(1*/,6+

'HDU&XVWRPHU

7KDQN \RX IRU FKRRVLQJ D /RIUDQV

SURGXFW

/RIUDQVVUOLVDOHDGHUFRPSDQ\LQWKH

SURGXFWLRQ DQG ZRUOGZLGH GLVWULEXWLRQ

RI QDXWLFDO V\VWHPV PDQXIDFWXUHG

DFFRUGLQJ WR WKH PRVW PRGHUQ

WHFKQRORJLHV LQ FRPSOLDQFH ZLWK

LQWHUQDWLRQDO UHJXODWLRQ UHTXLUHPHQWV

DQG WKH PRVW LPSRUWDQW FHUWLI\LQJ

ERGLHV $OO RXU SURGXFWV DUH

PDQXIDFWXUHG ZLWK H[FHOOHQW PDWHULDOV

VXLWHG IRU RSHUDWLRQV LQ PDULQH

HQYLURQPHQWV DQG DUH VXEMHFW WR

FRQWLQXRXV FKHFNV WR LPSURYH WKH

TXDOLWDWLYH OHYHOV DQG PDNH WKHP

ZLWKRXW DQ\ PDQXIDFWXULQJ GHIHFWV

7RJHWKHU ZLWK VXFK UHTXLUHPHQWV

/RIUDQV VUO DQFKRU ZLQGODVVHV DUH D

