7/72

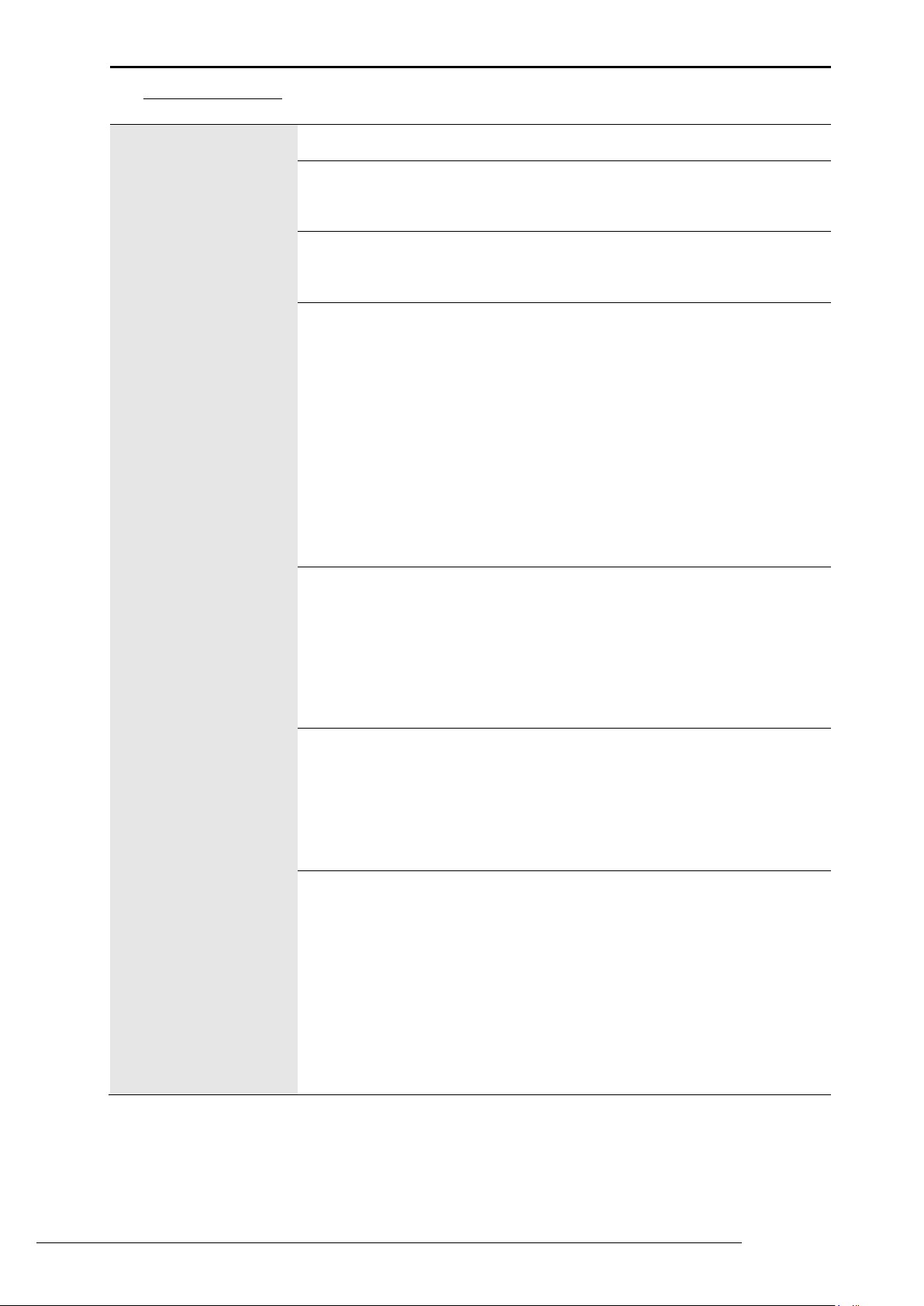

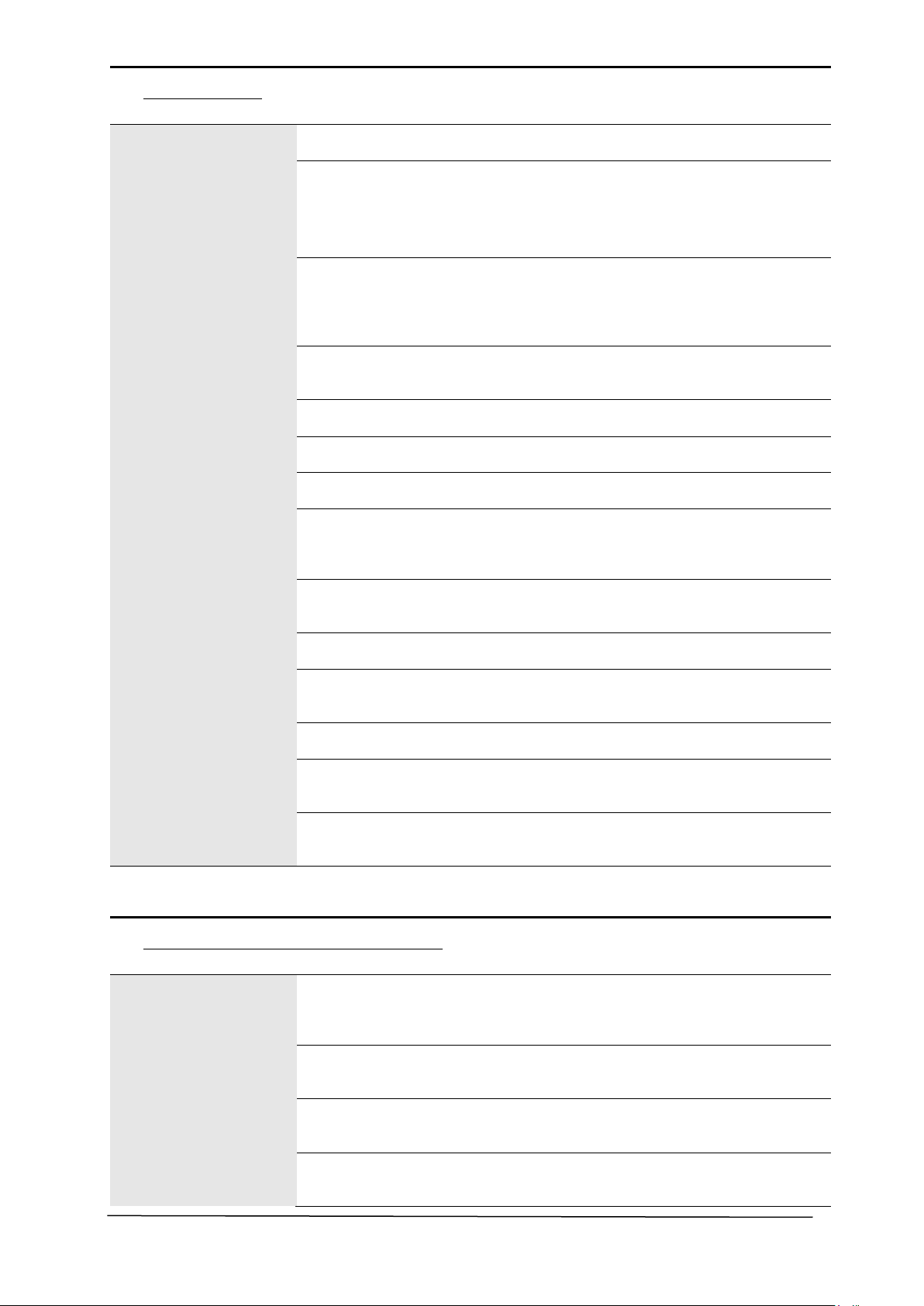

1. Features & Benefits ......................................................................................................... 8

1.1. Principle of intended use...................................................................................................9

1.2. Organizational action ......................................................................................................10

1.3. Personnel selection and qualifications; general duties...................................................10

1.4. Safety information during the various operating phases ................................................11

1.4.1. Transport, assembly and installation .....................................................................11

1.4.2. Assembly and commissioning ................................................................................11

1.4.3. Operation................................................................................................................12

1.4.4. Special work whilst using the machine..................................................................12

1.5. Information about special types of dangers....................................................................13

1.5.1. Electrical energy.....................................................................................................13

1.6. Dust.................................................................................................................................13

1.7. Noise...............................................................................................................................13

1.8. Transport.........................................................................................................................13

1.9. Packaging and bearing....................................................................................................14

1.10. Environmental protection ..............................................................................................14

1.11. Waste disposal .............................................................................................................14

