Sorvall WX 100 Ultra User manual

50105750-4 October 2010

Thermo Fisher Scientific

WX Ultra Series

WX 100, WX 90, WX 80

Instruction Manual

© 2010 Thermo Fisher Scientific Inc. All rights reserved.

WX is either a registered trademark or a trademark of Thermo Fisher Scientific.

Microsoft, Microsoft Excel, Windows, Windows XP, and Windows Vista are registered trademarks of

Microsoft Corporation in the United States and/or other countries.

All other trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries.

Thermo Fisher Scientific

Robert-Bosch-Straße 1

D - 63505 Langenselbold

Germany

Thermo Fisher Scientific Inc. provides this document to its customers with a product purchase to use in the

product operation. This document is copyright protected and any reproduction of the whole or any part of this

document is strictly prohibited, except with the written authorization of Thermo Fisher Scientific Inc.

The contents of this document are subject to change without notice. All technical information in this

document is for reference purposes only. System configurations and specifications in this document supersede

all previous information received by the purchaser.

Thermo Fisher Scientific Inc. makes no representations that this document is complete, accurate or error-

free and assumes no responsibility and will not be liable for any errors, omissions, damage or loss that might

result from any use of this document, even if the information in the document is followed properly.

This document is not part of any sales contract between Thermo Fisher Scientific Inc. and a purchaser. This

document shall in no way govern or modify any Terms and Conditions of Sale, which Terms and Conditions of

Sale shall govern all conflicting information between the two documents.

Release history: 50105750-4 printed in October 2010.

For Research Use Only. Not for use in diagnostic procedures.

Thermo Scientific WX Ultra Series i

C

Chapter 0 Preface - Intended use and safety definitions ............................................................................................... iii

Safety Definitions..................................................................................................................................iii

Important safety reminder .....................................................................................................................iv

Chapter 1 Description...........................................................................................................................................................1-1

General description............................................................................................................................. 1-1

External view of ultracentrifuge ...................................................................................................... 1-2

Design................................................................................................................................................ 1-3

Control panel ................................................................................................................................. 1-3

Rotor chamber................................................................................................................................ 1-6

Safety devices.................................................................................................................................. 1-7

Rotor adapter ................................................................................................................................. 1-8

Chapter 2 Operation..............................................................................................................................................................2-1

Run preparation ................................................................................................................................. 2-2

Starting up the ultracentrifuge ........................................................................................................ 2-3

Preparing tubes/bottles and rotor.................................................................................................... 2-4

Basic operation ................................................................................................................................... 2-4

Setting run conditions .................................................................................................................... 2-4

Setting user ID code ....................................................................................................................... 2-9

Using Rotor Life Management .....................................................................................................2-10

Basic operating procedure................................................................................................................. 2-11

Normal operation......................................................................................................................... 2-13

Zonal operation............................................................................................................................ 2-15

Acceleration and deceleration rates ................................................................................................... 2-17

How to use the FUNCTION field...................................................................................................2-19

Programmed operation ................................................................................................................. 2-21

Step-mode operation .................................................................................................................... 2-32

RTC (real-time control) feature.................................................................................................... 2-40

Displaying and setting RCF.......................................................................................................... 2-48

Setting w2T.................................................................................................................................. 2-56

Defrost function ........................................................................................................................... 2-58

Setting and resetting zonal operation ............................................................................................ 2-59

Rotor management........................................................................................................................... 2-60

Rotor life management ................................................................................................................. 2-60

Automatic rotor deration.............................................................................................................. 2-61

Automatic rotor exclusion............................................................................................................. 2-61

Registering a rotor ........................................................................................................................ 2-61

Deleting a registered rotor ............................................................................................................ 2-64

Updating the existing data for a rotor ........................................................................................... 2-65

When power failure occurs ............................................................................................................... 2-66

Features of the menu screen.............................................................................................................. 2-69

Contents

Contents

ii WX Ultra Series Thermo Scientific

Centrifuge scheduler..................................................................................................................... 2-69

User list ........................................................................................................................................ 2-71

Alarm information........................................................................................................................ 2-76

Rotor catalog ................................................................................................................................ 2-77

User Customizations..................................................................................................................... 2-77

Print utilities (option)....................................................................................................................... 2-81

Operating procedure..................................................................................................................... 2-82

Contents of print utilities ............................................................................................................. 2-84

Automatic run result printing....................................................................................................... 2-86

Printer fault handling ................................................................................................................... 2-87

Lockout (optional)............................................................................................................................ 2-88

Chapter 3 Maintenance........................................................................................................................................................3-1

Rotor chamber.................................................................................................................................... 3-1

Drive spindle ...................................................................................................................................... 3-2

Cabinet............................................................................................................................................... 3-2

Replacement parts .............................................................................................................................. 3-2

Service decontamination policy .......................................................................................................... 3-2

Chapter 4 Troubleshooting ..................................................................................................................................................4-1

Alarm indicators ................................................................................................................................ 4-1

Diagnosed problems - requiring maintenance..................................................................................... 4-3

Non-diagnosed problems ................................................................................................................... 4-3

Chapter 5 Preinstallation.....................................................................................................................................................5-1

Location Requirements....................................................................................................................... 5-1

