Littelfuse PGR-6100 User manual

Tel: +1-800-832-3873

E-mail: techline@littelfuse.com

www.littelfuse.com/PGR-6100

Copyright © 2018 Littelfuse

All rights reserved.

Document Number: PM-1100-EN

PGR-6100 MANUAL

GROUND-FAULT & INSULATION MONITOR

Revision 2-C-050818

Page i

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

This page intentionally left blank.

Page ii

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

TABLE OF CONTENTS

1 GENERAL ................................................................1

2 OPERATION............................................................1

2.1 Output Relay Operating Mode ................1

2.2 PGR-6100 Operating Mode .....................1

2.2.1 Online Operation .....................................1

2.2.2 Ofine Operation .....................................1

2.3 Front-Panel Controls................................1

2.3.1 Ground-Fault Trip Level ...........................1

2.3.2 Ground-Fault Trip Time ............................1

2.3.3 Insulation Resistance Response................

1

2.3.4 Reset........................................................1

2.3.5 Test ..........................................................2

2.4 Front-Panel Indication .............................2

2.4.1 Power.......................................................2

2.4.2 >∆I...........................................................2

2.4.3 CT ............................................................2

2.4.4 Active.......................................................2

2.4.5 <R.............................................................2

2.5 Analog Outputs........................................2

