Operating Manual

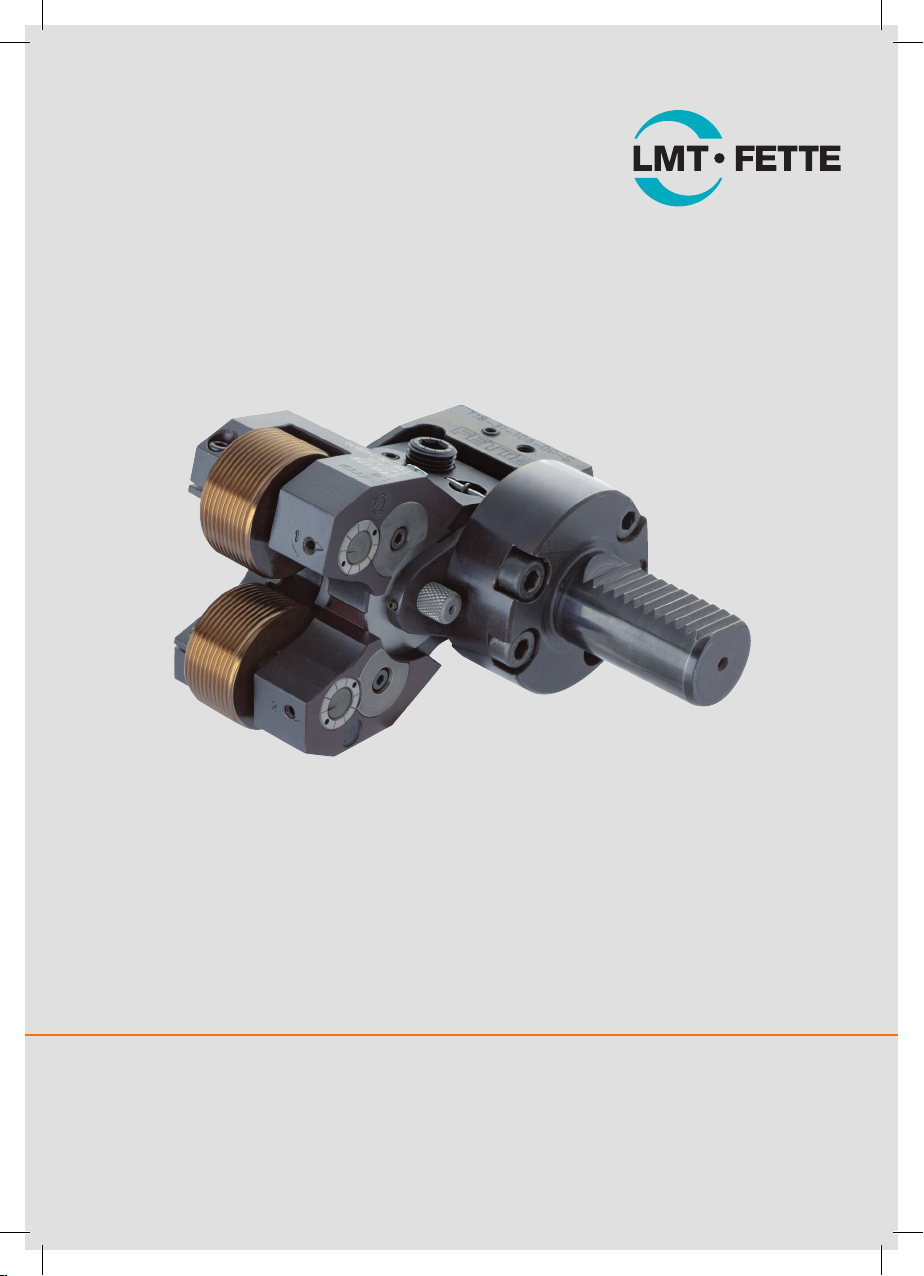

Tangential Rolling System T18F - T27F

Table of contents

1 Introduction .............................................................................. 1

2 Safety ...................................................................................... 3

3 Design and function ................................................................... 7

3.1 The method ............................................................................... 7

3.2 Application area/working range ...................................................... 7

3.3 Materials ................................................................................... 8

3.4 Thread length ............................................................................. 8

3.5 Position of the thread run-out ........................................................ 9

4 The rolling equipment ................................................................ 11

4.1 The rolling head – selecting the size ................................................ 11

4.2 The rolling head holder ................................................................. 13

4.3 The thread rolls .......................................................................... 14

4.3.1 Tool life ..................................................................................... 14

4.3.2 Versions ................................................................................... 15

4.3.3 Labeling .................................................................................... 17

4.4 The setting gauge ....................................................................... 17

5 Assembly and installation ........................................................... 19

5.1 Preparing the rolling head ............................................................. 19

5.1.1 Checking the gear settings ............................................................ 19

5.1.2 Inserting the thread rolls ............................................................... 20

5.1.3 Adjusting the axial rolling clearance ................................................ 21

5.1.4 Functional testing ........................................................................ 22

5.1.5 Adjusting the distance between the axes ......................................... 22

5.2 Installation on the machine tool ...................................................... 23

5.2.1 Preparing the workpiece ............................................................... 23

5.2.2 Inserting the rolling head into the holder .......................................... 24

5.2.3 Adjusting the pendulum clearance .................................................. 25

5.2.4 Coolants and lubricants ................................................................ 27

6 Putting into operation and setup .................................................. 28

6.1 Rolling speed and RPM ................................................................ 28

6.2 Working feed – number of workpiece rotations .................................. 28

6.3 Traverse paths ........................................................................... 30

6.4 Tangential force, drive power and torque ......................................... 32

6.5 Rolling time ............................................................................... 33

7 Special applications ................................................................... 34

7.1 Rolling tapered threads ................................................................ 34

7.2 Knurling and burnishing ................................................................ 35

7.3 Thread rolling on pipes ................................................................. 37

LMT_Bedienungsanleitung_T18F_T27F_e.indd 3 02.08.11 17:40