Lintec VU-0430N Series User manual

LN0405E2107B0

Vaporizer Unit Instruction Manual

VU-0430N Series

Safety Precautions

Incorrect handling can cause serious injury or death.

(1) Before connecting the fittings, check that no damage or defects are found

on the fittings. Make connections properly and make sure that a leak test is

conducted before actual operation to prevent liquid and gas from leaking

into the atmosphere.

(2) DO NOT apply any corrosive fluid to materials exposed to liquid and gas.

Corrosion may cause liquid or gas to leak into the atmosphere. Please

confirm the physical properties of liquid or gas before using.

(3) This device is not designed as an explosion-proof structure. DO NOT use

this device in a place where explosion-proof structures are required. Doing

so may cause fire or explosion.

(4) Prepare temperature controller unit when operating Vaporizer/Heat Exchanger

and do not set the temperature over than maximum operating temperature.

Wring temperature setting may cause fire or destruction of the device. It is

recommended to add abnormal overheating detectorifnecessary.

(5) This device must be earthed before use. Otherwise, there is the rink of

electric shock.

(6) Thermal switch is equipped in Vaporizer/Heat Exchanger to prevent

overheating. However, the operating temperature of thermal switch would

vary due to operating conditions and ambient temperature.

(7) Attach/remove connector and terminals, please make sure that power

supply turning off. It may cause fire or shock hazard.

Incorrecthandlingcancausemediumor slightinjuryor

maycause damageto,orlossof,facilitiesorequipment.

(1) Observe the precautions listed in the WARNING (above).

(2) Not using the voltage can cause fire, damage to sensors or malfunction or

cause electric shock.

(3) This device is not designed to be waterproof. DO NOT locate this product

outdoors or in a place where it may be splashed with water. Doing so may

cause fire, trouble or malfunction of this product.

(4) DO NOT modify this product. It may cause fire or other problems.

(5) A warm-up period of 60 minutes is recommended after reaching the set

temperature. Otherwise, the output gas temperature will be low.

(6) This device is a precious device, please handle it carefully. Dropping

down or handling it carelessly will cause damage. Please use assist

instrument while moving or setting the device.

(7) Depends on the character of the liquid and process condition, the

temperature of tube, carrier gas, and the VU, also the flow rate of carrier

gas should be set properly.

(8) Please use Helium (He) to pressure liquid. It easily lead to bubbles if use

N2, Ar, O2, etc, that have higher than Helium (He) solubility to pressure.

(9) Regular maintenance is recommended for the steady use of this product.

This product uses a seal material made from the Kalrez®, in order to

reduce leakage, Changing the seals annually is recommended. The

maintenance cycle changes according to precursor type and operating

conditions, so please consult about the maintenance cycle for the steady use

of this device.

1. Introduction

This instruction manual explains the basic operation of Vaporizer unit

VU-0430N Series (Hereafter called “VU”). Please read through this manual

carefully to become familiar with the features of this device.

2. Features

The VU has the following features.

(1) By using the VU in combination with the liquid mass flow meter

(Hereafter called “LM”) and the gas mass flow controller (Hereafter

called “MFC”), precise flow control and effective vaporization can be

assured.

(2) Maximum operating temperature of 200℃.

(3) Compact size

3. Specification/ Dimensions

(1) Specification

Product name

Vaporizer

Model name

VU-0430N

Ratedpower

supply voltage

andheater

capacity

Vaporizer model: D01

Inner AC 120V 80W

Outer AC 120V 100W

Vaporizer model: D02

Inner AC 240V 225W

Outer AC 240V 400W

Thermal switch (Note1)

230±10°C OPEN

Thermal switch connection method

Outer block: 1piece, Inner block: 1piece

Direct connection (125V/15A, 250V/10A)

Operating primary pressure

150 to 300 kPa(G)

Operating secondary pressure

Less than 25 kPa(G)

Pressure Limit (Gauge pressure)

1MPa(G)

Leak integrity (External Leak)

Less than 5.0×10-10 Pa∙m3/sec (He)

Fittings

Precursor inlet

3.2mm (1/8”) VCR Male

Carrier gas inlet

6.35mm (1/4”) VCR Male

Gas outlet

6.35mm (1/4”) VCR Female

Thermocouple for temperature controller

K Type × 2pieces

Recommended temperature controller

PID control type

Wetted materials

StainlessSteel316L, Au, Ni-Co,

Polyimide or PEEK

Mounting direction

Piping line: horizontal.