2.5.1 Out I ...........................................................2

2.5.2 Out R ..........................................................2

2.6 Remote Test...............................................2

2.7 Remote Reset ............................................2

2.8 CT Verication............................................2

3 INSTALLATION ......................................................2

3.1 PGH-5000 and PGH-6000...........................4

4 TECHNICAL SPECIFICATIONS

..............................8

4.1 PGR-6100 ...................................................8

4.1.1 PGR-6100 Online Operation.......................8

4.1.2 PGR-6100 Ofine Operation ......................8

4.2 PGH High Tension Couplers.......................9

5 ORDERING INFORMATION..................................9

6 TESTS....................................................................10

6.1 Ground-Fault Test ....................................10

6.2 Insulation Test .........................................11

APPENDIX A PGR-6100 REVISION HISTORY

.......12

LIST OF FIGURES

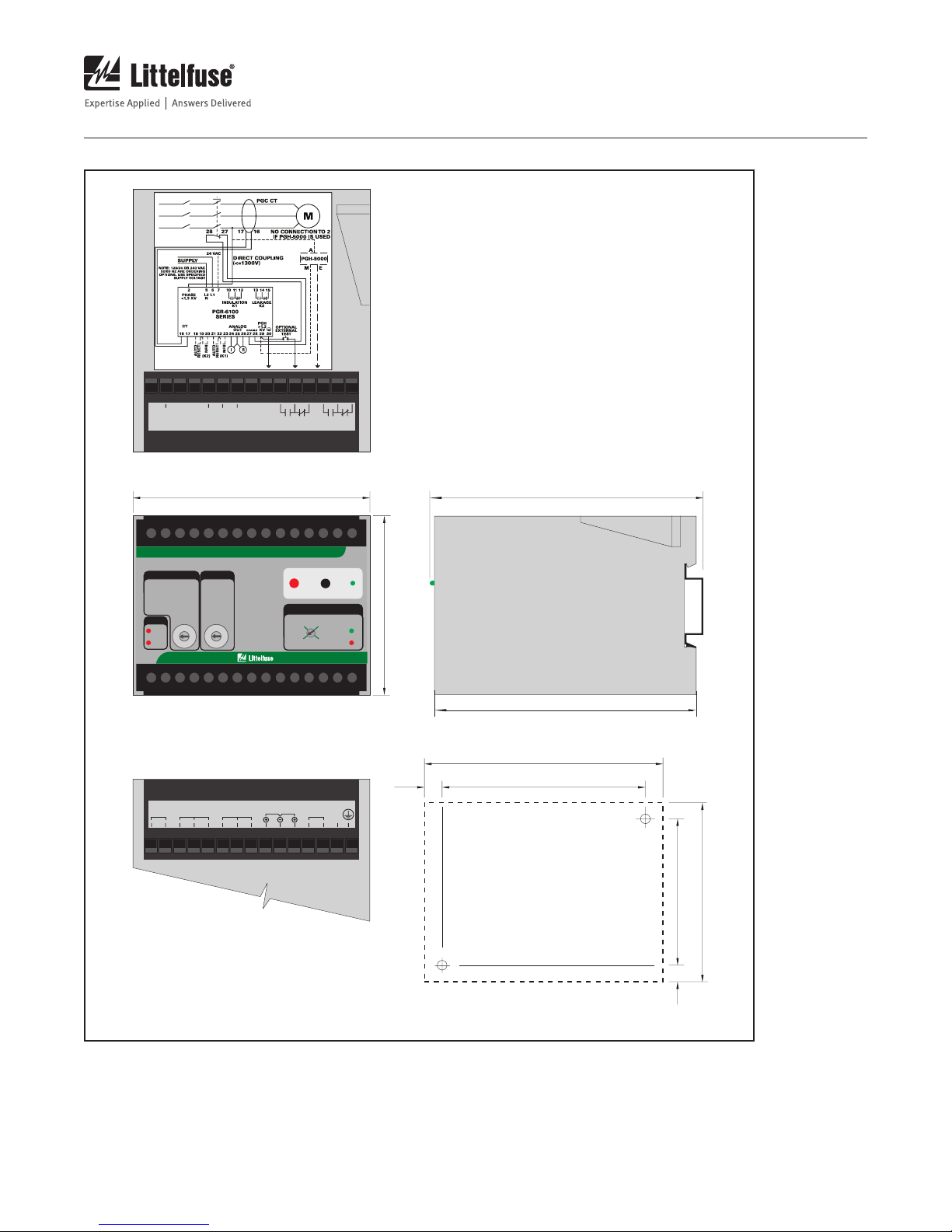

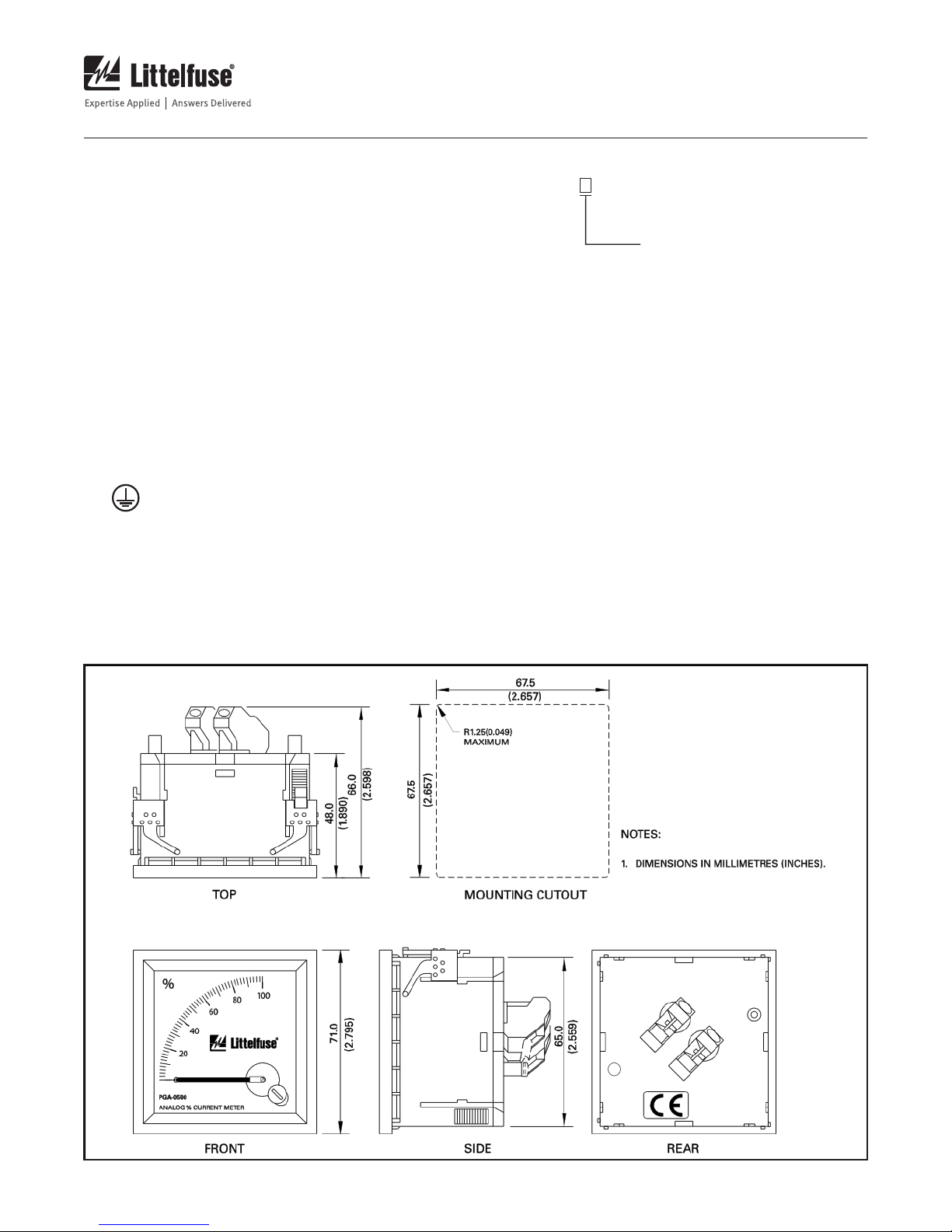

1 PGR-6100 Outline and Mounting Details ....................3

2 Typical Connection Diagram ........................................4

3 PGC-5000-Series Current Sensors...............................5

4 PGH-5000 Outline and Mounting Details ....................6

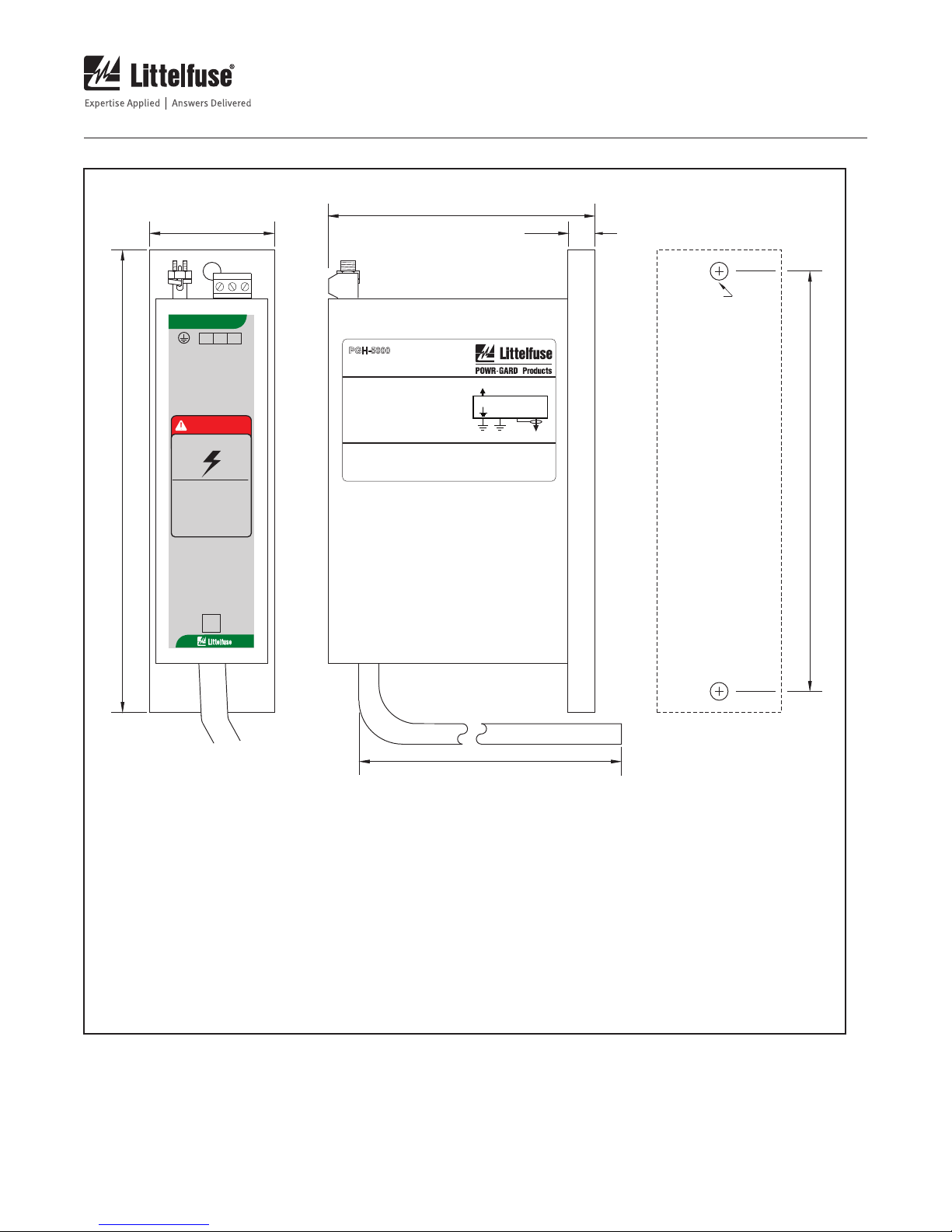

5 PGH-6000 Outline and Mounting Details ....................7

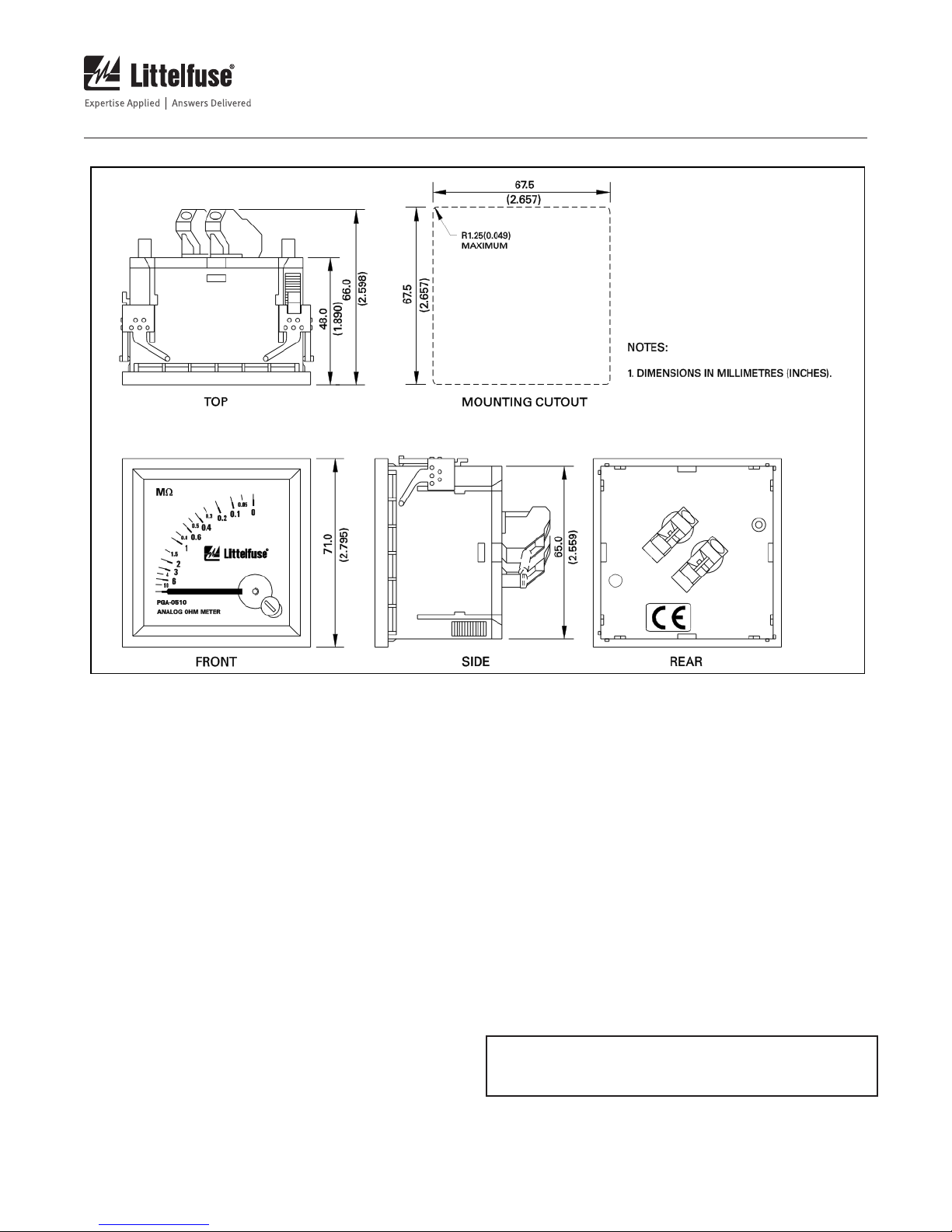

6 PGA-0500 Analog Percent Current Meter ...................9

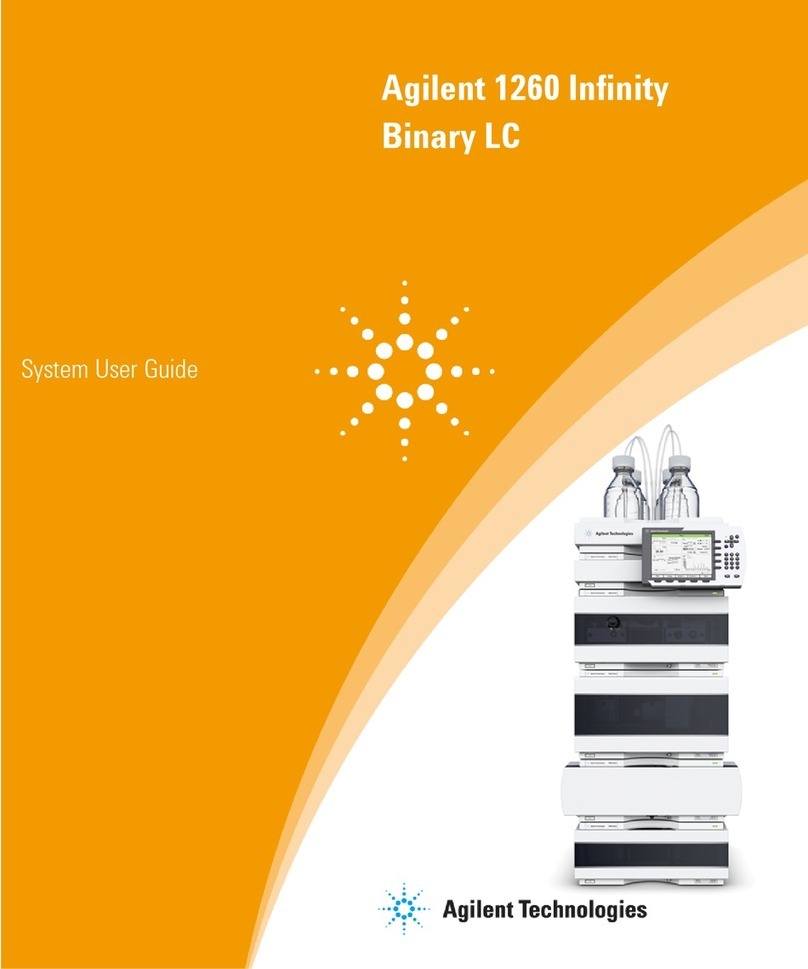

7 PGA-0510 Analog Ohm Meter ...................................10

