Linear Technology DC164 Quick setup guide

Other Linear Technology Media Converter manuals

Linear Technology

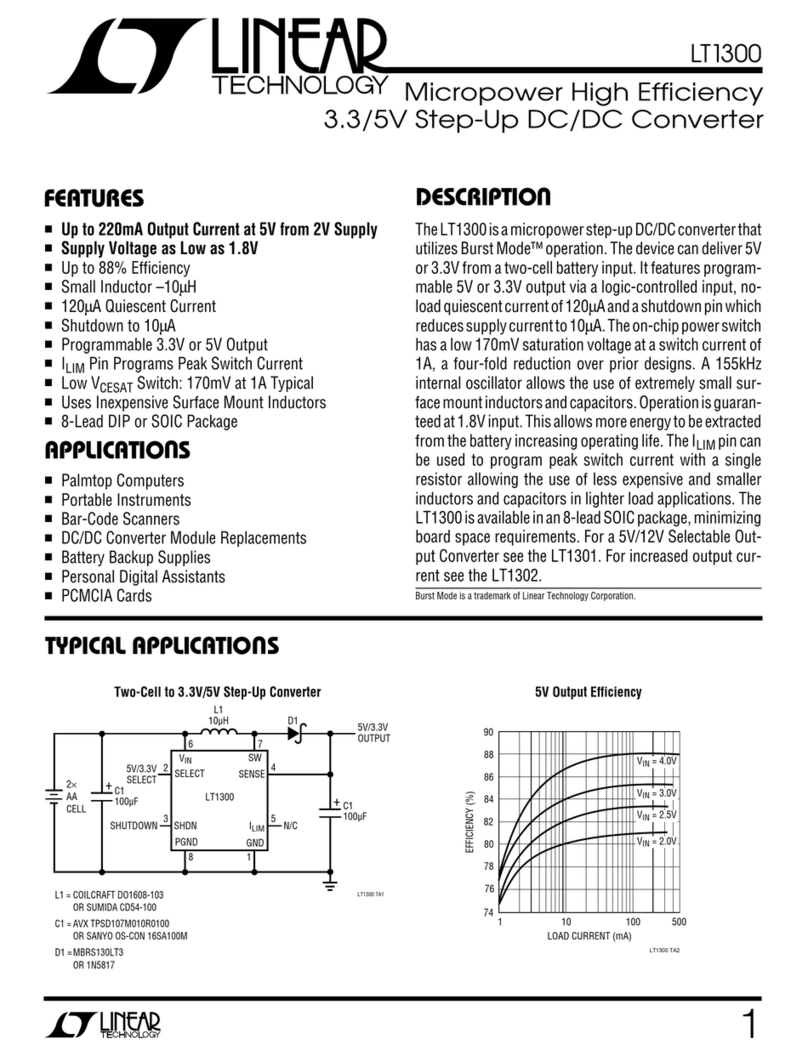

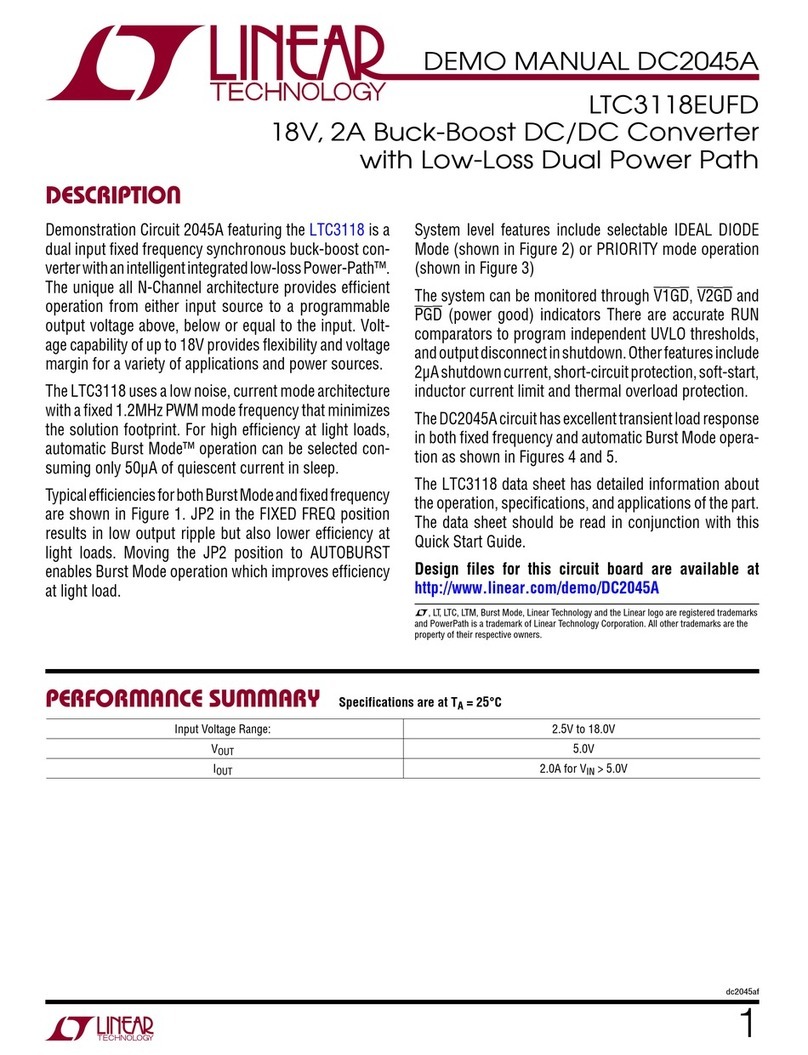

Linear Technology LTC3118EUFD Quick setup guide

Linear Technology

Linear Technology LTC1628 User manual

Linear Technology

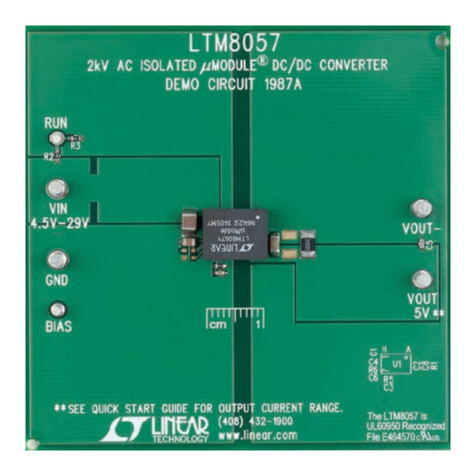

Linear Technology LTM8057 Quick setup guide

Linear Technology

