LIQUIP DFV102 Release note

LIQUIP PTY LIMITED - 13 HUME RD SMITHFIELD SYDNEY NSW AUSTRALIA 2164

Issue: A 15/05/13 Page 1

DFV102

ELECTRONIC COUNTER

FOR FLUID METERS

Driver Manual

May 2013

Issue: A

LIQUIP PTY LIMITED - 13 HUME RD SMITHFIELD SYDNEY NSW AUSTRALIA 2164

Issue: A 15/05/13 Page 2

CONTENTS

1. About the Manual

2. Front Panel Layout

3. Operation

3.1. Product Delivery –Simple Delivery

3.2. Product Delivery –Valves Fitted

3.3. Displaying or Changing Product Density

3.4. Displaying or Selecting the Product

3.5. Displaying the Meter Number

3.6. Displaying Accumulative total

4. Printing a Ticket

4.1. Printing a Delivery Ticket

4.2. Printing a Setup Report Ticket

5. Displayed Messages

6. Care and Maintenance

LIQUIP PTY LIMITED - 13 HUME RD SMITHFIELD SYDNEY NSW AUSTRALIA 2164

Issue: A 15/05/13 Page 3

1. ABOUT THE MANUAL

This manual illustrates the various operations and functions of the DFV102 electronic counter.

This manual is intended for the operator (driver) and assumes that the register is installed and ready for use. For full

installation, setup and wiring refer to the DFV technical manual.

LIQUIP PTY LIMITED - 13 HUME RD SMITHFIELD SYDNEY NSW AUSTRALIA 2164

Issue: A 15/05/13 Page 4

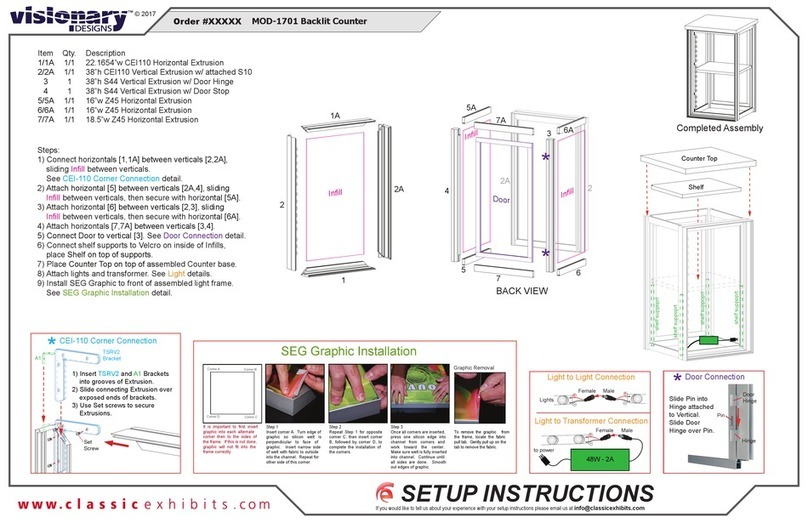

2. FRONT PANEL LAYOUT

MENU/DIP

Moves to the next calibration item.

BATCH

Moves cursor to the next position on the display.

TOTAL BUTTON

Displays cumulative total of the meter, displays uncompensated volume and

allows management tickets to be printed.

This also changes the number that the curser has highlighted to the next

number up (i.e. –increment).

START/STOP BUTTON

Used to program the meter.

This also starts the delivery and stops the delivery if solenoids and valves are

used in the system.

RESET BUTTON

Resets the meter back to zero. Also enables printing of tickets or shows the

flow rate during delivery.

3. OPERATION

LIQUIP PTY LIMITED - 13 HUME RD SMITHFIELD SYDNEY NSW AUSTRALIA 2164

Issue: A 15/05/13 Page 5

3.1 Product Delivery –Simple Delivery

1. Ensure the register shows “0.0” on the display and that a ticket is inserted into the printer (option).

2. Start the delivery using the nozzle trigger.

3. When the delivery is complete, press the RESET button to reset the meter back to zero and print a

delivery ticket. “print delivery” will be displayed on the display when printing the ticket

3.2 Product Delivery –Valves Fitted

1. Press the START/ STOP button to start the delivery.

3.3 Displaying or Changing Product Density (LPG ONLY). If enabled in calibration mode.

This function is only available if the register is set for litres and the function is enabled.

1. Press the TOTAL button five times in five seconds.

2. The density value is then displayed.

Note: If no button is pressed for five (5) seconds, the DFV will exit and return to standby mode.

Changing Product Density

1. Ensure the current density is displayed (see above).

2. To change the current density, use the TOTAL and RESET buttons.

Press the TOTAL button to increment the value of the current digit and RESET button to move to the

next digit.

The density range must be between 0.500 –0.600 for LPG.

