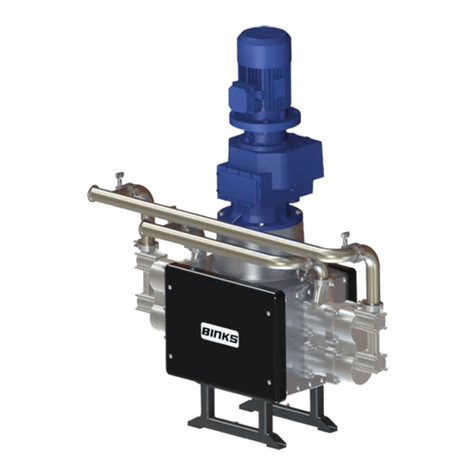

PUMP CONSTRUCTION

Little Giant tube pumps consist of a cylidrical aluminum housing

that accepts a flexible tube radially against the inside and an

impeller assembly consisting of ball bearings rotates in the cylinder.

As the impeller rotates, it squeezes tubing which will create a

suction on the intake side and draw fluid through the tubing, creating

a pumping action. Fluid being pumped never touches any pump

parts except for the tubing.

TUBING

Selection of proper tubing or each application is extremely impor-

tant. Tubing selected must be chemically inert to the materials

being pumped. Three types of tubing are most commonly used.

They are: rubber, Tygon R3602 and neoprene. All three types are

sufficiently flexible and can be squeezed shut and then rapidly

regain their shape after the rollers pass over them. Tubing with

the hardness of 60 durometer gives good performance. The wall

thickness for any tubing used should be 1/8". The LG-100 series

accepts 3/16" x 7/16" to 1/4" x 1/2" tubing. The LG-300 series

accepts 3/8" x 5/8" to 1/2" x 3/4" tubing. Do not use tubing with

wall thickness over 1/8".

PUMP DRIVE

Little Giant tube pumps work well at any speed up to 800 RPMs.

The pump is supplied with a 6" pulley. When combined with a

2-1/2" motor pulley and a 1,725 RPM motor, pump speed will be

appoximately 700 RPMs.

NOTE: Motor, motor pulley and V-belt are not included with the

LG-100 series and LG-300 series Tube Pumps.

Recommended motor for either pump series is a 1/3 HP, 60

hertz, 1,725 RPM NEMA 48 frame motor with rigid cradle base,

sleeve bearings, thermal protection, 40°C rise, 1.35 service factor,

and insulation class A. Suggested motors are Dayton 6K490,

General Electric 5XBH024, or Marathon Q48S17D596. The motor

pulley should be 2-1/2" OD for type A (or 4L) V-belt for 1/2" shaft

(Grainger 3X900 or equivalent). The belt should be a 4L width.

Belt length using Little Giant base should be 30" (Grainger 4L-300

or equivalent).

