I.B. 48008

Page 4

Effective 11/97

MarkV Controller Functions (Cont.)

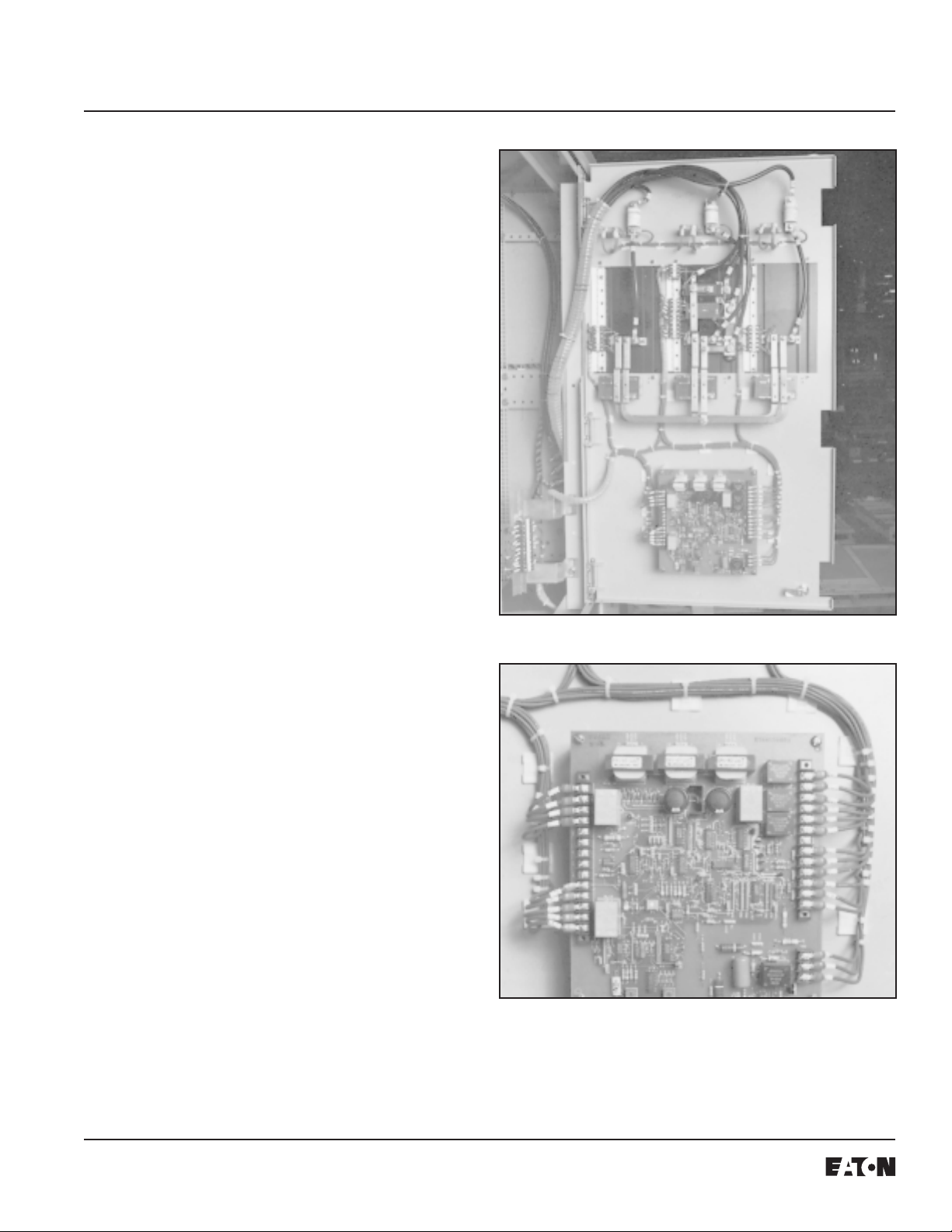

The SCR field power supply QA1, QB1, QC1, QA2, QB2,

andQC2suppliesvoltage(125 or 250VDC) and current to

the motor field. The power supply comes in three sizes,

50,100,or200amperesDC.

