13. Avoid unintentional starting.

Do not carry the tool with finger on the switch.

Be sure switch is off when plugging in.

Use switch lock behind trigger switch when not in use.

14. Avoid using an extension cord.

An extension cord should not be used unless absolutely necessary.

Use of an improper extension cord could result in a risk of fire and electric shock.

If an extension cord must be used, make sure the cord is properly wired, has a

wire size that is large enough for the amperage rating of the tool, and is in good

electrical condition.

15. Always keep alert.

Do not allow familiarity gained by frequent and long use cause a careless

mistake.

Always remember that a careless fraction of a second is enough to inflict severe

injury.

Watch what you are doing. Use common sense.

Do not operate the tool when you are tired or under the influence of drugs or

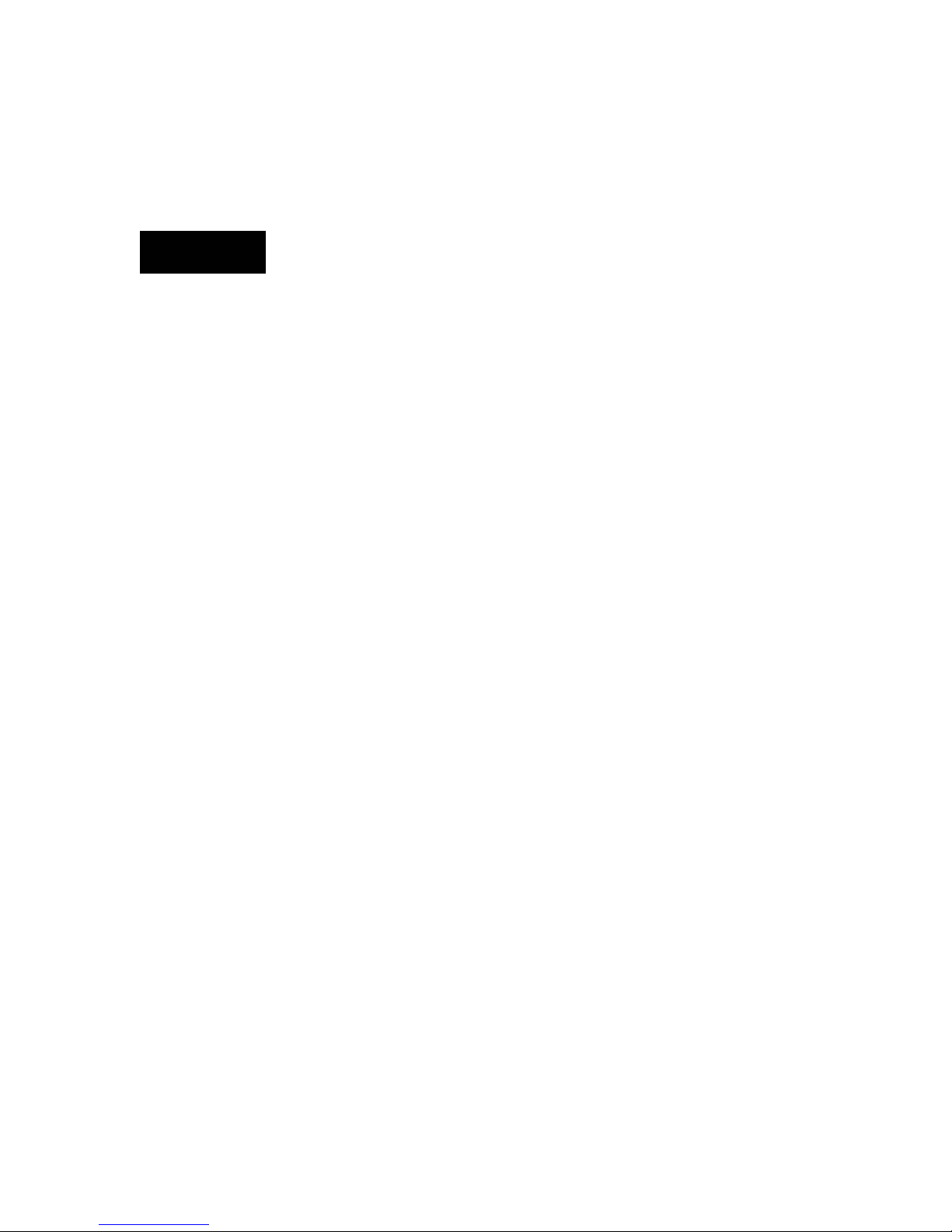

alcohol.