Electrical requirements ....................................................................................................................... 5-2

Leveling.............................................................................................................................................. 5-2

Moving the ultracentrifuge ................................................................................................................. 5-3

Chapter 6 Specifications .....................................................................................................................................................6-1

Chapter 7 Supply list.............................................................................................................................................................7-1

Appendix A Service Decontamination Policy ....................................................................................................................A-1

Appendix B Condensed operating instructions .................................................................................................................B-1

Appendix C Chemical Compatibility Chart .........................................................................................................................C-1

Appendix D WARRANTY.........................................................................................................................................................D-1

Appendix E Contact Information........................................................................................................................................... E-1

Thermo Scientific WX Ultra Series iii

P

Preface - Intended use and safety definitions

This manual is a guide to the use of the Sorvall WX Ultra series ultracentrifuge.

Information herein has been verified and is believed adequate for the intended use of the centrifuge.

Because failure to follow the recommendations set forth in this manual could produce personal injury

or property damage, always follow the recommendations set forth herein. Thermo does not guarantee

results and assumes no obligation for the performance of centrifuges or other products that are not

used in accordance with the instructions provided. This publication is not a license to operate under,

nor a recommendation to infringe upon, any process patents.

Safety Definitions

DANGER, WARNING, CAUTION, and NOTE within the text of this manual are used to

emphasize important and critical instructions.

DANGER, WARNING and CAUTION information is accompanied by a hazard symbol and appears

throughout the manual, both on the Important Safety Reminder pages and near the information it

corresponds to.

Before you operate the centrifuge, we recommend that you read this instruction manual thoroughly,

particularly all DANGERS, WARNINGS and CAUTIONS.

Never operate the centrifuge without first considering all items on the Important Safety Reminder

pages, and never operate the centrifuge in any manner not described in this instruction manual.

DANGER Informs the operator of an extreme hazard or an unsafe practice that will result

in death or serious injury.

WARNING Informs the operator of a hazard or an unsafe practice that could result in

serious injury or death, affect the operator's health, or contaminate the environment.

CAUTION Informs the operator of a hazard or an unsafe practice that could cause minor

injury, or result in damage of equipment or property.

Note Highlights essential information that is not hazard-related.

Preface - Intended use and safety definitions

Important safety reminder

iv WX Ultra Series Thermo Scientific

Important safety reminder

Certain potentially dangerous conditions are inherent to the use of all centrifuges. To ensure safe

operation of this centrifuge, anyone using it should be aware of all safe practices and take all

precautions described below and throughout these operating instructions.

DANGER

• Before removing any cabinet panel (such as for maintenance or repair), always turn

the main Power Switch OFF and unplug the centrifuge, then wait at least three

minutes to eliminate the potential for severe electric shock.

WARNING

• Never exceed the maximum rated speed of the installed rotor; to do so can cause rotor

failure.

• Always reduce (derate) rotor speed whenever:

1. The rotor speed/temperature combination exceeds the solubility of the gradient

material and causes it to precipitate.

2. The compartment load exceeds the maximum allowable compartment load (or design

mass) specified for your rotor.

Failure to reduce speed under these conditions can cause rotor failure.

• Always inspect the rotor as specified in your rotor manual. Do not use a rotor that

shows signs of damage or corrosion.

• Centrifuges routinely deal with high energy levels and could move suddenly in the

unlikely event of rotor failure. During centrifuge operation, never lean on or move the

centrifuge, keep the surrounding area clear of objects (including all hazardous and

flammable materials), and do not work on top of or next to the centrifuge (as a rule,

keep people and objects at least 300 mm [12 inch] away).

• Never unlock the chamber door, attempt to open the door, or otherwise attempt to

touch the rotor while it is rotating. In the event of a power outage, it can take more

than three hours for the rotor to stop - be sure to wait at least three hours before

opening the door.

• Never attempt to override or otherwise disable any safety features.

• When using radioactive, toxic, or pathogenic materials, be aware of all characteristics

of the materials and the hazards associated with them in the event leakage occurs

during centrifugation. If leakage does occur, neither the centrifuge nor the rotor can

protect you from particles dispersed in the air. To protect yourself, we recommend

additional precautions be taken to prevent exposure to these materials, for example,

use of controlled ventilation or isolation areas.

• Always be aware of the possibility of contamination when using radioactive, toxic, or

pathogenic materials. Take all necessary precautions and use appropriate

decontamination procedures if exposure occurs.

Preface - Intended use and safety definitions

Important safety reminder

Thermo Scientific WX Ultra Series v

WARNING

• The use of sealed rotors, buckets and/or sample containers will provide increased

protection from contamination during routine operation. However, these items will

not guarantee contamination protection from accidents resulting in damage to the

rotor or buckets. Do not run hazardous materials in the centrifuge unless placed in a

biohazard enclosure and operated using all appropriate safety precautions.

• Never use any materials capable of producing flammable or explosive vapors, or

extreme exothermic reactions.

• The centrifuge is equipped with a three-wire power cord that has one wire for

connection to ground. The centrifuge must be correctly grounded to guard against

shock hazards.

CAUTION

• Do not operate the control keys using a ball-point pen or a sharp object.