8 Ground-Fault-Test Circuit..............................................

11

LIST OF TABLES

1 Ground-Fault-Test Record ..........................................11

DISCLAIMER

Specifications are subject to change without notice.

Littelfuse, Inc. is not liable for contingent or consequential

damages or for expenses sustained as result of incorrect

application, incorrect adjustment, or malfunction.

Page iii

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

This page intentionally left blank.

Page 1

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

1. GENERAL

The PGR-6100 Ground-Fault & Insulation Monitor can

detect a motor ground fault whether the motor is running

(Online mode) or stopped (Offline mode). The PGR-6100 can

also be used to protect a motor that is supplied by a solidly

grounded, resistance-grounded or ungrounded system. For

ungrounded systems, use only the Offline mode.

Grounded systems use a current transformer (CT) to detect

ground-fault currents as low as 10 mA when the motor is

running. Insulation resistance is measured to detect a fault

when the motor is stopped. Online or Offline mode is selected

with a digital input connected to a starter auxiliary contact.

In the Online mode, ground-fault current is sensed by

a PGC-5000-series zero-sequence CT. The trip level of the

ground-fault circuit is selectable from 10 mA to 3 A. Trip

time is selectable from <50 ms to 1.0 s. Additional current-

detection features include harmonic filtering, a relay output

that can operate in the fail-safe or non-fail-safe mode, CT-

connection detection, LED trip, LED power and LED open-CT

indication, autoreset or latching trips with front-panel and

