www.odencontrol.se 3

2.3. Terms concerning safety

It is of outmost importance that all users follow these instructions on how to install, maintain and use this series of

electric actuators. The safety terms DANGER, WARNING, CAUTION and NOTE are used in these instructions to

point out particular dangers and/or providing additional information on aspects which are not readily apparent.

−DANGER: Indicates that death, severe personal injury and/or substantial property damage will occur if

proper precautions are not taken.

−WARNING: Indicates that death, severe personal injury and/or substantial property may occur if proper

precautions are not taken.

−CAUTION: Indicates that minor personal injury and/pr property damage can occur if proper precautions

are not taken.

−NOTE: Indicates and provides additional information, which may not be very obvious even to qualified

personnel. Compliance with other, not particularly emphasized information, with regard to transport,

assembly, operation and maintenance and with regard to technical documentation such as operating

instructions, product documentation or on the product itself is essential, in order to prevent faults, which

may cause severe personal injury or property damage.

2.4. Operation and safety instructions

In English:

Read carefully this manual before installation and operation as well as before maintenance. The actuator must only

be used for controlling valves and similar applications. Incorrect use may harm the actuator. Hence, functions

cannot be guaranteed. Local regulations concerning technical equipments must be observed at installing or

maintenance. Warning texts must be followed and necessary steps to prevent accidents must be taken. This manual

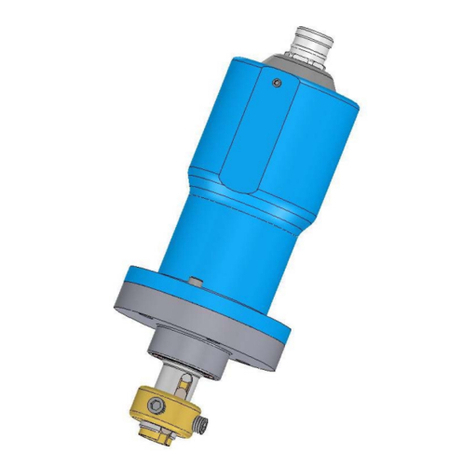

deals with the following types of Oden actuators: P30R/L

In Swedish:

Läs noggrant denna manual före installation och idrifttagande liksom vid service av ställdonet. Detta ställdon får

endast användas till att styra ventiler och liknande objekt. Felaktig användning kan skada ställdonet och därmed

kan inte funktionen garanteras. Lokala bestämmelser beträffande teknisk utrustning måste följas vid installation

och/eller underhåll. Varningstexter måste följas och nödvändiga åtgärder måste tas för att undvika olyckshändelser.

Denna manual behandlar följande typer av Oden ställdon: P30R/L

In German:

Bitte lesen Sie diese Manual genau bevor der Installation und in Betriebnahme. Gleichweise bevor Service von

dem Antrieb. Dieser Antrieb darf nur benutzt werden für Steuerung von Ventilen und Gleichartigen Objekte.

Falsche Verwendungen können dem Antrieb schaden und damit kann die Funktion nicht garantiert werden. Lokale

Vorschriften betreffend die technische Ausrüstung muss bei Installation und/oder Unterhaltarbeiten beachtet

werden. Warnungstexte müssen beachtet werden und notwendige Maßnahmen durchgeführt werden um Unglücke

zu vermeiden. Dieses Manual behandelt volgende Type von Oden Antriebe: P30R/L

In Finnish

Lue tarkkaan käyttöohje ennen asennusta, käyttöönottoa tai huoltoa. Tätä toimilaitetta saa käyttää ainoastaan

venttiilien ja vastaavien kohteiden ohjaamiseen. Väärä käyttö voi vahingoittaa laitetta. Tällaisessä tapauksessa

emme takaa virheetöntä toimintaa ja turvallisuutta. Toimilaitetta asennettaessa tai huollettaessa pitää noudattaa

paikallisia säännöksiä jotka koskevat teknistä laitteistoa. Turvallisuus ja varoitustekstejä pitää noudattaa tarkasti

jotta vältyttäisiin henkilövahingoilta ja toimilaitteen toiminta häiriöiltä: P30R/L