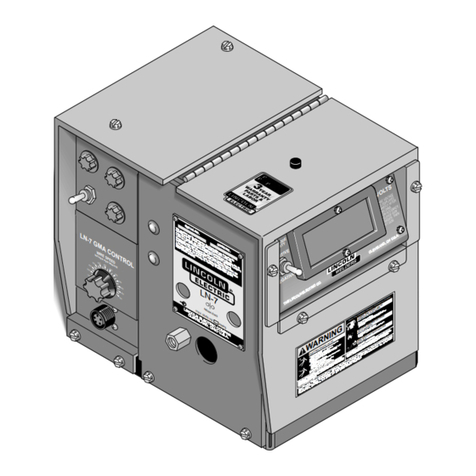

Model K2532-1 Magnum®100SG Spool Gun

Welding Process Aluminum GMAW (MIG), DC electrode positive

polarity with 100% argon welding shielding gas

Wire Alloys Aluminum only: alloys 4043 or 5356

Wire Sizes (Diameters) Solid wire 0.030 or 0.035 inches (0.8 or 0.9 mm)

Spool Size 1 lb. weight, nominal 4 inch diameter spool

Rated Welding Current 130 amps at 30% for 10-minute basis

and Duty Cycle

Overall Weight 3.5 lbs. (1.6 Kg) with cable but without case or spool

Cable Length 10 ft. (3 m)

Method of Guidance Semiautomatic (manually-guided)

Method of Cooling Air-cooled

A CLOSER LOOK

EXPENDABLE PARTS

CCoonnttaaccttTTiippss::

0.030” (0.8 mm) (10-pack) KP2039-2B1

0.035” (0.9 mm) (10-pack) KP2039-3B1

Gas Diffuser KP2040-1

Gas Cone Assembly KP1938-1

Gun Tube Assembly KP2631-1

Drive Roll Assembly KP2529-2

Liner Assembly KP2632-1

DDeessccrriippttiioonnOOrrddeerrNNuummbbeerr

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln

Electric for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such

information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s particular purpose, with respect to such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating

or correcting any such information or advice once it has been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsible manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained

in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

FEATURES

• Recommended power sources:

Power MIG®140C, 140T, 180C and 180T.

• 10 ft. (3.0 m) cable length.

WHAT'S INCLUDED

• Fully assembled K2532-1 spool gun with spring

for use with alloy 5356 wire.

• 1 spool of 0.035” (0.9 mm) aluminum alloy 4043 wire.

• 3 contact tips.

• Instruction manual.

• Electrical harness with toggle switch (must be installed in

welding machine).

• Cushioned carrying case.

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

RECOMMENDED WELDING MACHINES

DDeessccrriippttiioonnOOrrddeerrNNuummbbeerr

SPECIFICATIONS

DDeessccrriippttiioonn

PPoowweerrMMIIGG®®::

180T K2472-1

180C K2473-1

140T K2470-1

140C K2471-1

Great for quick projects and repairs.