Power supply connector: vertical and up.

(Please confirm the outline dimension drawing)

Standard

accessories

Thermocouple

connector

CMP01-K(RKC) × 2pieces

Heater/Thermal switch

connector

SRCN6A16-7S (JAE) × 1piece

LM-VU connect

cable

CC-LV-3-3M× 1piece

Note1) The temperature of thermal switch may be different from the temperature of a point of

controlling of VU.

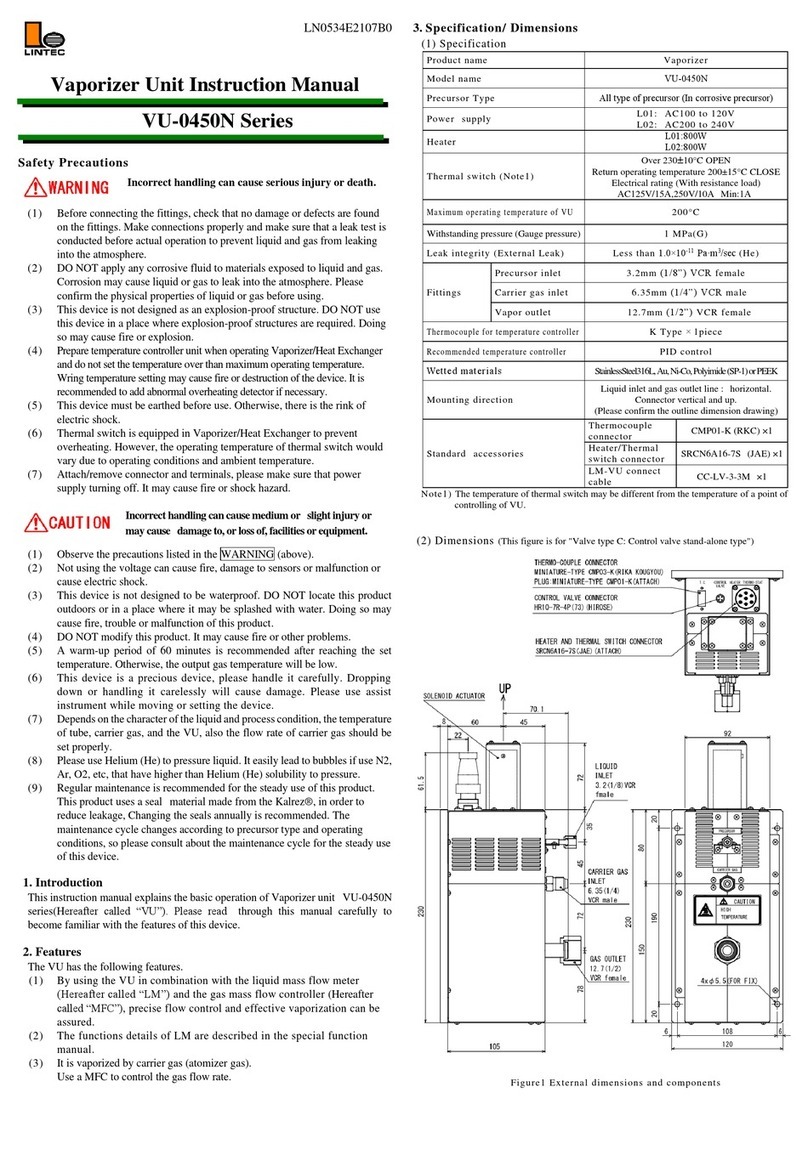

(2) Dimensions

Fig1. External dimensions and components

4. Ordering Information

VU –0430N -A CL -02 P NND01 T23 NNN

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10]

[1] Series model: VU: Vaporizer VU Series

[2] Valve type

A: Control valve and Shut-off valve all-in-one

F: Shut-off valve all-in-one

[3] Carrier gas

CL: Carrier gas-less type 01: Carrier gas type 1

02: Carrier gas type 2 03: Carrier gas type 3

[4] Capillary

02: Capillary type 2 03: Capillary type 3

[5] Valve

P: Polyimide E: PEEK

[6] Seal

N: Au

[7] Internal surface treatment

N: No treatment M: Electrical polishing(EP)

[8] Heater

D01: AC100 to 120V D02: AC200 to 240V

[9] Thermal switch

T23: 230±10°C

[10] Option

NNN: Standard specifications

※Notation other than NNN means customer options. The specification will be different

from this specification sheet, please refer to specific specification sheet. Please notice

that the pin assignment may be different as well.