V\QWKHVLV RI UHOLDELOLW\ DQG HIILFLHQF\

E\ JXDUDQWHHLQJ WKH PD[LPXP

SHUIRUPDQFHV GXULQJ HDFK SKDVH RI

PRRULQJ HYHQ LQ WKH PRVW GLIILFXOW

:LWK D /RIUDQV VUO SURGXFW \HDUV RI

UHOLDEOHRSHUDWLRQVDUHJXDUDQWHHG

/RIUDQVVUOGHFOLQHVDQ\OLDELOLW\IRU

SRVVLEOHLQDFFXUDFLHVGXHWRSULQWHUURUV

LQWKLVPDQXDODQGUHVHUYHVWKHULJKWWR

LQWURGXFHDQ\FKDQJHVGHHPHG

DSSURSULDWH

)RU WKLV UHDVRQ /RIUDQV VUO GRHV QRW

JXDUDQWHH WKH DFFXUDF\ RI WKH PDQXDO

DIWHU WKH GDWH RI LVVXH DQGGHFOLQHV DOO

OLDELOLW\ IRU SRVVLEOH HUURUV DQG

RPLVVLRQV

,1752'8&7,21

3XUSRVHRIWKHPDQXDO

7KLVPDQXDOZLOOVXSSO\LQIRUPDWLRQRQ

VDIHW\DQGFRUUHFWXVHRIWKHSURGXFW

