Load Cell Systems WDESK-G User manual

ENGLISH ENGLISH ENGLISH ENGLISH

Installation and User Manual

version 1.01

WDESK-G

WINOX-G/2G

WTAB-G/2G

Base

SYMBOLS

Here are the symbols used in the manual to draw the reader's attention:

Caution! Risk of electric shock.

Caution! This operation must be performed by skilled personnel.

Pay particular attention to the following instructions.

Further information.

WARRANTY

24 months from the date of the delivery note. Warranty covers only failures of defective components (due to construction

defects or defects in materials) and includes replacement or repair of the components and related labor costs.

Warranty is automatically forfeited in the event of:

- tampering, deletion, removal of the identification label and/or serial number of the product

- misuse, transformation, alteration, repair of products not carried out by Laumas personnel

Laumas provides a 1-year warranty from the date of the delivery note on defects in material or manufacture of the battery.

GUIDELINES FOR PROPER DISPOSAL

This symbol on the product or packaging indicates that:

-This is electrical/electronic equipment and cannot be disposed of as municipal solid waste, but must be delivered

to a recycling center

-Improper use or disposal can pollute the environment or damage human health

-Non-compliance with these guidelines will be penalized in accordance with the regulations in force in the country

of destination

-It is recommended to dispose of the packing and packaging as required by local regulations

TABLE OF CONTENTS

USER WARNINGS ...................................................................................................................1

RECOMMENDATIONS FOR CORRECT INSTALLATION OF WEIGHING INSTRUMENTS . 1

RECOMMENDATIONS FOR CORRECT INSTALLATION OF THE LOAD CELLS................2

LOAD CELL INPUT TEST (QUICK ACCESS) ................................................................................4

LOAD CELL TESTING.....................................................................................................................4

MAIN SPECIFICATIONS OF THE INSTRUMENT...................................................................5

BUFFER BATTERY..........................................................................................................................7

AFTER A BLACKOUT .............................................................................................................8

TECHNICAL SPECIFICATIONS .............................................................................................. 9

ELECTRICAL CONNECTIONS..............................................................................................10

BASIC INFORMATION...................................................................................................................10

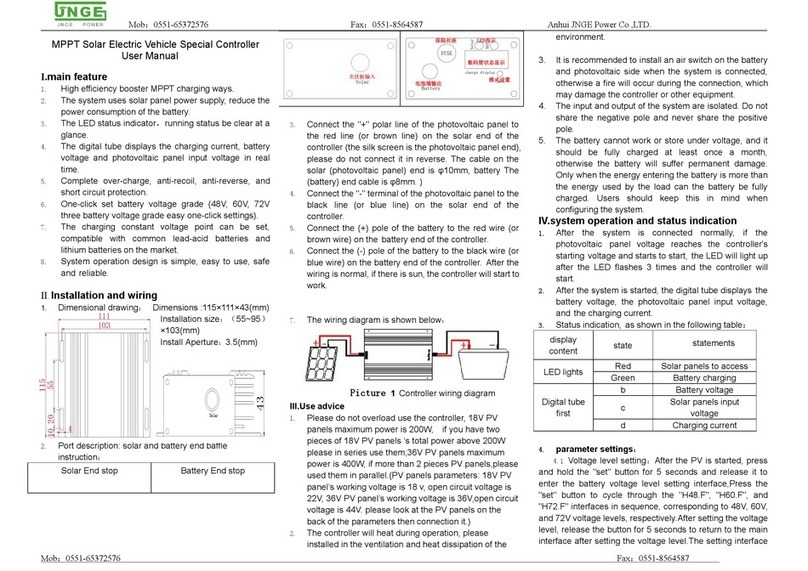

WIRING DIAGRAM.........................................................................................................................10

CHANGING VOLTAGE 115 VAC / 230 VAC (WDESK) .................................................................. 11

KEY TO P, Q, X TYPE CONNECTORS............................................................................................ 11

KEY TO D TYPE CONNECTORS..................................................................................................... 12

KEYS AND SYMBOLS FUNCTIONS.....................................................................................14

MENU MAP ............................................................................................................................ 15

SETPOINT ......................................................................................................................................15

