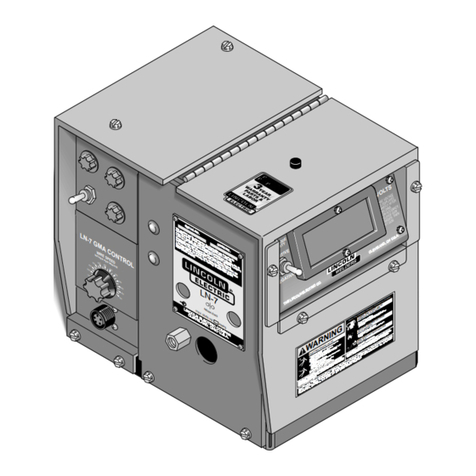

Lincoln Electric OPTIMARC CV355P User manual

Other Lincoln Electric Welding System manuals

Lincoln Electric

Lincoln Electric CLASSIC I SVM134-A User manual

Lincoln Electric

Lincoln Electric SAE-300 HE User manual

Lincoln Electric

Lincoln Electric COMMANDER 300 IM700-D User manual

Lincoln Electric

Lincoln Electric 12486 User manual

Lincoln Electric

Lincoln Electric LINC FEED 37 User manual

Lincoln Electric

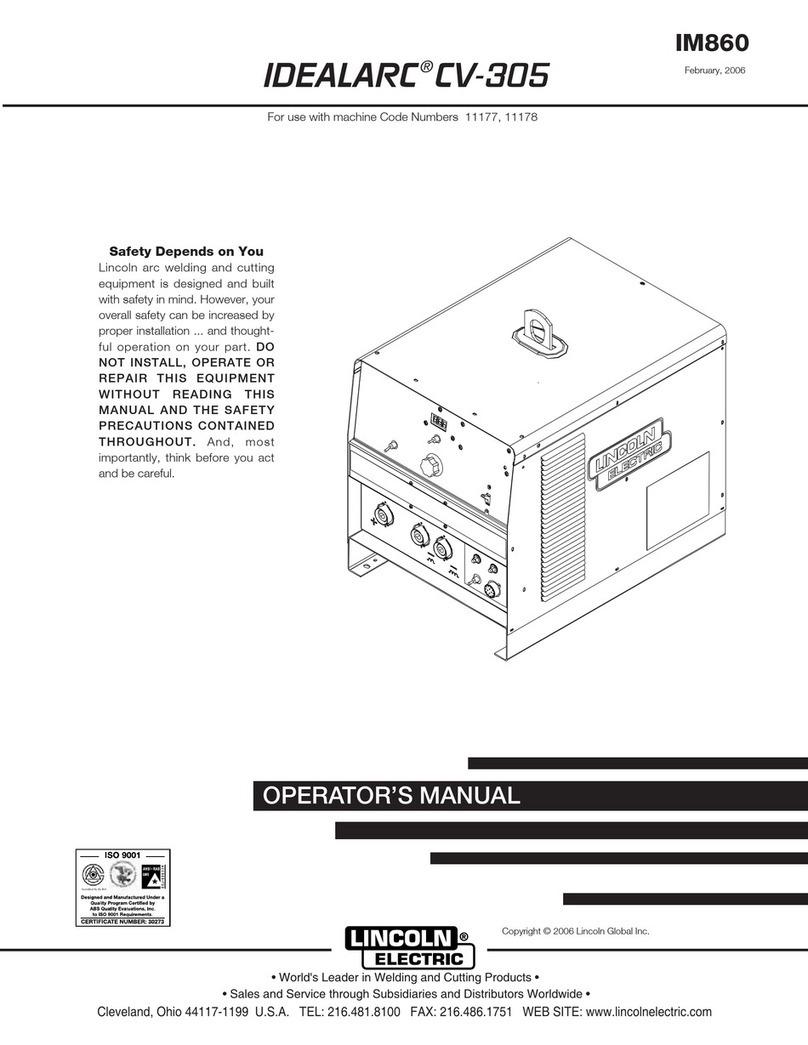

Lincoln Electric IDEALARC CV-305 User manual

Lincoln Electric

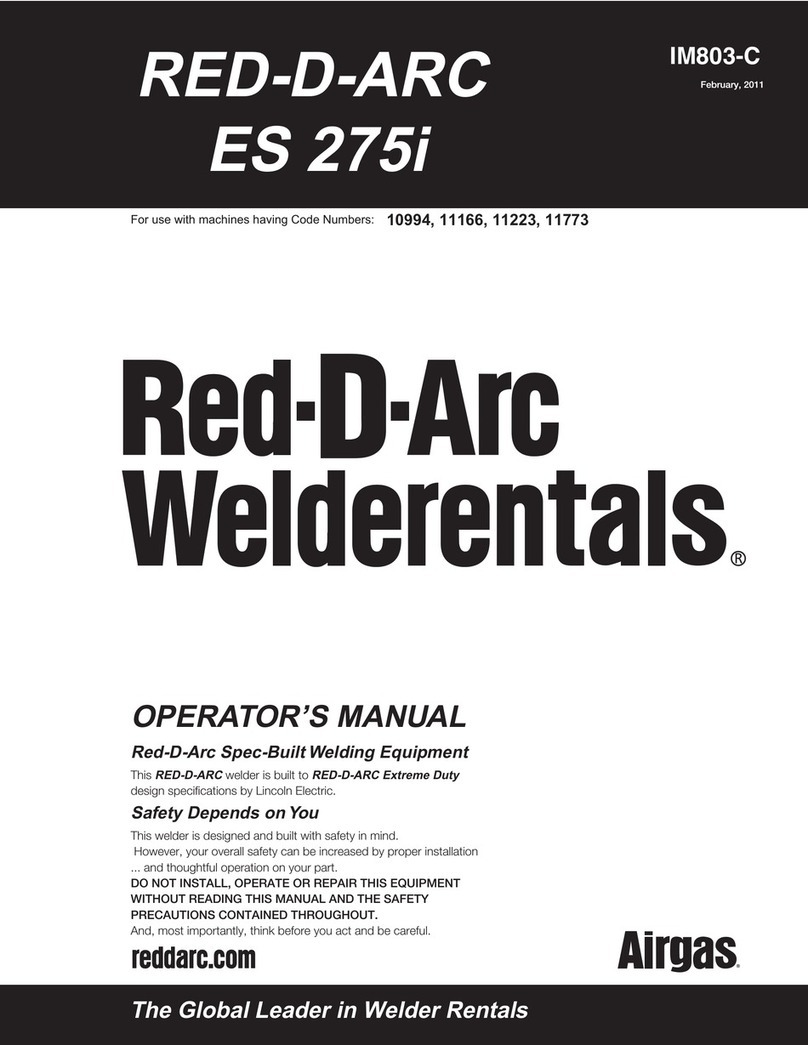

Lincoln Electric RED-D-ARC ES 275I User manual