• Do not run or precool the rotor at the critical speed as this will have a detrimental

effect on centrifuge component life (see rotor manual).

• Do not operate the centrifuge with a rotor that is not balanced within specification.

To do so can cause damage to the centrifuge drive assembly.

• Always make sure the rotor is correctly assembled and properly seated on the

centrifuge drive spindle before operation. If using a swinging-bucket rotor, always

make sure that a bucket is installed at each position and that each is properly seated

and can swing freely after installing the rotor on the centrifuge drive spindle (see rotor

manual).

• Do not exceed the maximum speed of the tubes, bottles, or adapters being used.

Check manufacturer's published specifications or see Sorvall Product Guide; if unsure,

to avoid loss of valuable sample, we recommend performing a test run.

• Do not continue to operate the centrifuge if abnormal sounds occur during operation.

Immediately discontinue use of the centrifuge and contact Thermo Service.

• Supply power must be checked before the centrifuge is connected to power because

the centrifuge can be damaged if connected to the wrong voltage. Thermo is not

responsible for incorrect installation and warranty is void if an initial installation or

electrical modification of the centrifuge is not performed by Thermo or a Thermo

representative.

• Before moving the centrifuge, always remove the rotor from the rotor chamber to

avoid damage to the drive assembly.

• Do not place fluids inside, on top of, or close to the centrifuge --- spillage can result in

electrical or mechanical failure.

• Always operate and maintain the centrifuge and all rotors as instructed in this manual

and in the rotor manual(s).

Preface - Intended use and safety definitions

Important safety reminder

vi WX Ultra Series Thermo Scientific

Thermo Scientific WX Ultra Series 1-1

1

Description

General description

The Sorvall WX Ultra series ultracentrifuges are designed and manufactured based on our long

experience in the development of centrifuges; they are easy to use and highly reliable. Features include

the following:

1. Maximum speed of 100,000 rpm (802,006 x g)

2. Control panel is simple with easy key operation and easy-to-see liquid crystal screen.

3. The displayed language can be switched over between English and Japanese.

4. The real-time control (RTC) feature enables setting a start time or a finish time, thus letting you

run your machine at a desired date and time.

5. Centrifugal force (RCFmax and RCFavg) can be displayed and set.

6. Twenty varieties of nine stepped modes can be programmed for a wide range of applications.

7. Various alarms notify users of causes and necessary actions when fault conditions are detected

allowing easier and quicker troubleshooting.

8. Space saving design. The installation area required is 0.81 m2 (90 x 90 cm) pr 9.0 ft2 (3.0 x 3.0 ft). Lower

top deck makes it easy to install and remove the rotor.

9. Low noise level makes the ultracentrifuge suitable for use in any laboratory.

10. Samples can be easily balanced visually.

11. CFC-free thermoelectric cooling system with greater cooling capacity.

Advanced features (options)

The options of the Sorvall WX Ultra series ultracentrifuges are: Compass Software, Lockout Kit, and a

Printer.

The Compass Software is a calculation/simulation system for centrifuge support that is compatible with

Windows R 2000 / XP Professional. Compass Centrifugation software helps determine appropriate run

conditions prior to starting centrifugal separation, and calculates optimum centrifuge and rotor run

conditions for materials in which proper run conditions are unknown. For more information on this

please consult the Compass Operator's Manual.

The Lockout Kit limits centrifuge access to a group of registered users (up to 40) which is controlled by

lab managers/supervisors (up to 3). For more information on this see page 2-95, Lockout.

The printer provides hard copy reports of information maintained in the centrifuge including: Set and

actual run conditions, rotor use, programmed memory contents, and others. For more information on

this see page 2 - 89, Print Utilities.

