turck BC10-P30SR-VP4X2/3GD User manual

Other turck Industrial Equipment manuals

turck

turck IMC-DI-22Ex-PN Series User manual

turck

turck IO-Link Master V1.1 User manual

turck

turck DI80-N User manual

turck

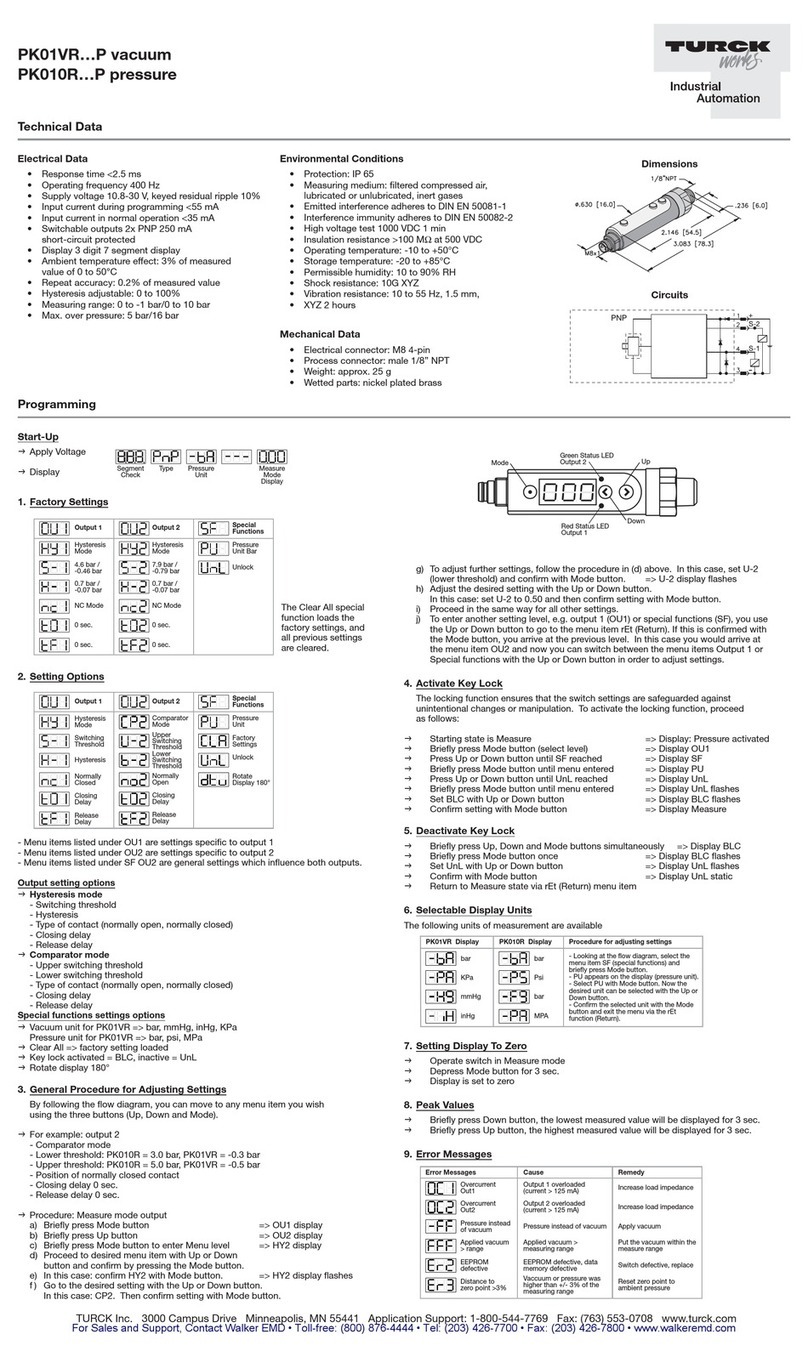

turck PK01VR P Series User manual

turck

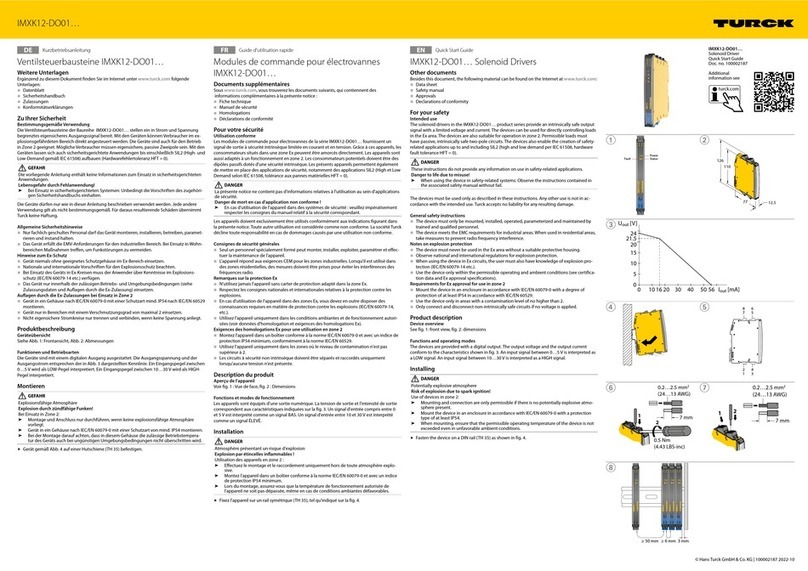

