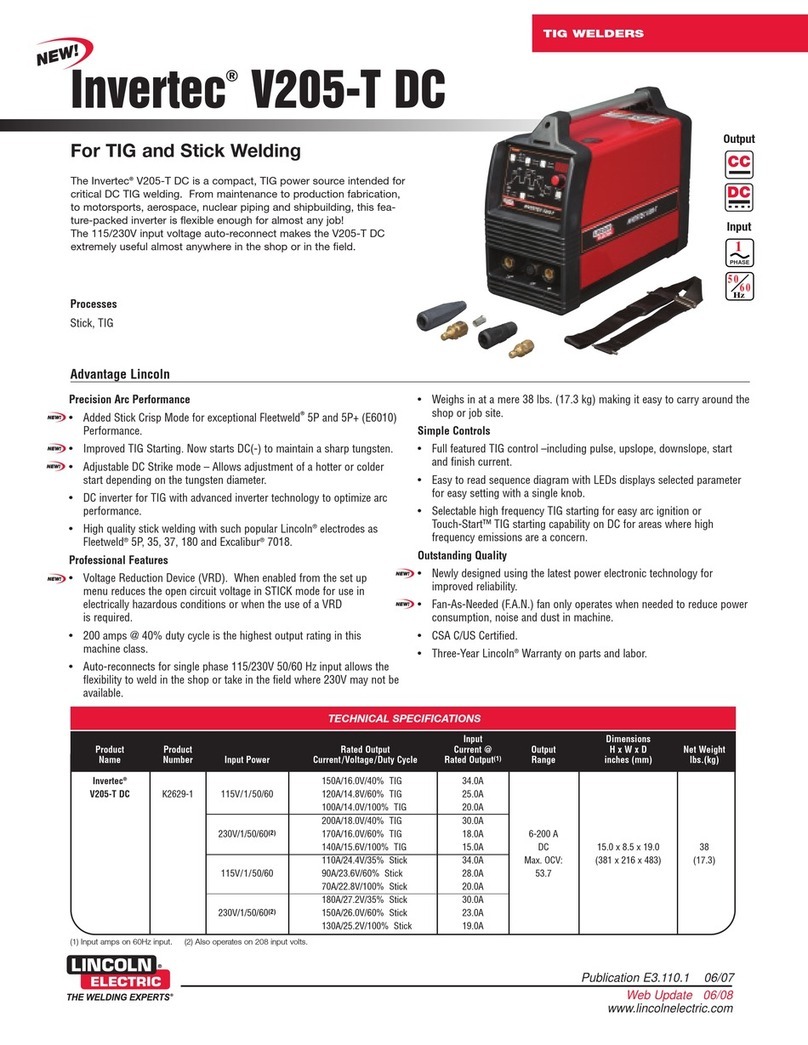

Product

Name

Product

Number

Input

Power

Rated Output

Current/Voltage/Duty Cycle

Input Current

@ Rated Output

Output

Range

H x W x D

inches (mm)

Net

Weight

lbs. (kg)