)ROORZ WKHVH ZDUQLQJV FDUHIXOO\ WR

DYRLGSRVVLEOHDFFLGHQWVRUGDPDJHV

'$1*(5

$ ZDUQLQJ VXFK DV WKLV

LQGLFDWHV WKH H[LVWHQFH RI D

VHULRXV ULVN WKDW KDV KLJK

SUREDELOLWLHV WR FDXVH GHDWK RU

D VHULRXV DFFLGHQW LI

DSSURSULDWH SUHFDXWLRQV DUH

QRWWDNHQ

$77(17,21

$ZDUQLQJVXFKDVWKLVLQGLFDWHV

DUHIHUHQFHWRWKHDSSOLFDWLRQRI

VDIHW\SUDFWLFHVRUGUDZVWKH

DWWHQWLRQ RQ XQVDIH EHKDYLRXUV

WKDWPLJKWFDXVHSHUVRQDO

LQMXULHVRUGDPDJHVWRWKHERDW

$VVLVWDQFH

7KH /RIUDQV VUO SURGXFWV DUH EDFNHG

WKURXJKRXW WKH ZRUOG E\ D QHWZRUN RI

DXWKRULVHG GLVWULEXWRUV DQG DVVLVWDQFH

,Q FDVH RI QHHG SOHDVH FRQWDFW \RXU