SYSTEM PARAMETERS ...............................................................................................................15

LCD GRAPHIC DISPLAY.......................................................................................................16

BASIC INFORMATION...................................................................................................................16

SETPOINT VISUALIZATION .........................................................................................................17

LCD GRAPHIC DISPLAY CONFIGURATION...............................................................................17

LANGUAGE SETTING...................................................................................................................... 18

CUSTOMIZING MESSAGES OF LCD GRAPHIC DISPLAY ........................................................... 19

INSTRUMENT COMMISSIONING..........................................................................................20

PROGRAMMING OF SYSTEM PARAMETERS.................................................................... 21

THEORETICAL CALIBRATION.....................................................................................................21

MAXIMUM CAPACITY...................................................................................................................... 22

TARE WEIGHT ZERO SETTING ...................................................................................................... 22

ZERO VALUE MANUAL ENTRY...................................................................................................... 22

REAL CALIBRATION (WITH SAMPLE WEIGHTS)......................................................................23

FILTER ON THE WEIGHT..............................................................................................................24

ANTI PEAK........................................................................................................................................ 24

ZERO PARAMETERS....................................................................................................................25

RESETTABLE WEIGHT SETTING FOR SMALL WEIGHT CHANGES.......................................... 25

AUTOMATIC ZERO SETTING AT POWER-ON .............................................................................. 25

ZERO TRACKING ............................................................................................................................. 25

SETTING UNITS OF MEASURE....................................................................................................26

DISPLAY COEFFICIENT .................................................................................................................. 26

OUTPUTS AND INPUTS CONFIGURATION ................................................................................28

SEMI-AUTOMATIC TARE (NET/GROSS) .....................................................................................29

PRESET TARE (SUBTRACTIVE TARE DEVICE).........................................................................30

SEMI-AUTOMATIC ZERO (WEIGHT ZERO-SETTING FOR SMALL VARIATIONS) ..................30

PEAK ..............................................................................................................................................31

ANALOG OUTPUT(ONLY FOR INSTRUMENTS WHERE THIS OPTION IS AVAILABLE)........32

SERIAL COMMUNICATION SETTING..........................................................................................34

RS232 SERIAL COMMUNICATION ................................................................................................. 36

RS485 SERIAL COMMUNICATION ................................................................................................. 36

DIRECT CONNECTION BETWEEN RS485 AND RS232 WITHOUT CONVERTER ...................... 36

PROGRESSIVE WEIGHED VALUES ............................................................................................ 37

TEST ...............................................................................................................................................37

ENERGY SAVING ..........................................................................................................................37

DATE AND TIME SETTING ........................................................................................................... 38

INFO MENU ....................................................................................................................................38

SETPOINT PROGRAMMING.................................................................................................39

ITEM DATABASE...................................................................................................................40

SETTING AND SELECTION OF ITEMS........................................................................................40

TOTALIZER............................................................................................................................41

TOTALIZER SETTING ...................................................................................................................41

USING THE TOTALIZER ...............................................................................................................42

DISPLAY............................................................................................................................................ 42

INCREASING MANUAL TYPE ......................................................................................................... 43

DECREASING MANUAL TYPE........................................................................................................ 43

AUTOMATIC TYPE ........................................................................................................................... 43

AUTOMATIC DELETING .................................................................................................................. 43

TOTALIZER DEACTIVATION........................................................................................................ 43

PIECE COUNTER .................................................................................................................. 44

PIECE COUNTER SETTING..........................................................................................................44

USING THE PIECE COUNTER......................................................................................................45

DISPLAY............................................................................................................................................ 45

INCREASING OPERATION.............................................................................................................. 45

DECREASING OPERATION ............................................................................................................ 46

PIECE COUNTER DEACTIVATION ..............................................................................................46

STATISTICAL CHECKING OF PREPACKAGES..................................................................47

CHOOSING A SCALE....................................................................................................................47

TOLERANCE ZONES AND ACCEPTABILITY CRITERIA............................................................48

STATISTICAL CHECK ACTIVATION............................................................................................50

