LINSHANG LS230 User manual

Other LINSHANG Measuring Instrument manuals

LINSHANG

LINSHANG LS191 User manual

LINSHANG

LINSHANG LS232 User manual

LINSHANG

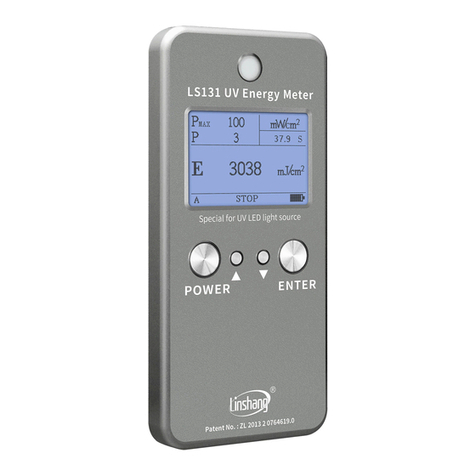

LINSHANG LS131 User manual

LINSHANG

LINSHANG LS101 User manual

LINSHANG

LINSHANG LS123 User manual

LINSHANG

LINSHANG LS212 User manual

LINSHANG

LINSHANG LS220B User manual

LINSHANG

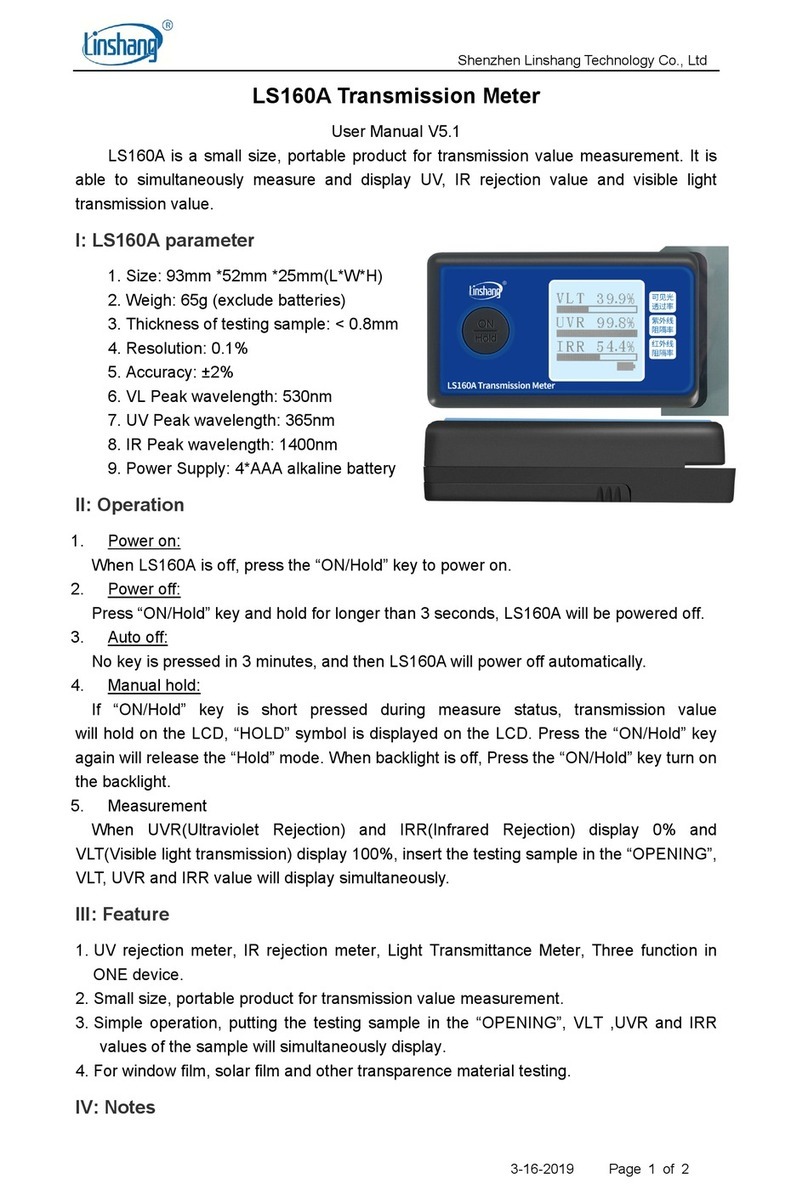

LINSHANG LS160A User manual

LINSHANG