ORFDO/RIUDQVVUOGLVWULEXWRU

5HFHLSWDQG6WRUDJH

8SRQ UHFHLSWRIWKHSDFNDJHYHULI\WKH

LQWHJULW\ RI SDFNLQJ 6KRXOG LW EH

QHFHVVDU\ WR VWRUH WKH SURGXFW IRU D

SURORQJHG SHULRG NHHS LW LQ D GU\ DQG

SURWHFWHGSODFH

•Anchor windl

asses used in an

LQDSSURSULDWH ZD\ FDQ FDXVH GDPDJHV

WRSHUVRQVDQGRUWKLQJV

• Pay the utmost attention during the

XVHRISRZHUIXOHTXLSPHQW

• Even the most careful use can be a

VRXUFHRIGDPDJHVHYHQVHULRXV

• Lofrans products are supplied

H[FOXVLYHO\ IRU UHFUHDWLRQDO QDXWLFDO

XVH /RIUDQV GHFOLQHV DOO UHVSRQVLELOLW\

IRULPSURSHUXVHV

• Pay the utmost attention so that arms,

OHJV ILQJHUV KDLU DQG FORWKHV GR QRW

JHWHQWDQJOHGLQWKHFKDLQRUJLSV\

• Before operating the capstans, make

VXUH WKDW WKHUH DUH QR SHUVRQV LQ ZDWHU

LQWKHYLFLQLW\

•• hen the capstan is not used, the

• The anchor windlass must never be

XVHG DV PRRULQJ SRLQW 7KH ORDG PXVW

DOZD\V EH KHOG E\ D VSHFLILF OHDW RU

VROLGSRLQW

• The capstan must not be used for

IXQFWLRQV RWKHU WKDQ SD\LQJ RXW RU

ZHLJKLQJWKHDQFKRU

• The chain must never be used on the

ZDUSLQJGUXP

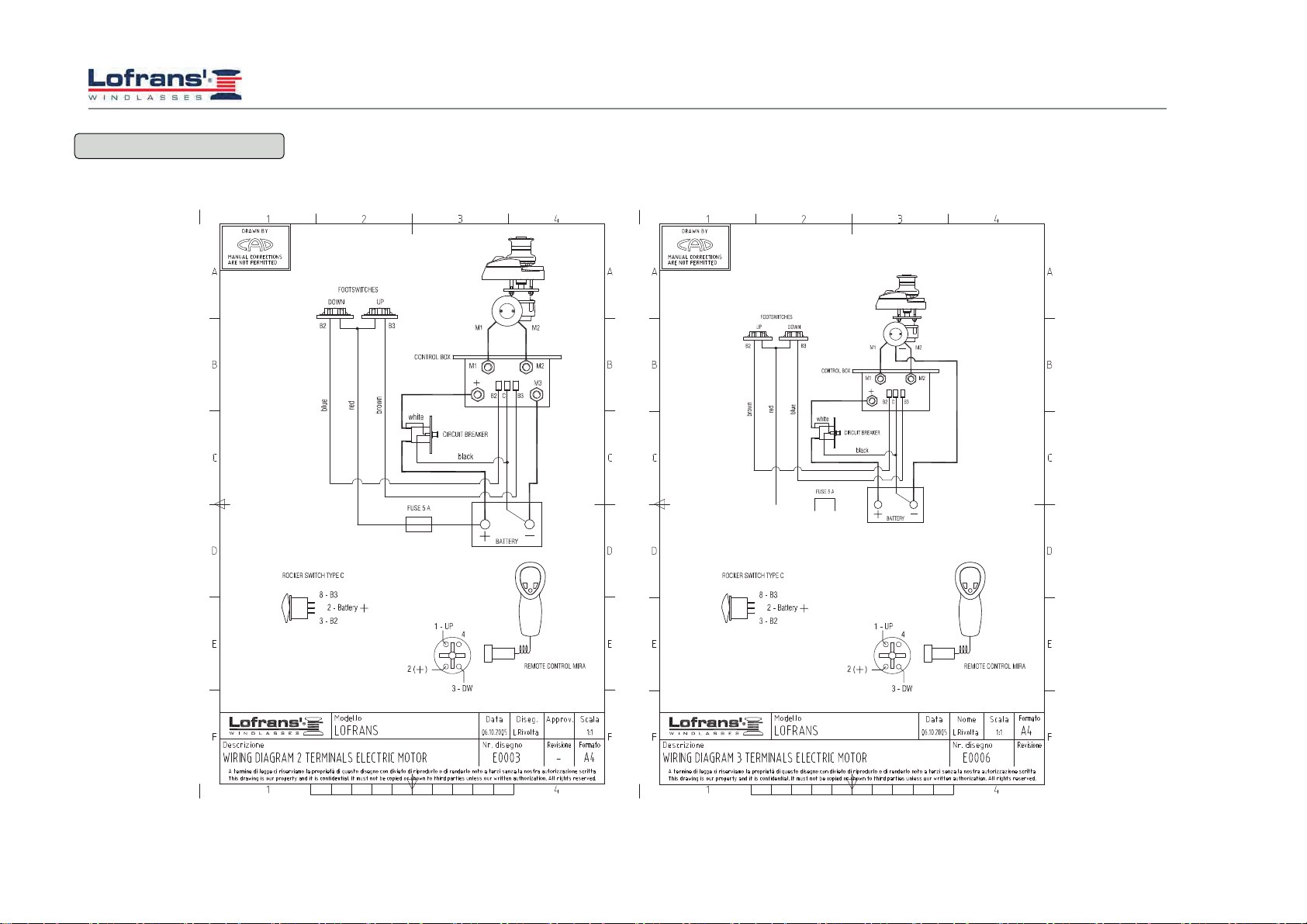

• The system must always be protected

E\DVXLWDEOHFLUFXLWEUHDNHU

WKHFLUFXLWEUHDNHUZKHQWKHDQFKRU

ZLQGODVVLVQRWLQXVH