SAMPLE CHECKING PROCEDURE.............................................................................................51

STATISTICAL CHECK DEACTIVATION.......................................................................................51

ALARMS.................................................................................................................................52

RESERVED FOR THE INSTALLER ......................................................................................58

MENU LOCKING............................................................................................................................58

MENU UNLOCKING.......................................................................................................................58

TEMPORARY MENU UNLOCKING...............................................................................................58

DATA DELETION AND PROGRAM SELECTION.........................................................................58

KEYPAD OR DISPLAY LOCKING ................................................................................................59

- 1 -

USER WARNINGS

RECOMMENDATIONS FOR THE PROPER USE OF WEIGHING INSTRUMENT

-Keep away from heat sources and direct sunlight

-Repair the instrument from rain (except special IP versions)

-Do not wash with water jets (except special IP versions)

-Do not dip in water

-Do not spill liquid on the instrument

-Do not use solvents to clean the instrument

-Do not install in areas subject to explosion hazard (except special Atex versions)

RECOMMENDATIONS FOR CORRECT INSTALLATION OF WEIGHING INSTRUMENTS

The terminals indicated on the instrument’s wiring diagram to be connected to earth must have

the same potential as the weighed structure (same earthing pit or earthing system). If you are

unable to ensure this condition, connect with an earthing wire the terminals of the instrument

(including the terminal –SUPPLY) to the weighed structure.

The cell cable must be individually led to its panel input and not share a conduit with other cables;

connect it directly to the instrument terminal strip without breaking its route with support terminal strips.

Use “RC” filters on the instrument-driven solenoid valve and remote control switch coils.

Avoid inverters in the instrument panel; if inevitable, use special filters for the inverters and separate

them with sheet metal partitions.

The panel installer must provide electric protections for the instruments (fuses, door lock switch etc.).

It is advisable to leave the equipment always switched on to prevent the formation of condensation.

MAXIMUM CABLE LENGTHS

-RS485: 1000 metres with AWG24, shielded and twisted cables

-RS232: 15 metres for baud rates up to 19200

-Analog current output: up to 500 metres with 0.5 mm2 cable

-Analog voltage output: up to 300 metres with 0.5 mm2cable

- 2 -

RECOMMENDATIONS FOR CORRECT INSTALLATION OF THE LOAD CELLS

SIZING OF LOAD CELLS CAPACITY

For safety reasons, in case of static weighing, it is advisable to use the load cells at a maximum of 70-

80% of its nominal capacity (assuming that the load is uniformly distributed over the entire weighed

structure); depending on the handling mode of the load to weigh, consider to further reduce the % of

load with respect to the nominal capacity (ex.: forklifts handling, bridge cranes, etc.).

In case of weighing with dynamic loads, the installer has to estimate the thrust speed, the acceleration,

the frequency, etc.

INSTALLING LOAD CELLS

The load cells must be placed on rigid, stable in-line structures; it is important to use the mounting

modules for load cells to compensate for misalignment of the support surfaces.

CONNECTING SEVERAL CELLS IN PARALLEL

Connect several cells in parallel by using - if necessary - a watertight junction box with terminal box.

The cell connection extension cables must be shielded, led individually into their piping or conduit and

laid as far as possible from the power cables (in case of 4-wire connections, use cables with 4x1 mm2

minimum cross-section).

PROTECTION OF THE CELL CABLE

Use water-proof sheaths and joints in order to protect the cables of the cells.

MECHANICAL RESTRAINTS (pipes, etc.)

When pipes are present, we recommend the use of hoses and flexible couplings with open mouthpieces

with rubber protection; in case of hard pipes, place the pipe support or anchor bracket as far as possible

from the weighed structure (at a distance at least 40 times the diameter of the pipe).

WELDING

Avoid welding with the load cells already installed. If this cannot be avoided, place the welder ground

clamp close to the required welding point to prevent sending current through the load cell body.

WINDY CONDITIONS - KNOCKS –VIBRATIONS

The use of weigh modules is strongly recommended for all load cells to compensate for misalignment

of the support surfaces. The system designer must ensure that the plant is protected against lateral

shifting and tipping relating to: shocks and vibration; windy conditions; seismic conditions in the

installation setting; stability of the support structure.

