Lockhard Alulift Series User manual

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 1

Operator's Manual

MOBILE ACCESS PLATFORM

TYPE Alulift

(Translation)

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 2

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 3

Table of Contents

1. GENERAL INFORMATION.............................................................................................................................6

1.1. Manufacturer...................................................................................................................................................6

1.2. Machinery Marking .......................................................................................................................................6

1.3. Definitions ........................................................................................................................................................7

1.4. Safety symbols used in this Manual.........................................................................................................7

1.5. National requirements.................................................................................................................................8

1.6. Declaration of Conformity..........................................................................................................................9

2. TECHNICAL DATA........................................................................................................................................ 10

2.1. Use of PRP type Alulift for its intended purpose.............................................................................. 10

2.2. Failure to use PRP type Alulift for the intended purpose............................................................. 10

3. DESCRIPTION OF THE PRP CONSTRUCTION AND OPERATION AND ADJUSTMENT OF

SAFETY COMPONENTS............................................................................................................................... 11

3.2. List of Components Necessary for PRP type Alulift Assembly .................................................... 14

4. DESCRIPTION OF THE DRIVE SYSTEM CONSTRUCTION, OPERATION AND ADJUSTMENT 16

4.1 Drive Unit....................................................................................................................................................... 16

4.2 Service brake ................................................................................................................................................ 16

4.3 Emergency Brake - Emergency Gripper.............................................................................................. 16

4.4 Control Pendant........................................................................................................................................... 16

4.5 Audio Alarms. ............................................................................................................................................... 17

4.6 Wheel Brakes................................................................................................................................................ 17

4.7 Safety system to prevent platform overloading............................................................................... 17

4.8 Drive operating time meter..................................................................................................................... 17

4.9 Battery charger............................................................................................................................................ 17

5. ASSEMBLY AND DISASSEMBLY INSTRUCTIONS................................................................................ 18

5.1. Assembly ........................................................................................................................................................ 19

5.2. Conditions of stability - variants of stabilizers................................................................................. 26

5.3. PRP type Alulift S anchoring instruction ........................................................................................... 28

5.4. Disassembly .................................................................................................................................................. 29

5.5. Battery Disassembly .................................................................................................................................. 30

6. OPERATOR'S MANUAL............................................................................................................................... 30

6.1. Control via control pendant..................................................................................................................... 31

6.2. Operator's working station...................................................................................................................... 31

6.3. Operator's qualifications.......................................................................................................................... 31

6.4. Handling PRP ................................................................................................................................................ 32

6.5. Troubleshooting .......................................................................................................................................... 32

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 4

7. HAZARDS IDENTIFICATION AND RESIDUAL RISK INFORMATION............................................. 34

8. SAFETY GUIDELINES................................................................................................................................... 35

8.1. Lighting........................................................................................................................................................... 36

9. MAINTENANCE INSTRUCTIONS.............................................................................................................. 36

9.1. Maintenance Operator .............................................................................................................................. 36

9.2. Maintenance and Inspection Schedule................................................................................................ 36

9.3. Pre-assembly reviews............................................................................................................................... 37

9.4. Maintenance Reviews................................................................................................................................ 37

9.5. Ad hoc and Service Reviews. .................................................................................................................. 38

10. CRITERIA FOR COMPONENTS REPLACEMENT.................................................................................. 38

11. STORAGE AND TRANSPORT..................................................................................................................... 38

12. AN INFORMATION BOARD PLACED ON THE PRODUCT ................................................................. 39

13. Guarantee and warranty .......................................................................................................................... 40

14. APPENDIX No. 1………………………………………………………………….………………………….......…………..42

15. APPENDIX No. 2……………………………………………………………………………………………………..………..43

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 5

Foreword

We would like to inform you that the Mobile Access Platform type Alulift has passed a detailed EC

type examination carried out by the certification body JOAiCW TEST Sp. z o.o. [Ltd] .

The confirmation of the positive result of the inspection carried out by JOAiCW TEST Sp. z o.o. is the

Type Examination Certificate issued.

Lockhard Sp. z o.o. [Ltd] is the only manufacturer of the Mobile Access Platform (Polish: PRP) type

Alulift with a mobile work platform.

This Operator's Manual is considered to be a fundamental part of the Mobile Access Platform type

Alulift. It contains all the necessary information on the assembly, disassembly and operation of the

device as well as users' work safety and the information on how to maintain its efficiency.