remote reset, a test button, and a 0-to-1-mA analog output.

In the Offline mode, insulation-resistance monitoring is

enabled with a selectable 250-k to 2-M alarm-setting

range. Additional insulation-monitoring features include

a relay output that can operate in the fail-safe or non-fail-

safe mode, LED active and low-resistance indication, and a

0-to-1-mA analog output.

The PGR-6100 can be directly connected to a supply up to

1.3 kV. For systems from 1.3 to 5 kV, use a PGH-5000 High

Tension Coupler. For systems from 5 kV to 6 kV, use a PGH-

6000 High Tension Coupler.

2. OPERATION

2.1 Output Relay Operating Mode

In the fail-safe mode the output relays energize when power

is applied and the ground-fault and insulation-resistance

circuits are not tripped. Fail-safe mode is the factory setting.

For a non-fail-safe operation, connect terminals 19-20 and

22-23. The respective output relay will energize when a fault

occurs. See Fig. 2.

2.2 PGR-6100 Operating Mode

Connect terminals 27 and 28 to a normally closed (Form B)

auxiliary starter contact. When terminals 27 and 28 are open,

Online mode is selected (insulation monitoring off). When

terminals 27 and 28 are connected, Offline mode is selected

(insulation monitoring active).

2.2.1 Online Operation

In Online mode, the PGR-6100 in conjunction with a

PGC-5000-series zero-sequence current sensor operates

as a ground-fault relay.

2.2.2 Ofine Operation

The PGR-6100 changes mode by means of an auxiliary

contact on the main contactor when the motor is off. It

becomes an insulation-resistance monitor and imposes a

small dc voltage to the motor windings and supply cable from

the motor starter. Leakage to ground is detected.