• Disconnect always the circuit through

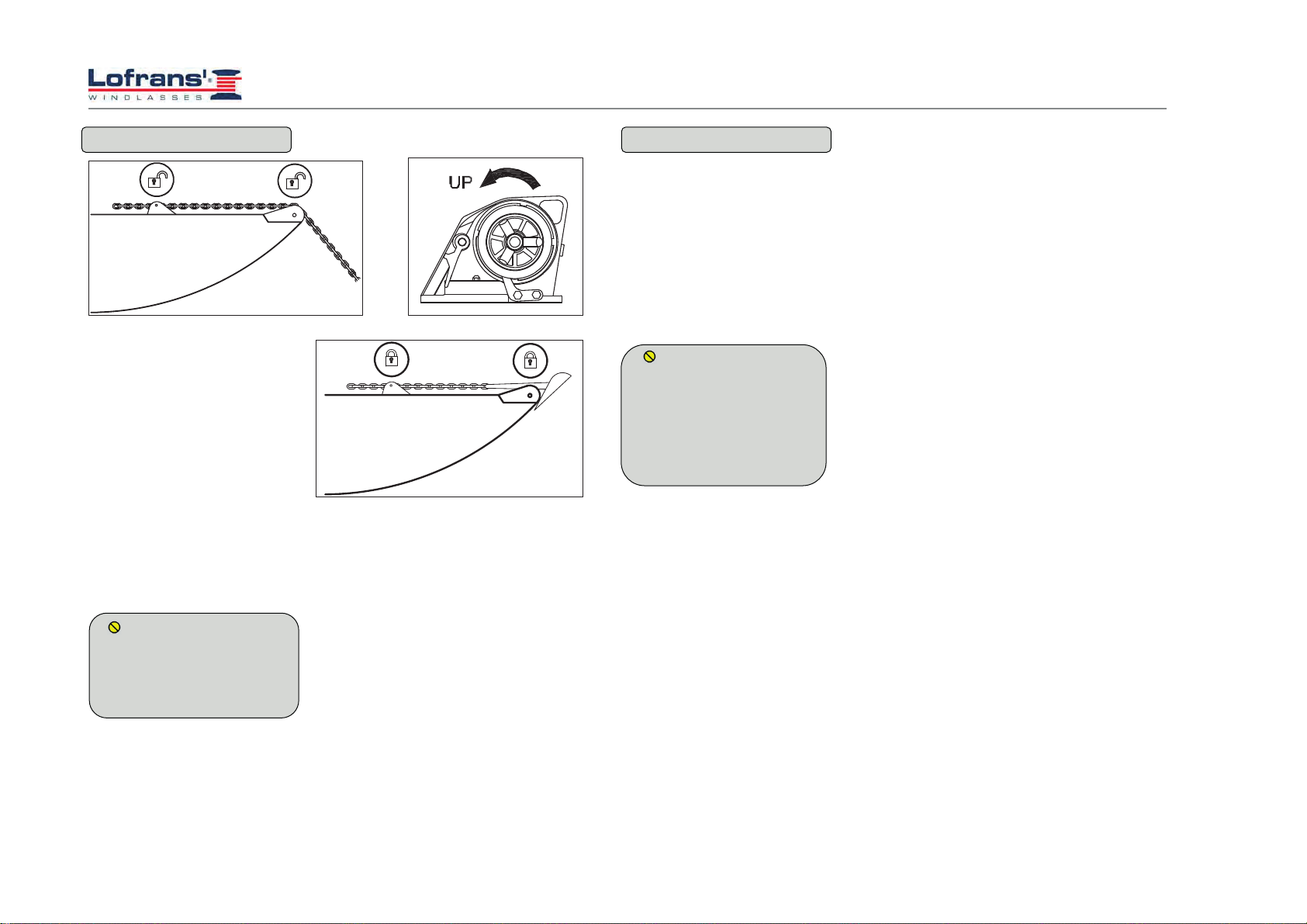

6$)(7<,1)250$7,21

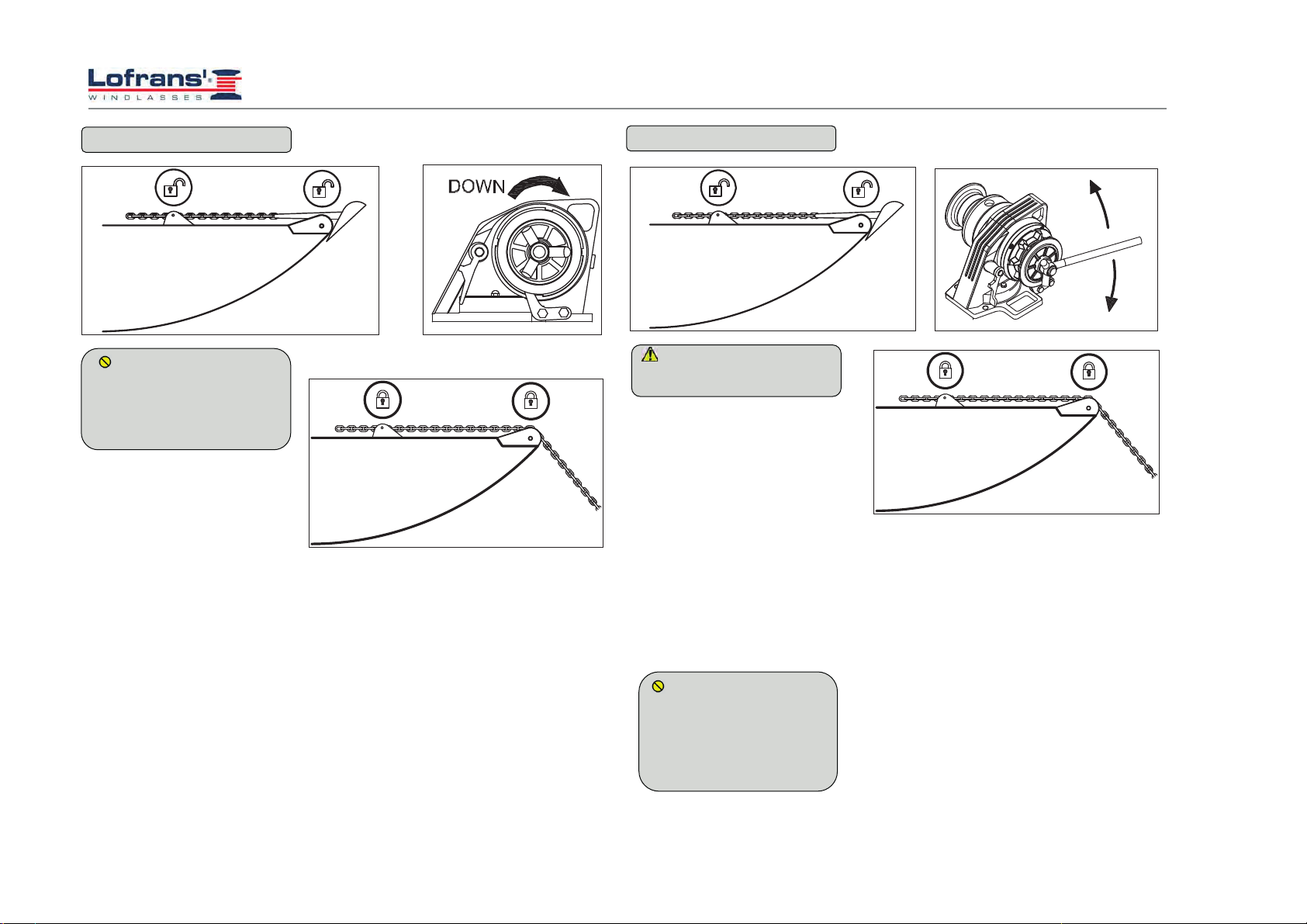

6DIHW\ VWDQGDUGV DQG FHUWLI\LQJ ERGLHV

UHTXLUH SHUHPSWRULO\ WKDW GXULQJ WKH

VWDQGLQJRIWKHDQFKRUWKHORDGPXVWEH

KHOG E\ D FKDLQ VWRSSHU RU D KLJK

UHVLVWDQFHIL[LQJSRLQW

7KHXVHULVUHVSRQVLEOHIRUJXDUDQWHHLQJ

WKDW GXULQJ QDYLJDWLRQ WKH DQFKRU LV

SURSHUO\ VWRZHG DQG IL[HG 7KLV

SUHFDXWLRQ LVPRUH LPSRUWDQW ZKHQ WKH

QDYLJDWLRQ VSHHG LV KLJKHU DQG VHD

FRQGLWLRQVDUHZRUVH,QGHHGDQDQFKRU

SDLG RXW E\ PLVWDNH GXULQJ QDYLJDWLRQ

FDQ KDYH YHU\ VHULRXV HIIHFWV