The printed circuit board provides gating signals for the

starting and discharge circuit and protective functions as

well as the SCR power supply.

Thefield power transformer must have either a 120or 240

volt three-phase AC secondary. A 120 volt AC secondary

is required for the 125VDC system. A supply of 240 volts

AC is required for the 250VDC system. It may be con-

nected wye or delta. Do not ground the system. The

transformer is sized KVA = .17 x rated amps DC @ 125

volts DC or KVA = .34 x rated amps DC @ 250 volts DC.

Currenttransformers arefurnished inthemotorstarter

(controller) to supply current to protective relays and

various meters in direct proportion to the line current.

CONTROLLEROPERATION

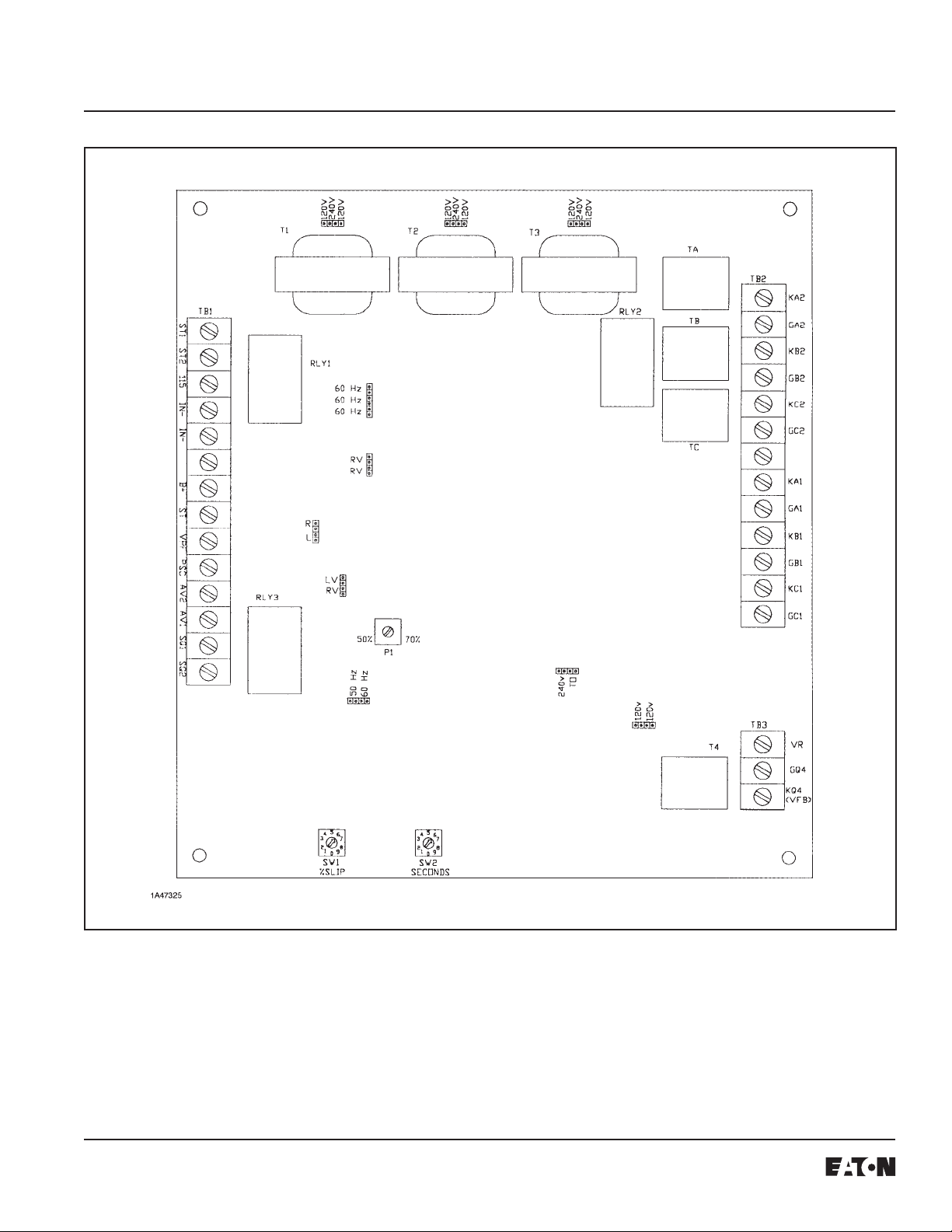

Figure 4 shows the field power supply controller in con-

junction with the motor controller for a synchronous motor

starter. Note that the connection to the field supply

transformer is between the contactor (M) and the IQ

component so that the current transformers sense motor

stator current only.