LINSHANG LS233 User manual

LINSHANG

LINSHANG LS236 User manual

LINSHANG

LINSHANG LS201 User manual

LINSHANG

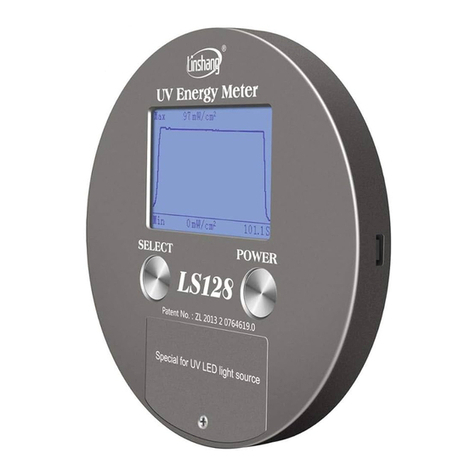

LINSHANG LS128 User manual

LINSHANG

LINSHANG LS301 User manual

LINSHANG

LINSHANG LS162A User manual

LINSHANG

LINSHANG LS137 User manual

LINSHANG

LINSHANG LS251D User manual

LINSHANG

LINSHANG LS193 User manual

LINSHANG

LINSHANG LS252DL User manual

LINSHANG

LINSHANG LS213 User manual

LINSHANG

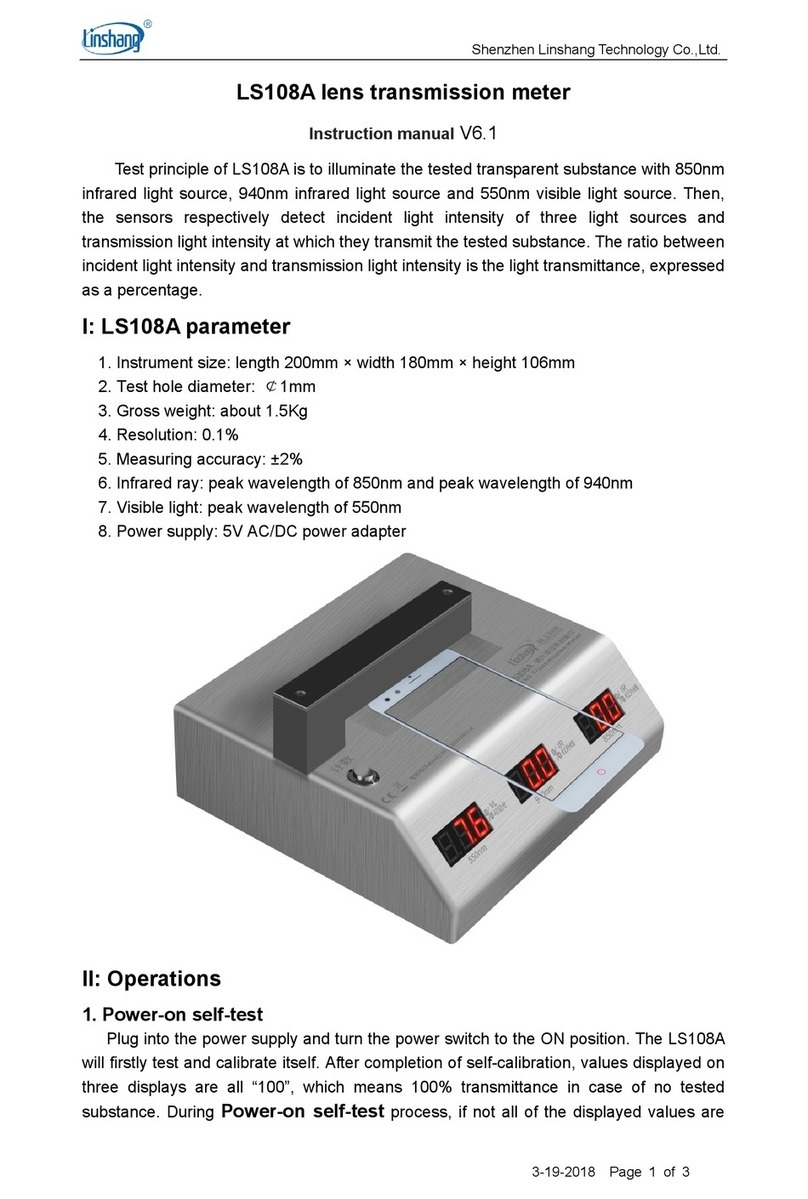