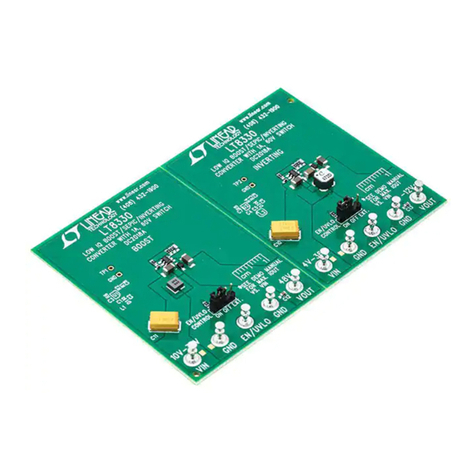

Linear Technology LT8330 User manual

Linear Technology

Linear Technology DC242 Quick setup guide

Linear Technology

Linear Technology DC2050A User manual

Linear Technology

Linear Technology DC1739A-B Quick setup guide

Linear Technology

Linear Technology LTC3130EUD-1 User manual

Linear Technology

Linear Technology DC1687A Quick setup guide

Linear Technology

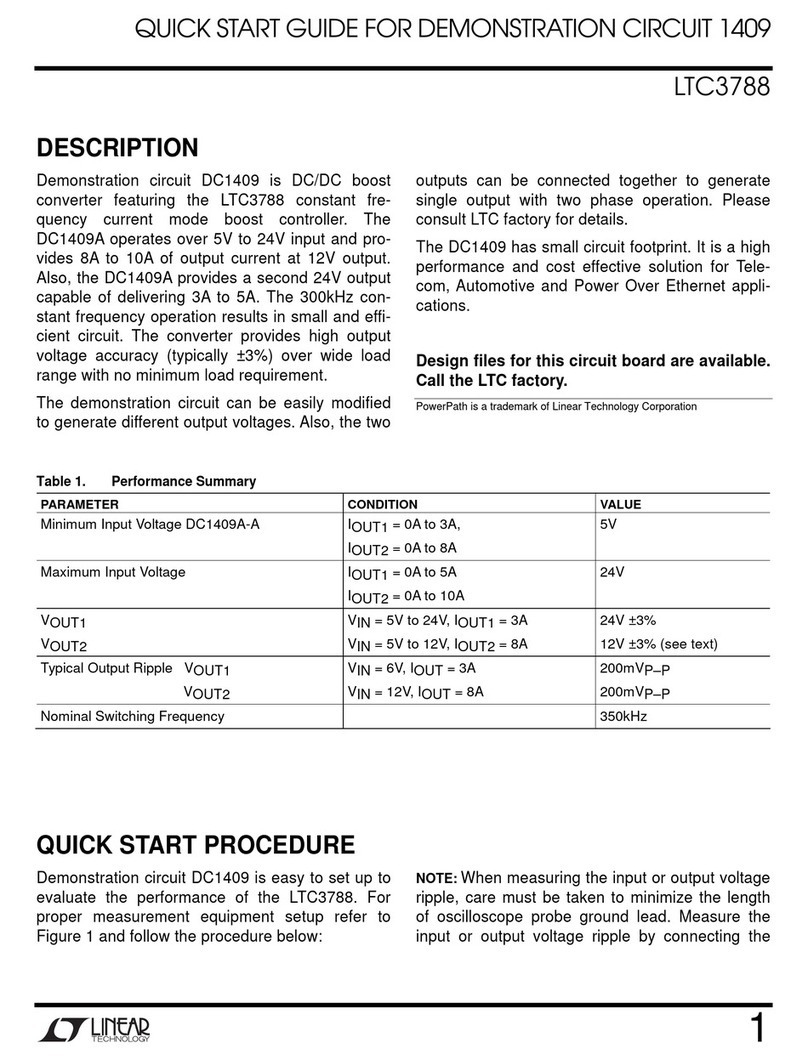

Linear Technology DC1409 User manual

Linear Technology

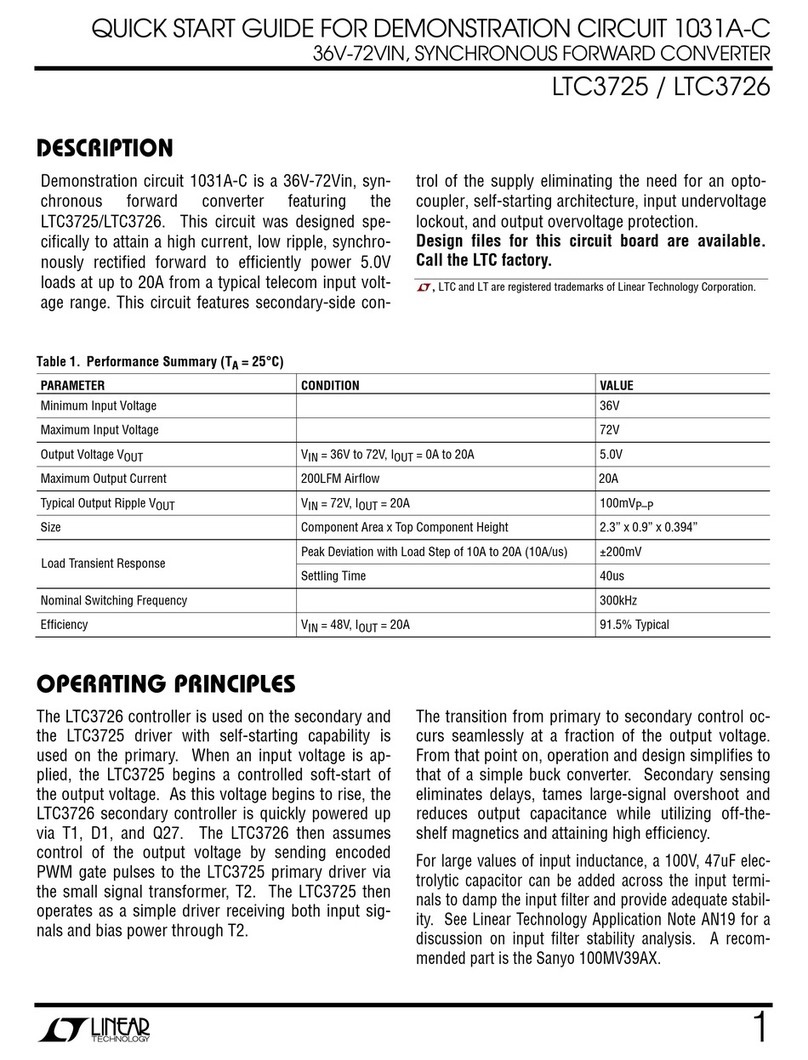

Linear Technology LTC3725 User manual

Linear Technology

Linear Technology DC1887A Quick setup guide

Linear Technology

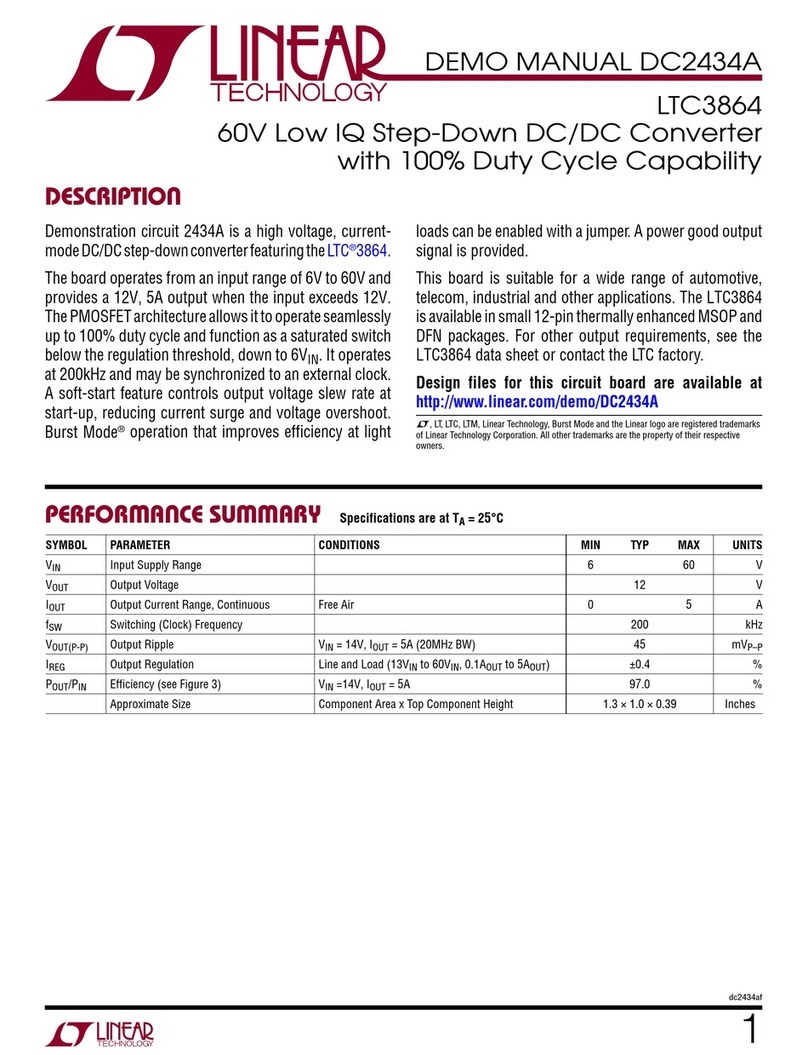

Linear Technology DC2434A Quick setup guide

Linear Technology

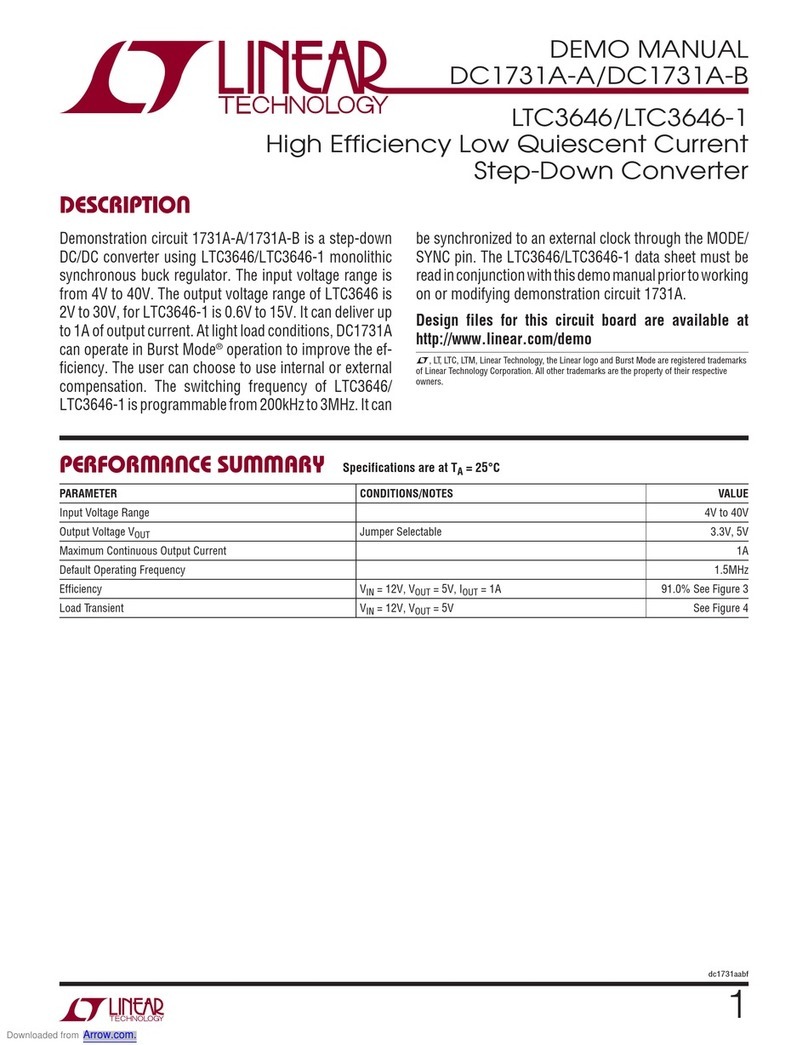

