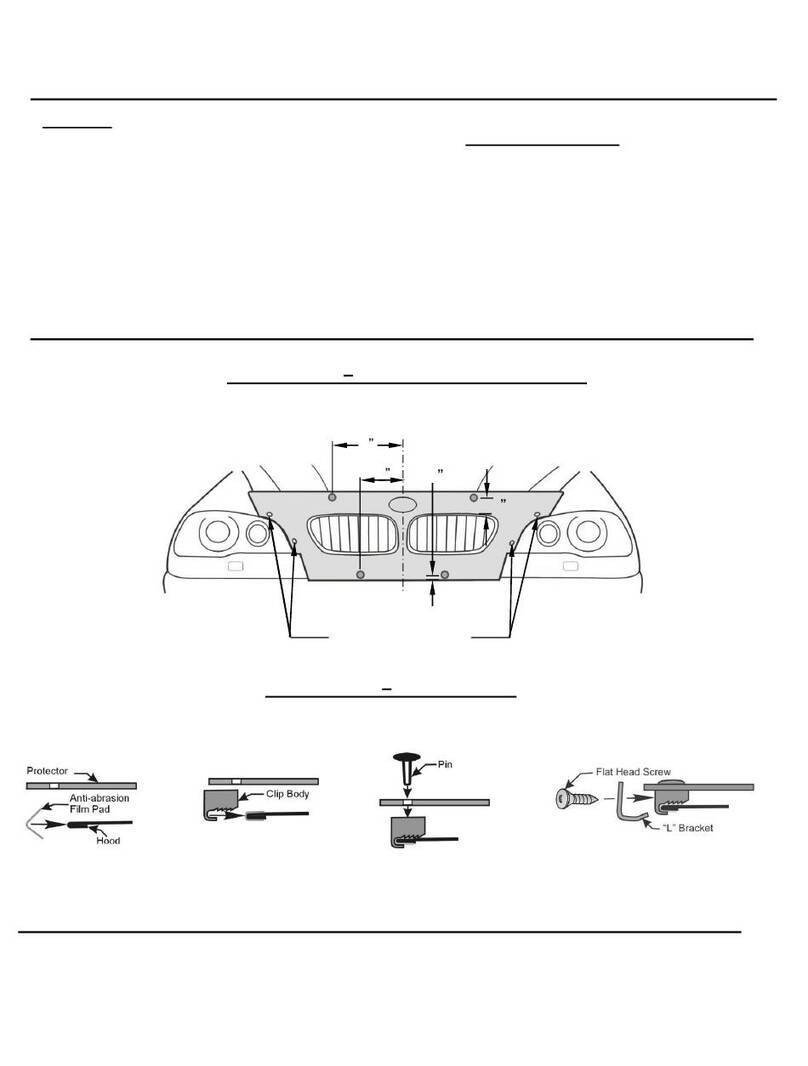

Insert correct sized hose into dipstick tube.

Small engines; Remove dipstick from engine. Since most small engines have larger dipstick tubes, the larger

diameter clear plastic hose may be used without the narrower white suction probe/hose. The larger diameter hose can

make oil changes even faster.