A full and legible user's manual must be accessible at all times. "Mobile Access Platform type Alulift"

will be hereinafter abbreviated as "PRP".

In order to avoid unnecessary damage and risks, the operator's and the assembly worker's

responsibility is to read, understand and comply with this Operator's Manual.

In addition to this PRP Operator's Manual, general legal provisions and regulations concerning

accident prevention and environmental protection in force in the user's country shall apply.

You should refer to all the national and local rules for operating PRP type Alulift on site.

LOCKHARD is not liable for any damage resulting from failure to

comply with this Manual.

Any risk in this respect shall be borne by the user.

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 6

1. GENERAL INFORMATION

1.1. Manufacturer

LOCKHARD Sp. z o.o.

Gorzyce Wielkie ul. Ostrowska 74a

63-410 Ostrów Wielkopolski

e-mail: office@lockhard.eu

www.lockhard.eu

1.2. Machinery Marking

Alulift S

Alulift M

Alulift XL

Lockhard Sp. z o.o.

Gorzyce Wielkie ul.Ostrowska 74a

63-410 Ostrów Wielkopolski

POLSKA

Product:

Mobile Access Platform type Alulift S

Alulift Type: S

Weight: 48.3 kg –330 kg

Safe working load: 250 kg

Voltage: 24V DC

Platform dimensions:

660x1720mm

Engine power: 600 W

Lift height: 8 m

Serial number: xxx

Platform speed:10 m/min

Year of manufacture: 2015

Lockhard Sp. z o.o.

Gorzyce Wielkie ul.Ostrowska 74a

63-410 Ostrów Wielkopolski

POLSKA

Product:

Mobile Access Platform type Alulift M

Alulift Type: M

Weight: 55 kg –475 kg

Safe working load: 250 kg

Voltage: 24V DC

Platform dimensions: 660x2400mm

Engine power: 600 W

Lift height: 12 m

Serial number: xxx

Platform speed: 10 m/min

Year of manufacture: 2015

Lockhard Sp. z o.o.

Gorzyce Wielkie ul.Ostrowska 74a

63-410 Ostrów Wielkopolski

POLSKA

Product:

Mobile Access Platform type Alulift XL

Alulift Type: XL

Weight: 67 kg –524 kg

Safe working load: 250 kg

Voltage: 24V DC

Platform dimensions:

1100x2400mm

Engine power: 600 W

Lift height: 12 m

Serial number: xxx

Platform speed: 10 m/min

Year of manufacture: 2015

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 7

1.3. Definitions

Mobile Access Platform (PRP) - is a mobile machine intended to move persons to working

positions on which they carry out work from the work platform, on the assumption that these

persons enter the platform and exit the platform in its one lower access position, and which

consists of the work platform with controls, a load-bearing structure, a wheel assembly.

Work platform - a part of the mobile platform, a platform with railings, which can be moved

under load to a desired working position, and from which you can perform installations, repairs,

inspections or similar works.

Operator - a designated person, suitably trained to operate devices of this type subject to laws

and regulations applicable in a particular country. In Poland an operator must have proper

qualifications awarded by the Office of Technical Inspection (an operator may also work as a

service technician).

Service technician is a person who has been sufficiently trained by the manufacturer of the

device type Alulift, namely Lockhard Sp. z o.o. Each periodic replacement of parts or ad hoc

repairs of the device may be carried out by the manufacturer's service technicians or service

units authorized by the manufacturer.

Safe working load - the maximum weight carried by the work platform provided for by the

manufacturer in the design/specifications of the device. The safe working load comprises the

weight of persons, tools and materials placed on the platform.

1.4. Safety symbols used in this Manual

In order to draw your attention to the areas in this Manual which contain important information or

indicate danger, the following symbols are used. Special attention should be paid to areas marked

with these symbols as you study the instructions for use.

Danger

This symbol indicates an immediate threat to person's life and health.

Failure to comply may result in a risk to life or a risk of serious injury and a

significant property damage.

Caution

It is a warning against possible damage to PRP or another item, if the action

marked in this way is performed incorrectly.

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 8

1.5. National requirements

In addition to this Operator's Manual, attention should be given to the need to know and comply

with the generally applicable national and local laws and other binding regulations relating to work

safety and environmental protection in the country where the machine is used.

