Little Giant EC-1-DV User manual

Other manuals for EC-1-DV

1

This manual suits for next models

1

Table of contents

Other Little Giant Water Pump manuals

Little Giant

Little Giant PE-2YSA User manual

Little Giant

Little Giant PES-70 User manual

Little Giant

Little Giant 1-EAYS Service manual

Little Giant

Little Giant PCPK-N User manual

Little Giant

Little Giant 5.5-ASPA Series User manual

Little Giant

Little Giant SPBS-12 User manual

Little Giant

Little Giant VCMA-20-PRO Series User manual

Little Giant

Little Giant 9EH User manual

Little Giant

Little Giant 1-YS User manual

Little Giant

Little Giant PCP550 User manual

Little Giant

Little Giant 5.5-ASP User manual

Little Giant

Little Giant B-1000 Series User manual

Little Giant

Little Giant 9S-SMPXC-LG Reference manual

Little Giant

Little Giant 9E-CIA-RFS User manual

Little Giant

Little Giant APCP-1700 User manual

Little Giant

Little Giant VCMA Series User manual

Little Giant

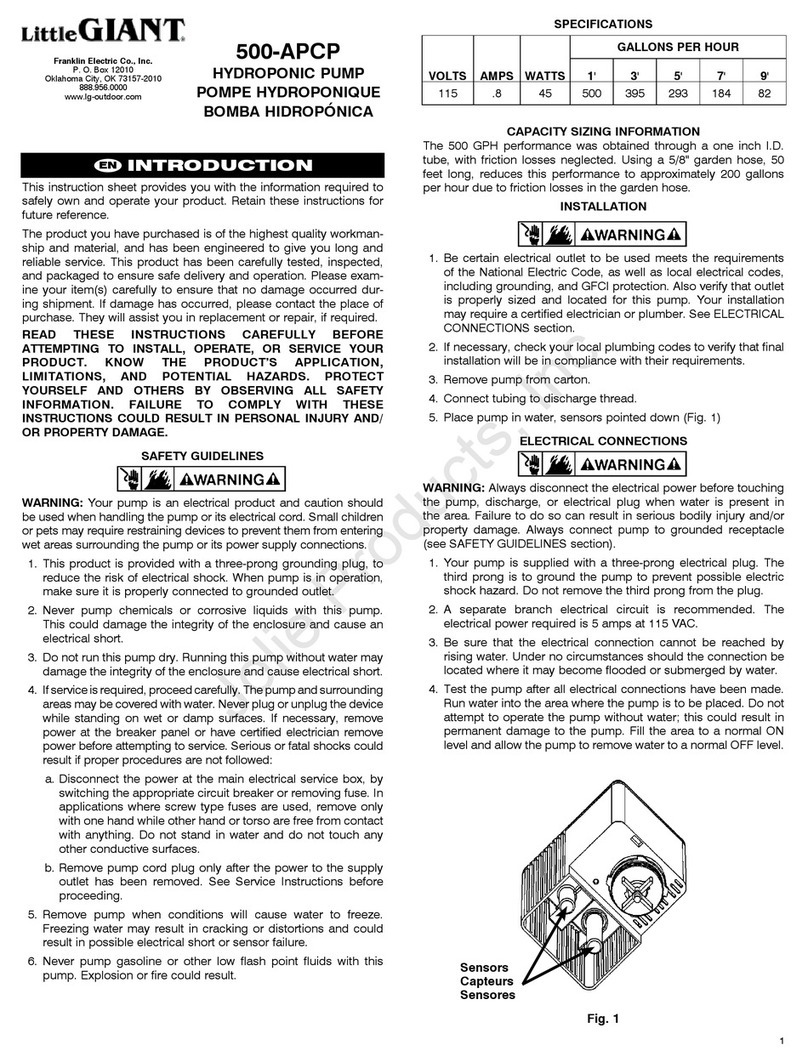

Little Giant 500-APCP User manual

Little Giant

Little Giant BSC33 User manual

Little Giant

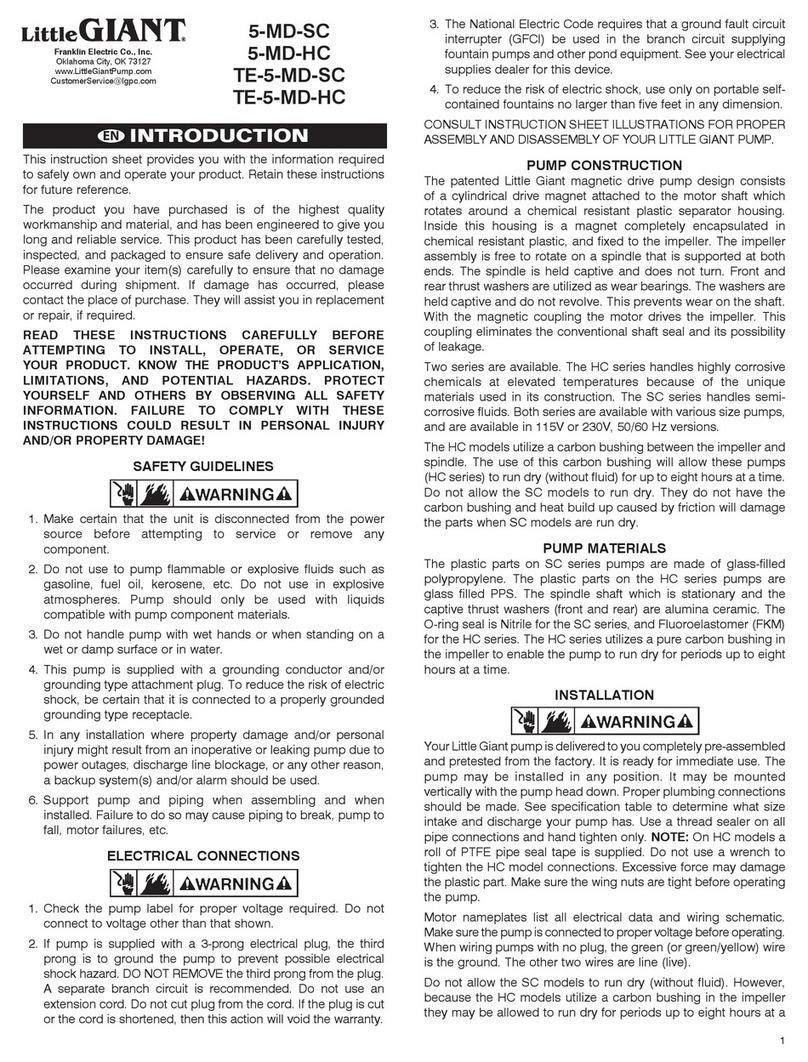

Little Giant 5-md-sc User manual

Little Giant