- 3 -

EARTHING THE WEIGHED STRUCTURE

By means of a copper wire with suitable cross-section, connect the cell upper support plate with the

lower support plate, then connect all the lower plates to a single earthing system. Electrostatic charges

accumulated because of the product rubbing against the pipes and the weighed container walls are

discharged to the ground without going through or damaging the load cells. Failure to implement a

proper earthing system might not affect the operation of the weighing system; this, however, does not

rule out the possibility that the cells and connected instrument may become damaged in the future. It

is forbidden to ensure earthing system continuity by using metal parts contained in the weighed

structure.

FAILURE TO FOLLOW THE INSTALLATION RECOMMENDATIONS WILL BE CONSIDERED

A MISUSE OF THE EQUIPMENT

- 4 -

LOAD CELL INPUT TEST (QUICK ACCESS)

From the weight display, press for 3 seconds; the response signal of the load cells is displayed,

expressed in mV with four decimals.

LOAD CELL TESTING

Load cell resistance measurement (use a digital multimeter):

-Disconnect the load cells from the instrument and check that there is no moisture in the cell junction

box caused by condensation or water infiltration. If so, drain the system or replace it if necessary.

-The value between the positive signal wire and the negative signal wire must be equal or similar

to the one indicated in the load cell data sheet (output resistance).

-The value between the positive excitation wire and the negative excitation wire must be equal or

similar to the one indicated in the load cell data sheet (input resistance).

-The insulation value between the shield and any other cell wire and between any other cell wire

and the body of the load cell must be higher than 20 Mohm.

Load cell voltage measurement (use a digital multimeter):

-Take out the load cell to be tested from underneath the container, or alternatively, lift the container

support.

-Make sure that the excitation of two wires of the load cell connected to the instrument (or amplifier)

is 5 VDC ±3%.

-Measure the response signal between the positive and the negative signal wires by directly

connecting them to the tester, and make sure that it is comprised between 0 and ±0.5 mV.

-Apply load to the cell and make sure that there is a signal increment.

IF ONE OF THE ABOVE CONDITIONS IS NOT MET, PLEASE CONTACT THE TECHNICAL

ASSISTANCE SERVICE.