In the Republic of Poland "Mobile Access Platform type Alulift" serving as a device for the movement

of persons and loads is a device qualifying for handling equipment and is subject to technical

supervision. It is the user's responsibility to report the equipment to UDT [Polish Office of Technical

Inspection].

Legal basis:

Regulation of the Council of Ministers of 7 December 2012 on types of technical devices subject to

technical inspection (Official Journal of Laws 2012 No. 0, item 1468), issued pursuant to Article 5,

paragraph 2 of the Law on technical inspection.

Pursuant to the Regulation of the Minister of Economy, Labour and Social Policy of 29 October 2003

on the technical conditions of technical supervision relating to operating certain types of handling

equipment. Pursuant to art. 25.1 item, 6 after changing the location of handling equipment due to

its disassembly and reassembly, a device with single-phase power supply does not require interim

in-service testing.

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 9

1.6. Declaration of Conformity

EC DECLARATION OF CONFORMITY

Manufacturer: LOCKHARD Sp. z o.o.

Gorzyce Wielkie ul. Ostrowska 74a

63-410 Ostrów Wielkopolski

Product: Mobile Access Platform type Alulift

Serial number: ……………………….

We declare under our sole responsibility that the product referred to above fulfils the essential

health and safety requirements of the Directive 2006/42/EC OF THE EUROPEAN PARLIAMENT AND

OF THE COUNCIL.

The EC type examination was carried out by the notified body JOAiCW Test Sp. z o. o., number

NB2057, 41-103 Siemianowice Śl. ul. Wyzwolenia 14, which issued the CE Type Examination

Certificate No. ………………………….

The Product carries the mark:

The technical documentation is stored at:

LOCKHARD Sp. z o.o.

Gorzyce Wielkie ul. Ostrowska 74a

63-410 Ostrów Wielkopolski

Gorzyce Wielkie, dated ……………

Technical Manager:

Łukasz Leonhard

……………………………………………

……...

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 10

2. TECHNICAL DATA

ALULIFT S

ALULIFT M

ALULIFT XL

Safe working load

250 kg (2 persons,

tools and materials)

250 kg (2 persons,

tools and materials)

250 kg (2 persons,

tools and materials)

Work platform dimensions

660x1720 mm

1100x2400 mm

1100x2400 mm

Maximum platform lifting

and lowering speed

10 m/min (at full

battery power)

10 m/min (at full

battery power)

10 m/min (at full

battery power)

Maximum height

approx. 330 kg

approx. 475 kg

approx. 530 kg

Maximum PRP weight

8m- internal height

12 - external height

8 m –internal height

12 - external height

8 m –internal height

12 - external height

Supplied voltage

VDC 24

VDC 24

VDC 24

Engine power

600 W

600 W

600 W

Maximum drive motor speed

3000 rpm.

3000 rpm.

3000 rpm.

Transmission ratio

1:100

1:100

1:100

Battery capacity

33 Ah

33 Ah

33 Ah

Battery voltage

2x12 V

2x12 V

2x12 V

Operating temperature

-15° C up to +40 ° C

-15° C up to +40 ° C

-15° C up to +40 ° C

Noise

does not exceed 70dB

adjusted individually

does not exceed 70dB

adjusted individually

does not exceed 70dB

adjusted individually

2.1. Use of PRP type Alulift for its intended purpose

"Mobile Access Platform type Alulift" is a mobile machine intended to move persons to working

positions on which they carry out work from the work platform, on the assumption that these

persons enter the platform and exit the platform in its one lower access position. "Mobile Access

Platform type Alulift” consists of the work platform with controls, a load-bearing structure and a

wheel assembly. "Mobile Access Platform type Alulift " can be used indoors and outdoors.

2.2. Failure to use PRP type Alulift for the intended purpose

It is prohibited to use the PRP as a crane.

It is prohibited to apply a point load - the load must be equally distributed across the

platform. Applying a high load on a small area (a point load) may damage the platform.

It is prohibited to use and move the PRP when wind speed exceeds (12m/s - 6 on the

Beaufort scale).

It is prohibited to use the PRP during a storm.

It is prohibited to move the PRP using any motor vehicles such as a car, forklift truck, tractor,

etc.

It is prohibited to use lifting devices (hand or mechanical winches) on the PRP.

Do not increase (obscure) the side surface of the PRP. Increasing the area exposed

to the wind will decrease machine stability.