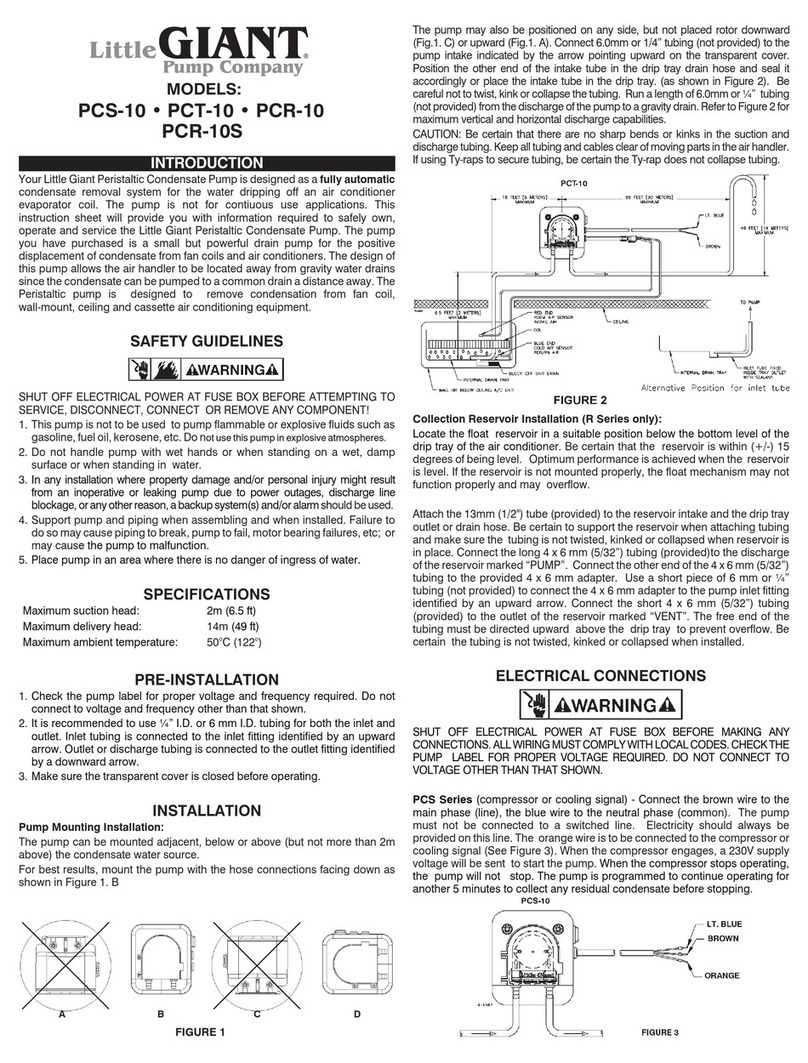

TUBING INSTALLATION

Remove the pump housing cover by removing the three cover

thumb screws. Position the impeller parallel to the pump’s base.

Place the tubing in one of the grooves in the pump housing and

rotate the impeller while placing the tubing in the position behind

the turning impeller. Seat the tubing fully up against the back of

the housing. Be sure the impeller bearings press the tubing evenly

against the housing and does not overhang the bearings as they

turn. Improper positioning of the tubing will cause wear and tubing

will be cut by the impeller bearings. Silicon lubricant on the tubing

where the impeller bearings rub will increase the tubing life. When

replacing the cover, adjust the tubing clamps until they hold the

tubing tight enough so that it cannot be pulled through the pump

when the cover is installed. For 3/4" O.D. tubing, use the #10-24

x 1/2" screws installed at the factory. For 5/8" O.D. tubing, remove

the clamp screws (2) and install the #10-24 x 5/8" screws which

are supplied with the pump in a seperate plastic bag. If the clamps

are too tight, the flow will be restricted.

OPERATION AND SERVICE

Do not restrict the pump’s output any more than necessary. The

pump can build up high pressures that could exceed the tubing’s

strength.

Some pulsating in the discharge is unavoidable because of the

peristaltic action and can be reduced by putting an expansion

tank in the discharge line. Using 1/8" wall thickness tubing, the

pump is self-priming.

Maintenance must be performed regularly. The roller’s constant

squeezing and releasing the tubing wears the tubing out. Silicon

lubricant on the tubing lengthens tubing life. If possible, install

tubing longer than is required and periodically loosen the cover

plate and slide the tubing through the pump approximately 1' to

allow the roller to wear on new sections of the tubing. Tubing

must be periodically replaced. All pump bearings are sealed and

require no maintenance.