5. Electrical Connection

(1) Heater / Thermal switch connector

Mounted connector : SRCN2A16-7P (JAE)

Pair connector : SRCN6A16-7S (JAE)

Pin No.

Signal name

1,2

Inner block heater power supply

3,4

Outer block heater power supply

5

Case Gnd.

6,7

Thermal switch

(2) Thermocouple connector

Mounted connector : CMP03-K (RKC Instrument Inc.)

Pair connector : CMP01-K (RKC Instrument Inc.)

Pin No.

Signal name

K

Thermocouple (-)

+

Thermocouple (+)

(3) LM-VU connect cable

Mounted connector : HR10-7R-4P (73)

Pair connector : HR10-7P-4S (73)

Pin No.

Signal name

1

Valve control signal

2

Valve control signal (-15VDC)

3,4

N.C.

6. Connection diagram

Fig2. Connection diagram (Heater specifications: D01: 120V)

Fig3. Connection diagram (Heater specifications: D02: 240V)

7. Preparation and Operational Procedure

(1) Checktheliquidtype, and attachthe VUfittingsinthedirectionofthe fluid flow.

(2) Prepare a MFC for carrier gas (including power indicator and cable) and

connect it to the carrier gas lines.

(3) Attach filters to liquids and carrier gases lines.

(4) Prepare temperature control units and connect to the VU and outlet tubing

heaters.

(5) Electrical connections should be made correctly, taking account of power

source voltage, polarity and capacity.

(6) Supply power to the LM and the MFC, and warm-up for 30 minutes. Please

turn on the VU heaters and confirm that the temperature has reached the set

temperature after a period of 90 minutes.

(7)Check that there are no leaks from the fittings using a helium (He) leak detector.

(8) Evacuate and purge the tubing line, the LC and the VU to remove

moisture, thoroughly.

(9) Thermal switch may work by temperature overshoot in the first operation.

Please adjust PID by auto turning.

(10) When using a liquid mass flow meter and carrier gas mass flow controller

together with this device to control and introduce liquid, vaporized gas will be

transported from the outlet.

(11) Please use helium (He) to pressure liquid (To lower the possibility of

generating bubbles).

(12) It is necessary to set the VU, line and carrier gas temperature as well as

carrier gas flow rates to appropriate values in order to meet the liquid physical

properties and process conditions.

8. Product Warranty

(1) Period

This product is guaranteed for a period of 1 year from the date of

shipment. Defects are repaired according to the following regulations.

(2) Scope

Warranty coverage is restricted to this product only. Any other

damage caused by this product is not covered.

(3) Disclaimer facts

The following repairs are not covered by the warranty.

1) Failure caused by by-product of liquid or gas used.

2) Failure caused by misuse (including careless operation), incorrect

repair or modification.

3) Failure cause by falling or dropping after purchase.

4) Failure caused by fire, earthquake, flood, lightning or other

natural disasters.

Even if the warranty period is still in effect, repair service may not

be provided in the following cases.

1) When the kind of fluid used in the product is unclear.

2) The product is returned with fluid remaining inside, and

safety cannot be confirmed.

This instruction manual is subject to revision without notice.

http://www.lintec-mfc.co.jp

CorporateHeadquarters

4-1-23Sekinotsu,OtsuCity, ShigaPref.520-2277,Japan

TEL. +81-(0)77-536-2210FAX.+81-(0)77-536-2215

TokyoBranchOffice

3FHattoriBuild.,4-30-14YotsuyaShinjyuku-kuTokyo160-0004,Japan

TEL. +81-(0)3-5366-2801FAX.+81-(0)3-3341-3513

Other Lintec Vaporizer manuals