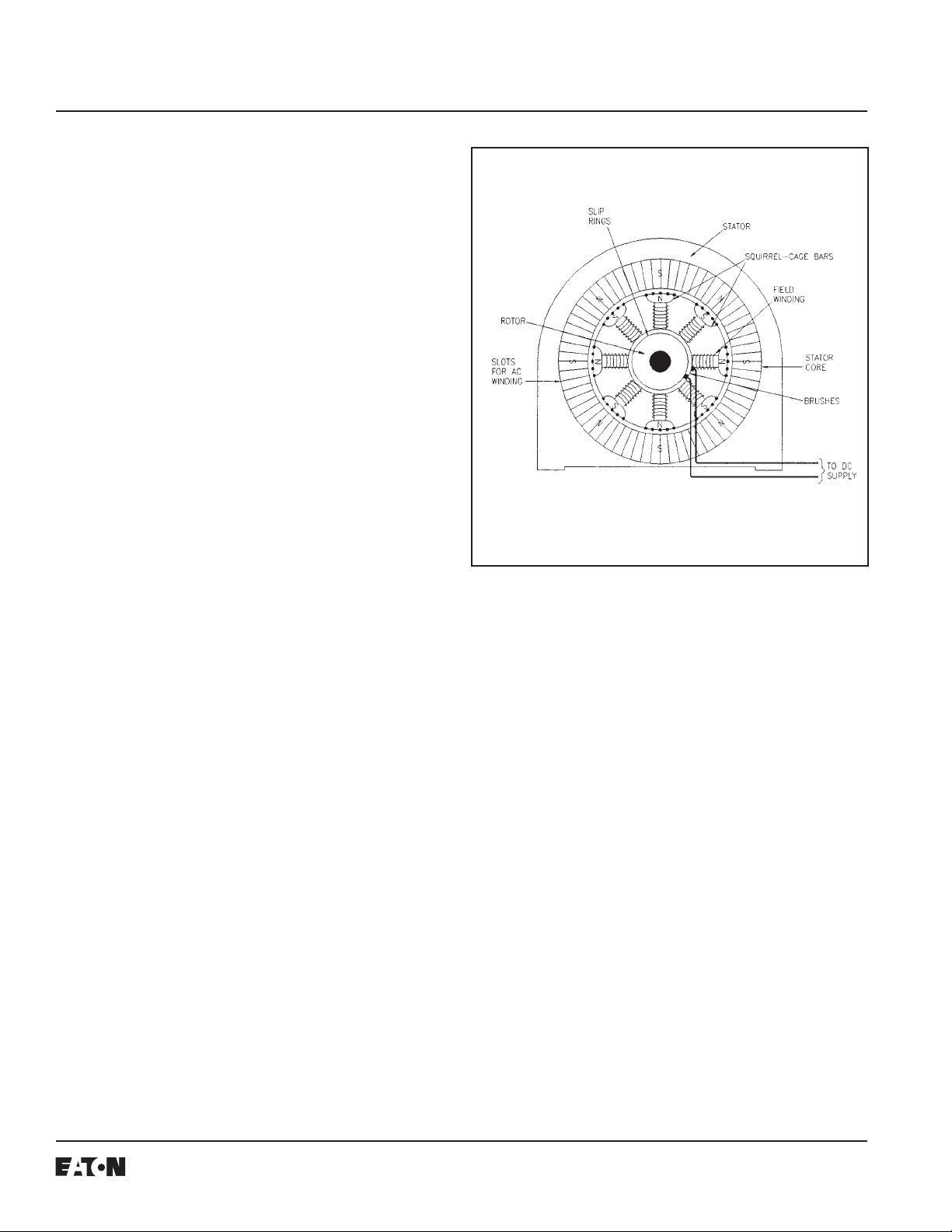

The field power supply controller consists of three types of

circuits, one each dedicated to (1) field power, (2) control,

and (3) motor starting. The six thyristors (SCR’s), QA1

throughQC2,arethemaincomponentsofthefield power

circuit. The control circuit controls the starting circuit and

the output of the field power circuit.

A motor start sequence is initiated by closing the line

contactor (M). This results in the motor stator and the

solid-statefieldpowersupply being energized.

On start-up, three-phase voltage signals are supplied to

terminals KA2, KB2, and KC2. The open-fuse detection

circuit requires about 100 milliseconds to determine that

all voltages are present. It then causes RLY1 to close the

circuitbetweenterminals ST1 and ST2 onTB1 (Figure 5).

The light emitting diode, LED1 is lit. If any fuse opens

and voltage is lost at terminals KA2, KB2, or KC2, RLY1

will drop out to open the control circuit.

RLY1andRLY3maypulse open andclosedduringcertain

types of faults causing the interposing relay “MX” to drop

out,insuring that the“M”contactor hasdroppedout.SYTR

remainsenergizeduntil “M”dropsout.

The motor starter, being energized, causes the motor field

to generate an output voltage at the instantaneous slip

frequency of the motor. This voltage is controlled by the

independentlyoperatingthyristor-controlled startingcircuit

D1-Q4.

The voltage across the field starting and discharge

resistor (S/D RES) is monitored during the starting

sequencetodeterminetheinstantaneousslipofthemotor.

A motor slip condition of less than 75% (more than 25%

