Little Giant PE-2YSA User manual

Other Little Giant Water Pump manuals

Little Giant

Little Giant CIA Series User manual

Little Giant

Little Giant P-AAA User manual

Little Giant

Little Giant VCMA-20-PRO Series User manual

Little Giant

Little Giant EC-400 Series User manual

Little Giant

Little Giant 500-APCP User manual

Little Giant

Little Giant B-1000 Series User manual

Little Giant

Little Giant WFW User manual

Little Giant

Little Giant 6EN-CIA-SFS User manual

Little Giant

Little Giant HT-10EN-CIM User manual

Little Giant

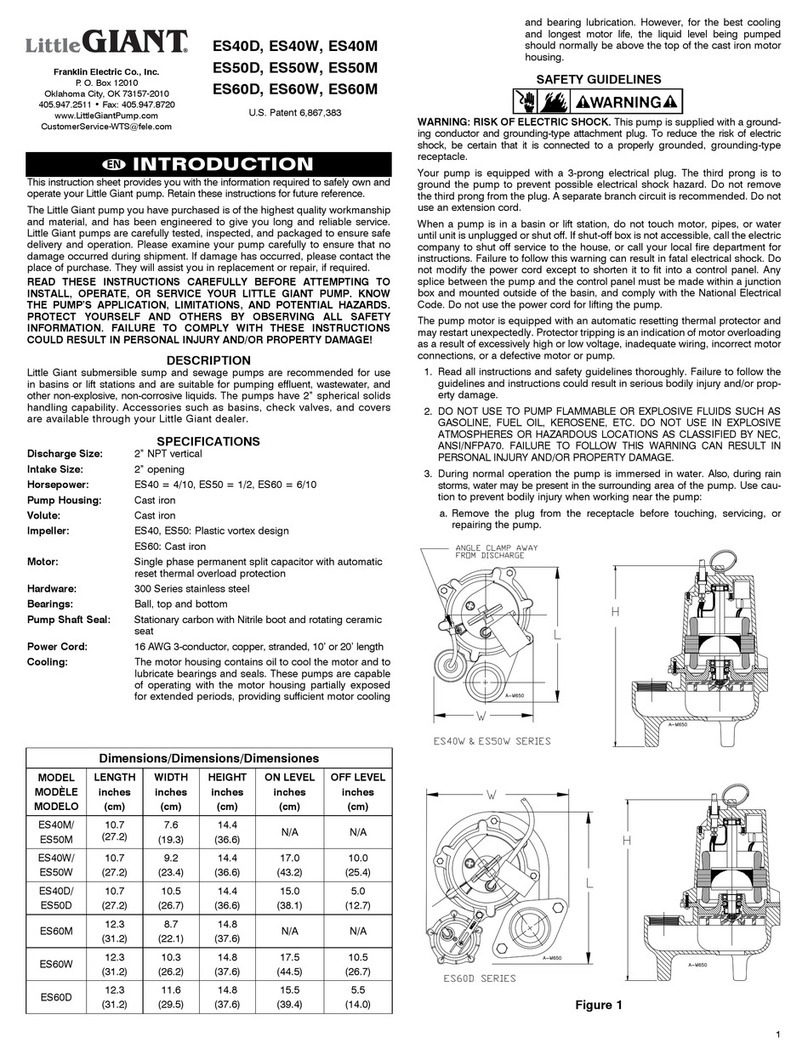

Little Giant ES40D User manual

Little Giant

Little Giant WCR-9SP User manual

Little Giant

Little Giant SPBS-12 User manual

Little Giant

Little Giant HRK-360S User manual

Little Giant

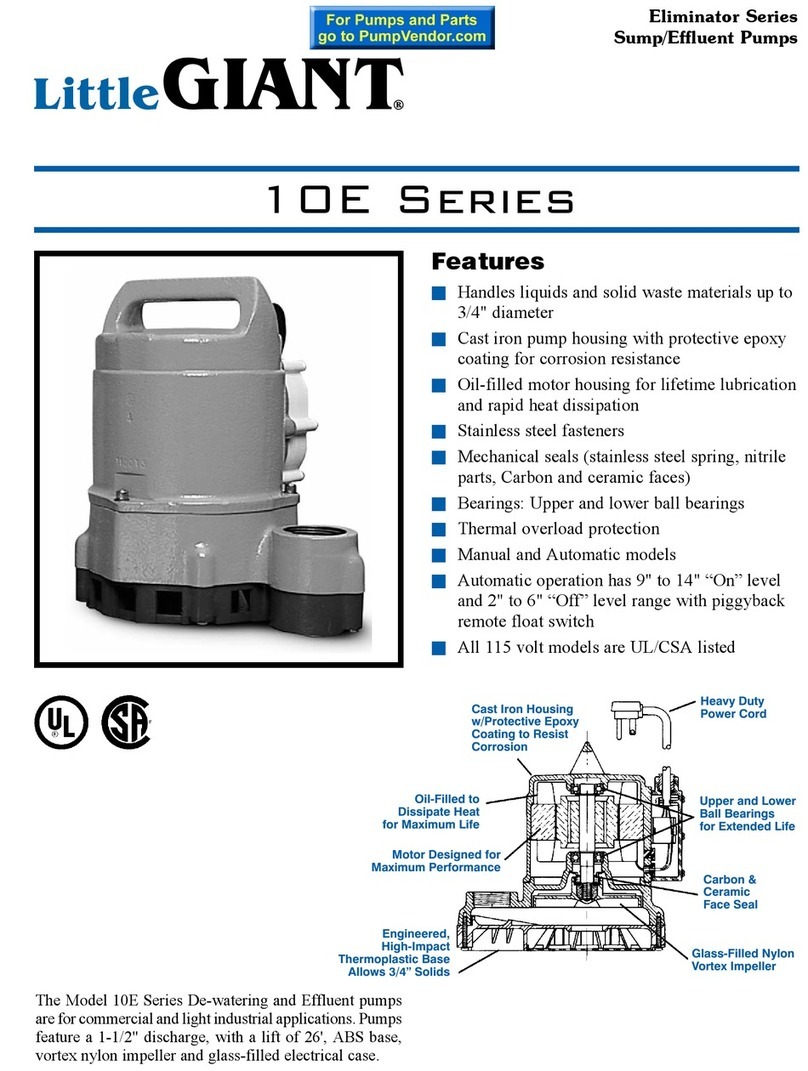