Little Giant 5-MSP Series User manual

Popular Water Pump manuals by other brands

PSG

PSG Wilden PS4 Saniflo Hygienic Series Engineering, operation & maintenance

Sibata

Sibata LV-40BW Operation manual

Air-Aqua

Air-Aqua FlowFriend HFP90 Installation and user guide

Armstrong

Armstrong 79730-90 user manual

Bestway

Bestway Built-in Sidewinder P3150 owner's manual

Kremlin-Rexson

Kremlin-Rexson AIRMIX 20-15 Original manual

KRAL

KRAL W Series operating instructions

K2 Pumps

K2 Pumps WPS05001K owner's manual

KSB

KSB Calio S Installation & operating manual

ALPHA DYNAMIC PUMPS

ALPHA DYNAMIC PUMPS Ruby 040 FDA Installation, operation and maintenance manual

WITA

WITA go.future Z+ TRANSLATION OF THE ORIGINAL INSTALLATION AND OPERATING INSTRUCTIONS

Speck pumpen

Speck pumpen V 30 Assembly instructions

Grundfos

Grundfos DMI 208 Installation and operating instructions

Pentair

Pentair MYERS MRGD200MC2 owner's manual

PSG Dover

PSG Dover WILDEN Accu-Flo A200 Engineering, operation & maintenance

BUSCH

BUSCH R5 Oxygen instruction manual

Barmesa Pumps

Barmesa Pumps BSP5CU Installation, operation & maintenance manual

Pfeiffer Vacuum

Pfeiffer Vacuum A 124H operating instructions