Linear Technology DC1731A-A Quick setup guide

Linear Technology

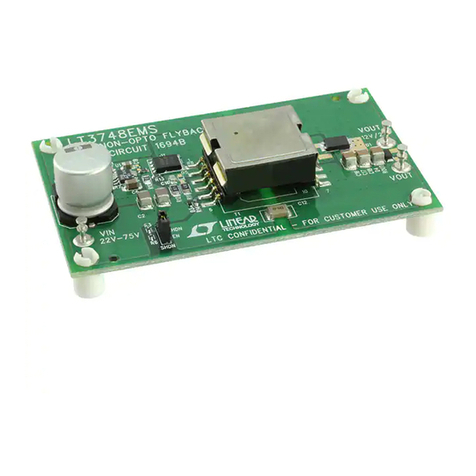

Linear Technology LT3748 Quick setup guide

Linear Technology

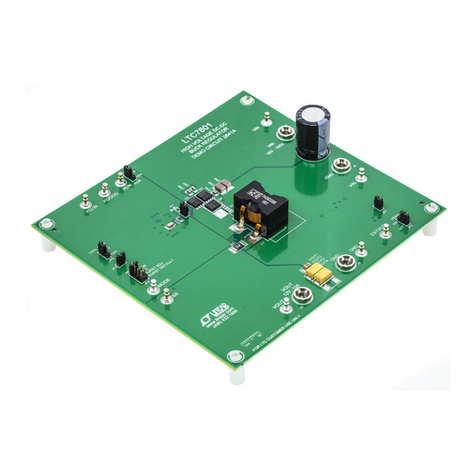

Linear Technology DC1929A Quick setup guide

Linear Technology

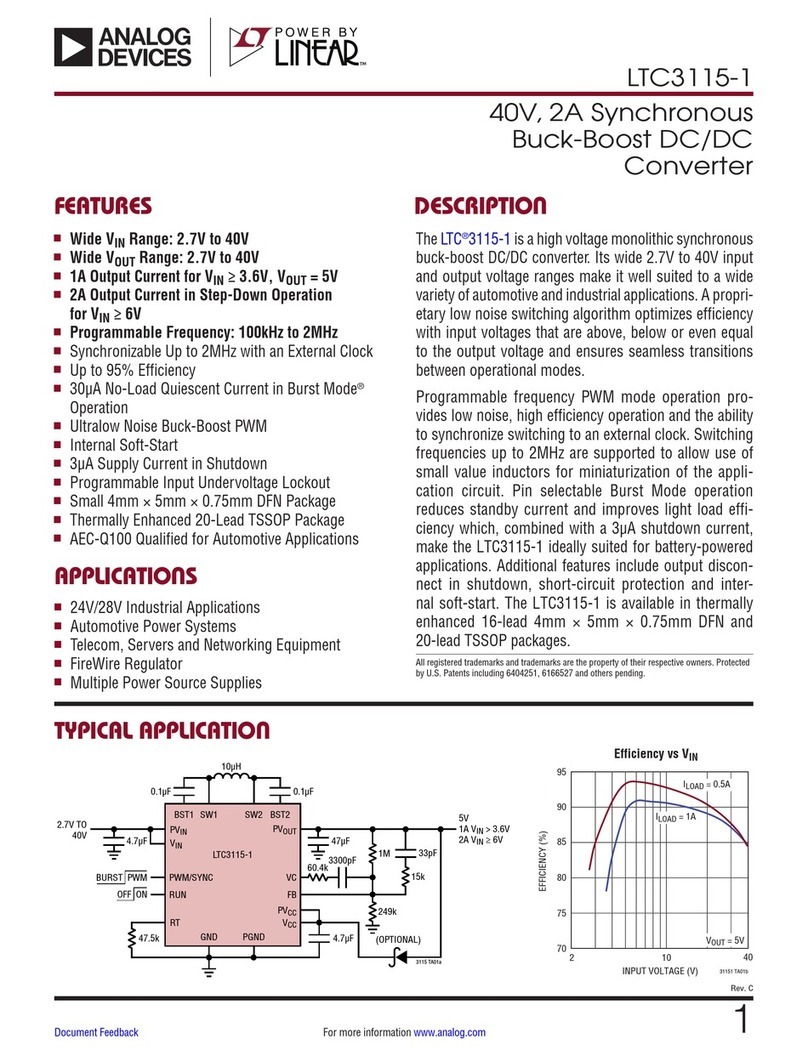

Linear Technology LTC 3115-1 User manual

Linear Technology

Linear Technology LTC3725 User manual

Linear Technology

Linear Technology LTC3118 User manual

Linear Technology

Linear Technology DC2641A Quick setup guide

Popular Media Converter manuals by other brands

H&B

H&B TX-100 Installation and instruction manual

Bolin Technology

Bolin Technology D Series user manual

IFM Electronic

IFM Electronic Efector 400 RN30 Series Device manual

GRASS VALLEY

GRASS VALLEY KUDOSPRO ULC2000 user manual

Lika

Lika ROTAPULS I28 Series quick start guide

Weidmuller

Weidmuller IE-MC-VL Series Hardware installation guide

Optical Systems Design

Optical Systems Design OSD2139 Series Operator's manual

Tema Telecomunicazioni

Tema Telecomunicazioni AD615/S product manual

KTI Networks

KTI Networks KGC-352 Series installation guide

Gira

Gira 0588 Series operating instructions

Lika

Lika SFA-5000-FD user guide

GoMax Electronics

GoMax Electronics SP-2003 user manual