Description

General description

1-2 WX Ultra Series Thermo Scientific

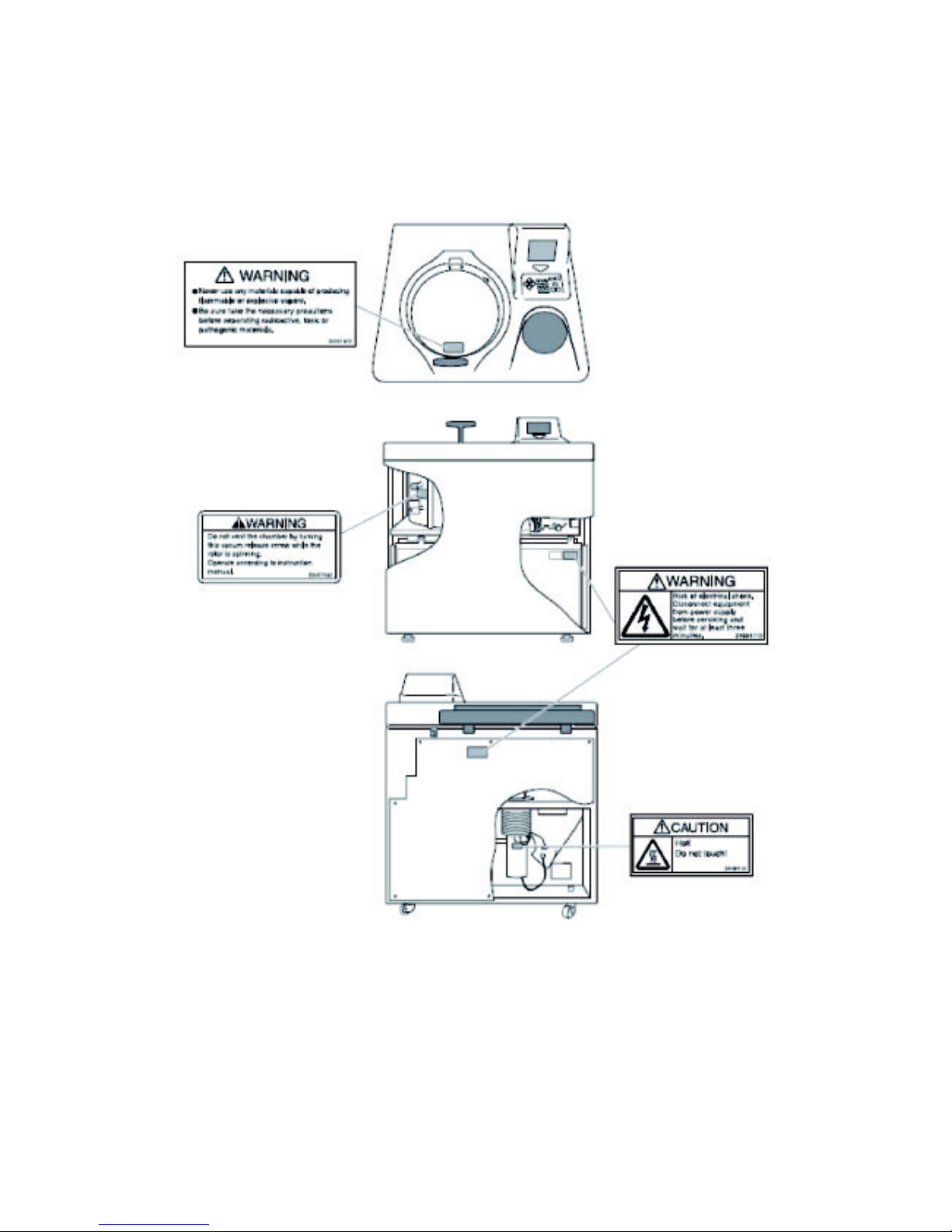

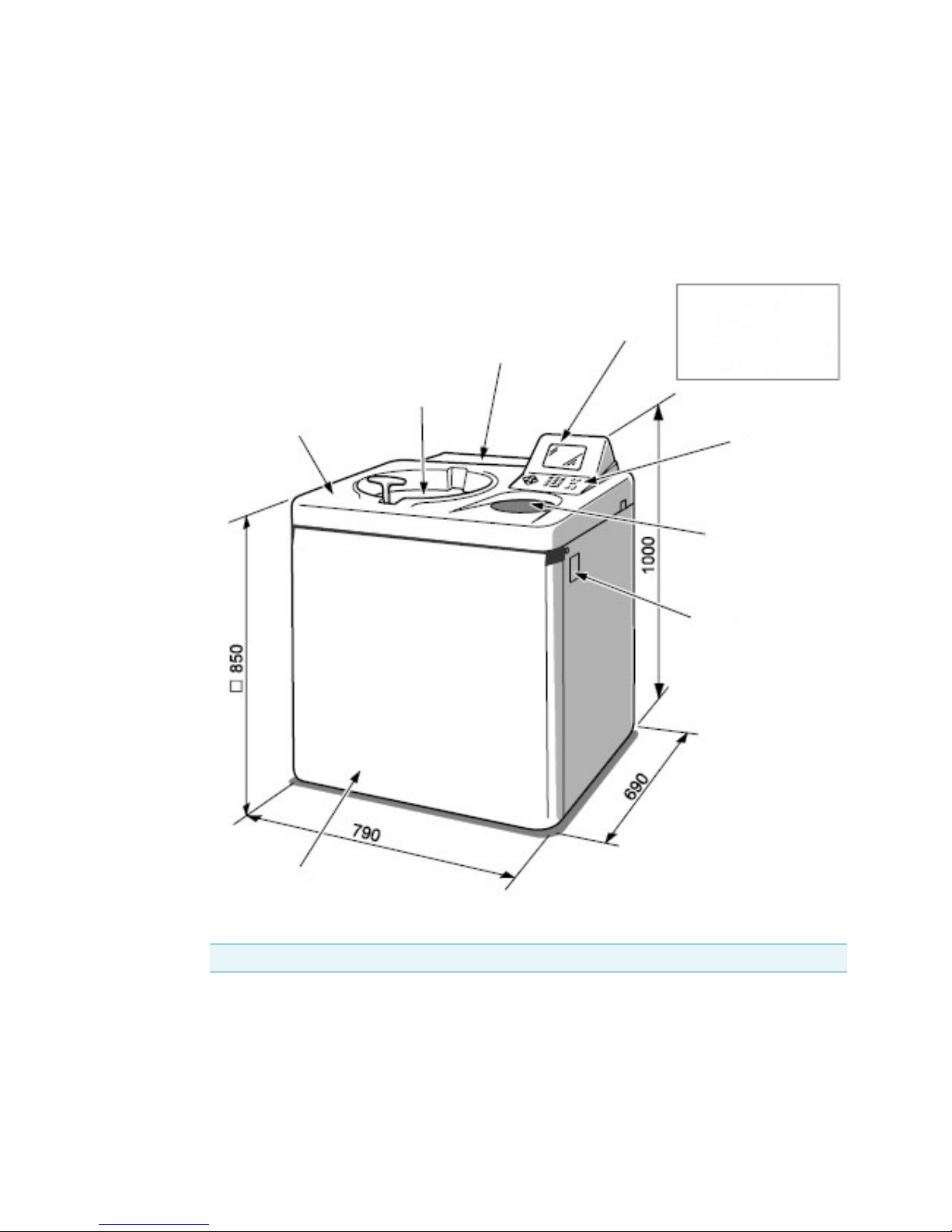

External view of ultracentrifuge

The WX Series ultracentrifuge have the same external view, except for the model name printed on front

cover. The following is the external view of the WX ultracentrifuge.

External view of ultracentrifuge

Figure 1-1 External view of the Sorvall WX Ultra series

Note * This height is measured from level floor surface.

Top deck

Door

Safety cover

Display panel

690 mm (27.2 in)

790 mm (31.1in)

850 mm (33.5 in)

1000 mm (39.4 in)

Operation key

Rotor rubber mat

Power switch

Front cover

Description

Design

Thermo Scientific WX Ultra Series 1-3

Design

Control panel

The control panel for the Sorvall WX Ultra series consists of a color screen, a touch sensitive display

panel and a keyboard.

The display panel incorporates an easy-to-read liquid crystal display. The display panel (field display)

displays running conditions and running status (this screen is called the Run Screen), along with

features such as Programmed Run, Rotors List, and User Customization Screens. Fig. 1-2 shows the

display panel, and Fig.1-3 represents the keyboard.

Figure 1-2 Display panel

Figure 1-3 Keyboard

(3) Message indicator

{

(1) Field display

(5) Vacuum indicator

(4) RUN mode indicator

(2) FUNCTION field

}

}

Operation state display field

Setting value display field

(12) Key pad

(11) Cursor key

(6) START key

(7) STOP key

(8) VACUUM key

(10) MENU key

(9) ESC key

Description

Design

1-4 WX Ultra Series Thermo Scientific

Table 1-1 [Functions of the display panel-keyed by item no. to fig. 1-2]

No. Name and Symbol Functions and actions

(1) Field display

SPEED

TIME

TEMP

Displays various fields.

The SPEED, TIME, and TEMP fields give the current status indicator in the top row and the

setting indicator in the bottom row. (For setting, see Section “Setting run conditions”.)

• SPEED (Speed indicator)

(Top row) Displays speeds in increments of 10 rpm at lower than 5,000 rpm, and in steps of 100

rpm at 5,000 rpm or more.

(Bottom row) Sets speeds from 1,000 to maximum speed in increments of 100 rpm. The lower two

digits (one, ten positions) display zeros.

• TIME (running time indicator)