- 5 -

MAIN SPECIFICATIONS OF THE INSTRUMENT

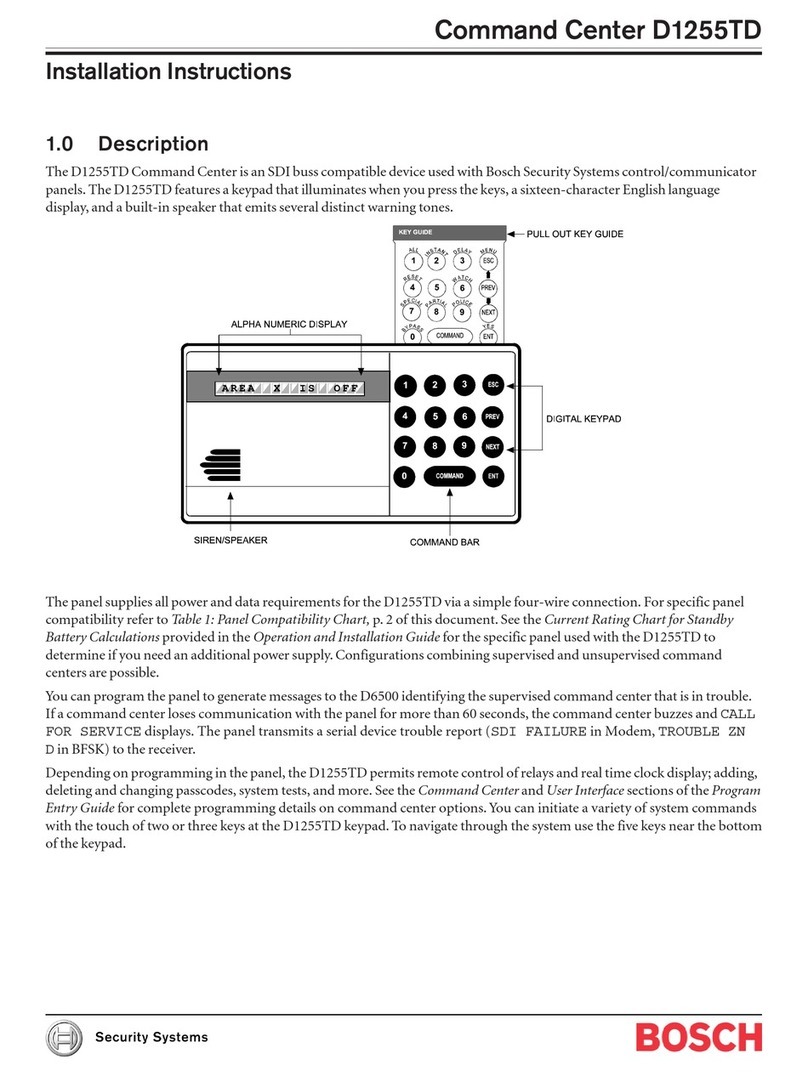

Indicator with 6-wire load cell input installable on table, panel front, wall or column; 6-key membrane

keypad with buzzer, real-time clock/calendar with buffer battery.

Two serial ports (RS485 and RS232) for connection to: PC/PLC up to 32 instruments (max 99 with

line repeaters) by ASCII Laumas or ModBus R.T.U. protocol, remote display, printer. Optional:

integrated Profibus DP, DeviceNet, CANopen, Profinet IO, Ethernet/IP, Ethernet TCP/IP,

Modbus/TCP output.

Instruments with P, D type connectors: included switching power supply plug 24 V 450 mA, input

100÷240 VAC, 3 meters long cable.

Display:

Model

Display

Resolution

Viewing area

WDESK-G

WINOX-G

WTAB-G

STN transmissive graphic LCD, white on

blue, backlit

240x64 pixel

133x39 mm

WINOX-2G

WTAB-2G

STN transmissive graphic LCD, white on

blue, backlit

240x128 pixel

128x75 mm

Dimensions:

WDESK

Version

Max. encumbrance

Drilling

P- M16x1.5 cable gland

IP67 protection rating

Power supply included

122x226x164 mm

(connectors included)

96x186 mm

Q- Removable terminal strip

(panel front)

Front panel IP67 protection

rating

122x226x152 mm

(connectors included)

92x186 mm

D–D-Sub connector

IP40 protection rating

Front panel IP67 protection rating

Power supply included

122x226x189 mm

(connectors included)

96x186 mm

- 6 -

X- Atex cable gland

IP67 Atex II3GD version

(areas 2 -22)

IP67 protection rating

122x226x164 mm

(connectors included)

96x186 mm

Wall installation with bracket

(can also be installed on table)

122x230x250 mm ca.

(bracket included)

WINOX

Type of connectors

Max. encumbrance

Drilling

P- M16x1.5 cable gland

IP68 protection rating

Power supply included

206x286x108 mm

(connectors included)

160x248 mm

Q- Removable terminal strip

(panel front)

Front panel IP68 protection rating

206x286x96 mm

(connectors included)

160x248 mm

D–D-Sub connector (table)

IP40 protection rating

Front panel IP68 protection rating

Power supply included

206x286x85 mm

(connectors included)

X- Atex cable gland

IP68 Atex II3GD version

(areas 2 -22)

IP68 protection rating

206x286x108 mm

(connectors included)

160x248 mm

Wall installation with bracket

(can also be installed on table)

206x286x187 mm ca.

(bracket included)

- 7 -

WTAB

Type of connectors

Max. encumbrance

Drilling

D–D-Sub connector

IP40 protection rating

Power supply included

315X315X180 mm

BUFFER BATTERY

The instrument is equipped with an internal battery that allows to keep active the internal clock even

in the event of power failure.

At the first start and after long periods of inactivity, leave the instrument on for at least 12

hours to fully charge the battery.

- 8 -

AFTER A BLACKOUT

After a blackout the instrument DOES NOT come on again automatically, you have to press ON.