2.3 Front-Panel Controls

2.3.1 Ground-Fault Trip Level

The Leakage Current ∆Iselector switch is used to set the

ground-fault trip level from 10 mA to 3 A. For ground-fault

detection, the switch setting must be set substantially below

the prospective ground-fault current. To avoid sympathetic

tripping, the switch setting must be above the charging

current of the protected feeder.

2.3.2 Ground-Fault Trip Time

The PGR-6100 has a definite-time trip characteristic. In

tripping systems, the TIME DELAY selector is used to set the

ground-fault trip time for coordination with upstream and

downstream ground-fault devices. Trip time is selectable

from < 50 ms to 1.0 s. Coordination requires the same trip

level for all ground-fault devices in a system and the trip

time to progressively increase upstream. The amount of

equipment removed from the system will be a minimum if the

first ground-fault device to operate is the one immediately

upstream from the fault.

2.3.3 Insulation Resistance Response

The PGR-6100 insulation resistance function has an

adjustable alarm range of 250 k to 2 M . There is no

selectable time delay. The unit will operate in less than three

seconds.

2.3.4 Reset

The front-panel RESET button is used to reset latching trips.

After a fault has been cleared, cycling the supply voltage will

also reset the PGR-6100.

To use the PGR-6100 in autoreset mode, connect terminals

18-19 and 21-22. See Fig. 2.

Press the RESET button for several seconds. The reset

function is not instantaneous.

Page 2

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

2.3.5 Test

The TEST button will test both leakage-current and

insulation-resistance circuits regardless of the selected

operating mode. Press the TEST button for at least eight

seconds to complete the test. All LED’s will light and relay

contacts will change to fault/alarm state. In the default mode

(latching), the tripped state will remain until reset. Allow

eight seconds before operating the RESET button.

2.4 Front-Panel Indication

2.4.1 Power

The green LED labeled “PWR’’ indicates presence of supply

voltage.

2.4.2 > ∆I

The red LED labeled > I indicates a ground-fault trip.

2.4.3 CT

The red LED labeled “CT’’ indicates that a PGC-5000-series

current sensor is not connected. See Section 2.8.

2.4.4 Active

The green LED labeled ACTIVE indicates that the Offline

monitoring function is active. The insulation monitoring

or lockout function is active when terminals 27 and 28 are

connected. See Section 2.2.

2.4.5 <R

The red LED labeled “<R’’ indicates a low resistance.

2.5 Analog Outputs

2.5.1 Out I

A non-isolated, 0- to 1-mA output (terminals 24 and 25)

indicates ground-fault current sensed by the CT. The full-

scale value corresponds to the ground-fault trip setting. For

example, if the ground-fault trip setting is 30 mA, then 1 mA

output will be indicated when the measured current is 30 mA.

The output is linear between zero and full scale. See Figs. 2

and 6.

2.5.2 Out R

A non-isolated, 0- to 1-mA output (terminals 25 and 26)

indicates insulation resistance. The metering output relates

to an insulation-resistance range of 0 to infinity. See Figs. 2

and 7.

2.6 Remote Test

Use external switches to test the current-sensor detection,

insulation-monitoring activation, and insulation-monitoring

functions. See Fig. 2. Response to a test input can take several

seconds.

2.7 Remote Reset

For remote reset, connect a switch or button with a normally

closed contact between the neutral side of the supply voltage

and terminal 5. See Fig. 2.

For an alternate configuration, connect a normally open,

double-pole, single-throw switch across terminals 18 and

19, and terminals 21 and 22. A momentary connection across

these terminals will reset the PGR-6100.

2.8 CT Verication

A ground-fault trip will occur and the red CT LED will light

when a PGC-5000-series CT is not connected to terminals 16

and 17.

3. INSTALLATION

NOTE: Mounting, terminal block connections and wiring

must conform to applicable local electrical codes. Check all

applicable codes prior to installation.

This ground-fault monitoring system consists of a PGR-

6100-series Ground-Fault & Insulation Monitor, a PGC-5000-

series CT, and for systems over 1.3 kV, a PGH-5000 or PGH-

6000 High Tension Coupler connection, as shown in Fig. 2.

A PGR-6100 can be surface- or DIN-rail mounted. See Fig. 1.

Use terminal 6 (L1) as the line terminal for a 120 or 240

Vac supply. Use terminal 7 as the line terminal for a 24 Vac

supply. Use terminal 5 (L2/N) as the neutral terminal. Connect

terminal 30 to ground.

Pass the phase conductors through the CT window and

position them in the center of the opening (for four-wire and

single-phase systems, also pass the neutral conductor through

the CT window). Do not pass ground conductors through the

CT window. In applications that require shields or drain wires

to pass through the CT window, return them through the

CT window before connecting them to ground. CT connections

are not polarity sensitive. Applications in electrically noisy

environments require twisted-pair or shielded twisted-pair

CT-secondary conductors. Connect the CT secondary leads to

terminals 16 and 17, and connect the shield to terminal 17.

See Fig. 3 for PGC-5000-series CT dimensional drawings.

If insulation monitoring is required, connect terminals 27

and 28 to a contact on the motor starter that is normally

closed.

For systems up to 1.3 kV, connect terminal 2 to one phase of

the load side of the starter.

Connect an optional PGA-0500 Analog Current Meter and

PGA-0510 Analog Ohm Meter as shown in Fig. 2. Meter

outlines, dimensions, and cutout sizes are shown in Figs. 6

and 7.