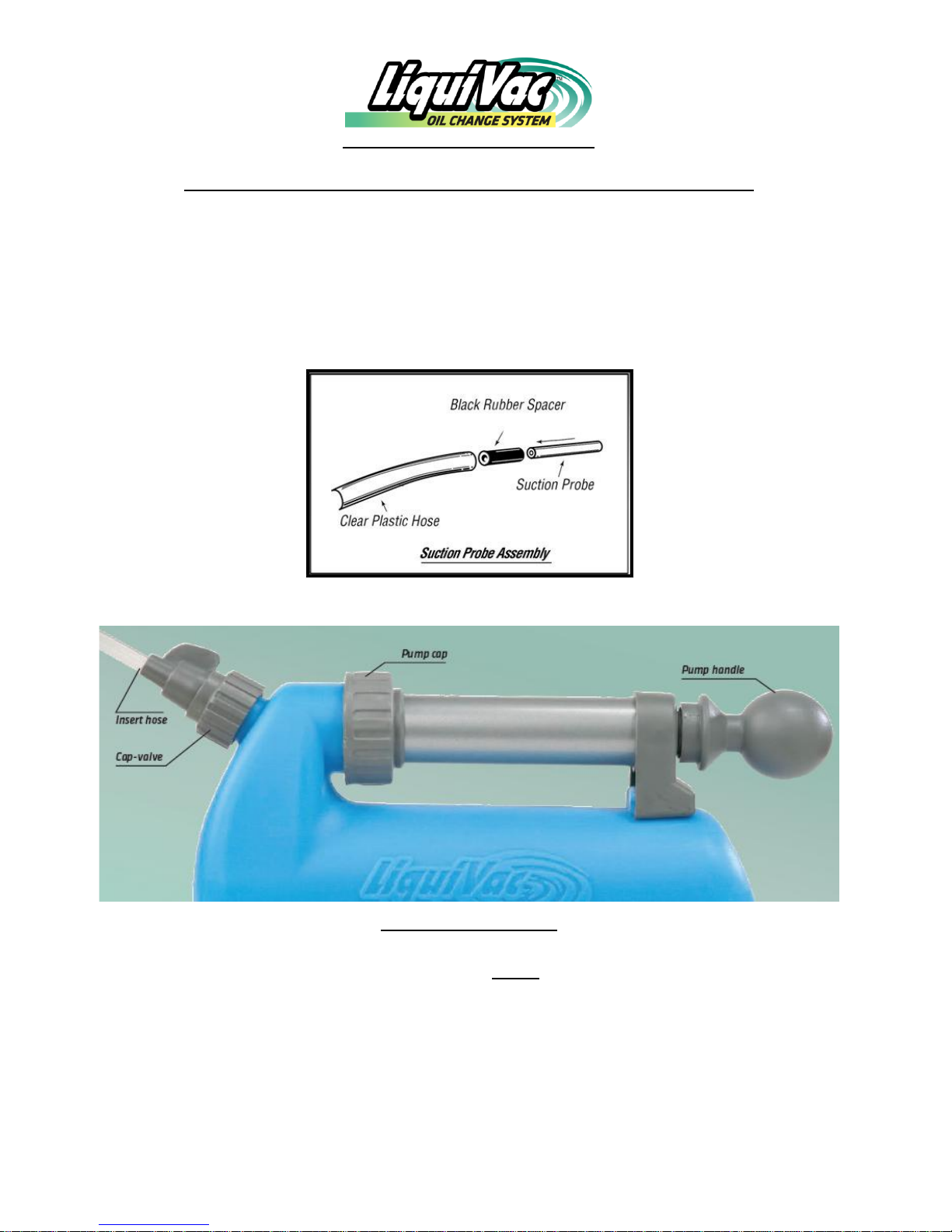

Large engines; Remove dipstick from engine. Straighten the narrow white suction probe and measure the length of

the dipstick against the suction probe. In fact we highly recommend that you mark this length with a pen.Slowly insert

the marked suction probe into dipstick tube. When you reach your mark on the probe then insert it carefully another 1 to 3

inches until you feel it “bump” into the oil pan. Stop inserting.

Careful: Do not insert the suction probe more than 3 inches beyond dipstick length.

Suction probe may become lodged in the engine cavity.

