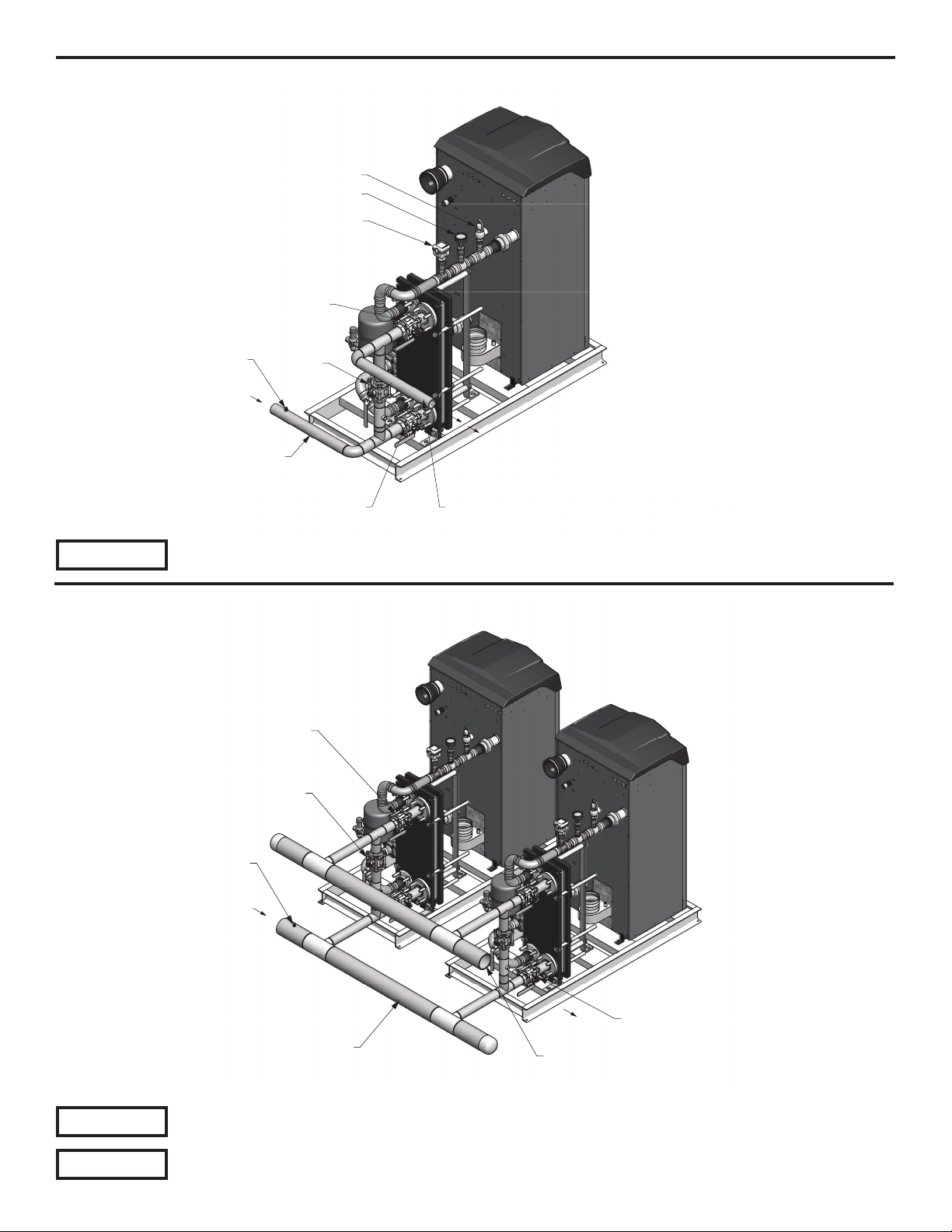

Cascade

When multiple boilers are installed, they can be wired together

in a cascade sequence. A maximum of eight boilers can be

controlled from a single control. In this application one boiler

would be designated as the Leader control and all others would

be designated as Member controls.

If the water temperature at the inlet side of the indirect heat

exchanger sensor is less than the set point + the turn-off offset -

the off-on differential, then the control will initiate a call for heat

on the Cascade (see the FTXL Service Manual for an explanation

of the offset and differential). The Leader will energize the lead

boiler on the Cascade. For a new startup this will be the Leader

boiler.

The boiler will fire at its ignition speed and will then modulate

its firing rate to maintain the set point. If the first boiler reaches

100% of its firing rate, the Leader will calculate at what point the

second boiler could fire at 20% of its firing rate. At this point,

the Leader will fire the second boiler on the Cascade. For a new

startup, this would be the first Member boiler. The boiler will

fire at its ignition speed and will then modulate its firing rate to

maintain the set point.

If the set point still cannot be met, the Leader will continue

firing more Members until either the heat demand is met or all

boilers on the Cascade are firing. As the heat demand decreases,

the last boiler on will modulate down to 20% of its firing rate.

Once the demand for that boiler is zero, it will shut down. As

the heat demand decreases further, the second to last boiler will

modulate down and shut off. This will continue until the demand

is satisfied and all boilers are shut off.

Wiring of the Cascade

When wiring the boilers for Cascade operation, select one boiler

as the Leader boiler. The remaining boilers will be designated

as Members. See “Configuration of the Cascade” for a detailed

explanation of this procedure.

Communication between the Leader boiler and the Member

boilers is accomplished by using shielded, 2-wire twisted pair

communication cable. Connect one of the twisted pair wires

to terminal A on each of the Low Voltage Connection boards

(FIG. 3), and the other wire of the twisted pair to terminal B on

each of the Low Voltage Connection Boards. Connect the shield

wires to one of the shield ground terminals on the Low Voltage

Connection Boards. If more than two boilers are on the Cascade,

daisy chain the wiring from the Sequencing terminals on the

second boiler to the Sequencing terminals on the third boiler, then

from the third to the forth, and so on. The connections between

boilers can be made in any order, regardless of the addresses of

the boilers. Try to keep each cable as short as possible.

Configuration of the Cascade

Please note that the brackets ([]) denote screen

status.

NOTICE

When installed in a Cascade system, the individual controls must

be programmed for cascade operation. This is accomplished by

accessing the control parameters.

Press the [MENU] key for at least five (5) seconds. Input the

Installer code as described in the FTXL Service Manual. Once the

control parameters have been accessed, use the NAVIGATION

DIAL to select the Control Mode parameters. Press the

NAVIGATION DIAL to access these parameters.

Rotate the NAVIGATION dial to select the parameter “Cascade

Address”. Press the NAVIGATION dial to access this parameter.

Each appliance in the Cascade system must be programmed

with its own address. The boiler designated as the Leader will

have an address of 0. The remaining boilers in the Cascade

will be Members and have addresses from 1 - 7. Rotate the

NAVIGATION dial to select the appropriate address. Press the

RIGHT SELECT SAVE key. If installing the boilers in an

existing system, the new boilers should be programmed as the

Leader and/or the higher number addresses.

Press the RIGHT SELECT HOME key to upload the address

into the control. Repeat this procedure for all boilers in the

Cascade, designating the Leader control and the Member controls.

100326095_2000582397_Rev A 9 of 16