&RQVLGHULQJLWVSRVLWLRQDQGQRWDOZD\V

IUHTXHQW XVH WKH DQFKRU ZLQGODVV LV

SDUWLFXODUO\ H[SRVHG WR R[LGDWLRQ DQG

FRUURVLRQULVNWKHUHIRUHLWLVQHFHVVDU\

WR DUUDQJH D FRQVWDQW LQVSHFWLRQ RI LWV

SDUWVDQGDGXHPDLQWHQDQFH

0DNHVXUHWRKDYHUHDGDQGXQGHUVWRRG

HYHU\ SDUW RI WKLV PDQXDO EHIRUH

SURFHHGLQJ ZLWK LQVWDOODWLRQ DQG XVH

2QO\SHUVRQVZKRNQRZKRZWRRSHUDWH

VKRXOG EH DXWKRULVHG WR XVH WKH DQFKRU

ZLQGODVV6KRXOGWKHUHEHGRXEWVRQLWV

LQVWDOODWLRQ RU XVH UHIHU DOZD\V WR D

VNLOOHGFRQVXOWDQW

6$)(7<,1)250$7,21

DQFKRUPXVWDOZD\VEHIL[HGWRDVROLG

SRLQWLQRUGHUWRDYRLGGDPDJHV

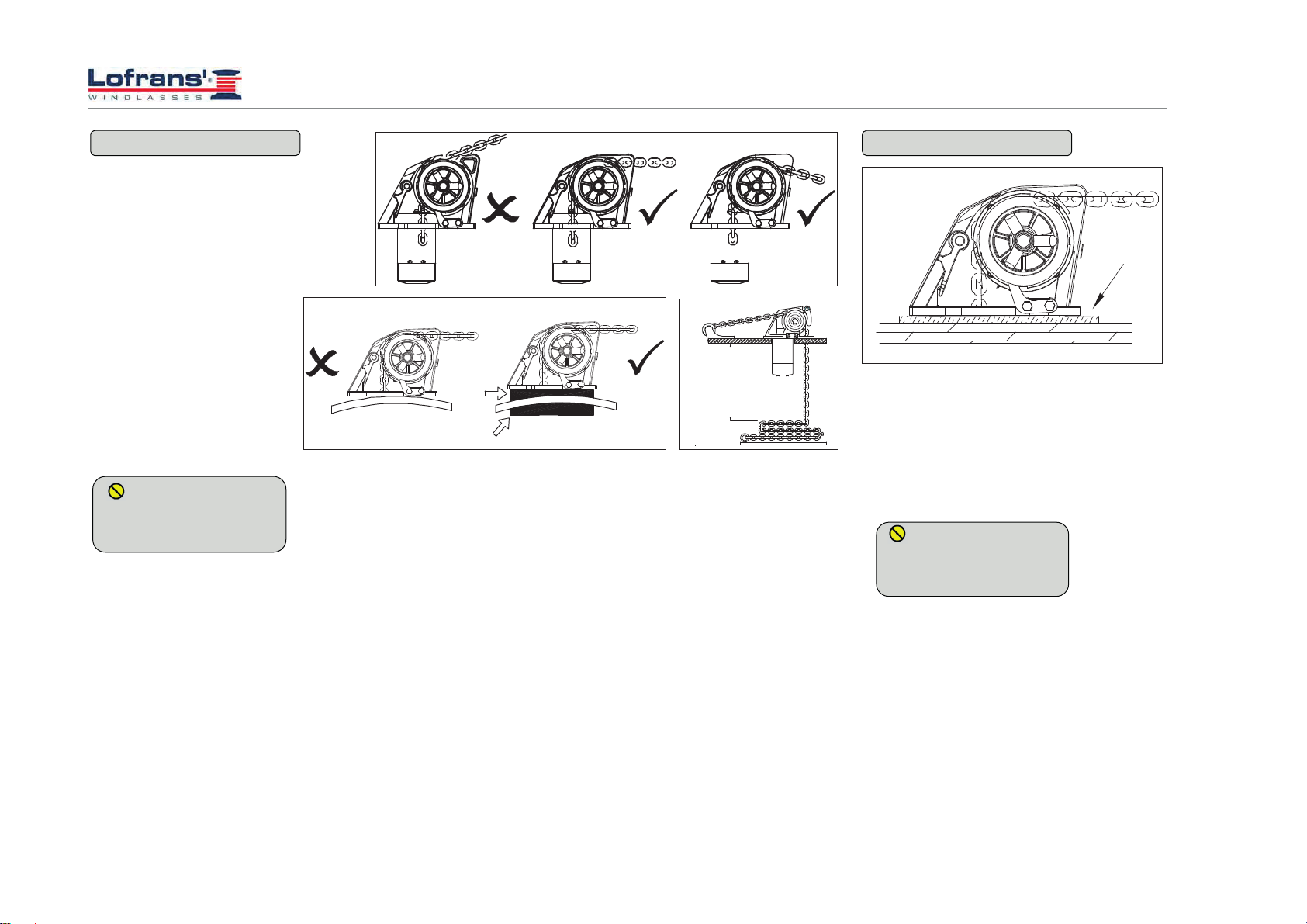

