3

Contents

1 Please observe the following ..................................................................................... 5

1.1 Emphasized Sections.................................................................................................... 5

1.2 For Your Safety.............................................................................................................. 6

1.3 Items Supplied............................................................................................................... 7

1.4 Field of Application (Intended Usage)............................................................................ 7

2 Description................................................................................................................... 8

2.1 Theory of Operation....................................................................................................... 8

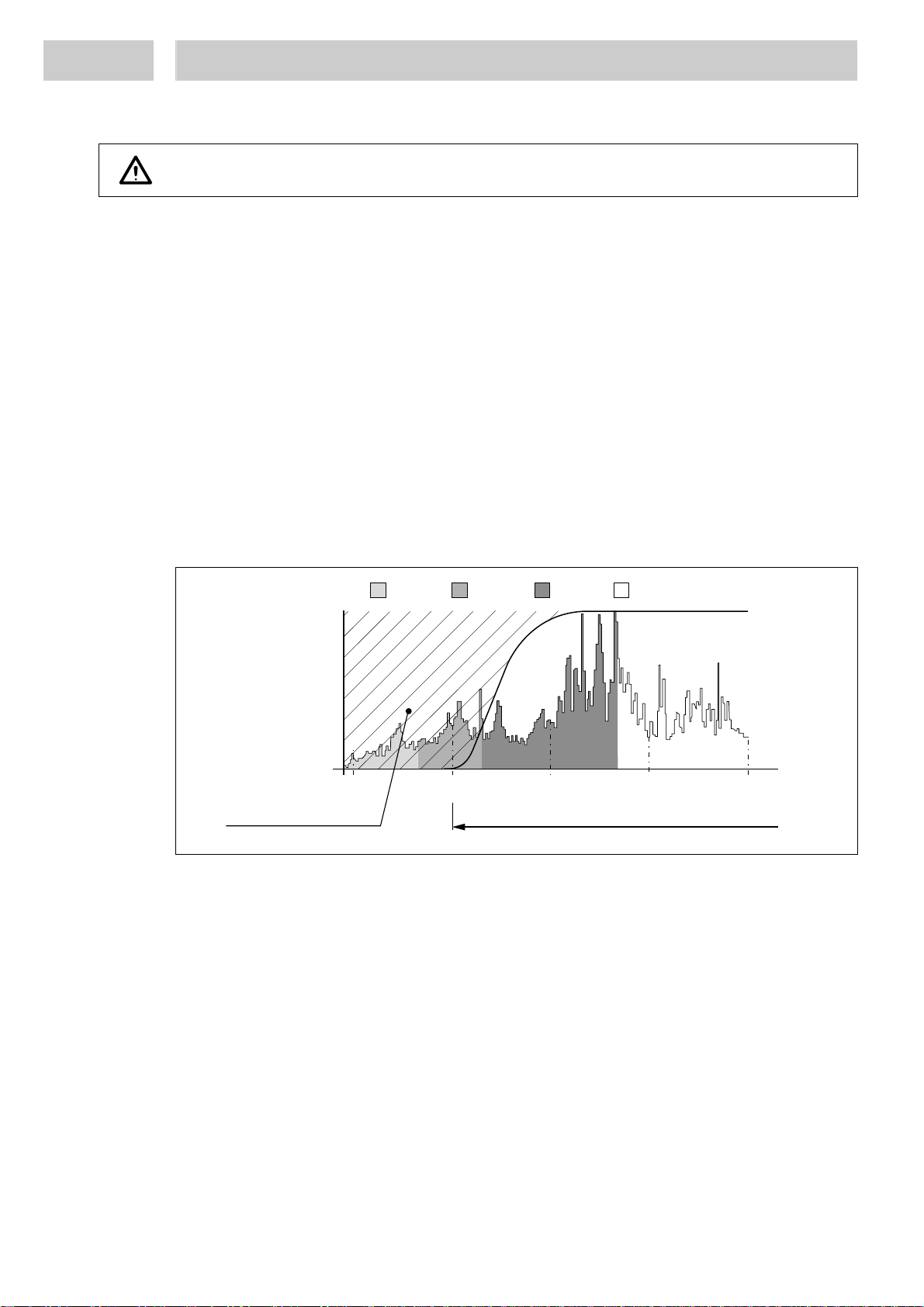

2.2 UV Spectra .................................................................................................................. 10