Page 3

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

0

9

8

7

6

5

4

3

2

1

0

3

2

1

123456 78 9101112131415

L1

L2/N 24 V

INSULATION

K1

LEAKAGE

K2

PHASE

<1.3 KV

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

CT

ANALOG

OUT I OUT R

AUTO

RESET

AUTO

RESET

NON

FAIL

SAFE

NON

FAIL

SAFE INSULATION

K2 K1

PGH

>1.3KV

NOTES:

1. DIMENSIONS IN MILLIMETRES (INCHES).

2. MOUNTING SCREWS: M4 x 13 OR 8-32 x 0.50.

3. OVERALL DIMENSION WHEN MOUNTED ON DIN

EN 50022 35.0 x 7. 5 (1.38 x 0.30)TOP- HAT RAIL.

4. 24 V INPUT IS AVAILABLE ONLY FOR THE

PGR-6100-120 ORDERING OPTION.

TOP

BOTTOM

FRONT

99.80

(3.93)

99.80

(3.93)

85.0

(3.35)

7. 4

(0.29)

61.2

(2.41)

75.0

(2.95)

6.9

(0.27)

MOUNTING DETAIL

SIDE

11 5.0 (NOTE 3)

(4.53)

PWR

TEST RESET

PUSH 8 s

POWR-GARD

GROUND-FAULT & INSULATION MONITOR

PGR-6100

SERIES

LEAKAGE CURRENT TIME DELAY

INSULATION RESISTANCE

FAULT ∆I

>∆I

CT

RESPONSE

ACTIVE

<R

75.0

(2.95)

0 = <50 ms

1 = 250 ms

2 = 500 ms

3 = 1. 0 s

500 kΩ1. 0 MΩ

250 kΩ

2.0 MΩ

0= 10 mA

1= 30 mA

2= 60 mA

3= 80 mA

4= 10 0 mA

5= 0.3 A

6= 0.6 A

7= 0.8 A

8= 1. 0 A

9= 3.0 A

110.0

(4.33)

FIGURE 1. PGR-6100 Outline and Mounting Details.

Page 4

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

3.1 PGH-5000 and PGH-6000

For 5-kV and 6-kV systems, connect the PGR-6100 to the

monitored circuit with a PGH-5000 and PGH-6000 respectively.

See Fig. 4 for PGH-5000 outline and mounting details. See

Fig. 5 for PGH-6000 outline and mounting details.

Connect protective-ground terminal ( ) to ground. Connect

terminal E to ground or to PGR-6100 terminal 30, which must

be grounded. Connect terminal M to PGR-6100 terminal 29.

For PGR-6100 to PGH-5000/PGH-6000 distances greater

than 10 m (30’), use shielded cable, and connect the cable

shield to the second PGH-5000/PGH-6000 terminal E

(PGR-6100 terminal 2 is not used). Connect terminal A to one

phase on the load side of the motor starter. See Fig. 2. The

PGH-5000/PH-6000 includes 915 mm (36”) of high-voltage

conductor.

L2/N

30

14

11

6L1

L2/N 5

10

12

13

15

18

19

K1

LOW INSULATION

PGR-6100

REMOTE RESET

CURRENT

SENSOR

24 V

K2

LEAKAGE CURRENT

16

17

20

21

22

23

S

27

28

24

25

26

A

+

-

MΩ

+

2

PGH-5000 / PGH-6000

A

EEM

29

NOTE 2

7

PGC-5000-SERIES

CURRENT SENSOR

STARTER

NOTE 3

HIGH TENSION COUPLER

FOR CONNECTIONS ABOVE

1,300 VAC

NOTE 3

STARTER

CONTACT

REMOTE TEST

120 VAC OR

240 VAC

NOTE 4

24 VAC

PGA-0500

0-100%

PGA-0510

0Ω - INFINITY

CONNECT 18 & 19 FOR AUTORESET

OPERATION OF K2

CONNECT 19 & 20 FOR NON-FAIL-SAFE

OPERATION OF K2

CONNECT 21 & 22 FOR AUTORESET

OPERATION OF K1

CONNECT 22 & 23 FOR NON-FAIL-SAFE

OPERATION OF K1

WARNING:

BEFORE CARRYING OUT MEGGER OR

DIELECTRIC-STRENGTHTESTS ONTHE

SYSTEM, DISCONNECTTHE PGR-6100.

NOTES:

1. RELAY CONTACTS SHOWN WITH

PGR-6100 DE-ENERGIZED.

2. INSULATION MONITORING IS

ONLY ACTIVE WHENTERMINALS

TERMINALS 27 AND 28 ARE

CONNECTED. JUMPERTHESE

TERMINALS FOR EXTERNAL

TESTING.

3. WHEN PGH-5000 OR PGH-6000 IS

USED, DO NOT CONNECT

TERMINAL 2.

4. 120 OR 240 VAC ARE ORDERING

OPTIONS. USE SPECIFIED

SUPPLY VOLTAGE.

5. ALTERNATE REMOTE-RESET

CONFIGURATION.

6. 24 VAC NOT AVAILABLE WITH THE

PGR-6100-240 ORDERING OPTION.

18

19

20

21

22

23

NOTE 5

LOAD

NOTE 6

FIGURE 2. Typical Connection Diagram.

Page 5

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

FIGURE 3. PGC-5000-Series Current Sensors.

Page 6

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

Revision:

Coupling Voltage:

PGH-5000

5 KV HIGH TENSION

COUPLER

Serial No:

1-800-TEC-FUSE (1-800-832-3873)

Made in Saskatoon, Canada

Impedance to Ground:

Current to Ground: 2.5 mA Max.

Formerly HTC 5000

E M

RELAY

E

HT

PGH-5000

A

5,000 Vac Max.

