Page Number - 8 Form 402140

SERVICE PARTS (CONT)

Lincoln Industrial Standard Warranty

LIMITED WARRANTY

Lincoln warrants the equipment manufactured and supplied by Lincoln to be free from defects in material and workmanship for

a period of one (1) year following the date of purchase, excluding therefrom any special, extended, or limited warranty published

by Lincoln. If equipment is determined to be defective during this warranty period, it will be repaired or replaced, within Lincoln’s

sole discretion, without charge.

This warranty is conditioned upon the determination of a Lincoln authorized representative that the equipment is defective. To obtain repair

or replacement, you must ship the equipment, transportation charges prepaid, with proof of purchase to a Lincoln Authorized Warranty and

Service Center within the warranty period.

This warranty is extended to the original retail purchaser only. This warranty does not apply to equipment damaged from acci-

dent, overload, abuse, misuse, negligence, faulty installation or abrasive or corrosive material, equipment that has been altered,

or equipment repaired by anyone not authorized by Lincoln. This warranty applies only to equipment installed, operated and

maintained in strict accordance with the written specifications and recommendations provided by Lincoln or its authorized field

personnel.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, THE WARRANTY OF MERCHANTIBILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

In no event shall Lincoln be liable for incidental or consequential damages. Lincoln’s liability for any claim for loss or damages arising out of

the sale, resale or use of any Lincoln equipment shall in no event exceed the purchase price. Some jurisdictions do not allow the exclusion

or limitation of incidental or consequential damages, therefore the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights. You may also have other rights that vary by jurisdiction.

Customers not located in the Western Hemisphere or East Asia: Please contact Lincoln GmbH & Co. KG, Walldorf, Germany, for

your warranty rights.

Lincoln Industrial Special Limited Warranties

SPECIAL LIMITED 5 YEAR WARRANTY

Series 20, 25, 40 Bare Pumps, Heavy Duty and 94000 Series Bare Reels

Lincoln warrants series 20, 25, 40 bare pumps, and Heavy Duty and 94000 series (94100, 94300, 94500) bare reels to be free from

defects in material and workmanship for five (5) years following the date of purchase. If equipment is determined by Lincoln, in

its sole discretion, to be defective during the first year of the warranty period, it will be repaired or replaced at Lincoln’s discretion,

without charge. In years two (2) and three (3), the warranty on this equipment is limited to repair with Lincoln paying parts and

labor only. In years four (4) and five (5), the warranty on this equipment is limited to repair with Lincoln paying for parts only.

Lincoln Industrial Contact Information

To find Lincoln Industrial’s Nearest Service Center call the following number, you may also use our website