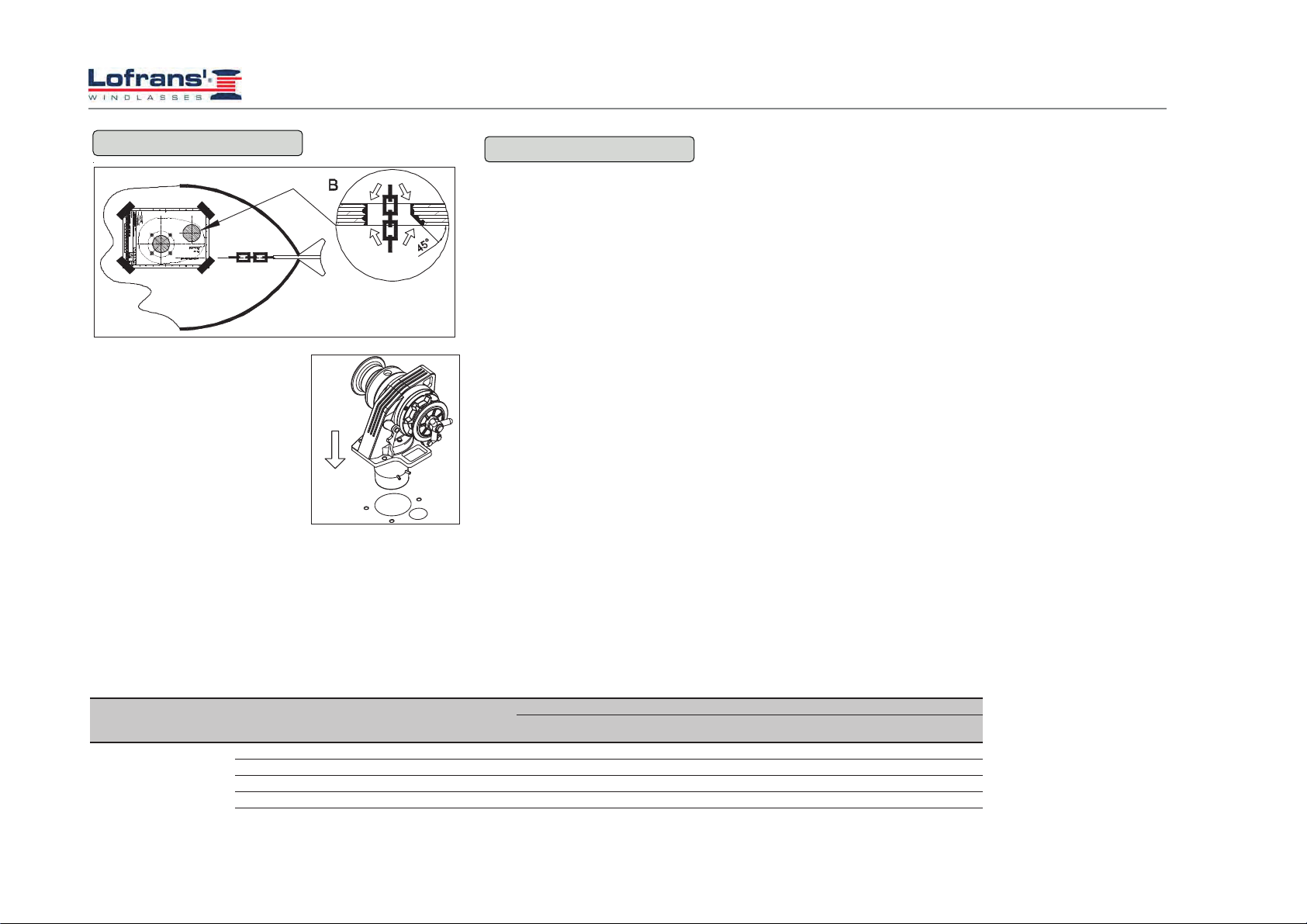

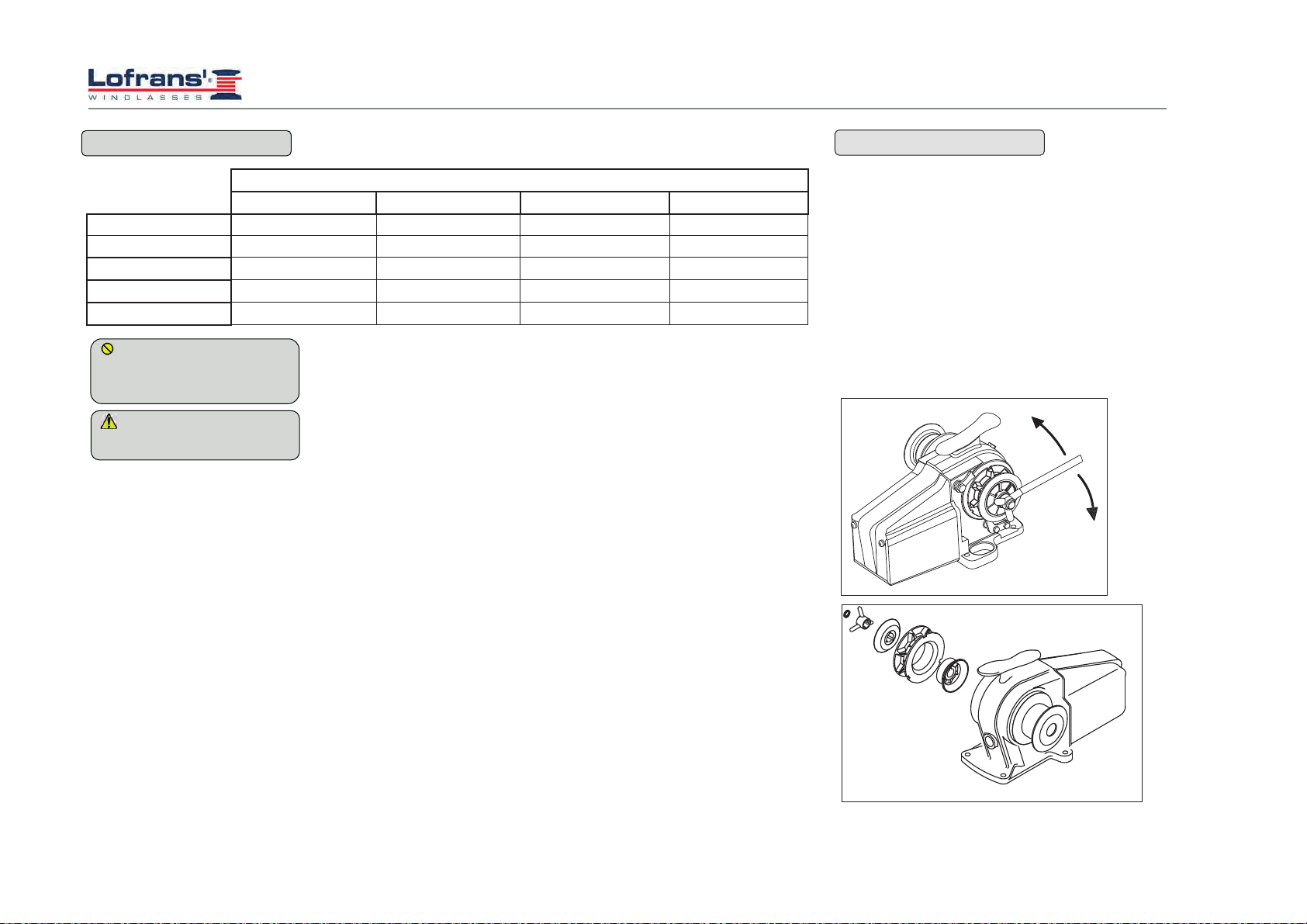

,167$//$7,21

&RQWHQWVRIWKHSDFNDJH

In addition to the present manual, the

package contains:

- Anchor windlass complete with motor

reducer

- Remote control switch/remote control

reverser box

- Drilling template

- Handle

- Screws

(TXLSPHQWQHFHVVDU\IRU

LQVWDOODWLRQ

- Drill

- 10 mm bit for wood and steel

- 10 mm., 13 mm., and 17 mm. hexagon

keys

5HFRPPHQGHGDFFHVVRULHV

Use exclusively original Lofrans

accessories and spare parts, designed

and manufactured to ensure

performances, duration and for keeping

valid the warranty.