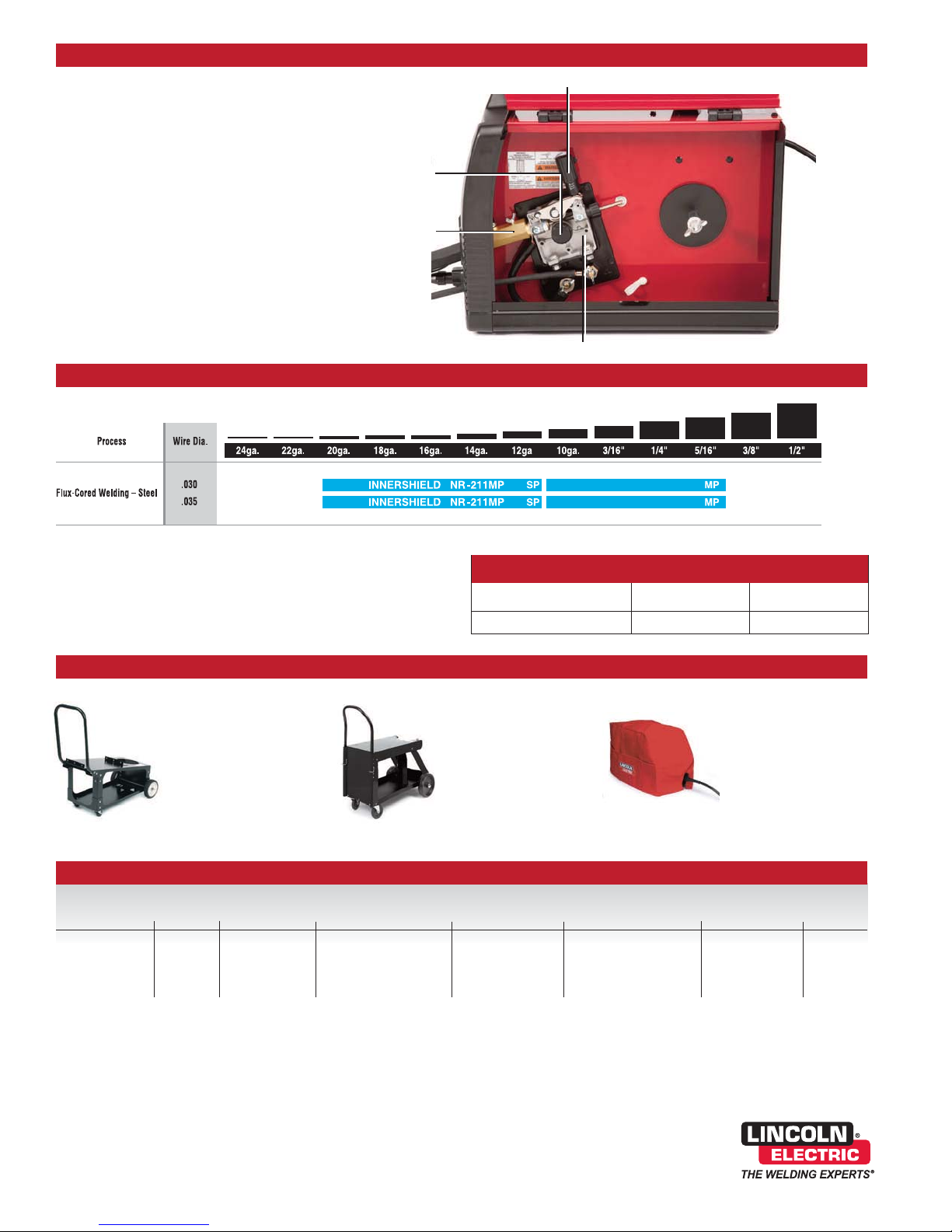

PRO CORE™125 K2479-1 120/1/60 90/19V/20% 20A 30-125 Amps DC

50-500 ipm WFS

(1.3-12.7 m/min)

Max. OCV: 33

13.7 x 10.15 x 17.9

(357 x 258 x 472)

49

(22.5)

PRODUCT SPECIFICATIONS

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our cus-

tomers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for information or advice about their use of our products. Our employees respond to inquiries to the best of

their ability based on information provided to them by the customers and the knowledge they may have concerning the application. Our employees, however, are not in a position to verify the infor-

mation provided or to evaluate the engineering requirements for the particular weldment. Accordingly, Lincoln Electric does not warrant or guarantee or assume any liability with respect to such infor-

mation or advice. Moreover, the provision of such information or advice does not create, expand, or alter any warranty on our products. Any express or implied warranty that might arise from the

information or advice, including any implied warranty of merchantability or any warranty of fitness for any customers’ particular purpose is specifically disclaimed.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the customer.

Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

For best welding results with Lincoln Electric equipment, always use Lincoln Electric consumables.

Visit www.lincolnelectric.com for more details.