Lincoln Electric

Lincoln Electric RANGER 10,000 User manual

Lincoln Electric

Lincoln Electric PRO-CUT 10474 User manual

Lincoln Electric

Lincoln Electric REDI-MIG Plus 215C User manual

Lincoln Electric

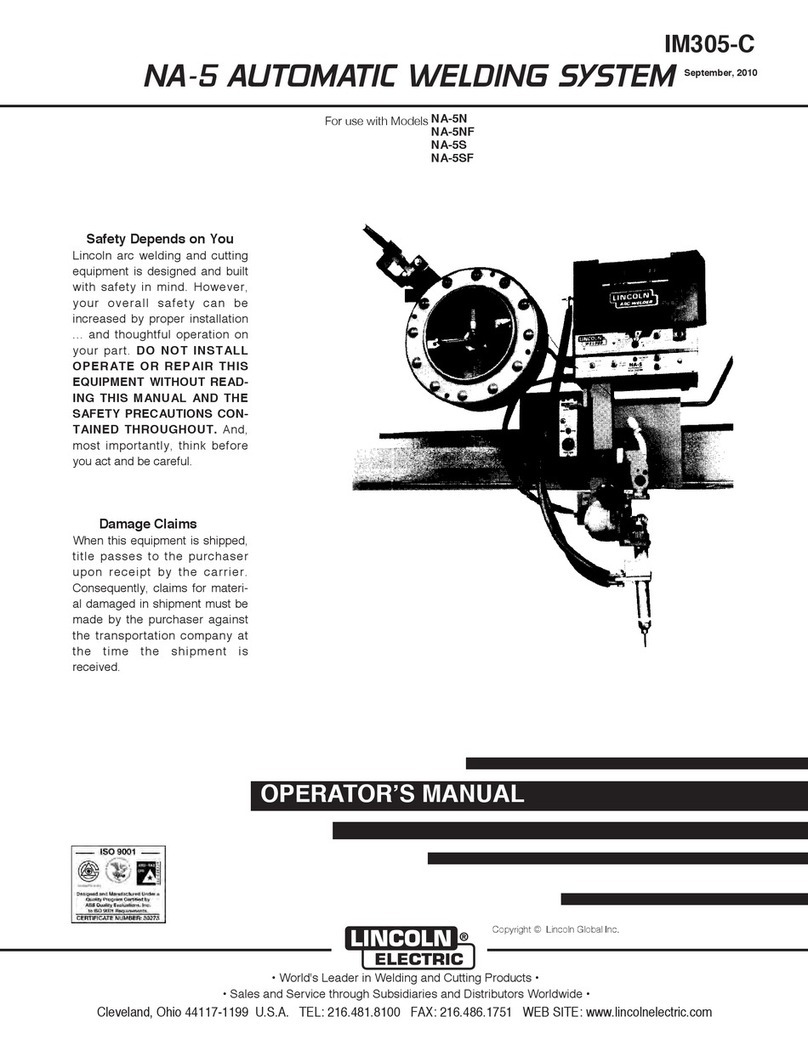

Lincoln Electric NA-5 IM305-C User manual

Lincoln Electric

Lincoln Electric REDI-MIG 455 Remote User manual