Little Giant Eliminator Series User manual

Little Giant

Little Giant VCL-45S User manual

Little Giant

Little Giant Bottom Pick-up 5-MSPR User manual

Little Giant

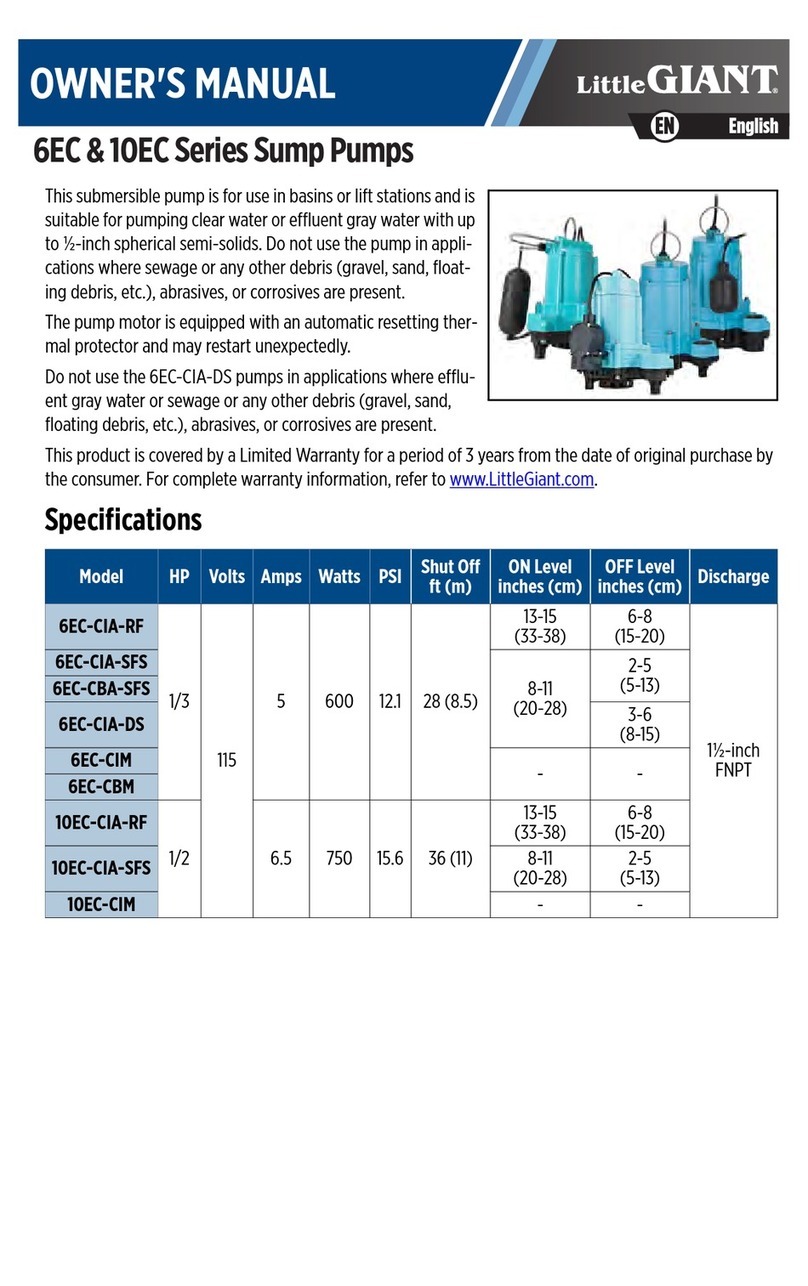

Little Giant 6EC Series User manual

Little Giant

Little Giant LG-100 Series User manual

Little Giant

Little Giant 1-YS User manual

Little Giant

Little Giant OPWG SERIES User manual

Popular Water Pump manuals by other brands

Barnes

Barnes 4030HCU Installation and operation manual

Edwards

Edwards XDS 5 instruction manual

GÜDE

GÜDE HWW 1000 E Original instructions

ITT

ITT Goulds Pumps 3405 Installation, operation and maintenance instructions

Metabo

Metabo P 2000 G instructions

Grundfos

Grundfos ALPHA1 L Installation and operating instructions

BA Pumps & Sprayers