It is prohibited to stand on the handrails, braces and stabilizers.

It is prohibited to tie rods (excluding anchors) between the PRP and another structure

(buildings, another scaffolding, etc.).

It is prohibited to lean any objects against the PRP structure during assembly and operation.

Not more than 2 persons may stay on the PRP work platform.

It is prohibited to use the PRP that is not properly maintained and inspected or is not in

good technical condition.

It is prohibited to use the device without pin bolts securing structure frames.

It is prohibited to use this device in explosive atmospheres.

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 11

3. DESCRIPTION OF THE PRP CONSTRUCTION AND OPERATION AND ADJUSTMENT OF

SAFETY COMPONENTS

List of the "Mobile Access Platform type Alulift" components

Each PRP component is marked with a catalogue number in order to identify the PRP system.

Table 1

Item

No.

Component

marking

Component photo

Component

description

Weight [kg]

S

M

XL

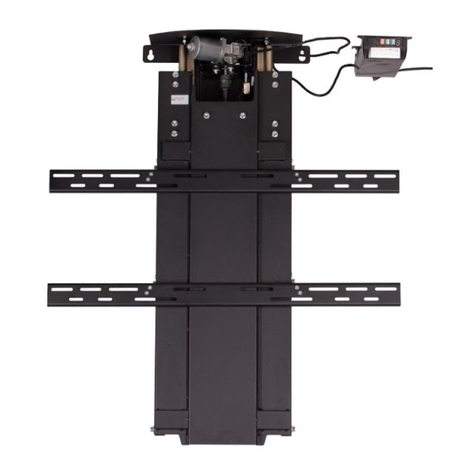

1.

PS

Work platform

with a drive

system

48,3

55

67

2.

H264

Horizontal

handrail

5

6

6

3.

HO 264

Handrail with

access gate

6,1

8.5

8.5

4.

TB264

Toe-boards

2,67

6.1

6.1

5.

H95

Side handrail

3.9

3.9

6,9

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 12

6.

FR139100

FG139100

Base frame (right

and left marked

with colours)

supplied with pin

bolts.

Running profile

mounted on the

base frame

10.6

10.6

12,10

7.

DB264

Diagonal braces

2,27

2.85

2.7

8.

HB264

Horizontal braces

2.18

2.70

2.7

9.

CC05

Control pendant

PKS-3/W05

0.5

0.5

0.5

10.

WHEEL125

Small wheel

61125 CB

1.2

1.2

1.2

11.

WHEEL200

Large wheel

61200 CB

5.3

5.3

5.5

12.

BAT33

Gel batteries

Bt-02-12

2x9,5

2x9,5

2x10,5

13.

TE04-0227

Battery charger

TE04-0227

0.8

0.45

0.8

14.

STAB3000

Stabilizer

4.28

4.28

4.28

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 13

15.

RA15

Gear rack

9,8

9,8

9,8

16.

SPR20

Gear

0,68

0,68

0,68

17.

GRA25

Gripper

(emergency

brake)

1,17

1,17

1,17

18.

BFK457

Service brake

BFK 457

19.

AN450

Anchor bolt

2

2

2

20.

LI10-60

Pin bolt

0,05

0,05

0,05

21.

OB

Weight - ballast

10

10

10

Safety guardrails are an integral part of the platform

Pin bolts are an integral part of the load-bearing structure

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 14

3.2. List of Components Necessary for PRP type Alulift Assembly Table 2

Alulift S

PRP height

2m

3m

4m

5m

6m

7m

8m

Component name

Number of components (pcs)

Red structure frame

2

3

4

5

6

7

8

Green structure frame

2

3

4

5

6

7

8

Diagonal braces

4

6

8

10

12

14

16

Horizontal braces

2

2

2

2

2

2

2

Horizontal handrail

1

1

1

1

1

1

1

Handrail with access gate

1

1

1

1

1

1

1

Side handrail

2

2

2

2

2

2

2

Toe-board

3

3

3

3

3

3

3

Stabilizer

-

-

4

4

4

4

4

Small wheel

8

8

8

8

8

8

8

Large wheel

4

4

4

4

4

4

4

Battery

2

2

2

2

2

2

2

Platform

1

1

1

1

1

1

1

Total weight in kg

159

185

227

253

279

305

330

Alulift M

PRP height

2m

3m

4m

5m

6m

7m

8m

9m

10m

11m

12m

Component name

Number of components (pcs)