(Top row) Displays the remaining operation time or the time elapsed during operation if settings

are performed on the User Customization screen. If the running time is set to HOLD, this field

displays time elapsed.

(Bottom row) Specifies a setting in the range from 1 minute to 99 hours 59 minutes in steps of

minutes and hours.

• TEMP (temperature indicator)

(Top row) Displays in steps of 0.1 °C.

(Bottom row) Sets a setting in the range from 0 °C to 40 °C in increments of 0.1 °C

• ACCEL (acceleration mode indicator). Displays acceleration modes 1 through 9.

• DECEL (deceleration mode indicator). Displays deceleration modes 1 through 9, along

with free coast (F).

(2) Function field • ID CODE Sets an ID code.

• RLM Switches to the Rotor Management screen.

• PROG • RTC Sets, recalls programmed runs or sets the time and the end time for a

programmed run.

• RCF • ω2T Sets and displays the centrifugal force or sets an ω2T

• DEF Sets and resets the defrost function.

• ZONAL Sets the zonal operation mode.

(3) Message indicator Displays an alarm message and various suggestions for operation.

(4) Run mode indicator The following terms are displayed:

STOP, ACCEL, RUN (running at the set speed)

DECEL, WAIT (waiting for vacuum during acceleration)

ZONAL (for zonal operation)

DELAY (until the start time in an RTC run)

(5) VACUUM indicator Displays the following four stages according to the vacuum of the rotor chamber.

(1) Atmospheric state. The vacuum pump is not activated.

(2) Low vacuum. The rotor waits at 4,000 rpm until the vacuum reaches an inter-

mediate level

(3) Intermediate vacuum.

(4) High vacuum.

Note If the sample is sensitive to a temperature rise, do not press the START key until the

chamber is at high vacuum level.

Description

Design

Thermo Scientific WX Ultra Series 1-5

Table 1-2 [Functions of keyboard-keyed by item no. to fig. 1-3]

No. Name and Symbol Functions and actions

(6) START key Starts rotor rotation. If VACUUM is off, this key activates the vacuum pump and starts

temperature control.

(7) STOP key Stops rotor rotation.

(8) VACUUM key Starts up the vacuum pump and activates air vent (As soon as vacuum pump is on, tem-

perature control starts.) Air vent for vacuum chamber after a run cannot be opened as

long as the rotor is spinning.

