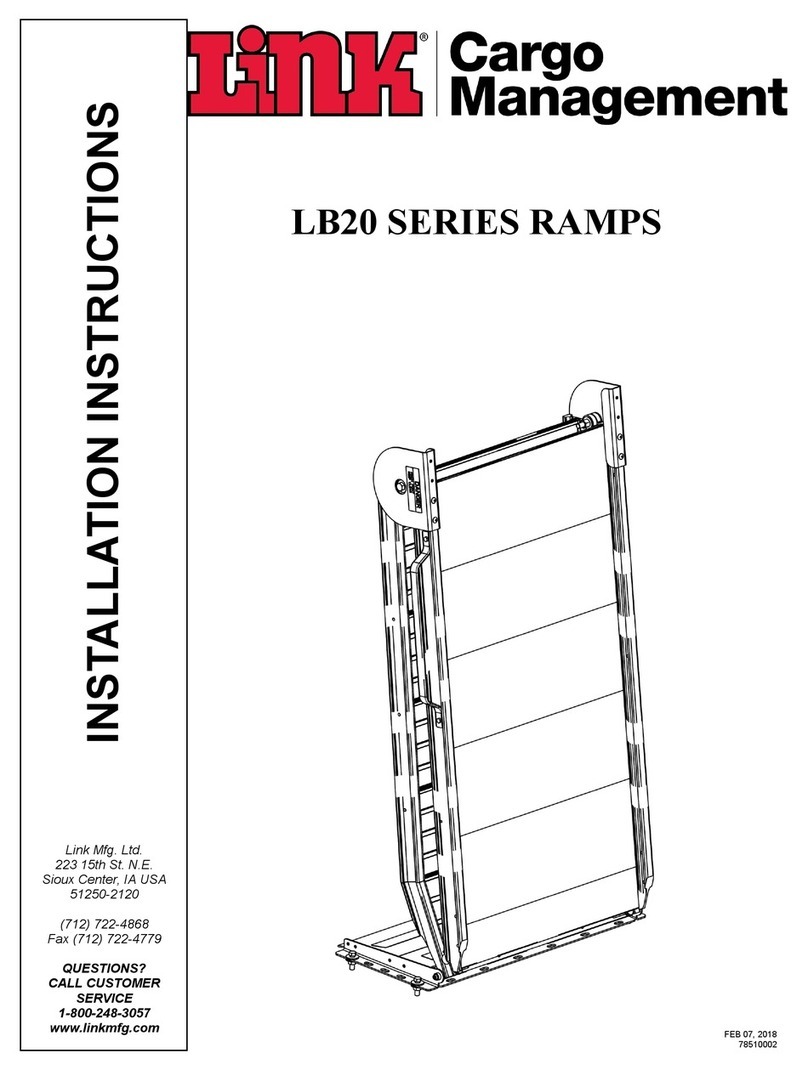

5. OPERATION

5.1 Ramp Operation

1. With the vehicle in park and the parking brake se-

cured, open the rear door of the vehicle.

2. Release the rotatory latch (midway up the side of

ramp on the passenger side near the handle).

3. Fold ramp out of the rear of the vehicle.

5.2 Ramp Swivel Out Operation

1. With the vehicle in park and the parking brake

secured, open the rear door of the vehicle.

2. To swivel the ramp out of vehicle.

3. Release the latch on the passenger side of vehicle

by pulling the rear yellow handle upward.

4. Swing the ramp out till the ramp swivel lock en-

gages.

5. To release ramp pull the swivel lock and swing

ramp until latched into latch.

5.3 Ramp Swivel In Operation

1. With the vehicle in park and the parking brake

secured, open the rear door of the vehicle.

2. To swivel the ramp into vehicle.

3. Release the latch on the passenger side of vehicle

by pulling the forward yellow handle upward.

4. Swing the ramp in till the ramp swivel lock engag-

es and the ramp is resting on the inside deck

catch .

5. To release ramp pull the swivel lock and swing

ramp outwards until latched into latch.

6. MAINTENANCE

The LSR90 is designed to last for many years without any

major maintenance. Periodically, check

the following items:

Each Time the Ramp is Used:

• Listen for unusual noises and watch to ensure prop-

er movement of the ramp. If there is a problem,

correct it before continuing to use the system.

Annually:

• Check tightness of all fasteners. (Refer to Torque

Table below)

• Visually inspect for cracks or damage at all pivots

on the framework and replace if necessary.

• Make certain the vehicle is in park and the parking

brake is engaged before loading / unloading the vehi-

cle.

• Vehicle movement during loading / unloading could

cause operator injury or death.

WARNING

• Loading beyond the capacity may result in equip-

ment damage or failure that may result in severe inju-

ry or death.

WARNING

• Do not use ramp if not locked into latch. Damage or

failure of ramp may occur that may result in severe

injury or death.

WARNING

• Do not use ramp if not locked into latch. Damage or

failure of ramp may occur that may result in severe

injury or death.

WARNING

• Park the vehicle in a level, flat area,

and apply the parking brake before

performing any maintenance.

CAUTION

TORQUE TABLE

FASTENER TORQUE

3/8-UNC NUTS 30-40 FT-LBS

7/16-UNC NUTS 50-60 FT -LBS

1/2-UNC NUTS 80-100 FT-LBS