turck IMXK12-DO01 Series User manual

turck

turck NIC EM30-IOL Series User manual

turck

turck NIC...-M30 Series User manual

turck

turck EZ-track LT Q35 Series User manual

turck

turck TN-IOL2 Series User manual

turck

turck BL20 User manual

turck

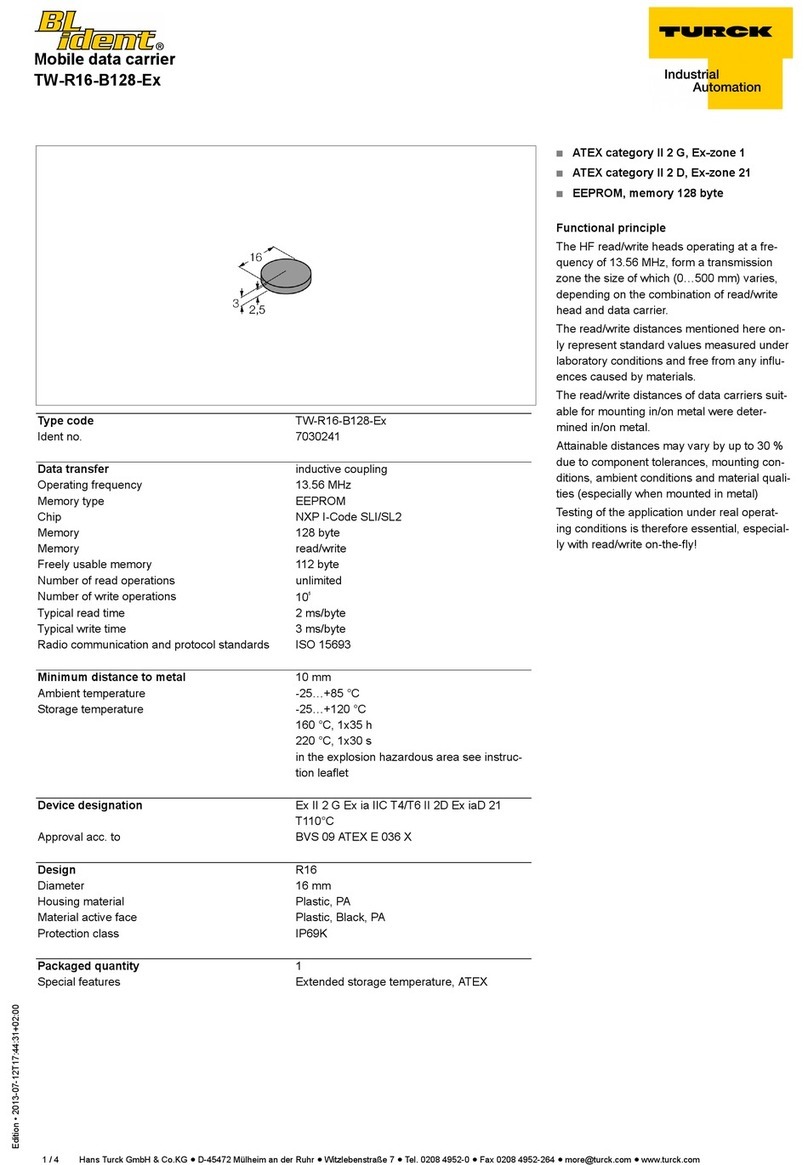

turck BL ident TW-R16-B128-Ex User manual

turck