To guarantee an automatic restart after a blackout, disable the ON key as follows:

-disconnect power supply and open the instrument;

-identify flat connectors coming from the keypad on the main board;

-extract the 4-pole connector;

-short-circuit the following pins using the unused jumper inside the instrument:

▫WDESK: the two pins further in compared to the main board (see picture to the left);

▫WINOX - WTAB: the two outer pins compared to the main board (see picture to the right);

-connect the 4-pole flat to the two pins still free complying with initial orientation.

WDESK

WINOX - WTAB

- 9 -

TECHNICAL SPECIFICATIONS

POWER SUPPLY and CONSUMPTION (VDC)

12/24 VDC ±10%; 6 W (standard)

POWER SUPPLY and CONSUMPTION (VAC)

115/230 VAC; 50-60 Hz; 6 VA

(optional only for WDESK –WINOX-P)

NO. OF LOAD CELLS IN PARALLEL and SUPPLY

max 8 (350 ohm); 5 VDC / 120 mA

LINEARITY / ANALOG OUTPUT LINEARITY

< 0.01% F.S.; < 0.01% F.S.

THERMAL DRIFT / ANALOG OUTPUT THERMAL

DRIFT

< 0.0005% F.S./°C; < 0.003% F.S./°C

A/D CONVERTER

24 bit (16000000 points)

MAX DIVISIONS

(with measurement range: ±10 mV = sens. 2 mV/V)

±999999

MEASUREMENT RANGE

±39 mV

MAX SENSITIVITY OF USABLE LOAD CELLS

±7 mV/V

MAX CONVERSIONS PER SECOND

300 conversions/second

DISPLAY RANGE

±999999

NO. OF DECIMALS / DISPLAY INCREMENTS

0÷4 / x 1 x 2 x 5 x 10 x 20 x 50 x 100

DIGITAL FILTER / READINGS PER SECOND

0.012÷7 s / 5÷300 Hz

RELAY OUTPUTS

N. 5 - max 115 VAC; 150 mA

(N. 4 –analog output version)

DIGITAL INPUTS

N. 3 - optoisolated 5 - 24 VDC PNP

(N. 2 –analog output version)

SERIAL PORTS

RS485, RS232

BAUD RATE

2400, 4800, 9600, 19200, 38400, 115200

HUMIDITY (non condensing)

85%

STORAGE TEMPERATURE

-30°C +80°C

WORKING TEMPERATURE

-20°C +60°C

OPTOISOLATED ANALOG OUTPUT (OPTIONAL)

16 bit - 65535 divisions

0÷20 mA; 4÷20 mA (max 300 ohm);

0÷10 V; 0÷5 V; ±10 V; ±5 V (min 10 kohm)

RELAY DIGITAL OUTPUTS

N. 5 - max 30 VAC, 60 VDC; 150 mA

(N. 4 –analog output version)

WORKING TEMPERATURE

-20°C +50°C

Equipment to be powered by 12-24 VDC LPS or Class 2 power source.

- 10 -

ELECTRICAL CONNECTIONS

BASIC INFORMATION

-It is recommended that the power supply negative pole be grounded (WDESK-D, WINOX, WTAB:

connect the earthing system to the dedicated external terminal ).

-It is possible to supply up to eight 350 ohm load cells or sixteen 700 ohm load cells.

-For 4-wire load cells, make a jumper between EX- and REF- and between EX+ and REF+.

-Connect terminal “– SUPPLY” to the RS485 common of the connected instruments in the event

that these receive alternating current input or that they have an optoisolated RS485.

-In case of an RS485 network with several devices it is recommended to activate the 120 ohm

termination resistance on the two devices located at the ends of the network, as described in

section RS485 SERIAL CONNECTION.

-Option E/EC: selects 12 groups of 5 setpoint.

WIRING DIAGRAM

5 outputs: settable setpoint or remote output management via protocol.

3 inputs: settable to have the following functions: NET/GROSS WEIGHT, SEMI-AUTOMATIC ZERO,

PEAK, PRINT or REMOTE CONTROL (see section OUTPUTS AND INPUTS CONFIGURATION).

(1) If the analog output is present (ANALOG OUTPUT OPTION) the following is no longer available:

▫IN3 input

▫OUT5 output

▫E/EC options

WARNING: connect power supply specified on the plate found on the back of the instrument.