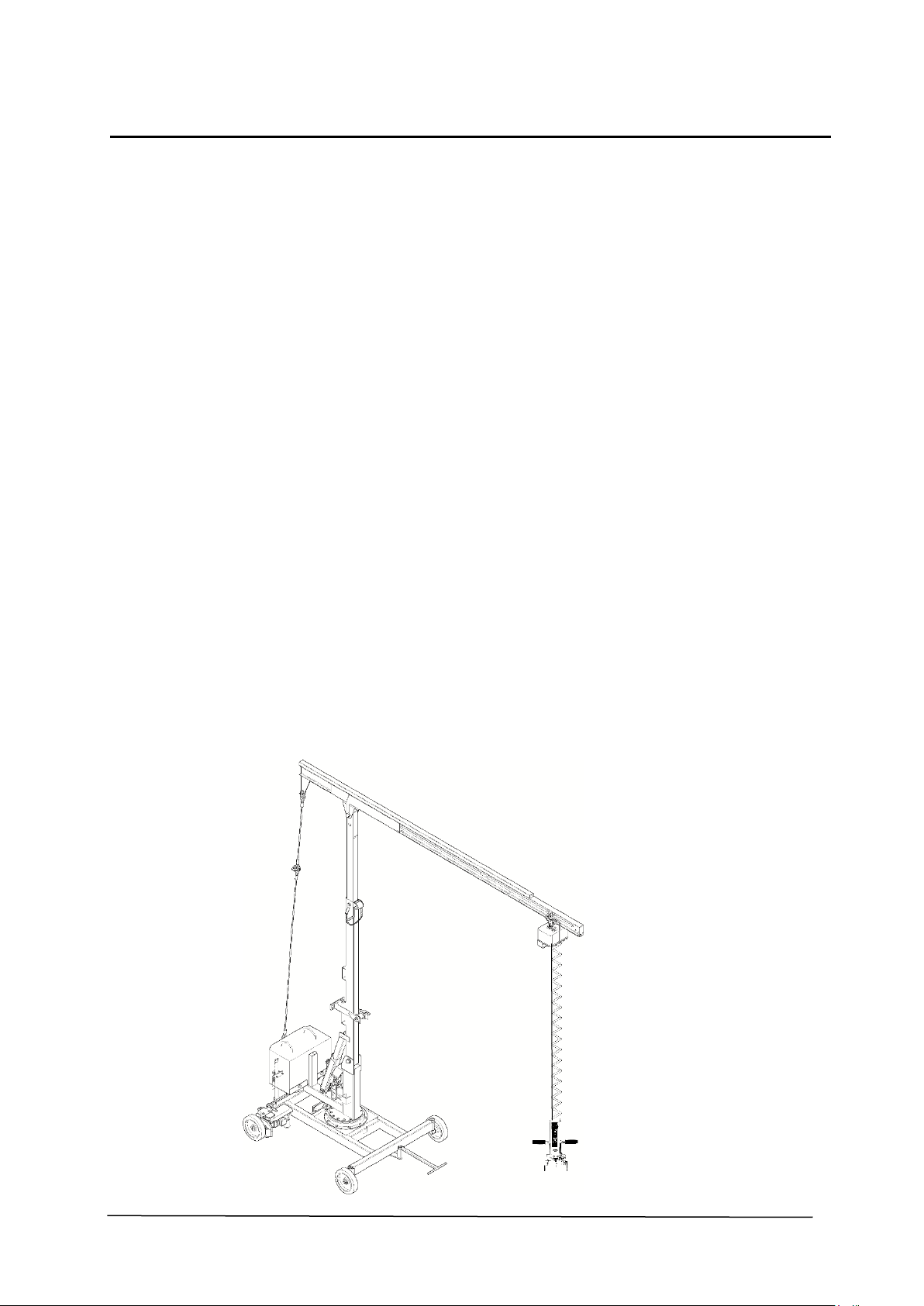

2. Device description......................................................................................................... 15

2.1. Designation of machine parts .........................................................................................17

2.2. Safety equipment............................................................................................................17

2.3. Technical Data ................................................................................................................18

2.4. Sound power level ..........................................................................................................19

3. Commissioning ............................................................................................................... 20

3.1. Connections and media...................................................................................................20

3.2. The surface on which the machine is installed and surrounding area ............................20

3.3. Parking brake ..................................................................................................................21

3.4. Ballast support and handle .............................................................................................22

3.5. Swivel lock......................................................................................................................23

3.6. Telescoping of the tower ................................................................................................24

3.7. Traction drive unit (ONLY LMK 400 TFE/DK) ...................................................................25

3.8. Trolley running gear (only LMK 400 TFE/DK)...................................................................26

3.9. Engage the rotary drive of the motor (only for LMK 400 TFE/DK)....................................26

3.10. Setting up the tower .....................................................................................................27

4. Transport ........................................................................................................................ 28

4.1. Transport position ...........................................................................................................28

4.2. Transport possibilities.....................................................................................................29

4.3. Relocation with building crane when assembled............................................................30

5. Operation ........................................................................................................................ 31

5.1. Safety..............................................................................................................................31

5.2. Lifting capacity................................................................................................................31

5.3. Radio control...................................................................................................................32

5.4. Mounting the EHS controller...........................................................................................33

5.5. EHS-Controller.................................................................................................................33

5.5.1. Connecting the EHS-Controller (Optional) ..............................................................34

6. Disassembly ................................................................................................................... 36

6.1. Disassembly....................................................................................................................36

6.2. Reset telescoping............................................................................................................37

7. Maintenance .................................................................................................................. 38

7.1. Servicing .........................................................................................................................38

7.2. Lube points......................................................................................................................39

7.3. Torque values for screw connections..............................................................................39

7.4. Troubleshooting ..............................................................................................................40

8. Regular inspection (maintenance book)....................................................................... 41

8.1. Check measurement........................................................................................................42

8.2. Maintenance schedule....................................................................................................43

9. Warranty......................................................................................................................... 44

10. Hydraulic plan .............................................................................................................. 45

11. Spare parts LMK 400 .................................................................................................... 46

12. Spare parts LMK 400 TFE/DK ....................................................................................... 50

13.

Circuit diagram............................................................................................................ 59