> 2 M

POWR-GAR D

E E M

A

A

Æ

Æ

44.5

(1.75)

165.1

(6.50)

95.2

(3.75) 9.5

(0.38)

NOTE 2

150.0

(5.91)

FRONT SIDE MOUNTING DETAIL

NOTES:

1. DIMENSIONS IN MILLIMETRES (INCHES).

2. MOUNTING HOLES: 5.00 mm (0.20).

3. ALL GROUND CONNECTIONS MUST BE

MADE AND SECURED BEFORE CONNECTIONS

TO RELAY AND HIGH VOLTAGE LINE.

4. CORD PROVIDED IS APPROXIMATELY

915.0 (36.00) LONG.

915.0

(36.00)

5kV HIGHTENSION COUPLER

PGH-5000

DANGER

HIGH VOLTAGE

ATTENTION!

BOTH GROUND CONNECTIONS

MUST BE MADE AND SECURED

BEFORE CONNECTIONS TO

THE RELAY AND THE

HIGH VOLTAGE LINE

MAXIMUM

V O LTAG E

AC 5000V

FIGURE 4. PGH-5000 Outline and Mounting Details.

Page 7

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

POWR-GARD

A

POWR-GARD

EEM

Revision:

Coupling Voltage:

PGH-6000

6 KV HIGH TENSION

COUPLER

Serial No:

1-800-TEC-FUSE (1-800-832-3873)

Made in Saskatoon, Canada

Impedance to Ground:

Current to Ground: 2.5 mA Max.

Formerly HTC 6000

E M

RELAY

E

HT

PGH-6000

A

6,000 Vac Max.

> 2 M

Æ

Æ

145.0

(5.71)

120.0

(4.72)

12.50

(0.49)

12.50

(0.49)

12.50

(0.49)

175.0

(6.89)

200.0

(7.87)

915 (36) LONG

98.5

(3.88)

FRONT SIDE

NOTES:

1. DIMENSIONS IN MILLIMETRES (INCHES).

2. MOUNTING HOLES: 6.35 mm (0.25).

3. ALL GOUND CONNECTIONS MUST BE

MADE AND SECURED BEFORE CONNECTION

TO RELAY AND HIGH VOLTAGE LINE.

4. CORD PROVIDED IS APPROXIMATELY

915.0 (36.00) LONG.

6kV HIGHTENSION COUPLER

PGH-6000

6kV HIGHTENSION COUPLER

PGH-6000

HIGH VOLTA GE

AT TENTION!

BOTH GROUND CONNECTIONS

MUST BE MADE AND SECURED

BEFORE CONNECTIONS TO

THE RELAY AND THE

HIGH VOLTAGE LINE

HIGH VOLTA GE

AT TENTION!

BOTH GROUND CONNECTIONS

MUST BE MADE AND SECURED

BEFORE CONNECTIONS TO

THE RELAY AND THE

HIGH VOLTAGE LINE

MAXIMUM

VOLTA GE

AC 6000V

MAXIMUM

VOLTA GE

AC 6000V

DANGER DANGER

FIGURE 5. PGH-6000 Outline and Mounting Details.

Page 8

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

4. TECHNICAL SPECIFICATIONS

4.1 PGR-6100

Supply:

120 Option ......................................5 VA, 120/24 Vac, (+10,

-15%) 50/60 Hz

240 Option.......................................5 VA, 240 Vac, (+10,

15%) 50/60 Hz

Operation Class ......................................Continuous

K1 and K2 Relay Contacts:

Configuration...................................N.O. and N.C (Form C)

Operating Mode..............................Fail-Safe or

....Non-Fail-Safe

UL Contact Rating ...........................5 A Resistive, 125 Vac

Switching Capacity .........................625 VA

Supplemental Contact Ratings:

Carry Continuous ................... 5 A maximum

Break:

30 Vdc ................................. 5 A

110 Vdc ............................... 0.3 A

Trip Mode ............................................... Latching or Autoreset

Reset ...................................................... Front-Panel Button and

Remote N.C. Contact

Test...........................................................Front-Panel Button and

Remote Contacts

Terminals................................................ Wire Clamping,

12-22 AWG

(0.3 to 2.5 mm2)

conductors

Tightening Torque .......................... 0.40 N∙m (3.54 lbf∙in)

Conductor Type .............................. Copper, Solid or

Stranded with

Ferrules

Conductor Rating ........................... 60/75°C

Dimensions:

Height..............................................75 mm (3.0”)

Width ..............................................100 mm (3.9”)

Depth...............................................113 mm (4.4”)

Including DIN rail....................115 mm (4.5”)

Shipping Weight .................................... 0.45 kg (1 lb)

Environment:

Operating Temperature .................. -10 to 60°C (14 to

140°F)

Storage Temperature ..................... -40 to 80°C (-40 to

176°F)

Humidity..........................................85% Non-Condensing

Enclosure Rating .............................IP20

Altitude ..........................................2,000 m (6,562 ft)

maximum

Overvoltage Category ....................II

Pollution Degree ............................2

Certification............................................UL Listed

................................................

................................................UL508 Industrial Control

Equipment

FCC

4.1.1 PGR-6100 Online Operation

Trip-Level Settings (∆I)...........................10, 30, 60, 80, 100, 300,

600, 800, 1,000, and

3,000 mA

Trip-Time Settings ..................................< 0.050, 0.250, 0.500,

1.0 s

Input:

CT ................................................PGC-5000-Series

CT Detection ..................................Open-Circuit Detection

Analog Output:

Mode..............................................Self Powered

Range .............................................0-1 mA

Output impedance..........................5 k maximum

4.1.2 PGR-6100 Ofine Operation

Maximum System Voltage:

Direct Connection ..........................1,300 V

With PGH-5000 ..............................5,000 V

With PGH-6000 ..............................6,000 V

Measuring Voltage.................................12 Vdc

Measuring Current.................................20 μA maximum

DC Resistance........................................600 k

AC impedance at 50-60 Hz.....................> 1 M

Response-Level Settings........................0.250 to 2.0 M

Response Delay......................................< 250 ms

Maximum Leakage:

Capacitance to Ground...........................< 1 μF

Maximum Stray Voltage ........................1,000 Vdc

Analog Output:

Mode..............................................Self-Powered

Range .............................................0-1 mA

Impedance......................................5 k maximum

Page 9

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

4.2 PGH High Tension Couplers

Maximum Line Voltage:

PGH-5000 ..................................5,000 Vac

PGH-6000...................................6,000 Vac

Current to Ground..............................2.5 mA maximum

Terminal M Maximum

Voltage ..............................................50 Vac

Terminals:

E, E, and M................................. Wire Clamping,

22 to 12 AWG

(0.2 to 2.5 mm2)

conductors

............................................ Wire Clamping,

10 AWG (5.26 mm2)

maximum

High Tension Lead A ......................... 8 AWG (8.36 mm²),

40 kVdc, 915 mm (36”)

5. ORDERING INFORMATION

PGA-0500 ......................................... Analog Percent Current Meter

PGA-0510 ......................................... Analog Ohm Meter

PGC-5025.......................................... Current sensor,

25.0 mm (0.98”) window

PGC-5060.......................................... Current sensor,

60.8 mm (2.40”) window

PGC-5095.......................................... Current sensor,

95.0 mm (3.74”) window

PGC-5130.......................................... Current sensor,

130.0 mm (5.12”) window

PGC-5200.......................................... Current sensor,

200.0 mm (7.87”) window

PGH-5000 ......................................... 5 kV High Tension Coupler

PGH-6000 ......................................... 6 kV High Tension Coupler

NOTES:

(1) 240 Vac option is not UL Listed.

FIGURE 6. PGA-0500 Analog Percent Current Meter.

PGR-6100-

Supply:

120 – 120- or 24-Vac Supply

240 – 240-Vac Supply(1)

Page 10

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

FIGURE 7. PGA-0510 Analog Ohm Meter.

6. TESTS

6.1 Ground-Fault Test

Some jurisdictions require periodic ground-fault

performance tests. A test record form is provided for

recording the date and the result of the performance tests.

The following ground-fault system tests must be conducted

by qualified personnel:

1. Evaluate the interconnected system in accordance

with the overall equipment manufacturer’s detailed

instructions.

2. Verify proper location of the PGC-5000-series CT. Ensure

the cables pass through the CT window. This check can

be done visually with knowledge of the circuit. The

connection of the current-sensor secondary to the PGR-

6100 is not polarity sensitive.

3. Verify that the system is correctly grounded and there are

no alternate ground paths bypassing the current sensor.

High-voltage testers and resistance bridges can be used

to determine the existence of alternate ground paths.

4. Verify proper reaction of the circuit-interrupting device

in response to a simulated or controlled ground-fault

current. To simulate ground-fault current, use CT-primary

current injection. Fig. 8 shows a test circuit using the

SE-400 Ground-Fault-Relay Test Unit. The SE-400 has a

programmable output of 0.5 to 9.9 A for a duration of

0.1 to 9.9 seconds. Fig. 8 shows the use of resistors

that reduce the injected current to 10% of the SE-400

setting. Set the test current to 120% of the PGR-6100

setting. Inject the test current through the CT window for

at least 2.5 seconds. Verify that the circuit under test has

reacted properly. Correct any problems and re-test until

the proper reaction is verified.

5. Record the date and the results of the test on the attached

test-record form.

NOTE: Do not inject test current directly into CT-input

terminals 16 and 17.

Page 11

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

FIGURE 8. Ground-Fault-Test Circuit.

TABLE 1. GROUND-FAULT-TEST RECORD

DATE TEST RESULTS

Retain this record for the authority having jurisdiction.

6.2 Insulation Test

Perform this test with the starter open and appropriate

lock-out procedures.

Connect a 10-k resistor between one phase and

ground at the line side of the starter or motor terminal box.

Select a phase that is not connected to PGR-6100 terminal

2 (or the PGH-5000 or PGH-6000). The PGR-6100, operating

in Offline mode (as indicated by the green ACTIVE LED),

will alarm, operating the K1 low insulation output relay and

lighting the red <R LED.

PGR-6100

Page 12

REV. 2-C-050818

PGR-6100 Ground-Fault & Insulation Monitor

MANUAL RELEASE

DATE MANUAL REVISION PRODUCT REVISION

(REVISION NUMBER ON PRODUCT LABEL)

May 8, 2018 2-C-050818

01

November 10, 2014 2-B-111014

January 30, 2014 2-A-013014

January 12, 2010 1 00

APPENDIX A

PGR-6100 REVISION HISTORY

MANUAL REVISION HISTORY

REVISION 2-C-050818

SECTION 4

Specifications added.

REVISION 2-B-111014

SECTION 3

Figs. 1 and 2 updated.

SECTION 4

PGR-6100 supply options updated.

SECTION 5

Ordering information updated.

APPENDIX A

Revision history updated.

REVISION 2-A-013014

SECTION 1

Product name changed to PGR-6100 Ground-Fault & Insulation Monitor.

SECTION 3

Fig. 3 updated.

SECTION 4

UL Certification and contact rating specifications added.

REVISION 1

Initial release.

PRODUCT REVISION HISTORY

PRODUCT REVISION 01

UL Certification.

PRODUCT REVISION 00

Initial release.

Table of contents

Popular Laboratory Equipment manuals by other brands

THORLABS

THORLABS GANYMEDE II HR operating manual

Agilent Technologies

Agilent Technologies Agilent 1260 Infinity System user's guide

Retsch

Retsch Mixer Mill MM 500 control manual

Global Focus

Global Focus SILENCER S12V Series Service manual

Vertex

Vertex Omega 130 owner's manual

BiOptic

BiOptic Qsep Series Operation manual