In 115 V and 230 V versions, terminals “+ SUPPLY” and “– SUPPLY” generate continuous voltage at

24 VDC only to be used as power supply for instrument inputs.

(1) ANALOGOUTPUTOPTION

12

EC OPTION

3

21

7

68

5

410

11

9

8

E OPTION

1 32 4 5 671411910 1312 1615

4

to instrument

Current output:

max load 300 ohm

Voltage output:

min load 10 kohm

Buttons not included in the supply

1 2 3 4 5 678 9 10 1112 13 14 15 16 17 18 19 20 2122 23 24

12-24 VDC

supply

RS485

IN 3

INPUT

supply

5-24 VDC

toINCOMMMON OUT 5

to E-EC OPT.

-

+

SUPPLY +

SUPPLY -

TXD

RXD

OUT 1

OUT 2

OUT 3

OUT 4

OUT COMMON

IN 1

IN 2

EXCITATION -

REF./SENSE +

IN COMMON

EXCITATION +

REF./SENSE -

SIGNAL -

SIGNAL +

RS232

LOAD CELLS

6-WIRE load cell

connection

INPUTS

supply

5-24 VDC

OUTPUTS

max 115 VAC

150 mA

2 3 4

+ 0-10 VDC

- COMMON

+ 0-20 4-20 mA

19 20 2122 23 24

EXCIT. -

EXCIT. +

SIGNAL -

SIGNAL +

4-WIRE load cell connection

8

84

+ -

WARNING!

115 V / 230 V OPTIONS

(WDESK-P / WINOX-P)

L115/230

VAC

N

7SUPPLY

OUT + 24 VDC

OUTPUT

8SUPPLY

OUT -

- 11 -

CHANGING VOLTAGE 115 VAC / 230 VAC (WDESK)

Access instrument board by removing the six bottom screws and work on the welding side: join the

red points using a stiff wire.

KEY TO P, Q, X TYPE CONNECTORS

Terminal

Signal

Terminal

Signal

1

14

OUTPUT No. 4

2

INPUT No. 3

(+VDC min 5 V max 24 V)

otherwise:

+ANALOG OUTPUT

(0÷20 o 4÷20 mA)

15

OUTPUT COMMON

3

OUTPUT No. 5

otherwise:

+ANALOG OUTPUT (0÷10 V)

16

INPUT No. 1

(+VDC min 5 V max 24 V)

4

E/EC OPTION

otherwise:

-ANALOG OUTPUT COMMON

17

INPUT No. 2

(+VDC min 5 V max 24 V)

5

RS485: -

18

INPUT COMMON (-VDC 0 V)

6

RS485: +

19

-LOAD CELL EXCITATION (-Exc)

LOAD CELL SHIELD

7

+SUPPLY (12/24 VDC)

115/230 VAC optional version:

+OUTPUT (24 VDC)*

20

+LOAD CELL EXCITATION (+Exc)

8

-SUPPLY (12/24 VDC)

RS232, RS485: SHIELD, GND

E/EC OPTION: GND

115/230 VAC optional version:

-OUTPUT (24 VDC)*

RS232, RS485: SHIELD, GND

E/EC OPTION: GND

21

+LOAD CELL REF/SENSE

9

RS232: TXD

22

-LOAD CELL REF/SENSE

10

RS232: RXD

23

-LOAD CELL SIGNAL (-Sig)

11

OUTPUT No. 1

24

+LOAD CELL SIGNAL (+Sig)

230 Vac

230

115

115

115 Vac

230

115

115

- 12 -

12

OUTPUT No. 2

L

PHASE (115/230 VAC optional ver.)

13

OUTPUT No. 3

N

NEUTRAL (115/230 VAC optional ver.)

GROUND (115/230 VAC optional ver.)

*) Use only as power supply for instrument inputs.

To access the terminal strip on the WDESK instruments with cable glands, you need to

remove the bottom of the instrument unscrewing the six screws.