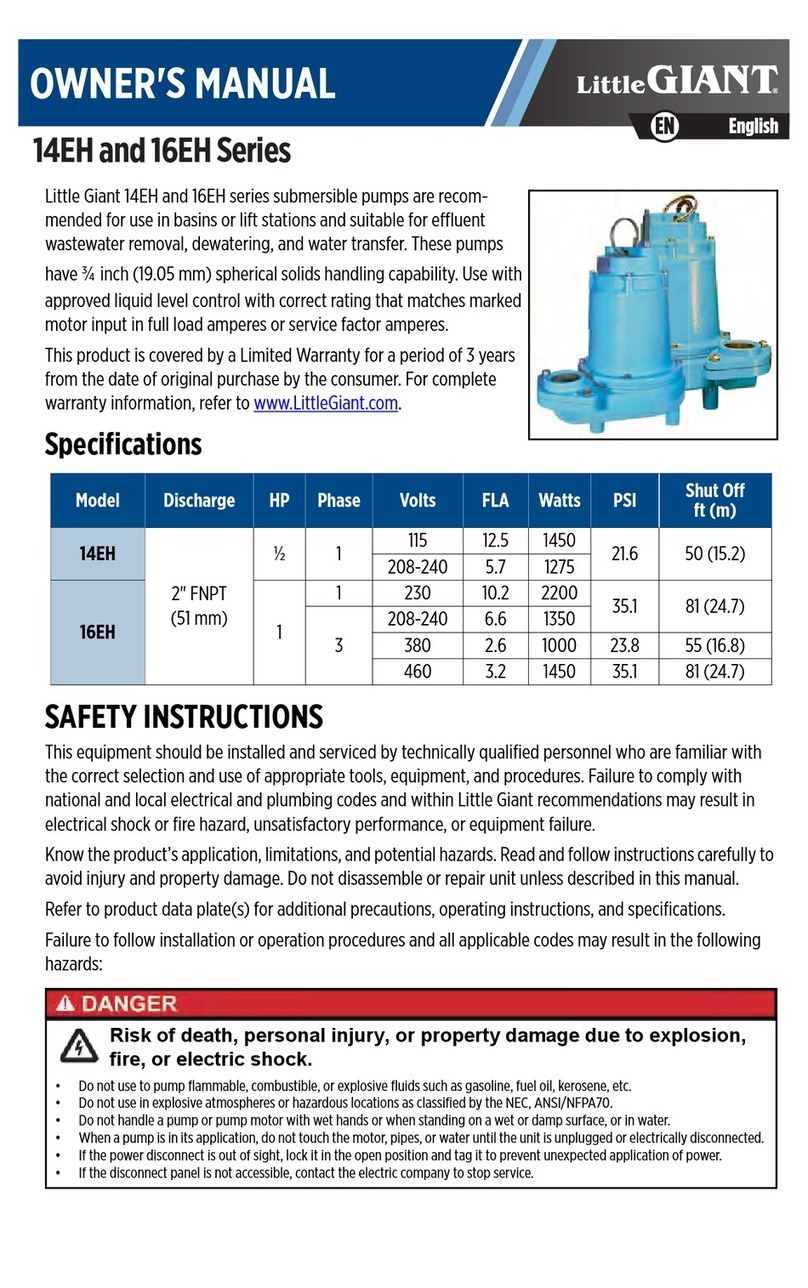

1

LG-100 SERIES

LG-300 SERIES

MODEL LENGTH HEIGHT WIDTH

GALLONS PER MINUTE @ TUBING SIZE

R.P.M. WEIGHT3/16 x 7/16 1/4 x 1/2 3/8 x 5/8 1/2 x 3/4

LG-10 0 6" 6 1/2" 4 7/8" .6 1 — —575 4.6

LG-101 15" 9 3/8" 9 5/8" .6 1 — —575 25.2

LG-300 6 1/8" 6 1/2" 5 1/2" — — 2.8 4.8 575 6.6

LG-301 15" 9 3/8" 9 5/8" — — 2.8 4.8 575 26.12

The above G.P.M. remains almost constant at any pressure from 1-20 P.S.I.

Franklin Electric Co., Inc.

P. O. Box 12010

Oklahoma City, OK 73157-2010

405.947.2511 • Fax: 405.947.8720

www.LittleGiantPump.com