Red structure frame

2

3

4

5

6

7

8

9

10

11

12

Green structure frame

2

3

4

5

6

7

8

9

10

11

12

Diagonal braces

4

6

8

10

12

14

16

18

20

22

24

Horizontal braces

2

2

2

2

2

2

2

2

2

2

2

Horizontal handrail

1

1

1

1

1

1

1

1

1

1

1

Handrail with access gate

1

1

1

1

1

1

1

1

1

1

1

Side handrail

2

2

2

2

2

2

2

2

2

2

2

Toe-board

3

3

3

3

3

3

3

3

3

3

3

Stabilizer

-

-

4

4

4

4

4

4

4

4

4

Small wheel

4

4

4

4

4

4

4

4

4

4

4

Large wheel

4

4

4

4

4

4

4

4

4

4

4

Battery

2

2

2

2

2

2

2

2

2

2

2

Platform

1

1

1

1

1

1

1

1

1

1

1

Total weight in kg

192

218

262

292

315

342

368

395

420

448

475

Alulift XL

PRP height

2

m

3

m

4

m

5

m

6

m

7

m

8

m

9

m

10m

11m

12m

Component name

Number of components (pcs)

Red structure frame

2

3

4

5

6

7

8

9

10

11

12

Green structure frame

2

3

4

5

6

7

8

9

10

11

12

Diagonal braces

4

6

8

10

12

14

16

18

20

22

24

Horizontal braces

2

2

2

2

2

2

2

2

2

2

2

Horizontal handrail

1

1

1

1

1

1

1

1

1

1

1

Handrail with access gate

1

1

1

1

1

1

1

1

1

1

1

Side handrail

2

2

2

2

2

2

2

2

2

2

2

Toe-board

3

3

3

3

3

3

3

3

3

3

3

Stabilizer

-

-

4

4

4

4

4

4

4

4

4

Small wheel

4

4

4

4

4

4

4

4

4

4

4

Large wheel

4

4

4

4

4

4

4

4

4

4

4

Battery

2

2

2

2

2

2

2

2

2

2

2

Platform

1

1

1

1

1

1

1

1

1

1

1

Total weight in kg

211

240

287

316

346

376

405

435

464

495

524

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 15

Drawing 1 Main PRP components

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 16

4. DESCRIPTION OF THE DRIVE SYSTEM CONSTRUCTION, OPERATION AND ADJUSTMENT

4.1 Drive Unit

The drive system in the PRP type Alulift is an electric motor with 24 V, 600 W and 3000 rpm

speed. It is permanently attached to the CM063 type worm gear of 1 to 100 ratio. The worm

gear output rotational speed is 30 rpm. Actuating force is 114 Nm. A drive shaft φ 25 is

mounted on the worm gear, by which the device driving force is transferred to two extreme

ends of the shaft, where gears are mounted. The gears are splined to the gear rack located in the

vertical structure of the device. Upon starting the drive, the drive shaft is moved by the worm

gear. The rotary motion of the shaft makes the gear rotate, which enables vertical movement of

the platform.

4.2 Service brake

The service brake system is composed of:

The INTORQ BFK457-08 COMPAKT type brake of rated voltage 24V, rated power 25 watt

and nominal braking torque 12 Nm.

CM 050 transmission of 1 to 10 ratio

The service brake has nominal braking torque of 120 Nm, which is sufficient to brake and

maintain a work platform with safe working load of 250 kg. The service brake is an

electromagnetic brake which automatically starts the braking process at the time of control

circuit interruption - power supply loss.

The braking process is carried out using springs pressing the brake pads on the discs. Brake

release occurs at the time voltage is supplied to the solenoid coil.

4.3 Emergency Brake - Emergency Gripper

The emergency brake is made up of two independent grippers which make the platform stop if

the lowering speed exceeds 0.5 m/s. The emergency gripper is triggered by centrifugal switches

forming an integral part of the gripper.

If the gripper and the emergency brake are triggered on the platform, it is necessary to replace the

emergency brake system, which gets damaged during the platform stop (the emergency gripper is

a single-use device) which does not allow its further operation; in this case you should notify the

manufacturer or an authorized service point to have the grippers replaced.

Note - the gripper can be right-side and left-side.

