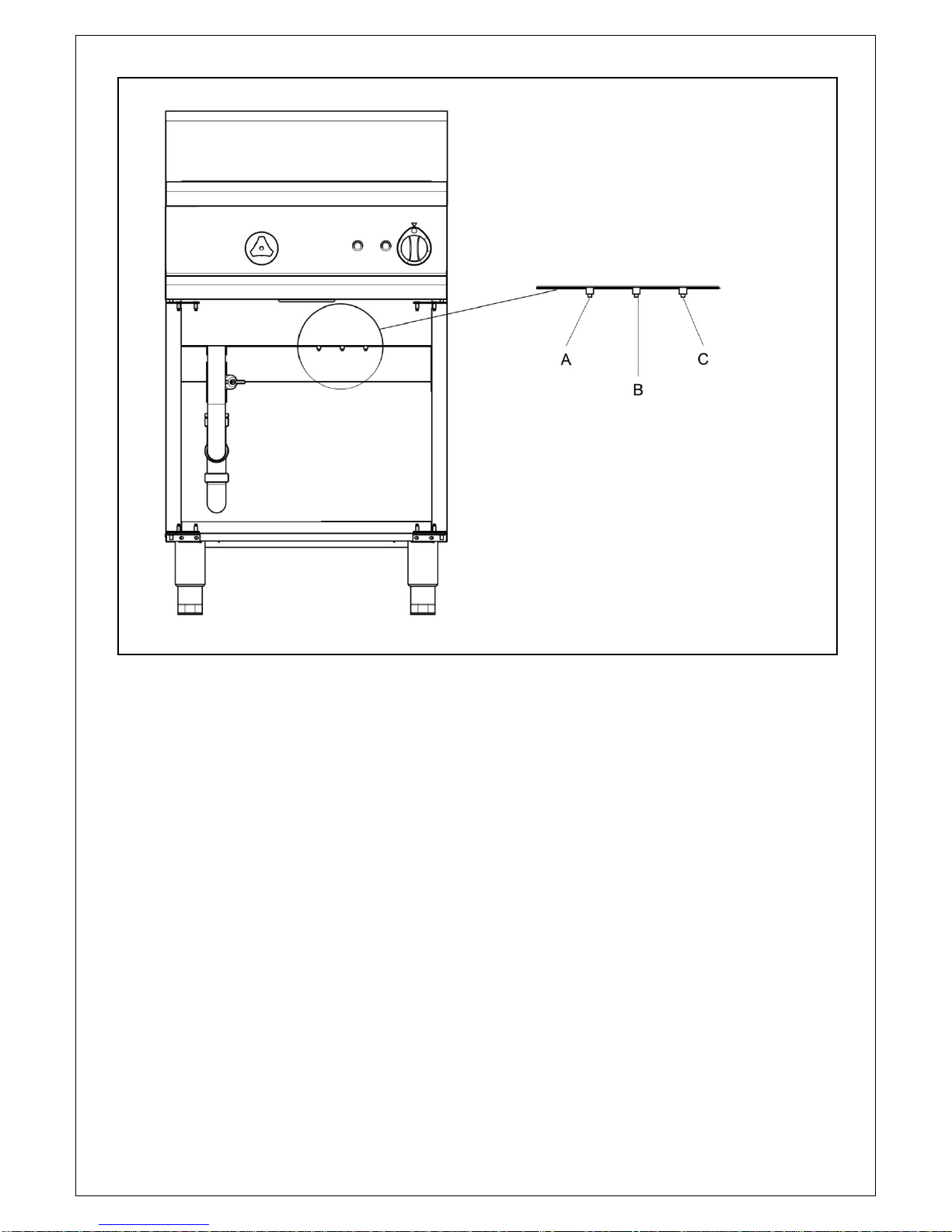

exposed buttons indicated in Fig 4. Note that Fig 4 shows OE7702 –the OE7701 has

only 2 cutout buttons.

Once reset, reconnect to supply and operate as normal. If the appliance still fails to

operate, consult one of our recommended Service Engineers.

Shutdown

To turn the appliance off, rotate the control knob to the ‘Off’ position and turn off the

electrical supply at the isolator.