2.3 Operating Elements and Connections......................................................................... 11

3 Technical Data ........................................................................................................... 13

4 Installation.................................................................................................................. 14

4.1 Environmental and Operating Conditions.................................................................... 14

4.2 Changing UV Bulb – Installation at Initial Start-up....................................................... 14

4.3 Connecting the Unit..................................................................................................... 15

4.4 Startup in Cold Conditions........................................................................................... 15

5 Adjustments for Curing............................................................................................. 16

5.1 Area of Optimum Radiation and Lighting Output......................................................... 16

5.2 Adjustments for Optimum Curing................................................................................. 17

5.3 Shutdown..................................................................................................................... 18

5.4 Returning to Operation ................................................................................................ 18

6 Protective Devices..................................................................................................... 18

6.1 Excess Temperature Protection .................................................................................. 18

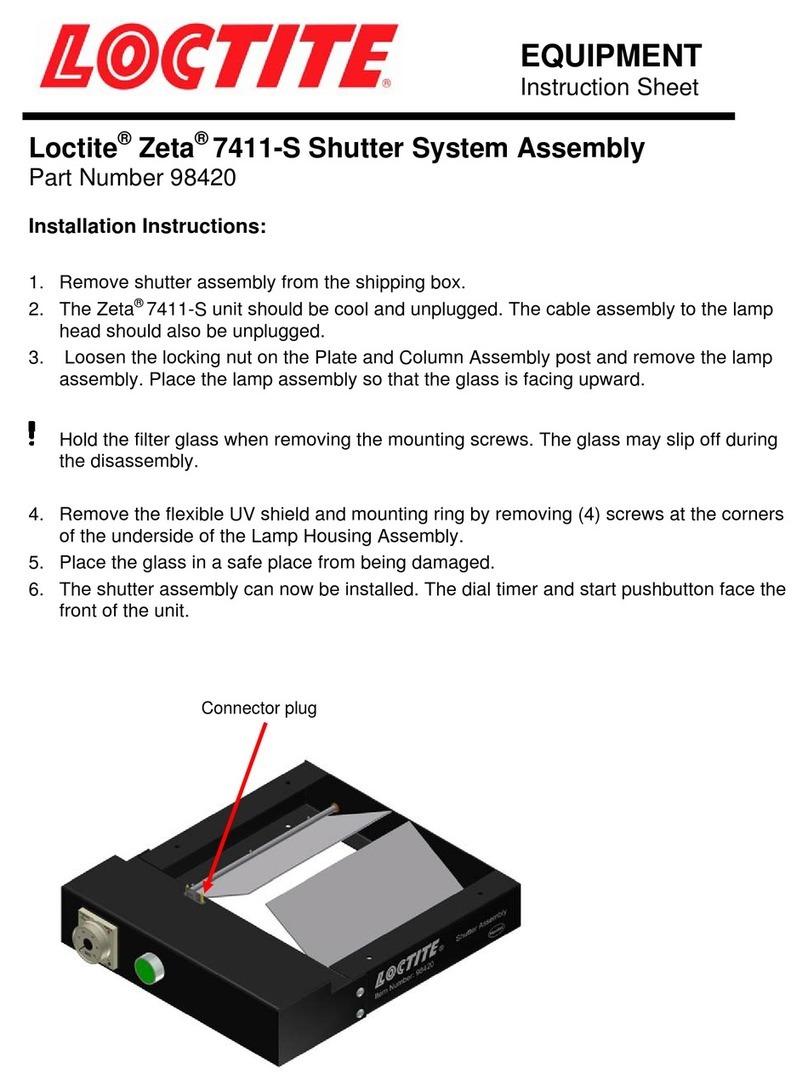

6.2 UV Protection Curtain.................................................................................................. 19

6.3 UV Protection Box ....................................................................................................... 20