3. Press the START/STOP button to set the value.

3.4 Displaying or Selecting the Product (NON-LPG and special versions only). If enabled in calibration mode.

This function is only available for some special versions of the register and only for NON-LPG products.

1. Press the TOTAL button five times in five seconds.

2. The product name is then displayed.

Note: If no button is pressed for five (5) seconds, the DFV will exit and return to standby mode.

Selecting the Product

1. Use the TOTAL button to select the product.

2. Press the START/STOP button to accept it.

3.5 Displaying the Meter Number

LIQUIP PTY LIMITED - 13 HUME RD SMITHFIELD SYDNEY NSW AUSTRALIA 2164

Issue: A 15/05/13 Page 6

This function displays the register/meter number. This function is only available if the register is set for litres.

1. Press the TOTAL button five times in five seconds.

2. Press the MENU button until “MeNoXXXX” is displayed on the display, where XXXX is the meter

number nominated.

Note: If no button is pressed for five (5) seconds, the DFV will exit and return to standby mode.

3.6 Displaying the Accumulative Total

To display the accumulative total, press the TOTAL button. The register will show whole litres (or gallons)

volume. This value continually changes during delivery and is displayed for 5 seconds.

4. PRINTING A TICKET

4.1 Printing a Delivery Ticket

1. Ensure a blank ticket is inserted into the printer or a paper roll is present.

2. Press the RESET button when delivery is complete. The “print dt” message is shown on the upper

display while printing. When printing is completed, the meter returns back to standby mode and the

display is reset back to “0.0”.

4.2 Printing a Setup Report Ticket

Setup report tickets display various settings of the register.

1. Ensure a blank ticket is inserted into the printer or a paper roll is present.

2. Press the TOTAL button five times in five seconds.

3. Press the MENU button until “REPORT?N” is displayed on the display.

Note: If no button is pressed for five (5) seconds, the DFV will exit and return to stand by mode.

4. Press the TOTAL button to change the display to “REPORT?Y”

5. Press the START/STOP button to start printing. The “print report” message is shown on the display

while printing. When printing is completed, the meter returns back to standby mode.

Pressing TOTAL immediately followed by RESET while in standby mode will print a management

ticket. This will reset the power interrupts and the delivery number to zero, but will not reset the register to

zero.

5. DISPLAYED MESSAGES

LIQUIP PTY LIMITED - 13 HUME RD SMITHFIELD SYDNEY NSW AUSTRALIA 2164

Issue: A 15/05/13 Page 7

“”(steady)

Temperature compensation is activated.

“”(flashing)

Temperature compensation is activated and one of the following has occurred:

Temperature probe is disconnected (or connection may be intermittent) or faulty

Probe is functioning correctly, but product temperature exceeds +65°C

“PRINT DELIVERY”

This message appears when printing a delivery ticket.

“PRINT M/T”

This message appears when printing a management ticket.

Retain ticket and give to your supervisor.

“PRINT REPORT”

This message appears when printing a setup report ticket.

BLANK SCREEN

This may be due to the following:

Power is not on

Power is on, but input voltage drops below 7 volts, even momentarily

Register faulty. Refer to service personnel

“TEMPERATURE PROBE

FAILURE”

While displaying the temperature of the product, this message appears if one of the following

occurs:

The temperature probe is disconnected

The temperature probe is faulty

The temperature of the product exceeds approx. 65°C

“DATA ERROR”

Some of the data stored in the memory was corrupted and replaced with the default value.

Refer to service personnel for repair.

“PORT” then “NO PAPER”

While printing a docket, this message appears if:

There is no paper inserted in the printer or

The paper is not the correct size

“PORT” then “COMM ERR”

While printing a docket or communicating with the Touch-PC this message appears if one of

the following conditions occurs:

The printer or Touch-PC is switched off.

The printer or Touch-PC is not connected to the correct port.

The connection between the register and the printer or Touch-PC is faulty.

Wrong setup in calibration for the communication port.

“PORT” then “PRNT ERR”

While printing a docket, this message appears if using Liquip Blaster printer and one of the

following conditions occurs:

The printer is switched off

The printer is not connected to the specified port

The connection between the printer and register is faulty

Indexing has been enabled, but there is no paper, or a paper jam has occurred in the

printer

Wrong setup in calibration for the communication port

“PULSER FAULTY”

Appears if one of the following occurs:

Neither the internal pulser nor the remote pulser are connected or properly selected

The connection between the register and either the remote pulser or internal pulser,

is faulty

Either the remote pulser board or the internal pulser board is faulty

Appears if either the remote pulser board or the internal pulser board is faulty. Refer

to service personnel for repair.

Refer to service personnel for repair

“WRNG DIR”

The pulser shaft is rotating in the opposite direction to register settings. Refer to service

personnel for repair.

6. CARE AND MAINTENANCE

Use a clean cloth and soapy water to wash the DFV.

Table of contents