Invertec®V160-T

www.lincolnelectric.com

[3]

RECOMMENDED OPTIONS

GENERAL OPTIONS

Welding Cart

Full-featured cart is designed to

store and transport a welder, 80

cubic foot gas cylinder, welding

cables and accessories. Includes

an angled top shelf for easy

access to welder controls, a lower

tray for added storage space, a

sturdy handle and a convenient

cable wrap hanger.

Order K2275-1

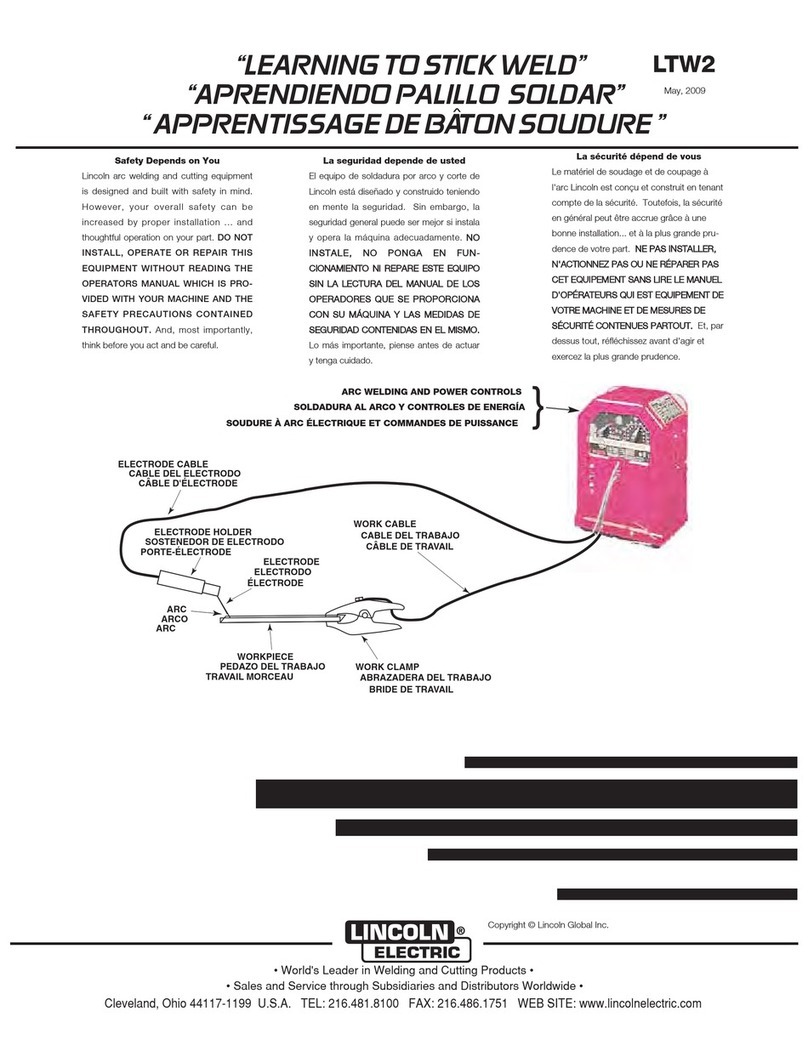

STICK OPTIONS

Stick Electrode Holder, Work

Clamp, Cable &Twist-Mate™Set

Includes 200 amp stick holder,

welding cable, work cable, work

clamp and Twist-Mate™set.

Order K2394-1

TIG OPTIONS

TIG-Mate™9 Air-Cooled TIG

Torch Starter Pack

Get everything you need for TIG

welding in one complete easy-to-

order kit packaged in its own

portable carrying case. Includes:

PTA-9 Ultra-Flex™torch, gas lens

parts kit, Harris®flowmeter/regula-

tor, Twist-Mate™adapter, gas

hose, work clamp and cable.

Order K2413-1

TIG-MateTM 17 Air-Cooled TIG

Torch Starter Pack

Get everything you need for TIG

welding in one complete easy-to-

order kit packaged in its own

portable carrying case. Includes:

PTA-17 torch, parts kit, Harris®

flowmeter/regulator, 10 ft. gas

hose, Twist-mateTM adapter, and

work clamp and cable.

Order K2266-1

TIG-MateTM 20 Water-Cooled

TIG Torch Starter Pack

Get everything you need for TIG

welding in one complete easy-to-

order kit packaged in its own

portable carrying case. Includes:

PTW-20 torch, parts kit, Harris®

flowmeter/regulator, 10 ft. gas

hose, Twist-MateTM adapter, work

clamp and cable and 10 ft. water

hose.

Order K2267-1

Pro-Torch™TIG Torches

One piece Air-Cooled PTA-9 or

-17 TIG torches may be connect-

ed directly with the included

K1622-1 TIG Torch Adapter.

Order K17 1-1 for PTA-9,

12.5 ft., 1-cable.

Order K17 2-1 for PTA-17,

12.5 ft., 1-cable.

A full line of TIG torches in various

lengths and types are available.

Request Lincoln Publication

E12.150 for more information.

Foot Amptrol®

Provides 25 ft. (7.6m) of remote

current control for TIG welding. (6

pin plug connection).

Order K 70

Hand Amptrol®

Provides 25 ft. (7.6m) of remote

current control for TIG welding.

(6-pin plug connection). Velcro

straps secure torch.

Order K963-3 (One size fits all

Pro-Torch™TIG Torches.)

Arc Start Switch

May be used in place of the Foot

or Hand Amptrol®. Comes with a

25 ft. (7.6m) cable. Attaches to the

TIG torch for convenient finger

control to start and stop the weld

cycle at the current set on the

machine.

Order K 14

Cool-Arc™40 Water Cooler

Energy efficient long life cooler for

water-cooled welding applications.

Order K1 13-1 for 115V.

Order K21 7-1 for 230V.

Cut Length Consumables

TIG welding filler metals are

available for welding stainless

steel, mild steel, aluminum and

copper alloys.

Request Lincoln Publication

C9.10 for more information.

Small Canvas Cover

Protect your machine when not in

use. Made from attractive red can-

vas that is flame retardant, mildew

resistant and water repellent.

Includes a convenient side pocket

to hold welding torch or gun.

Order K2377-1