(9) ESC key Moves the display back to the screen at the preceding level (for example, to switch

back from the Menu Screen to the Run Screen).

(10) MENU key Displays the Menu Screen.

The Menu Screen offers the choice of Centrifuge Scheduler, User List, Alarm Informa-

tion, Rotor Catalog, and User Customization Routines.

(11) Cursor key a. Displays the cursor on the Run Screen, putting the display into input wait status.

b. Move the cursor on the screen.

1. Moves the cursor up

2. Moves the cursor down

3. Moves the cursor to the right

4. Moves the cursor to the left

(12) Numeric key Used to type numbers for setting run conditions.

During time and temperature entry: Moves cursor from hours to minutes.

Acts as decimal point for data entry.

a. During operation time entry: sets continuous run.

b. When entering deceleration conditions: sets a free coast.

Use this when you have entered the wrong value while entering an

operating condition or entering a number or when the alarm device is

activated.

Functions of this key

a. This key clears the cursor-carrying input field and returns you to the

preinput state.

b. Use this key to clear an alarm signal. If more than one alarm signal is

on, this key will clear them one by one.

Registers the entered value.

Description

Design

1-6 WX Ultra Series Thermo Scientific

Rotor chamber

The structure of the rotor chamber (vacuum chamber) is shown in Fig. 1-4.

Figure 1-4 Rotor chamber

Note If sample or water drops to the window of the temperature sensor, it may cause an incorrect

detection. Whenever the sensor is wet, wipe it with a clean, dry cloth. Take care not to scratch the

surface of the sensor.

Drive spindle

Speed sensor

Chamber door seal

Handle Chamber door

Temperature sensor (measuring

the temperature of the rotor)

Door lock system

Vacuum chamber

Bowl (Rotor Chamber)

Thermoelectric cooling element

(cooling the rotor)

Guard

Overspeed detector

(detecting any instance

exceeding the maximum

allowable speed of the

rotor)

Description

Design

Thermo Scientific WX Ultra Series 1-7

Safety devices

(1) Containment

Should a rotor failure occur, the guard ring will contain the contents of the rotor inside the centrifuge

(Fig. 1-4).

(2) Imbalance detector

If during operation the vibration of the rotor becomes excessive due to serious imbalance or improper

bucket setting, the imbalance detector detects the situation and decelerates the rotor immediately.

However, the ultracentrifuge is designed to tolerate imbalance associated with visual balancing-it is

equipped with an imbalance tolerant drive. (For more information on the balancing of rotors, see

Section 2-1-2, “Preparing tubes/bottles and rotor”.)

(3) Door lock system

The chamber door automatically locks for safety while the rotor is spinning. When the power supply is

off, the door remains locked. The door can only be opened and closed when the rotor is at rest and the

rotor chamber is vented. Unless the door is closed, the rotor will not start rotating except in zonal

mode. To open the door in the event of a power failure, see Section 2-7, “When power failure occurs”.

(4) Speed sensor and overspeed detector

For protection in the event of entry errors the ultracentrifuge is provided with an automatic system to

stop the rotor when its speed exceeds the maximum allowable speed. If a speed higher than the

maximum permitted speed is set, the ultracentrifuge will detect the mistake before the speed reaches

3000 rpm, and then will display an alert message and decelerate the rotor to a stop.

Description

Design

1-8 WX Ultra Series Thermo Scientific

Rotor adapter

Overspeed Decal

The overspeed decal located on the rotor base has alternating black and white bands. The number of

bands corresponds to the maximum permitted speed of the rotor. (See Fig. 1-5.)

Figure 1-5 Standard rotor

To protect the overspeed decal, be sure to store the rotor on the rotor stand provided. (See Fig. 1-6.)

Figure 1-6 Rotor stand

Overspeed decal

Standard rotor with

overspeed decal

Thermo Scientific WX Ultra Series 2-1

2

Operation

The Sorvall WX Ultra series ultracentrifuges are capable of operation in more than one mode to meet a

wide range of applications. The outline of each available mode is given below:

Outline Reference

Normal operation Section Normal opera-

tion

Optional features

Programmed opera-

tion

You can store set run conditions in memory for later use in

repeated operation. Section How to use the

FUNCTION field

Section Programmed

operation

Step-mode operation

More than one normal operation can be combined into a

sequence of operations or step for successive centrifuga-

tion. Section Step-mode

operation

RTC (real-time con-

trol) operation

Run starts or completes at a required date and time.

Section RTC (real-time

control) feature

RCF (centrifugal

force)

value display setting

This feature calculates centrifugal force (RCF) values from

set speed. It can also calculate reversely, i.e., finding

speed from such values. Section Displaying and

setting RCF

Speed

Time

Speed

Speed

Time Time

Store Recall

Speed

Time

Speed

Time

A finish date

and time re-

quired

START

key ON

Speed

Time

RCF

value setting

Operation

Run preparation

2-2 WX Ultra Series Thermo Scientific

Run preparation

Optional features

ω2T setting

Calculates and displays the running time from the set val-

ues of speed and ω2T.

Section Setting w2T.

Zonal operation

Zonal operation is a mode of operation using a zonal

rotor.

