2

Table of Contents

1. Radio Frequency Immunity (RFI) Scanning Outline ........................................................ 3

Configuration Diagram....................................................................................................................................... 3

Main Components of RFI Scanning ............................................................................................................... 3

Diagram of RFI measurement wiring........................................................................................................... 5

2. RFI Scanning Operation Procedures................................................................................... 5

Setup test environment ..................................................................................................................................... 5

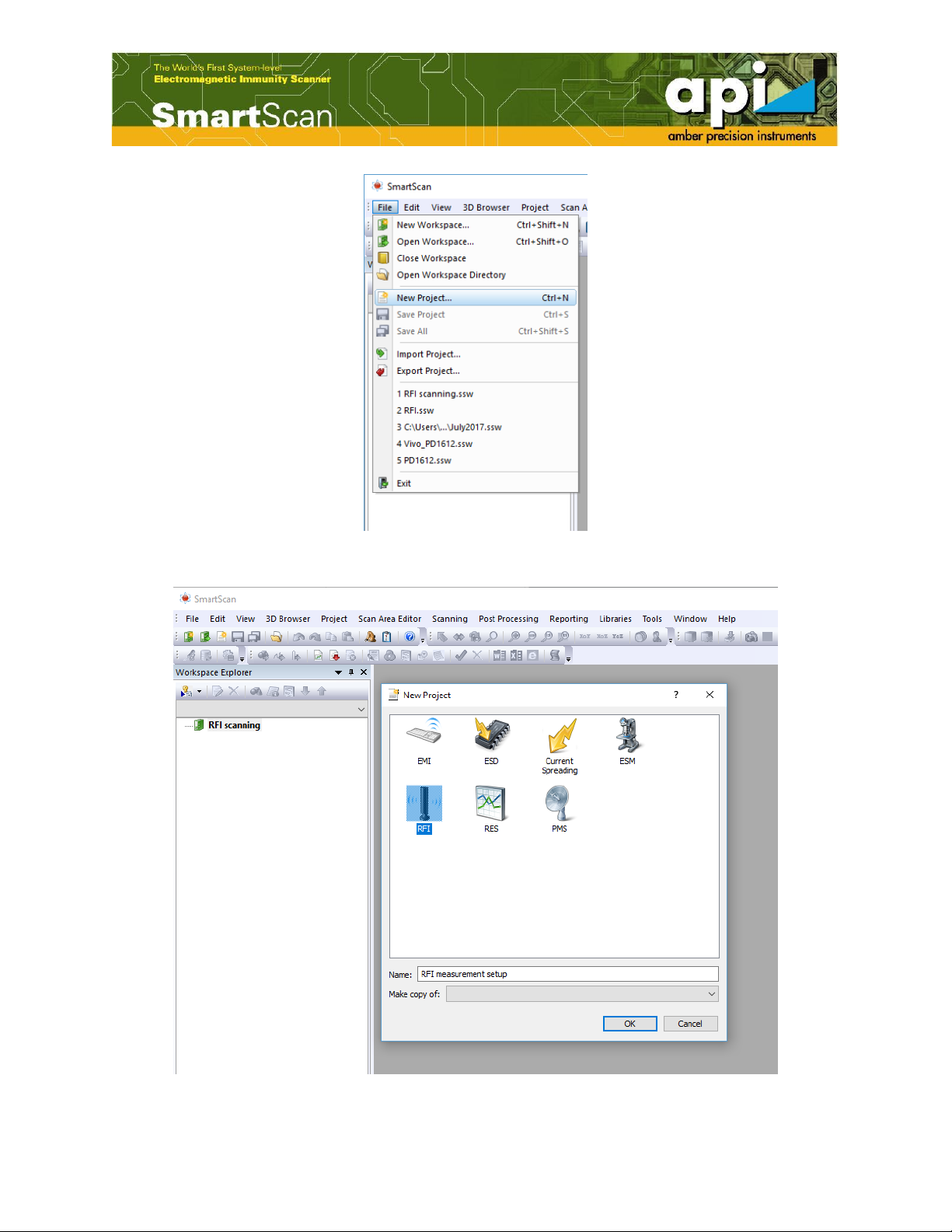

Create a project..................................................................................................................................................... 5

Capture the DUT image...................................................................................................................................... 8

Define probe Z offset........................................................................................................................................... 8

Define a reference point to get DUT height and calibrate probe XY offset................................... 9

Define scan area and scan height.................................................................................................................11

Check instrument and SmartScan software connection ....................................................................11

Open “Instrument Settings” window and set parameters.................................................................12

Run measurement..............................................................................................................................................13

List of Figures

Figure 1: Block diagram of RFI scanning. ................................................................................. 3

Figure 2: Measurement setup diagram of RFI scanning. ......................................................... 5

Figure 3: Create a new workspace.............................................................................................. 6

Figure 4: Name the workspace and save in a directory. ........................................................... 6

Figure 5: Create a new RFI project. ........................................................................................... 7

Figure 6: Name the RFI project. ................................................................................................. 7

Figure 7: Capture DUT image..................................................................................................... 8

Figure 8: Probe Z offset icon........................................................................................................ 8

Figure 9: Probe Z offset calibration window.............................................................................. 9

Figure 10: Reference point........................................................................................................... 9

Figure 11: Detect DUT height by touch sensor........................................................................ 10

Figure 12: Get DUT height manually........................................................................................ 10

Figure 13: Calibrate probe XY offset........................................................................................ 10

Figure 14: Probe XY offset calibration window....................................................................... 11

Figure 15: Open “Options” window.......................................................................................... 11

Figure 16: Signal generator communication setting window. ................................................ 12

Figure 17: Instrument settings................................................................................................... 12

Figure 18: Run measurement. ................................................................................................... 13