Table of contents

1. Description and operation ..................................................................................... 4

1.1. Purpose ........................................................................................................ 4

1.2. Terms of Use ................................................................................................. 4

1.3. Specifications ................................................................................................ 4

1.4. Content of delivery ........................................................................................ 4

1.5. Main functions ............................................................................................... 4

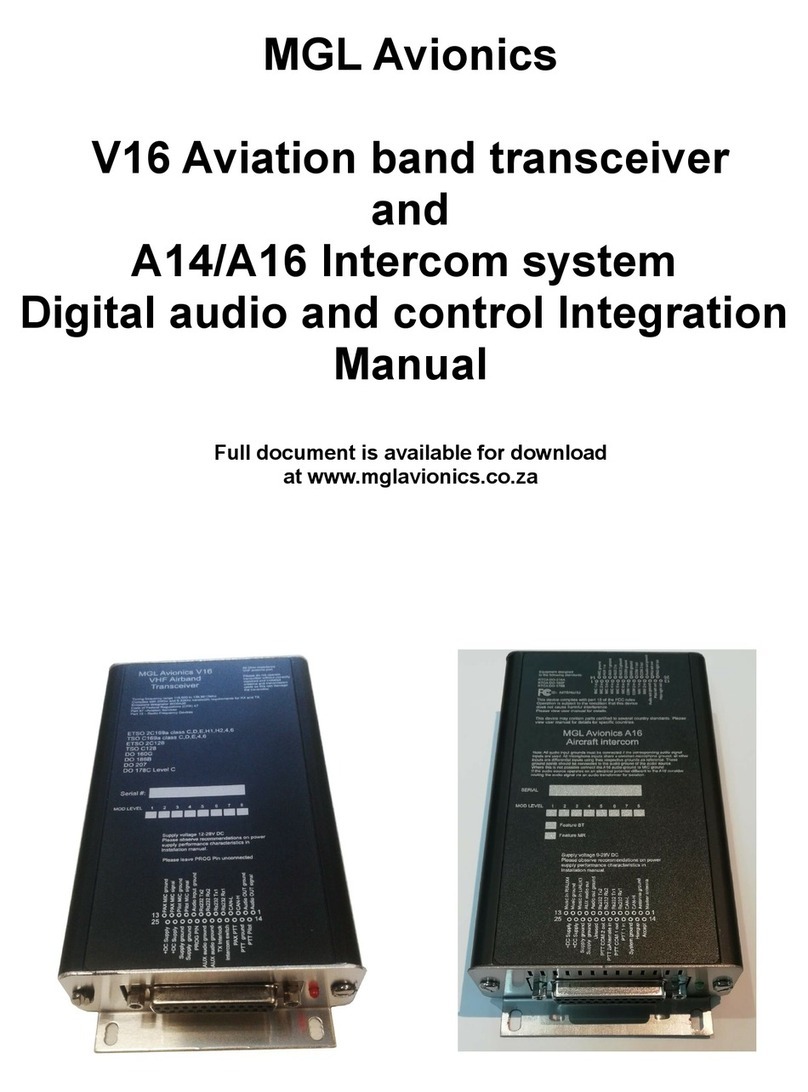

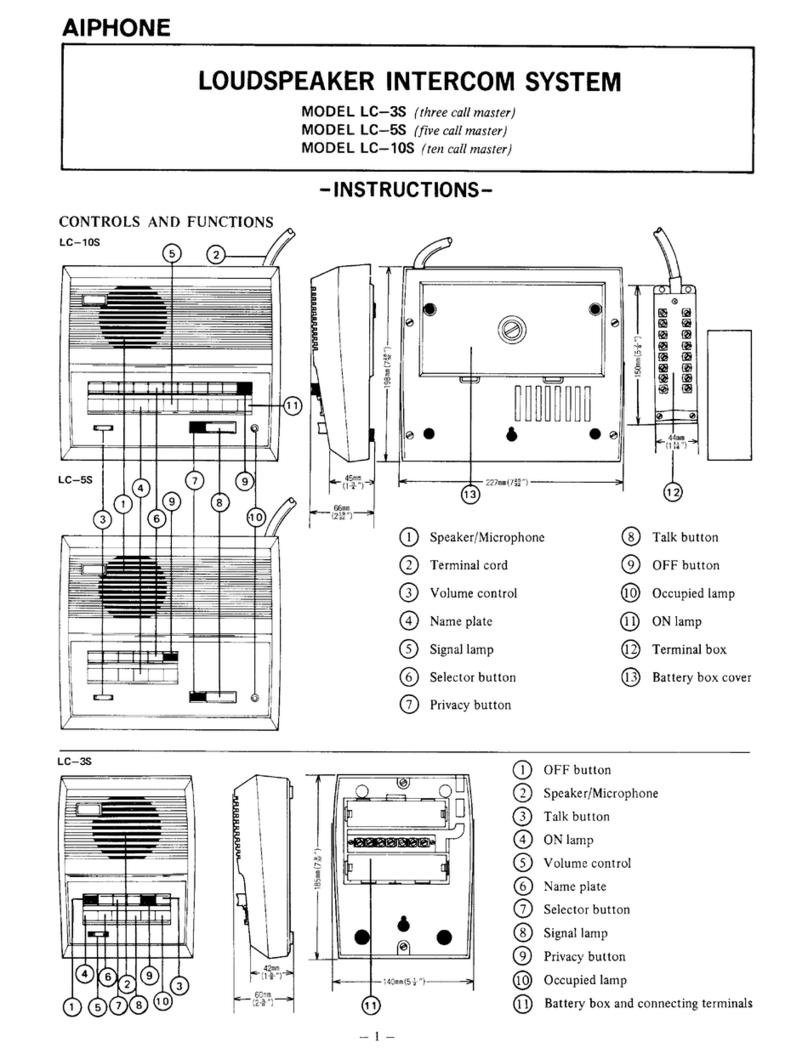

1.6. IU 7.2 design................................................................................................. 4

1.7. IU 7.2 operation ............................................................................................ 7

1.7.1. Voice negotiation with dispatch. ............................................... 7

1.7.2. Using intercom ........................................................................ 7

1.8. Safety precautions ......................................................................................... 7

2. SETTING UP ......................................................................................................... 7

2.1. Setting up the device ..................................................................................... 7

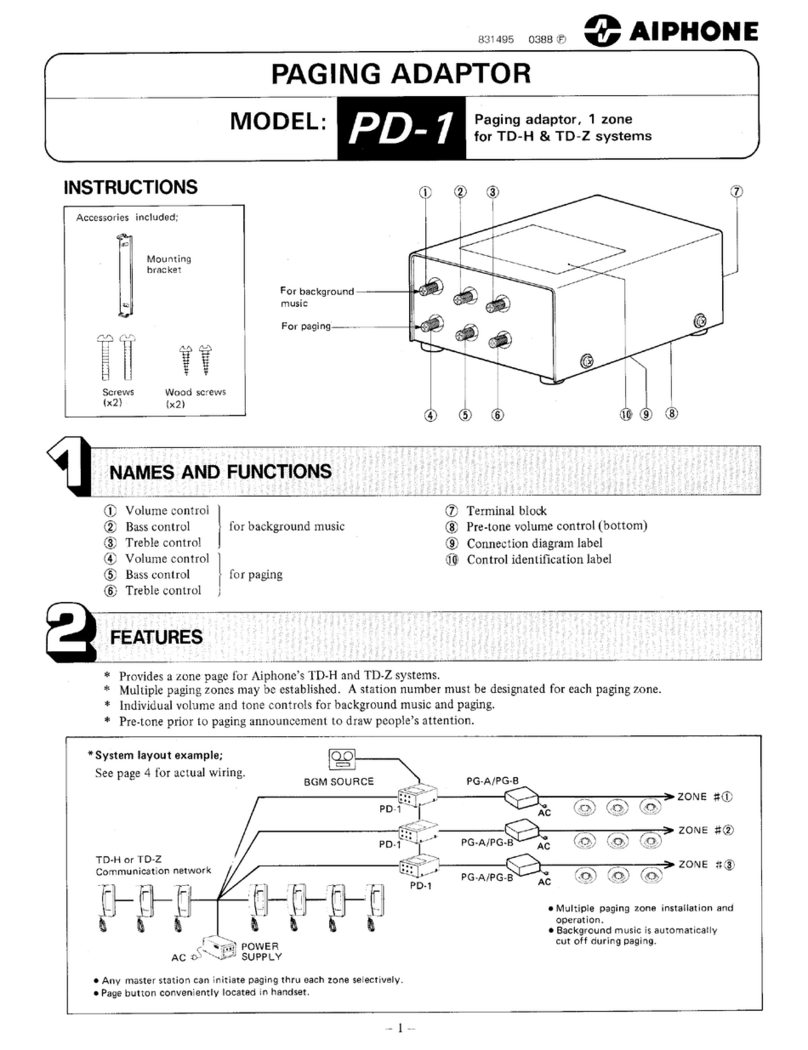

2.2. Making internal network ................................................................................. 8

2.3. Connecting internal battery ............................................................................ 9

2.4. Wiring IU 7.2 ............................................................................................... 10

3. MAINTENANCE ................................................................................................... 10

3.1. General instructions ..................................................................................... 10

3.2. Quarterly maintenance ................................................................................. 10

4. PERMANENT REPAIR .......................................................................................... 11

5. INSTALLATION ................................................................................................... 11

5.1. Organizational and technical activities ........................................................... 11

5.2. Safety regulations ........................................................................................ 11

5.3. Before installing ........................................................................................... 11

5.4. Installing IU 7.2 ........................................................................................... 11

6. TESTING ............................................................................................................ 11

7. STORAGE ........................................................................................................... 12

8. TRANSPORTATION ............................................................................................. 12

Appendix 1……………………………………………………………………………………………………………………. 13

Appendix 2 ……………………………………………………………………………………………………………………..14

Appendix 3 ……………………………………………………………………………………………………………………..15

Appendix 4 ……………………………………………………………………………………………………………………..16