Section Zonal opera-

tion.

Speed

Time

Speed

Time

Zonal speed

WARNING

1. Never use any materials capable of producing flammable or explosive vapors, or extreme

exothermic reactions.

2. When using radioactive, toxic, or pathogenic materials, be aware of all characteristics

of the materials and hazards associated with them in the event leakage occurs during

centrifugation. If leakage does occur, neither the centrifuge nor the rotor can protect

you from particles dispersed in the air. To protect yourself, we recommend additional

precautions be taken to prevent exposure to these materials, for example, use of

controlled ventilation or isolation areas.

CAUTION Do not place fluids inside, on top of, or close to the centrifuge---spillage can result

in electrical or mechanical failure.

Operation

Run preparation

Thermo Scientific WX Ultra Series 2-3

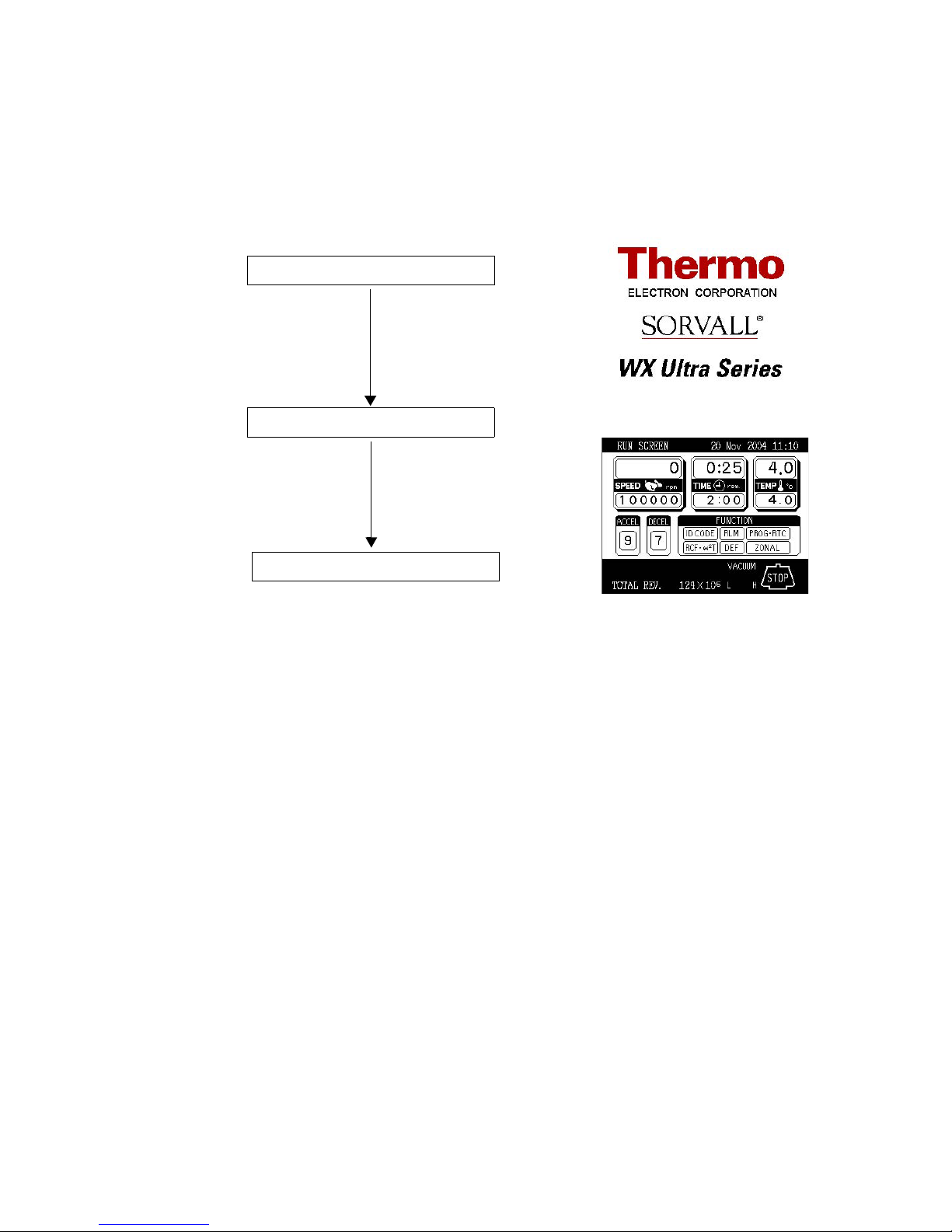

Starting up the ultracentrifuge

Before setting run conditions, display the run screen (screen for setting run conditions)

(1) Displaying the Run Screen (screen for setting run conditions)

