Installation Instruction

EnergyLogicIQ Generator

Read the instruction guide carefully before the installing and the first use of the EnergyLogicIQ

Generator

1. Insert GSM/GPRS SIM in the device SIM Slot 1, ensure the SIM has an active data pack and can receive

SMS

OR

2. Connect to a DHCP & internet enabled Ethernet network via the Ethernet port.

3. Power on the device by connecting the 24V DC power adapter provided.

4. Sign In into https://generator.energylogiciq.com using your username or password.

5. If this is the first device, you will automatically guide on the screen through a wizard to provision your

device.

6. If this is your second or subsequent device click on Click on icon in the right top corner.

7. Click on “Manage Devices” menu item

8. Click on “Add Device”. This will open up the configuration wizard. Follow the instructions on the screen

to provision a new device and create associated sites, generators, and tanks.

9. Once you have provisioned the device and it's online on the platform proceed to site for installation

and install the IoT cloud connector. Please refer to the wiring diagram on the next page for details.

Tools Required: Measuring tape, Hexa, screw driver set, multimeter, drill machine, cutter etc.

IMP! These instructions are for 300, 500, 1000 mm range sensors. For sensors with greater range

consult the respective sensor manual.

⚠ WARNING! Empty the diesel tank before carrying out any installation work. Follow the local safety

regulations in your country.

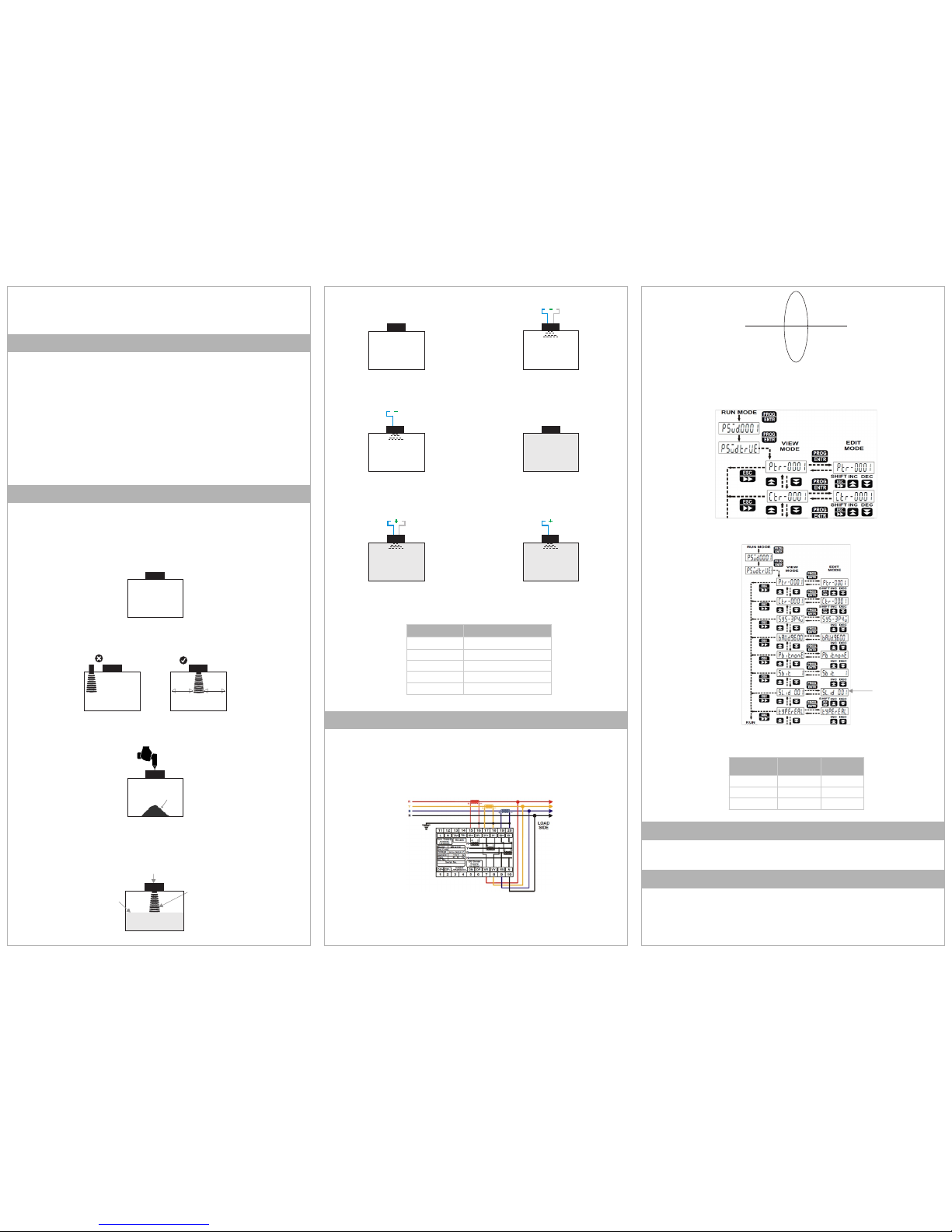

1. Empty and clean the tank of residual oil, sludge, gas etc.

100mm 100mm

a. Mount the sensor on the tank and empty the

fuel tank for calibration at minimum fuel level.

Empty Tank

Ultrasonic

Pulse Beam

Ultrasonic

Transducer

Process Fluid

Correct Installation

b. Calibrate by applying -UB to the Teach-In

input (yellow LED flashes).

Apply -UB to tech-In

until yellow LED flashes

-UB Tech-In

Remove

Iron Filing

6. Power on the sensor and calibrate it.

⚠ Avoid the iron filing from falling

into the tank, you can use a strong

magnet to attract them and prevent

them from falling into the tank.

4. Mount the ultrasonic sensors with a plastic gasket to avoid acoustic energy absorption through the

sensor body.

5. Drill the smaller sensor mounting holes to match sensor gasket holes.

c. Disconnect the Teach-In input from -UB to

save the min level calibration.

Disconnect -UB from Teach-

In for saving calibration

-UB

d. Now fill the tank with diesel to the maximum

level.

Full Tank

Clean Tank

Step 2: Ultrasonic Fuel Level Sensor Installation

Step 1: IoT Cloud Connector Provisioning (Do this before going to site)

f. Disconnect the Teach-In input from +UB to

save the maximum level calibration.

Apply +UB to tech-In

until yellow LED flashes

+UB Tech-In

Disconnect +UB from Teach-

In for saving calibration

+UB Tech-In

e. Calibrate for maximum level by applying +UB

to the Teach-In input (yellow LED flashes).

⚠ WARNING! Qualified Electrician should perform this job only and in accordance with local regulations.

1. Calculate the right CT and PT required based on your load and voltage levels to bring current and

voltage in the input range of the energy meter (6A current and 350 L-N Voltage).

P1 should be always in the current source direction and P2 should always be in the load direction.

3. Check and set up the following energy meter settings. Check out the manual for more details:

Full Tank

Step 3: Energy Meter Installation

2. Select the drilling point on the center of the oil tank surface at least 100 mm away from any

sidewall. Corner installation will cause inner wall reflection and erroneous readings.

3. Use an appropriately sized hole saw, based on the sensor size, to drill the sensor mounting holes.

2. Install the CT and PT as per the diagram below. This configuration is a 4-wire 3 phase (star) system for

any other configurations (like Delta) please refer to the installation manual.

> >

P1 P2

From Source To Load

CT Coil Connection Diagram

a. CT & PT ratio

b. 485 communication and modbus settings