Customer Service 314-679-4200

Website lincolnindustrial.com

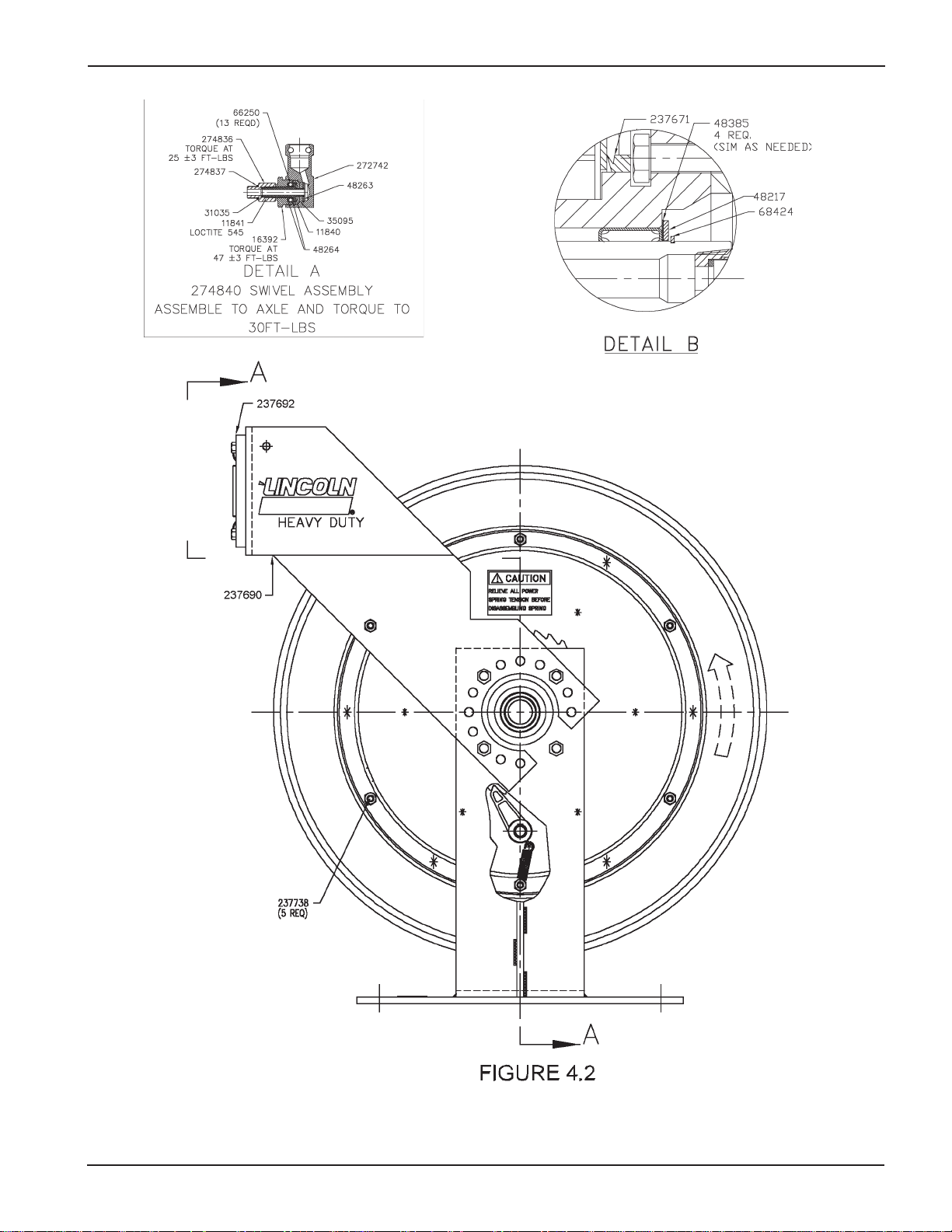

PART QTY DESCRIPTION PART QTY DESCRIPTION PART QTY DESCRIPTION

11840 1 Packing retainer 51022 7 Hex nut 237692 1 Roller outlet assembly

11841 1 Swivel stud 51304 5 Lock nut 237695 1 Extension spring

13162 1 Pin 51412 10 Hex nut 237738 6 Carriage bolt

15674 2 U-keeper 66250 13 Ball 237739 1 Carriage bolt

16392 1 Swivel nut 66316 1 Tru-arc 247136 1 Hose clamp

31035 1 Gasket 68424 1 Tru-arc 272167 1 Hose Clamp

35095 1 Swivel packing 237656 1 Support asembly 272168 1 Hose Clamp

48217 1 Washer 237670 1 Arbor and ratchet casting 272742 1 Swivel body

48263 1 Packing washer 237671 1 V-ring seal 273065 1 Adapter assembly

48264 2 Thrust washer 237672 1 Power spring assembly 273212 1 Outlet adapter

48327 1 Washer 237673 1 V-ring seal 274835 1 Axle

48385 4 Shim washer 237680 1 Sheave assembly 274836 1 Swivel adapter©

50014 4 Hex head screw 237683 1 Latch pawl 274837 1 O-Ring

50033 4 Screw 237690 1 Roller outlet arm assembly 274840 1 Swivel assembly©

© Indicates change