speed) must be reached within the preset time (rotary

switch SW2), ranging from 0 to 9 seconds, or a stalled

rotorcondition will be indicated by the incomplete-se-

quencerelay(RLY3)being energized.

As the motor continues to accelerate and the motor slip

frequency becomes less than the level established by the

setting of rotary switch SW1 (0-9%), the gate drives to the

field power supply thyristors activate and the soft turn-on

circuit begins to apply DC voltage to the motor field. If the

motor does not synchronize, Q4 is gated on. At the same

time gating to QA1 - QC2 is inhibited until Q4 stops

conducting.

Once again QA1-QC2 is gated on, applying voltage to the

motor field. This process is repeated until the motor

synchronizes or until a fixed time in the range of 2.5 to 3.5

secondselapses.

Should the motor continue to slip poles after the 2.5 to 3.5

second period has elapsed, as indicated by the starting

circuit thyristor (Q4) continuing to conduct, the incom-

plete-sequencerelay(RLY3)will be energizedindicatinga

failure to synchronize.

If the motor fails to reach the expected slip frequency

within 34 or 40 seconds from the beginning of the start

sequence,the timeout (TO)function will operateand the

incomplete-sequencerelay(RLY3) willagainbeenergized

if this option is chosen (by inserting jumper TO). See

OPTIONS onPage 6.

Whenmotor synchronizationisbeing established,the

output voltage is sensed and regulation of the field voltage

isaccomplishedbyappropriatecontrolof the gating

patternstothe field power supply thyristors QA1-QC2.