16. Check for damaged parts.

Before use of the tool, check for any damaged parts. Carefully determine that all

parts operate properly.

17. Use only accessories and attachments that come with this tool.

Use of accessories or attachments not listed in this manual may result in a risk of

accident such as fire, electric shock or personal injury.

18. Return tool to Fascut Industries for repair.

Other than the remedies shown in the Trouble Shooting table, do not attempt to

disassemble or repair the tool.

Do not modify the tool. Any modifications will void the warranty and may cause a

hazardous situation.

FOR ELECTRO-HYDRAULIC REBAR CUTTERS

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

1. Tool should only be plugged into a power supply that satisfies the power

rating as indicated on the tool.

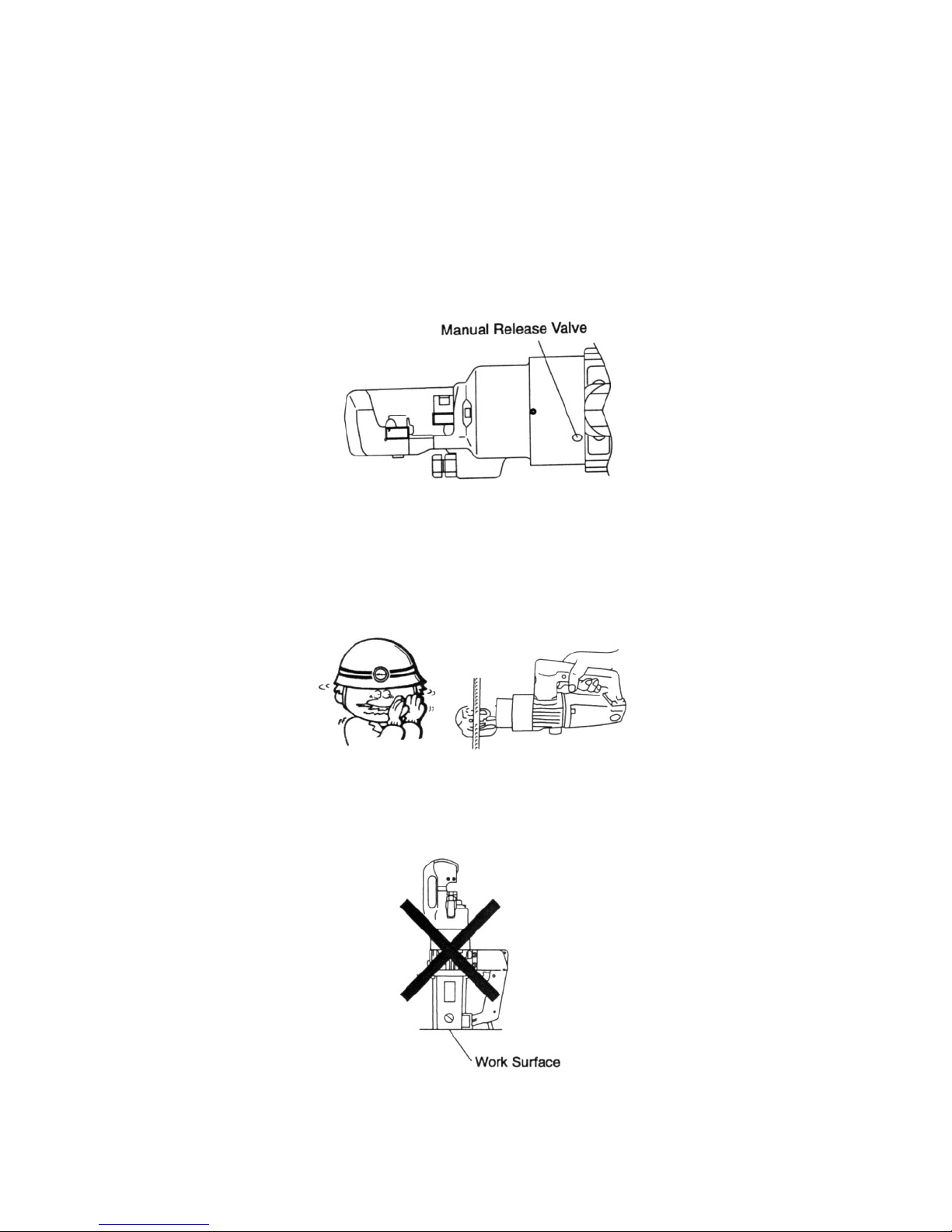

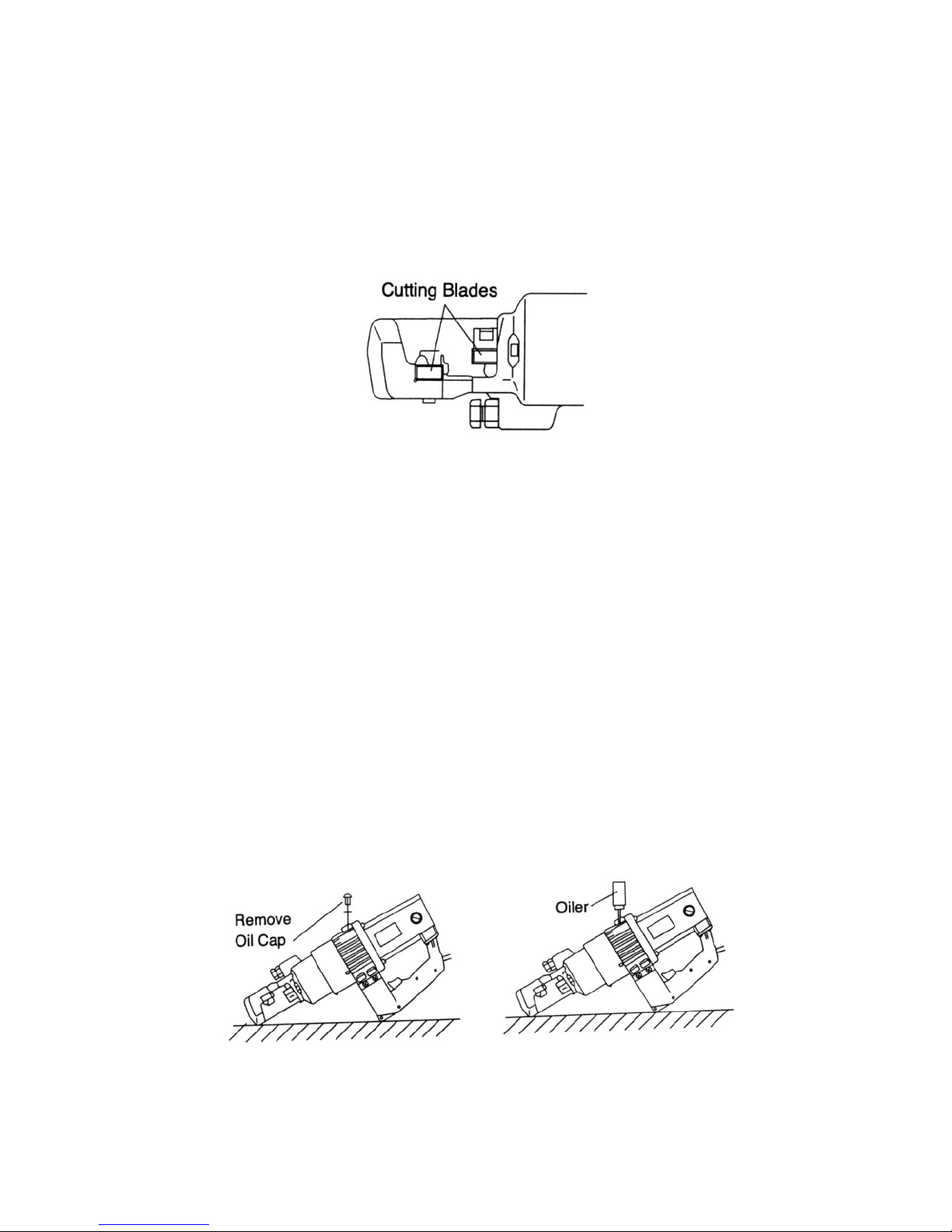

2. Never touch the blades and piston during operation.

3. Make it a habit to check that the cutting blades are securely tightened before

operation.