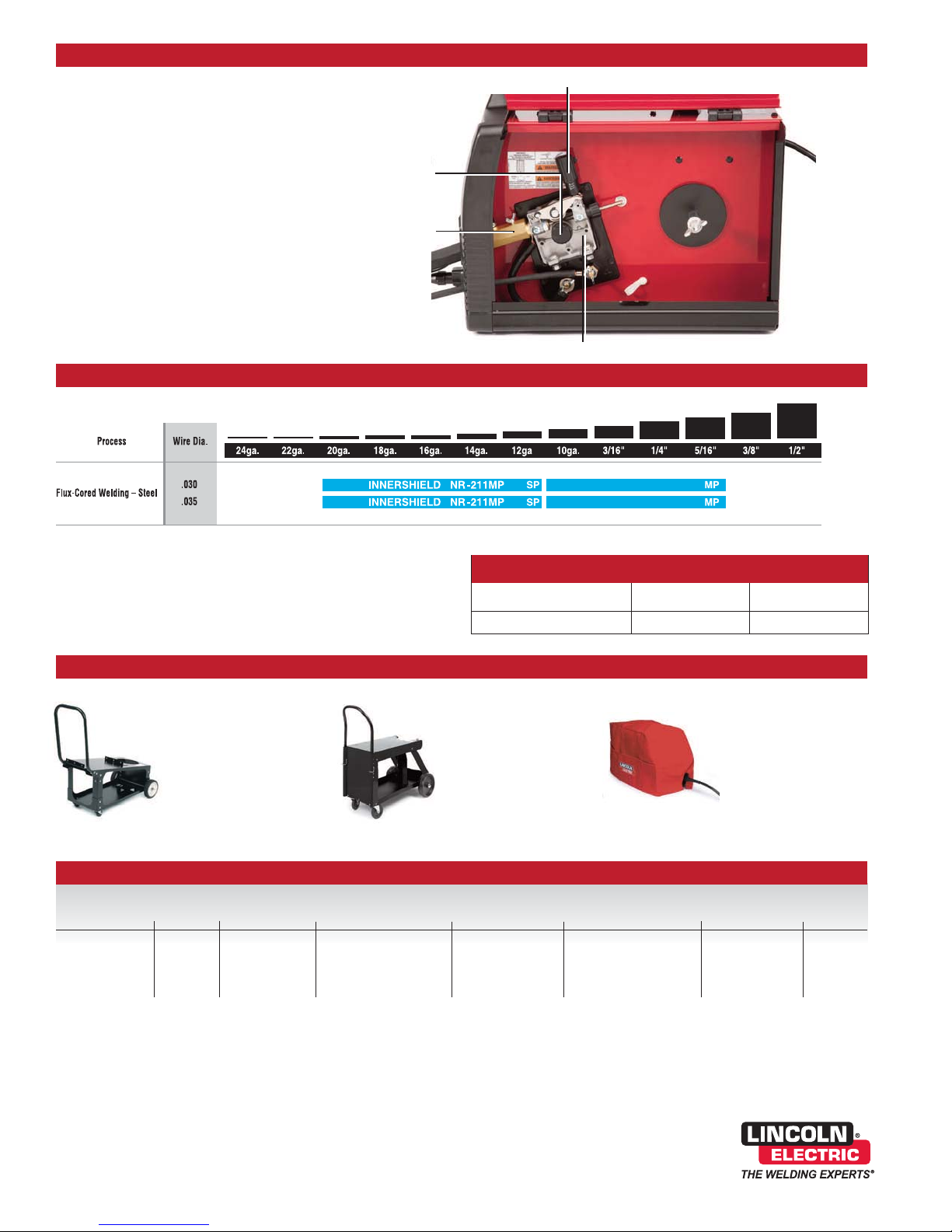

HEAVY DUTY WIRE DRIVE

PERFORMANCE PLUS

Enhanced Quality

1. Brass-to-brass gun connection enhances

conductivity.

2. Rigid drive aids wire alignment. The cast aluminum

body with an enclosed multi-stage gear box delivers

improved torque and quiet operation.

Easy to Use

3. Easy-turn drive tension adjustment with numeric

tension indicators.

4. Fast tool-less drive roll changeovers. The dual track

drive roll ensures positive flux-cored wire feeding

with common wire diameters.

3

4

2

1

in.

in.

Material Thickness

®

®

®

®

DRIVE ROLLS

Product

Number

Wire Diameter

in. (mm) Process

KP2948-1 .025 - .035 (0.6 - 0.9) Flux-Cored

L12603-9

SP - Single Pass

MP - Multiple Pass

GENERAL OPTIONS

Welding Cart

Full-featured cart is designed to

store and transport a welder, 80

cubic foot gas cylinder, welding

cables and accessories. Includes an

angled top shelf for easy access to

welder controls, a lower tray for

added storage space, a sturdy

handle also used as a convenient

cable wrap hanger.

Order K2275-1

Utility Cart

Heavy duty cart stores and

transports welder, 150 cubic foot

shielding gas cylinder, welding

cables and accessories. Includes

stable platforms for welder and gas

bottle platform, lower tray for added

storage capacity and adjustable

height handle.

Order K520

Small Canvas Cover

Protect your welder when not in use.

Made from attractive red canvas that

is flame retardant, mildew resistant

and water repellent. Includes a

convenient side pocket to hold your

welding torch or gun.

Order KH495

RECOMMENDED ACCESSORIES