The allowsadjustmentsof±5.0°Cintheroomsensor(S1)

inrelationtothestandardcalibration.Forthisjustpressthekeyfor15secondsuntil

appearingtheindication .Usethe same procedure to modify the value of

thisfunction.

TC-900RG2 slim

Theluminouspointerinthefrontalsignalsthestatusofthecontroller:

Thecontrollerisinrefrigerationmode,withthecompressor

andfan ON. Whenthe instrument isin refrigeration withthe stopped indicationled

blinksinalesserfrequency.

Thecontrollerisinrefrigerationmode,withthecompressor

andthefanOFF. mode

a

Ledblinking

Ledturnedoff

Ledturnedon Thecontrollerisindefrost ,withthecompressorand

fanOFFandtheresist ncesON.

RoomsensorinshortcircuitortemperatureaboveofP8

s openedor

E sensordamagedortemperatureinthesensorbelowof

-30 ºC or above of ºC. In this situation the duration of the thawing will be of 10

minutes.

Room ensor temperaturebelowofP7

vaporator50

INDICATION DISPLACEMENT (OFFSET)

SIGNALLING

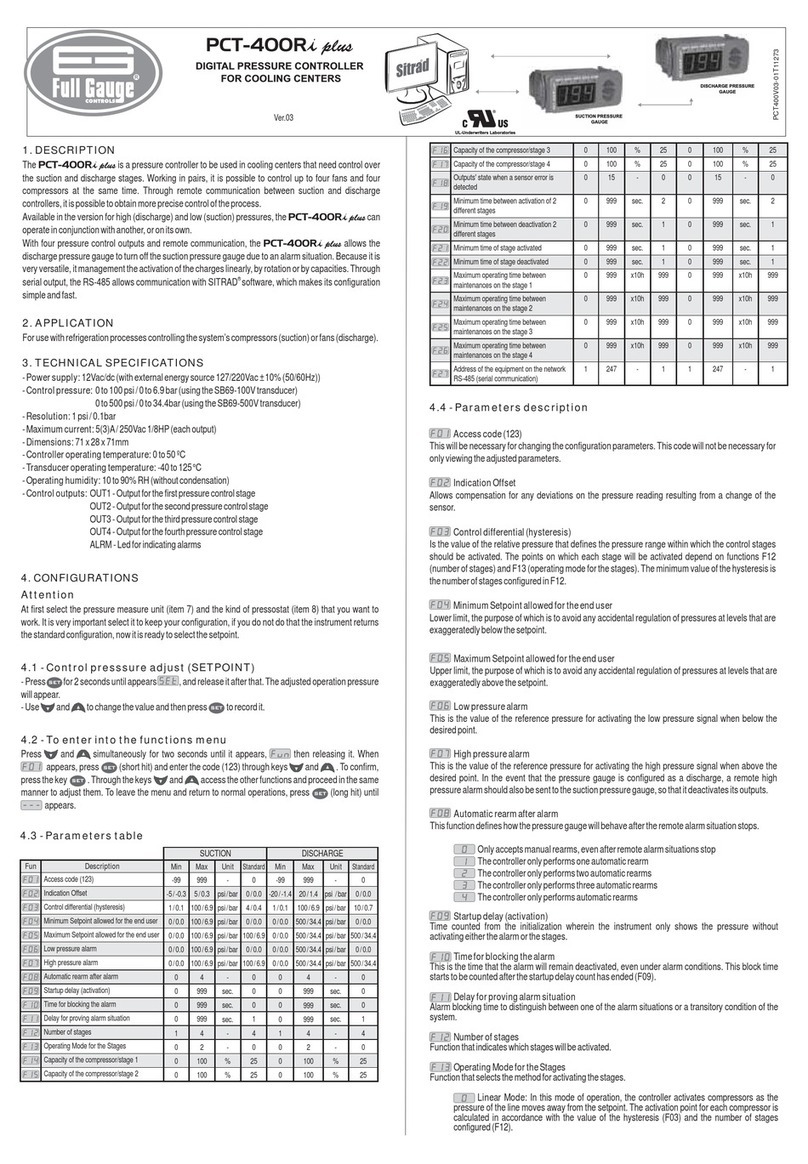

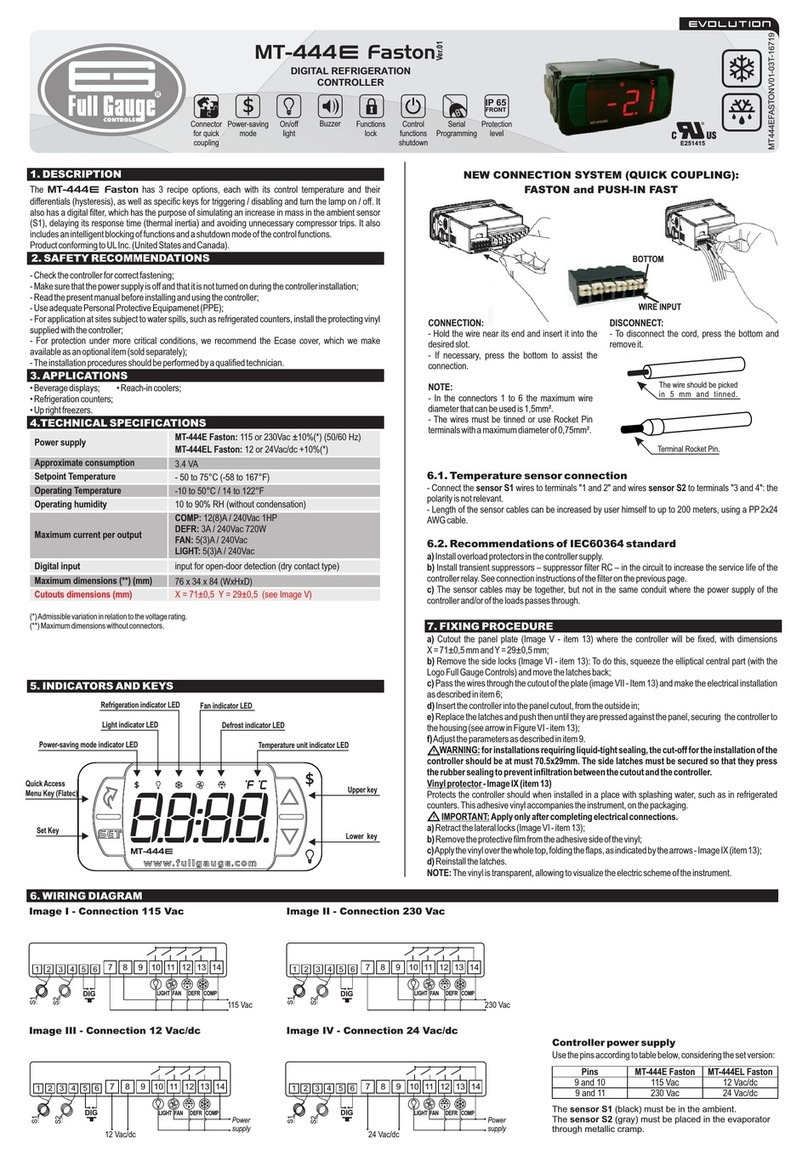

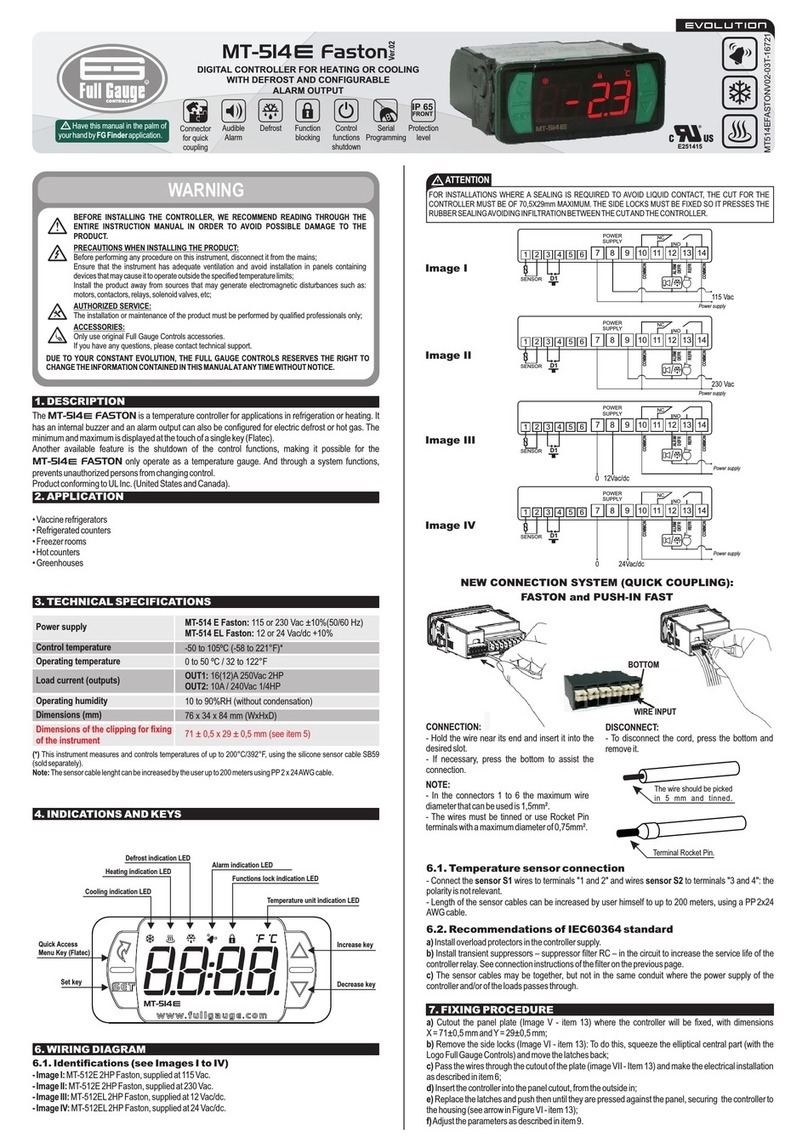

DIGITAL CONTROLLER FOR

REFRIGERATION AND DEFROST

Version 01

The is a digital temperature with outputs to

compressor,fananddefrost.