BA Pumps & Sprayers TSX400 Series SAFE OPERATING PROCEDURES

BOILER-M8

BOILER-M8 RS 25/6JG-130 Installation & operating manual

Outbound

Outbound 076-5583-2 operating instructions

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 2D-E.50 3P Installation, operation, and maintenance manual with parts list

Lincoln

Lincoln 83167 installation instructions

Polaris

Polaris TBM 50 LH Series Installation, operation and maintenance manual

Half Off Ponds

Half Off Ponds VARIABLE FLOW Series owner's manual

K2 Pumps

K2 Pumps Contractor Series owner's manual

Pentair

Pentair Myers MCU20S INSTALLATION, OPERATING, SAFETY AND WARRANTY MANUAL

Utilitech

Utilitech PPTP1 manual

Neptun

Neptun Classic NCTF-O 5000 operating instructions

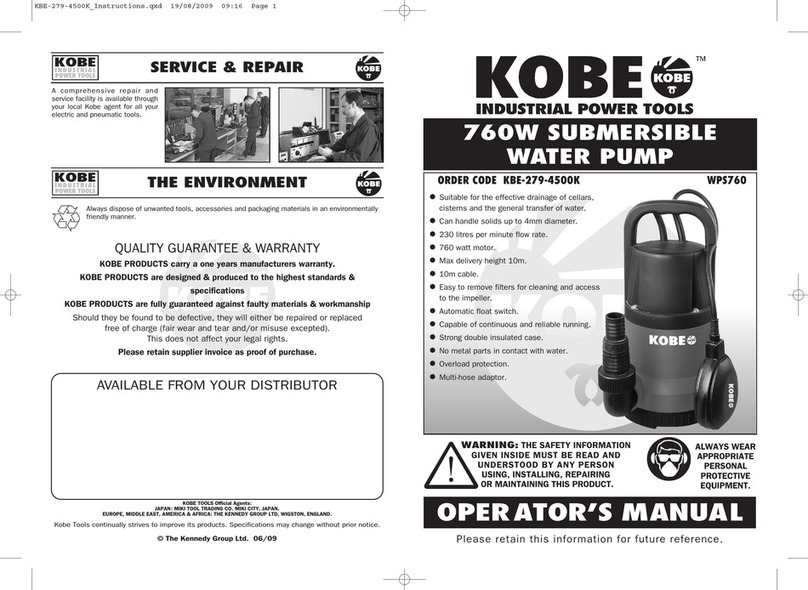

KOBE

KOBE WPS760 Operator's manual