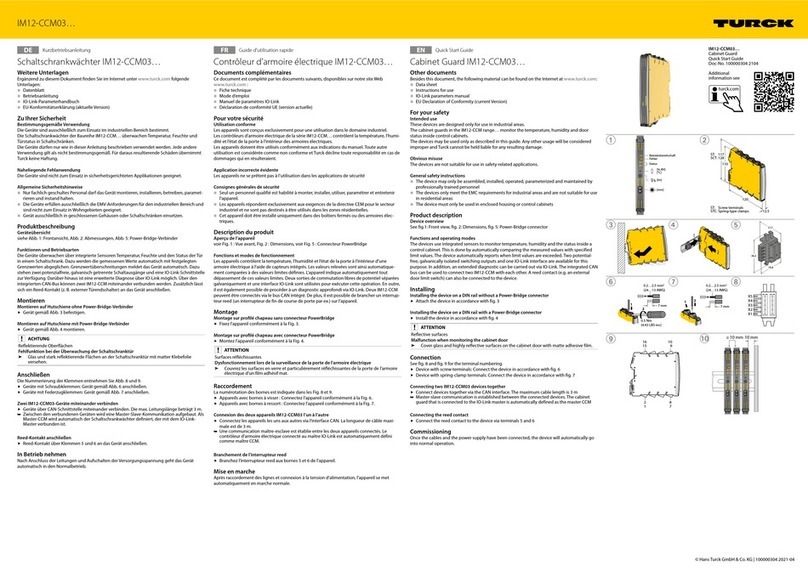

turck IM12-CCM03 Series User manual

turck

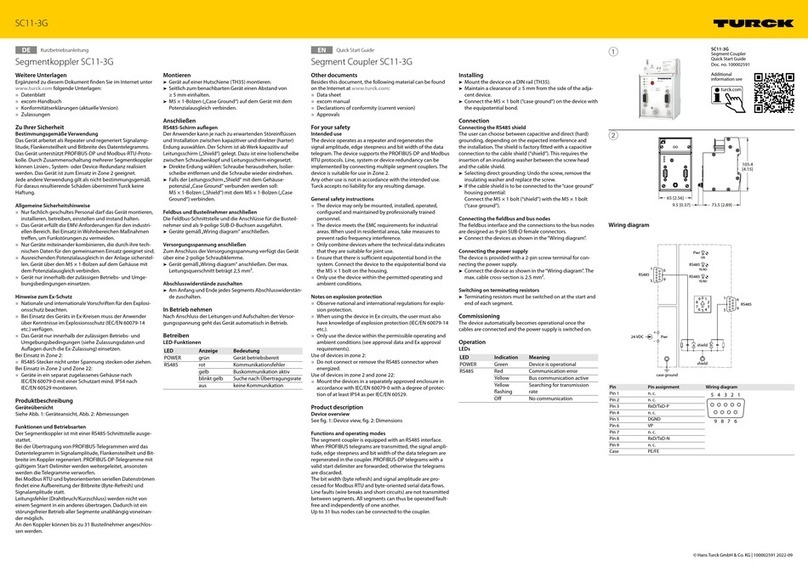

turck SC11-3G User manual

turck

turck PT1000 User manual

turck

turck RA-SAB-15-36 User manual

turck

turck M12-AO01 Series User manual

turck

turck IMC-DI-22EX-PN 24VDC Series User manual

turck

turck MBD49-T41./Ex User manual