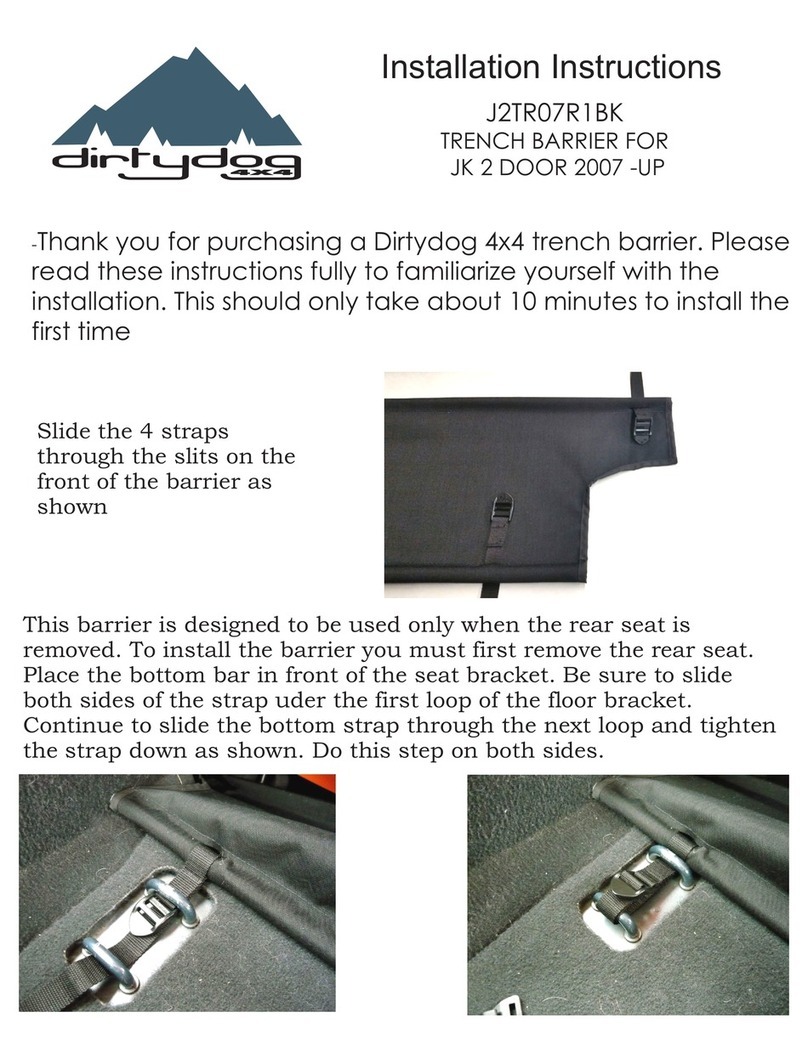

Open cap-valve.

Twist cap-valve dial counter clockwise to the open position. Watch for oil to flow through

the hose and into the tank.

Move hose to vacuum all oil.

If you hear a gurgling sound and perhaps see bubbles in the hose, immediately move the hose

slowly up and down just a fraction of an inch to ensure thorough and efficient oil removal. If more

vacuum power is needed to completely remove oil, twist the spout cap-valve dial back to the

closed position, pump 10 to 15 times, then twist dial to open and continue vacuuming oil.

Careful: Do not pump with dial in open position to avoid pulling oil into pump and possibly

out the handle.

Close cap-valve. Replace dipstick. Refill engine oil. Recycle used oil.

Twist cap-valve to closed position and screw pump handle onto tank in locked position.

Replenish oil supply following manufacturer’s recommended engine oil type and

capacity. To find a recycling center nearest you, visit www.recycleoil.org

Warning: Never use with gasoline or other flammable liquids. Do not use with hot liquids!

Troubleshooting

1. The key problem most people have operating the LiquiVac is that the gaskets are not sealing properly to hold the

vacuum. You can check this by listening for air leaks. Unscrew cap-valve from tank and remove gasket. Reinsert

gasket into cap-valve and screw onto tank as tight as possible using only your hands. Remove pump from tank.

Make sure the large black gasket is seated properly against the tank rim. Screw pump back onto tank and hand

tighten. If a leak is detected, check gaskets for wear and misalignment. Lubricate with motor oil, replace gaskets

and tighten cap until snug.

2. Make sure dial on cap-valve is in closed position when pumping, and hose is fully inserted tightly

into cap-valve.

3 If you have tried the above and each pump stroke does not result in increased resistance, then the internal leather

seals in the pump may need lubrication. Just apply several drops of oil onto the pump rod (at the handle end),

draw on the handle a few times to distribute the oil. Let pump rest in vertical position, handle side up, for 12–24

hours to allow leather to soften. After this time period, draw on handle a few more times then reattach to tank

making sure the large gasket is seated onto the tank rim. This may be necessary when the pump has been stored

for several months.

4 If you have accidentally over filled your tank or if the oil happens to enter the pump, you can unscrew the pump from

the tank and let the oil flow into a container (knob side down and unscrewed). After the oil is drained pump the

handle a few times to get the remaining drops of oil out. Keep in mind a small amount of oil in the pump is good for

the unit and actually prolongs the life of the pump by adding lubricity.

5 If you use the LiquiVac to extract water, please take the pump assembly off after use and allow water to drain out,

then add oil onto the pump rod at the handle end. This is necessary because the seal in the pump is made of

leather and must remain lubricated.

Customer Service: If you need further assistance or replacement parts, call the makers of the LiquiVac

(toll-free) at 1.800.225.2224 or visit our web site: www.liquivac.com . Parts Included: Clear vacuum hose,

suction probe, cap-valve, black rubber spacer and 1¼" gasket.