KEY TO D TYPE CONNECTORS

Connector

Pin

Signal

Internal

terminal

Internal

colour

P1

Power supply

+ SUPPLY (12/24 VDC)

7

red

- SUPPLY (12/24 VDC)

8

black

D1

Female

Load cell

1

-LOAD CELL EXCITATION (-Exc)

19

black

2

-LOAD CELL REF/SENSE

22

yellow

3

4

5

LOAD CELL SHIELD

19

6

+LOAD CELL EXCITATION (+Exc)

20

red

7

+LOAD CELL REF/SENSE

21

blue

8

-LOAD CELL SIGNAL (-Sig)

23

white

9

+LOAD CELL SIGNAL (+Sig)

24

green

D3

Male

I/O

Analog output

E/EC option

1

OUTPUT No.1 (max 24 V)

11

yellow

2

OUTPUT No.2 (max 24 V)

12

blue

3

OUTPUT No.3 (max 24 V)

13

white

4

OUTPUT No.4 (max 24 V)

14

green

5

OUTPUT No. 5 (max 24 V)

otherwise:

+ ANALOG OUTPUT (0÷10 V)

3

orange

6

OUTPUT COMMON (max 24 V)

15

purple

7

INPUT No.1 (+VDC min 5 V max 24 V)

16

grey

8

INPUT No.2 (+VDC min 5 V max 24 V)

17

pink

9

INPUT No. 3 (+VDC min 5 V max 24 V)

otherwise:

+ANALOG OUTPUT (0÷20 o 4÷20 mA)

2

brown

10

INPUT COMMON (-VDC 0 V)

18

white/blue

11

E/EC OPTION

otherwise:

-ANALOG OUTPUT COMMON

4

red

12

E/EC OPTION: GND

ANALOG OUTPUT: SHIELD

8

black

13

- 13 -

14

15

D4

Male

RS232 serial port

1

2

RS232: RXD

10

yellow

3

RS232: TXD

9

blue

4

5

RS232: SHIELD, GND

8

black

6

7

8

9

D5

Male

RS485 serial port

with 24 VDC

output

1

+OUTPUT (24 VDC)*

7

red

2

-OUTPUT (24 VDC)*

8

black

3

4

RS485: +

6

yellow

5

RS485: SHIELD, GND

8

black

6

RS485: -

5

blue

7

RS485: -

5

blue

8

9

RS485: +

6

yellow

*) Not available if the instrument is battery powered.

Use only if the instrument is connected to the provided 24 VDC power supply.

Maximum load: 5 W.

- 14 -

KEYS AND SYMBOLS FUNCTIONS

KEYS

KEY

Short press

Long press (3 s)

Into menus

Power-on

Power-off

Semi-automatic zero

Tare resetting

Cancel or return to previous

menu

Gross Net

Net Gross

Select figure to be modified

Select figure to be modified

Show date and time on display

Modify figure or go to next

menu item

Print actual weight

mV load cell test

Modify figure or go to previous

menu item

Setting setpoint and hysteresis

Confirm or enter in submenu

…

Context-sensitive function keys: see

corresponding symbol on LCD

display

Context-sensitive function

keys: see corresponding

symbol on LCD display

+

Setting general parameters (press

immediately followed by )

+

Setting preset tare (press

immediately followed by )

SYMBOLS

SYMBOL

Function

LED POWER

power supply available

net weight (semi-automatic tare or preset tare)

zero (deviation from zero not more than ±0.25 divisions)

stability

not used

The symbols are activated in sequence within the menus to indicate that the display is not

showing a weight.

- 15 -

MENU MAP

Into menus changes are applied right after pressing the ENTER key (no further confirmation is required).

SETPOINT

SYSTEM PARAMETERS

…

…

…

3 s

optional

+

3 s

+

*

optional

optional

* WTAB

This manual suits for next models

4

Table of contents

Popular Controllers manuals by other brands

Danfoss

Danfoss CF-MC manual

Sun Microsystems

Sun Microsystems Sun StorageTek 2500 Series Removal and Replacement

Cambridge Technology

Cambridge Technology ScanMaster Technical bulletin

Watlow Electric

Watlow Electric Series 142 user manual

Nav TV

Nav TV SteerBlue NTV-KIT455 installation manual

JNGE Power

JNGE Power MPPT user manual