Beverage freezers

TC-900RG2 slim controller

Application:

- Power supply:

- Maximum load:

- Sensors:

90~264Vac (50/60 Hz)

COMP-1

FAN - 5(3)A/ 250Vac 1/8HP - Fan output

DEFR-10(3)A/250Vac1/4HP-Defrostoutput

6(8)A /250Vac1HP-Compressoroutput

S1 (Room)

S2 (Evaporator)

0 to 50°C

10 to 90% RH (without condensation)

- Operation temperature:

- Humidity operation:

CONTROLS

R

Find manuals of all line on Web:

www.fullgauge.com

Phone/Fax: +55 51 34753308

MADE IN BRAZIL

DESCRIPTION

TECHNICAL SPECIFICATIONS

Put the selector keys in the desired position and press the key for 10 seconds

until appear the indication . Release key and wait until appears the value

programmed for this function, use the key again to modify this value. After adjusted

the new value for the function wait 4 seconds. The controller will record the new

parameter and will pass to the function . Use the same procedure to modify

the value of this function. Repite this for the functions and that will be

the next to be showed in the display to be configured. After the alteration of the

parameters the display comes to the indication of temperature.

OPERATION PARAMETERS

Refrigeration time

Defrost time with the sensor of evaporator working

efrost time with the sensor of evaporator damaged

Control temperature (setpoint)

Differential of control (hysteresis)

inimum delay to restart the compressor

Low temperature or room sensor open

High temperature or room sensor in short circuit

Displacement of indication of room sensor (offset)

D

M

Parameters 00 11

12 hours

30 min.

10 min.

5.0 ºC

3.0 ºC

120 sec.

-20 ºC

45 ºC

0.0 ºC

10

30 min.

10 min.

2.0 ºC

3.0 ºC

120

-20 ºC

45 ºC

0.0 ºC

hours

sec.

01 10

6

30 min.

10 min.

-6.0 ºC

3.0 ºC

120

-20 ºC

45 ºC

0.0 ºC

hours

sec.

6

30 min.

10 min.

-1.0 ºC

3.0 °C

120

-20 ºC

45 °C

0.0 °C

hours

sec.

Item

P1

P2

P3

P4

P5

P6

P7

P8

P9

SELECTOR KEYS POSITION

Programmable parameter, indication at display

Programmable parameter, indication at display

Programmable parameter, indication at display

Programmable parameter, indication at display

Programmable parameter, indication in the display

Parametersv

Defrostonstart

Refrigeration

isualization

Whenthecontrollerisenergized,itwillappeartheparametersofconfigurationinthe

followingorder:

The controller will make defrost when energized if the temperature of the

sensor(S1)hewillbebelowof30ºCandtemperatureofthesensoroftheevaporator

(S2)belowof15ºC.

The

REFRIGERATIONTIME DEFROSTTIME SETPOINT DIFFERENTIAL

compressorturnsonandturnsoffbytemperature,accordingthevalueadjusted

in the P4 parameter (see table above) during the refrigeration time (P1). After

elapsed the time the controller will initiate a defrost cycle (if the temperature of the

sensorwill be below of 30ºC), turning offthe compressor andthe evaporator

fan.Duringthestageofrefrigeration remainsturnedononlywhilethe

compressorwillbefunctioning. evaporatorfan

room

room

PARAMETERSALTERATION

Defrost

Delay

Thedefrostwillbefinishedwhenthetemperatureintheevaporator(S2)reaches15ºC

orthetemperatureintheroom(S1)reach30ºC.Otherwise,thedefrostwill befinished

after elapsed the maximum defrost time configured (P2 or P3). During the defrost the

last temperature measured in the refrigeration cycle will be frozen in the display. The

indicationwillbedefrostedwhenthistemperaturebereachedagainor15minutesafter

theendofthedefrost.

When the instrument is energized or the temperature in the S1 sensor reaches the

setpoint (compressorturn off),thedelay(P6) starts tobecounted,preventingthatthe

compressormustberestartedinaperiodveryshort. Eventhanbytemperatureitwold

benecessarytoturnonthecompressorthedelay(P6)isrespected.

Externalselector

Theexternalselectorallows,withacombinationoftwokeys,todefinethefunctioningof

thecontrollerwithprogrammablepresets.

FUNCTIONINGDESCRIPTION

VISUAL ALARMS

KEY (ACCESS IN THE FRONT PANEL)

Tochangetherefrigerationtodefrostorvice-versa,justasimpletouchonthekey.To

visualize the temperature measured by the evaporator sensor (S2), keep pressed

thekeyfor5seconds.

TC-900RG2 slim

TC-900RG2 slim

UL-Underwriters Laboratories