4.4 Control Pendant

Mobile Access Platform type Alulift is able to move vertically up and down. In order to start the

drive which makes the platform move, the control pendant is used. There are three control buttons

on the control pendant. The emergency stop button is a master control button that is used to

disconnect control in the other two buttons. This button has a built-in control system of

continuous disconnection through key locking. The other two buttons located on the control

pendant are used to make the mobile platform move vertically UP and DOWN. These buttons are

marked by arrows and arranged by logical operation on the control pendant.

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 17

Photo 1: Control pendant

4.5 Audio Alarms.

The advance signal - before starting the platform a 5-second audio alarm is triggered

indicating that the platform is going to be started.

The operation signal - emitted while the platform is moving, which warns of possible

trapping, drawing-in or crushing.

4.6 Wheel Brakes

Wheel brakes are mechanical devices preventing the PRP from uncontrolled movement

during operation or stopping.

4.7 Safety system to prevent platform overloading

The PRP is equipped with a safety devices to protect the drive from overloading due to

platform overloading or blocking during upward movement. The overload protector

protects the drive motor during upward movement, and the redundant protector protects

the circuit current of the drive motor and brake. In the event that the safety system is

activated to prevent platform overloading, move downward, reduce the platform load and

wait 90 sec. until the system makes it possible to move upward.

4.8 Drive operating time meter

The drive operating time meter is located under the platform. The drive operating time

meter records and indicates the number of the PRP drive operating hours. In order to ensure

proper meter functioning you should check its status from time to time (preferably it should

be checked before and after operation).

4.9 Battery charger

The PRP drive is supplied with a set of two batteries. A special device is provided for

charging the PRP drive gel batteries.

To connect the battery to the charger, connect the plug of the charger to the distribution

board A. See the photograph below.

To charge emergency system batteries (see item 6.5.2) connect the plug of the charger to

the distribution board B. See the photograph below.

Photo 2 Distribution boards

A- The main distribution board

B- Emergency lowering device

distribution board

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 18

5. ASSEMBLY AND DISASSEMBLY INSTRUCTIONS

Below is the description of the procedure for assembling and disassembling the "Mobile Access

Platform type Alulift " produced by Lockhard Sp. z o.o.

Assembly, disassembly, operation and maintenance of the PRP may only be performed by properly

trained personnel, who must read and fully understand the following procedures and descriptions

before attempting to assemble or disassemble.

Two persons are required for assembly and disassembly. The area of the PRP assembly and

operation must be protected against unauthorized access by third parties.

Pre-assembly works

Before you begin the PRP assembly, check all the elements and components listed in

Table No. 2, which are necessary for its proper operation,

For assembly, use only undamaged and original manufacturer's parts.

Before commencing the PRP type Alulift assembly, check the surrounding area for safety, e.g. if there

are no electrical installations, ruins, rubble, excavations, mobile cranes, pedestrian traffic, any

vehicle or machine traffic, etc. in the area.

If there is a risk of coming into contact with overhead electrical power lines, these lines should be

shut off.

Electrical power lines which are in the distance of the level of free-swinging extreme cables from the

furthest possible outer edge of the transferred elements at the time of PRP operation, assembly and

disassembly do not require being shut off, with the said distance being not closer than:

2 m for a low voltage line of 400V

5 m for a line of up to 15 kV

10 m for a line of up to 30 kV

15 m for a line of over 30 kV

You should check the ground on which PRP will be installed. The ground must be horizontal and

hardened.

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 19

5.1. Assembly

The structure of the PRP provides for quick assembly without the use of tools.

Stage I - platform assembly

The PRP platform should be placed on the destination assembly location.

Photo 3

First, you must install the required side guardrails on the platform.

Photo 4 Photo 5

Connect side handrails to the horizontal handrail and build the handrail with access gate

Photo 6 Photo 7

Install toe-boards

Operator's Manual No. 1/2015 "Alulift type Mobile Elevating Work Platform"

August 2015 Page 20

Photo 8

Remove the covers protecting the gears and the roller guides of the drive system

Photo 9 Photo 10

Stage II - Load-bearing structure assembly

Put the frames of the load-bearing structure with the roller guides on the appropriate sides of

the mobile platform, in accordance with the markings - colour-coded green and red,

Photo 11 Photo 12

This manual suits for next models

3

Table of contents

Other Lockhard Lifting System manuals