LINSHANG LS108A User manual

Popular Measuring Instrument manuals by other brands

ABB

ABB 4690 Series user guide

Munters

Munters CO2 Sensor installation manual

Boumatic

Boumatic StepMetrix Installation, Operation Maintenance & Service Instructions

BIG

BIG LEVEL MASTER LVM-01 Operation manual

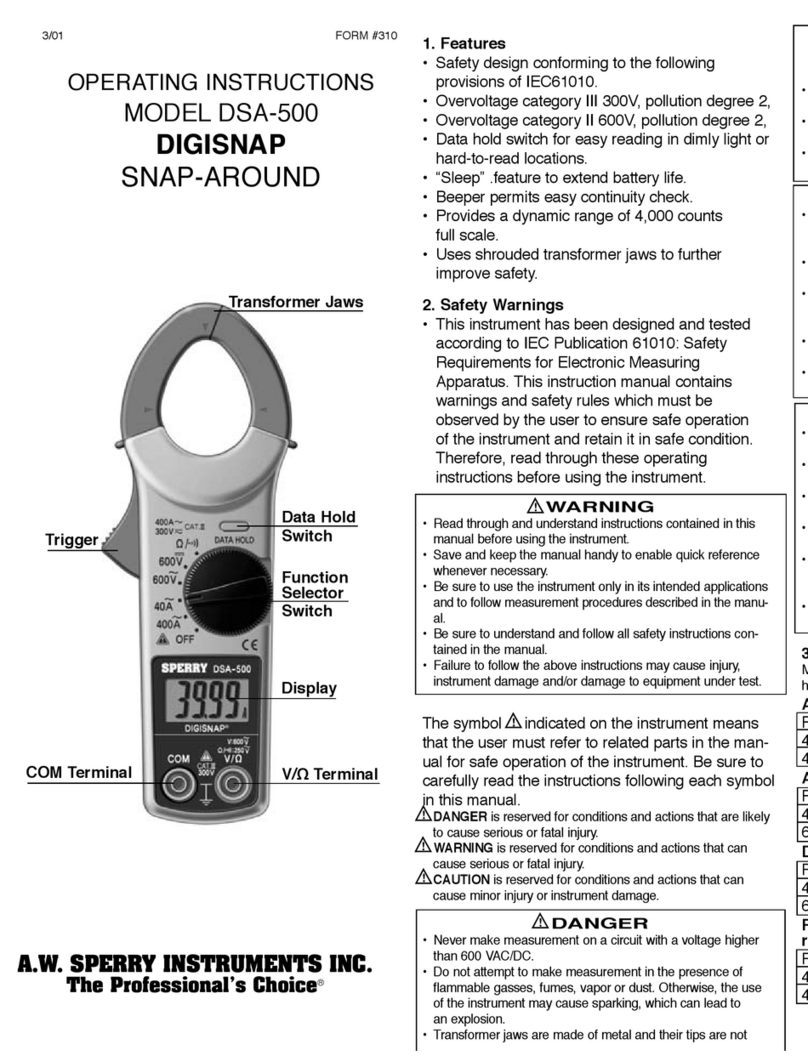

A.W. Sperry Instruments

A.W. Sperry Instruments DSA-500 operating instructions

Sun-Tech

Sun-Tech Vet30 user manual