Figure 2-1 Initial screen, and run screen

Initial screen

1. Turn on the POWER switch.

2. The initial screen appears.

3. The Run Screen appears.

Operation

Basic operation

2-4 WX Ultra Series Thermo Scientific

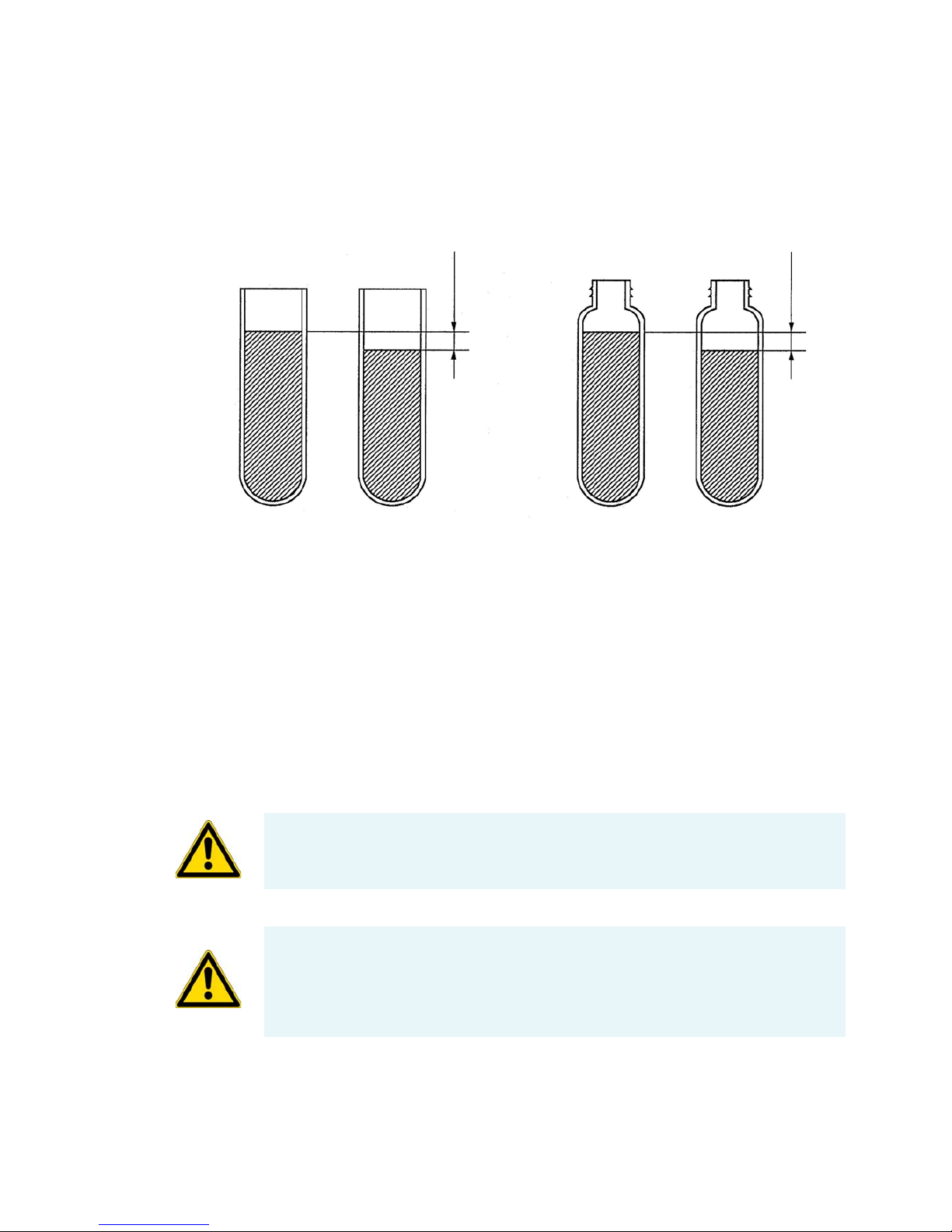

Preparing tubes/bottles and rotor

The Sorvall WX Ultra series ultracentrifuges allow you to balance, by eye, tubes or bottles containing a

sample solution and then centrifuge them. Make sure that the difference between meniscus levels of

sample solution in tubes or bottles in within 5 mm (0.197 in) (See fig. 2-2).

Figure 2-2 Balancing tubes/bottles containing a sample solution

To prevent tube or bottle failure, some tube and rotor combinations cannot be run to the maximum

speed of the rotor when partially filled. The tube or bottle must be full in the following cases:

1. When a thin tube or seal tube is used.

2. When a thick tube is used for swinging rotor.

3. When a bottle is used 100,000 x g or more.

Basic operation

Setting run conditions

This section will first describe the screen for basic operation (the run screen) and the cursor keys.

Within 5 mm

(0.197 in)

Within 5 mm

(0.197 in)

(1) Tubes (2) Bottles

WARNING Do not lean on, tilt or place anything on the centrifuge while in operation.

CAUTION

1. Do not operate the keyboard with a ball-point pen or a sharp object.

2. Do not continue to operate the centrifuge if abnormal sounds occur during operation.

Immediately discontinue use of the centrifuge and contact Thermo Service.

This manual suits for next models

2

Table of contents

Other Sorvall Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Julabo

Julabo CORIO CP Original operating manual

Planer

Planer 370 Series Original instructions

BIO RAD

BIO RAD Gel Doc XR 170-8170 instruction manual

Shodex

Shodex SUGAR EP SC1011-7F Operation manual

BRONKHORST

BRONKHORST IN-FLOW instruction manual

Thermo Scientific

Thermo Scientific NPD Tandem Upgrade Kit installation guide