4. Unplug the tool from outlet before starting any maintenance.

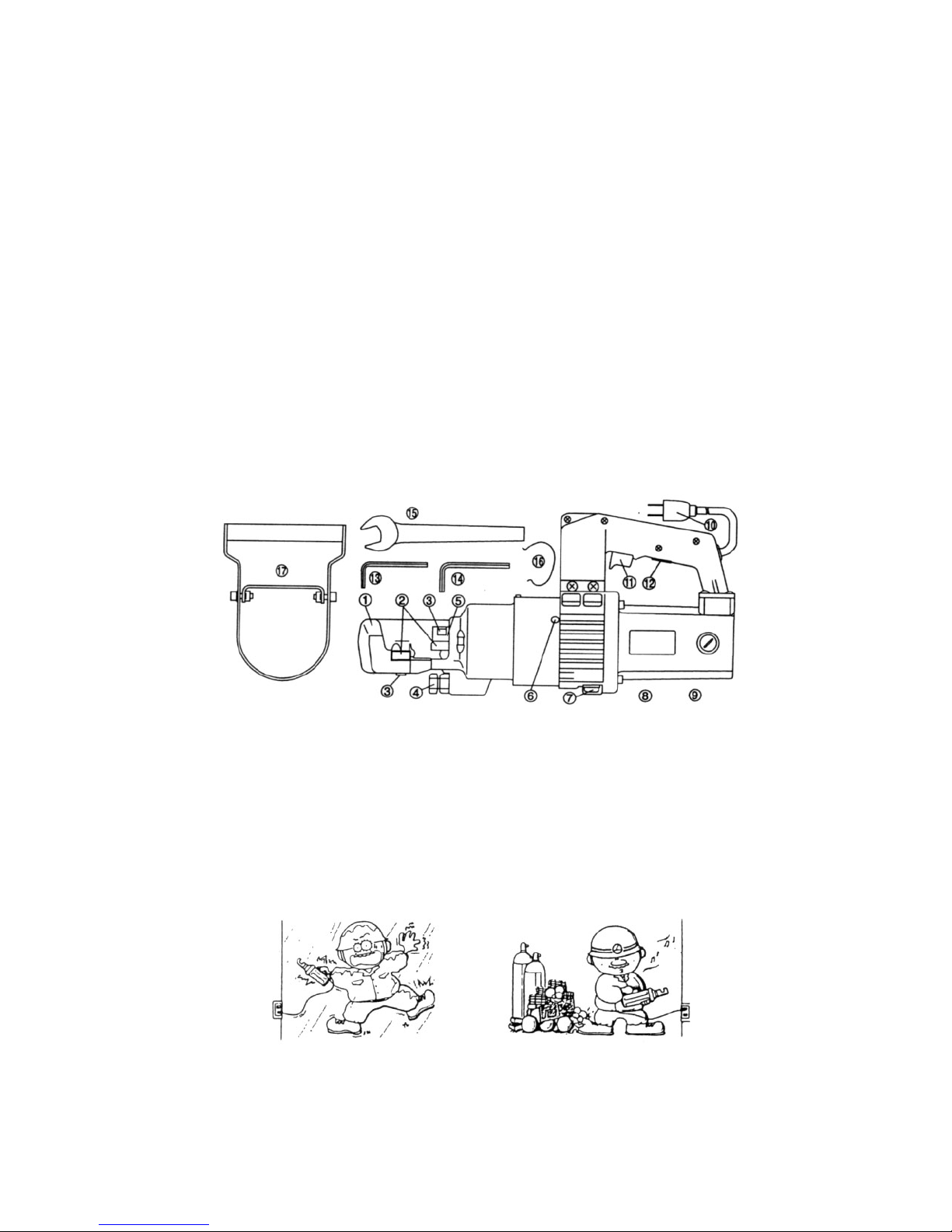

5. Never operate the tool before confirming the DANGEROUS ZONE as shown

in the Operation Procedure section of this manual.

Do not point the cutting head towards any person when operating.

Cut pieces may fly off with tremendous force and are dangerous.

Avoid cutting off small or short pieces of material.

6. Do not attempt to cut material with a size and/or hardness exceeding the

maximum cutting capacity.

7. When working in high places, check to make certain no person is under you.

Serious injury could result from dropped rebar pieces.