Lincoln Electric

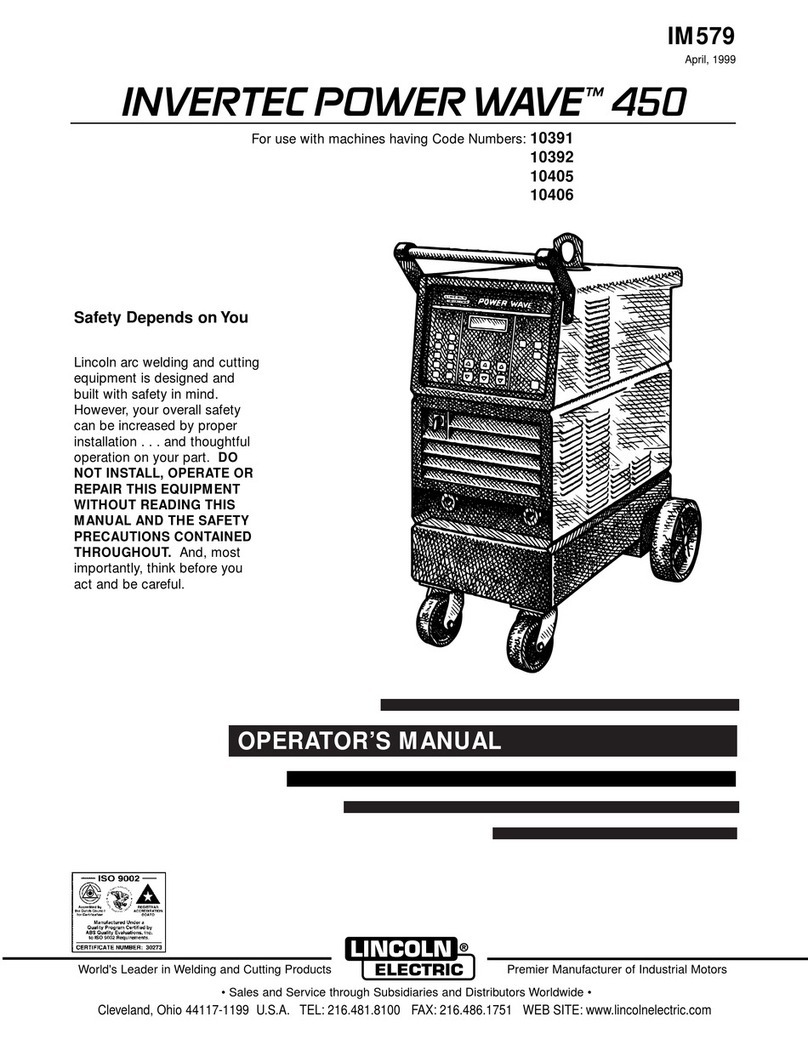

Lincoln Electric INVERTEC POWER WAVE 450 IM579 User manual

Lincoln Electric

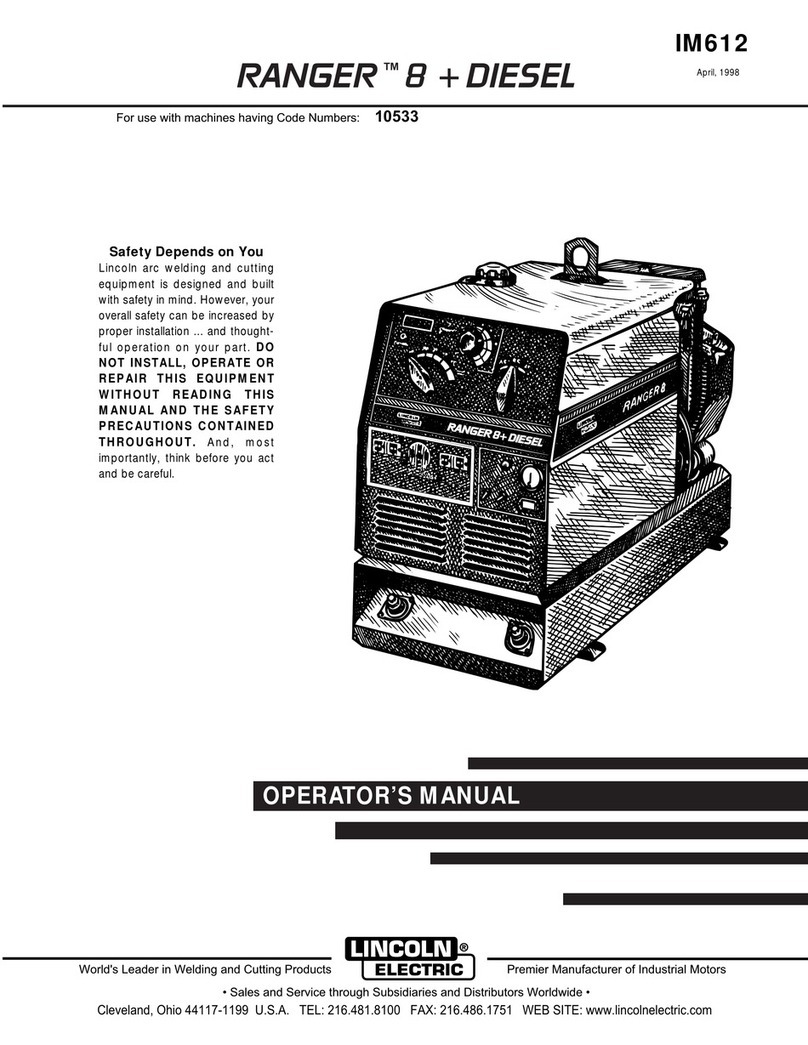

Lincoln Electric RANGER IM612 User manual

Lincoln Electric

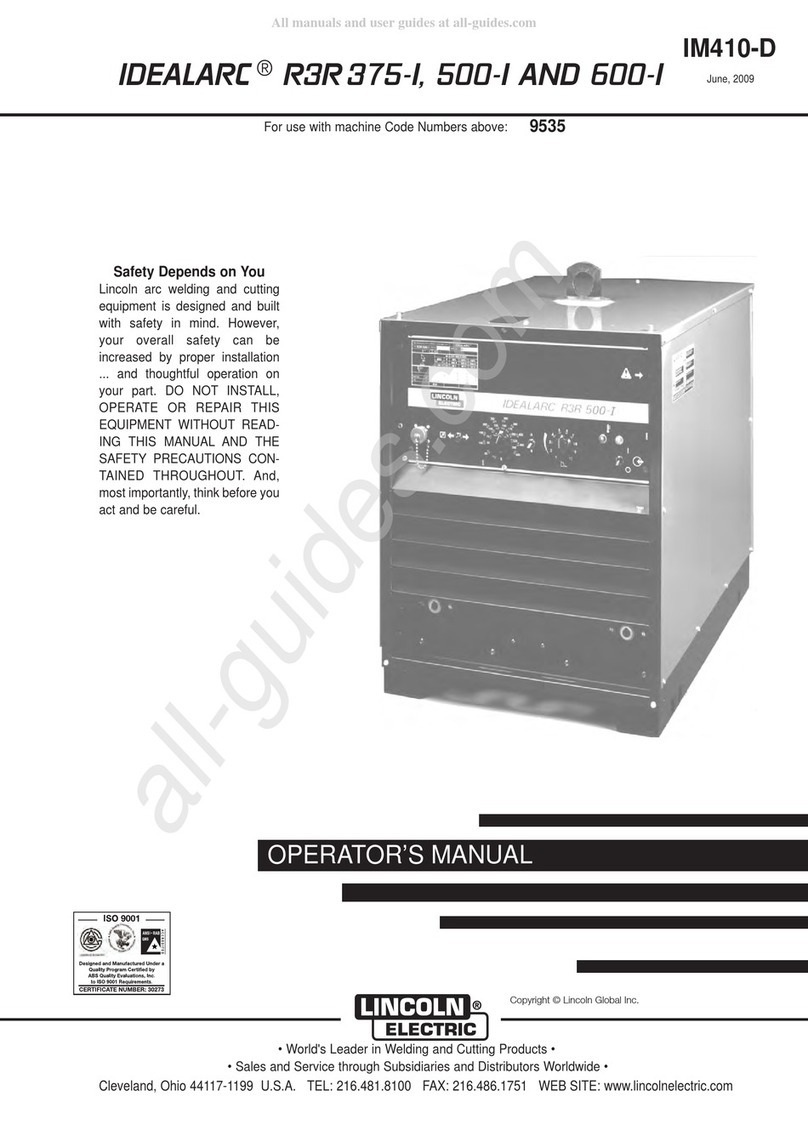

Lincoln Electric IDEALARK RSR 375-I User manual

Lincoln Electric

Lincoln Electric POWERTEC 205C Series User manual

Lincoln Electric

Lincoln Electric MAGNUM PRO AL G450W User manual

Lincoln Electric

Lincoln Electric INVERTEC 170TX Series User manual

Lincoln Electric

Lincoln Electric AC-225 User manual

Lincoln Electric

Lincoln Electric PRO 100 User manual