LTC4000

12

4000fb

For more information www.linear.com/LTC4000

operaTion

Overview

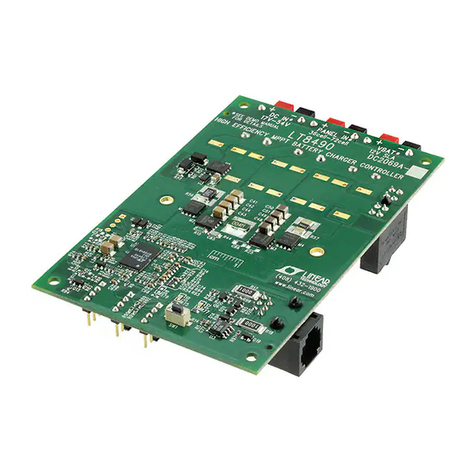

The LTC4000 is designed to simplify the conversion of

any externally compensated DC/DC converter into a high

performance battery charger with PowerPath control. It

only requires the DC/DC converter to have a control or

external-compensation pin (usually named VC or ITH)

whose voltage level varies in a positive monotonic way

with its output. The output variable can be either output

voltage or output current. For the following discussion,

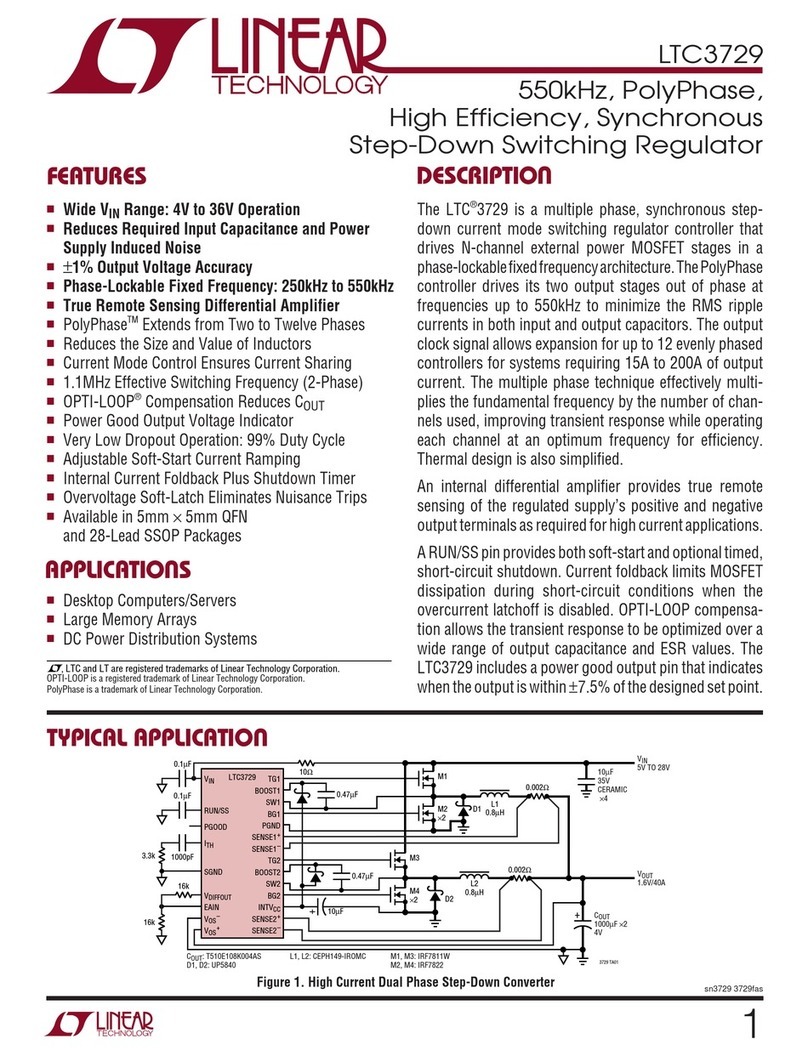

refer to the Block Diagram in Figure 1.

TheLTC4000includesfourdifferentregulationloops:input

current, charge current, battery float voltage and output

voltage (A4-A7). Whichever loop requires the lowest volt-

age on the ITH pin for its regulation controls the external

DC/DC converter.

The input current regulation loop ensures that the pro-

grammed input current limit (using a resistor at IL) is not

exceeded at steady state. The charge current regulation

loop ensures that the programmed battery charge current

limit(usinga resistor at CL)is notexceeded. The floatvolt-

age regulation loop ensures that the programmed battery

stack voltage (using a resistor divider from BAT to FBG

via BFB) is not exceeded. The output voltage regulation

loop ensures that the programmed system output voltage

(using a resistor divider from CSP to FBG via OFB) is not

exceeded. The LTC4000 also provides monitoring pins

for the input current and charge current at the IIMON and

IBMON pins respectively.

TheLTC4000 features anideal diodecontrollerat the input

from the IID pin to the CSP pin and a PowerPath controller

at the output from the BAT pin to the CSN pin. The output

PowerPath controller behaves as an ideal diode controller

whennot charging. Whencharging, theoutput PowerPath

controller has two modes of operation. If VOFB is greater

than VOUT(INST_ON), BGATE is driven low. When VOFB is

less than VOUT(INST_ON), a linear regulator implements

the instant-on feature. This feature provides regulation of

the BGATE pin so that a valid voltage level is immediately

available at the output when the LTC4000 is charging an

over-discharged, dead or short faulted battery.

The state of the ENC pin determines whether charging is

enabled. When ENC is grounded, charging is disabled and

thebatteryfloatvoltageloopisdisabled.Chargingisenabled

when the ENC pin is left floating or pulled high (≥1.5V)

The LTC4000 offers several user configurable battery

charge termination schemes. The TMR pin can be config-

uredforeitherC/Xtermination,chargetimerterminationor

no termination. After a particular charge cycle terminates,

the LTC4000 features an automatic recharge cycle if the

battery voltage drops below 97.6% of the programmed

float voltage.

Trickle charge mode drops the charge current to one

tenth of the normal charge current (programmed using a

resistor from the CL pin to GND) when charging into an

over discharged or dead battery. When trickle charging,

a capacitor on the TMR pin can be used to program a

time out period. When this bad battery timer expires and

the battery voltage fails to charge above the low battery

threshold (VLOBAT), the LTC4000 will terminate charging

and indicate a bad battery condition through the status

pins (F LT and CHRG).

The LTC4000 also includes an NTC pin, which provides

temperaturequalified charging whenconnected to an NTC

thermistorthermallycoupledtothebatterypack.To enable

this feature, connect the thermistor between the NTC and

the GND pins, and a corresponding resistor from the BIAS

pin to the NTC pin. The LTC4000 also provides a charging

status indicator through the F LT and the CHRG pins.

Aside from biasing the thermistor-resistor network, the

BIAS pin can also be used for a convenient pull up voltage.

This pin is the output of a low dropout voltage regulator

that is capable of providing up to 0.5mA of current. The

regulated voltage on the BIAS pin is available as soon as

the IN pin is within its operating range (≥3V).

Input Ideal Diode

The input ideal diode feature provides low loss conduction

and reverse blocking from the IID pin to the CSP pin. This

reverse blocking prevents reverse current from the output

(CSP pin) to the input (IID pin) which causes unneces-

sary drain on the battery and in some cases may result

in unexpected DC/DC converter behavior.

The ideal diode behavior is achieved by controlling an

external PMOS connected to the IID pin (drain) and the