STP-LCR-R Series

1

Table of Contents

Introduction

............................................................................................................................................................... 1

Customer Support

..................................................................................................................................................... 1

Tools Required

............................................................................................................................................................ 1

Components List

:....................................................................................................................................................... 1

Pre Assembly for Model STP-LCR/120

.................................................................................................................... 2

Step 1

:

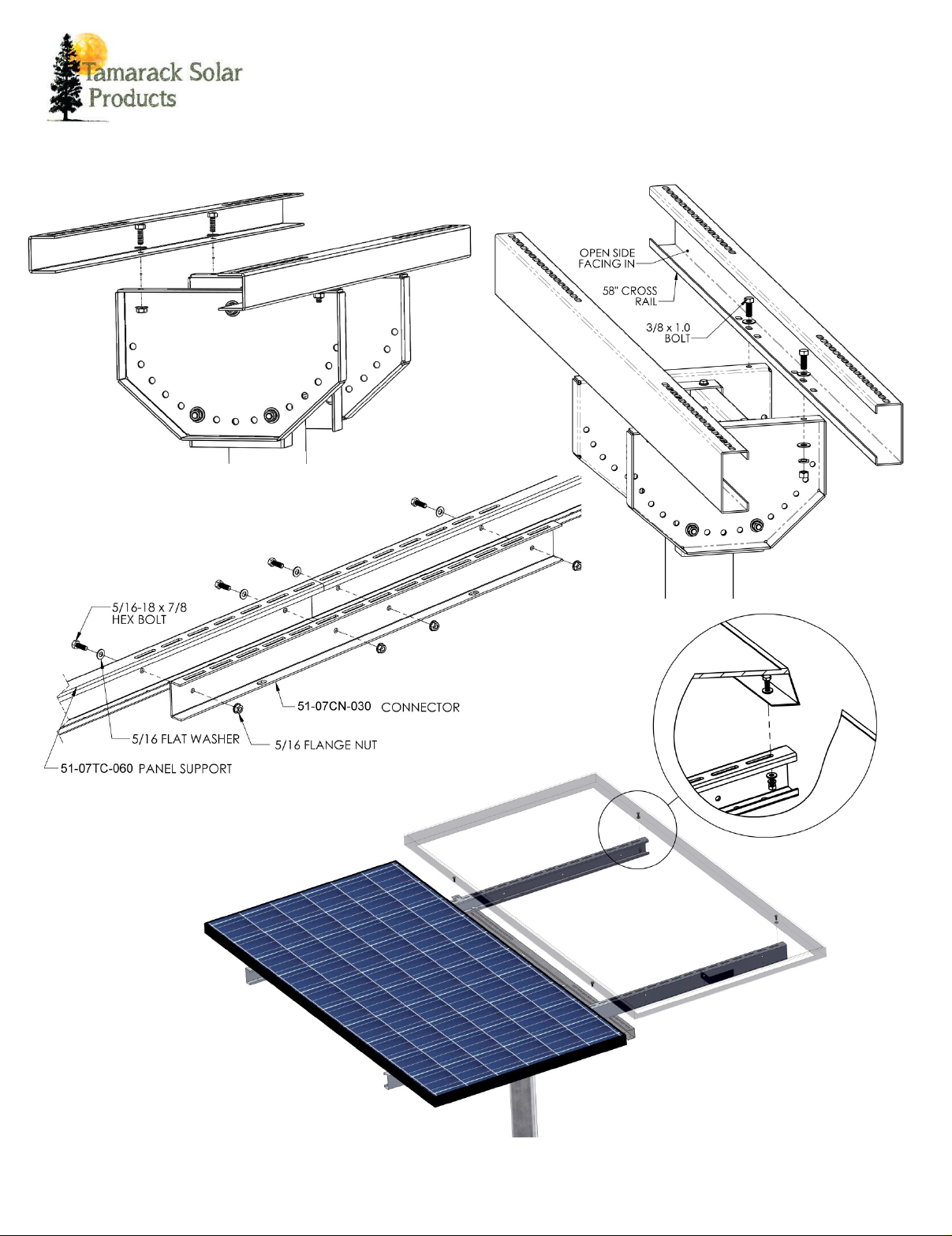

Connecting Panel Support Channels

.......................................................................................................... 3

Step2

:

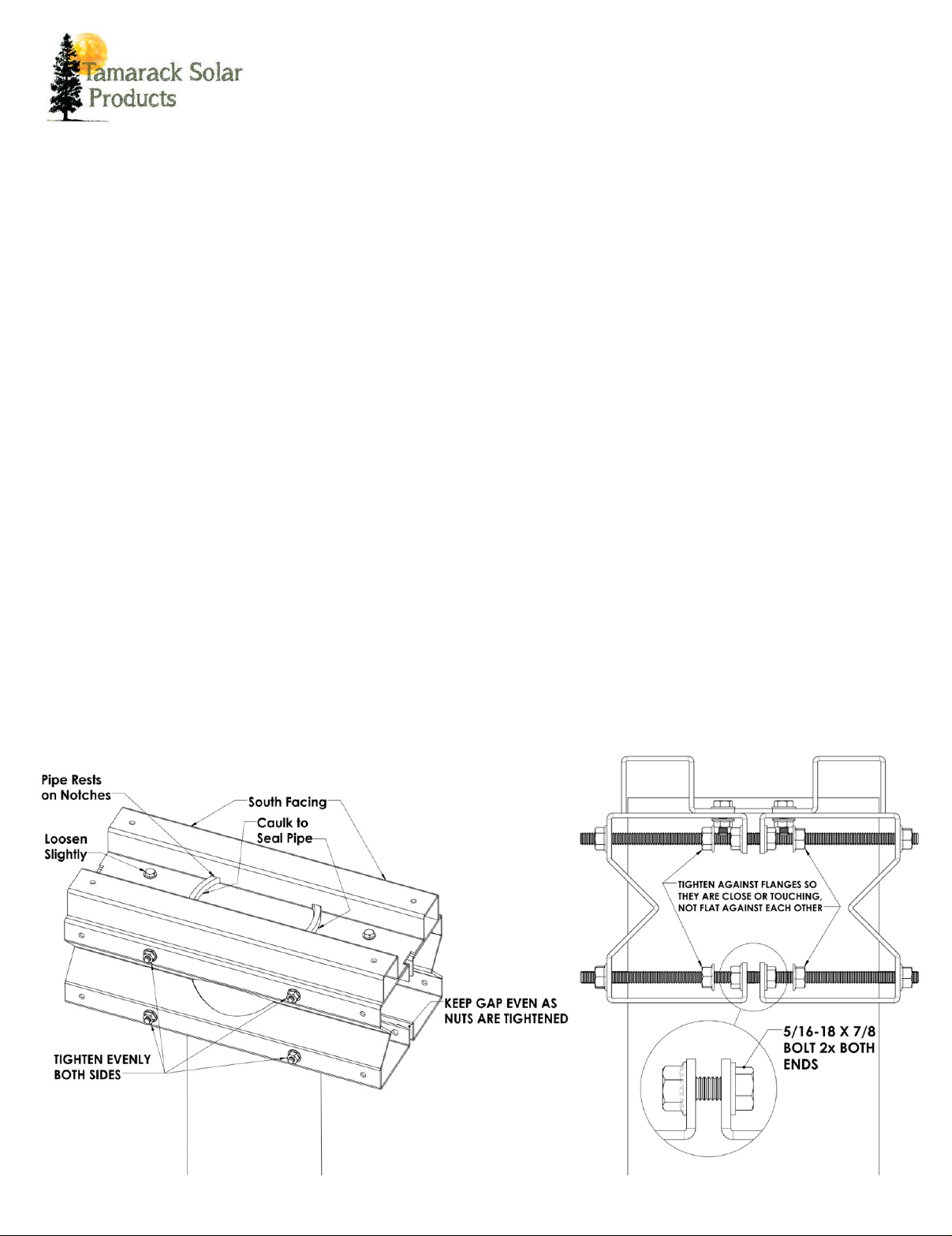

AttachPole Clamp Assembly toPole

........................................................................................................... 3

Step 3: Attach Tilt Plate Mounting Channel

.......................................................................................................... 3

Step 4: Attach Tilt plates

......................................................................................................................................... 3

Step 5: Attach Cross Rails to Tilt Plates.

................................................................................................................. 4

Step 6: Attach Panel Supports to Cross Rails

........................................................................................................ 4

Step 7 Attach Panels to the supports....................................................................................................................... 4

Step 8: Adjust Tilt Angle

........................................................................................................................................... 4

Detailed Diagrams for Assembly

............................................................................................................................. 4

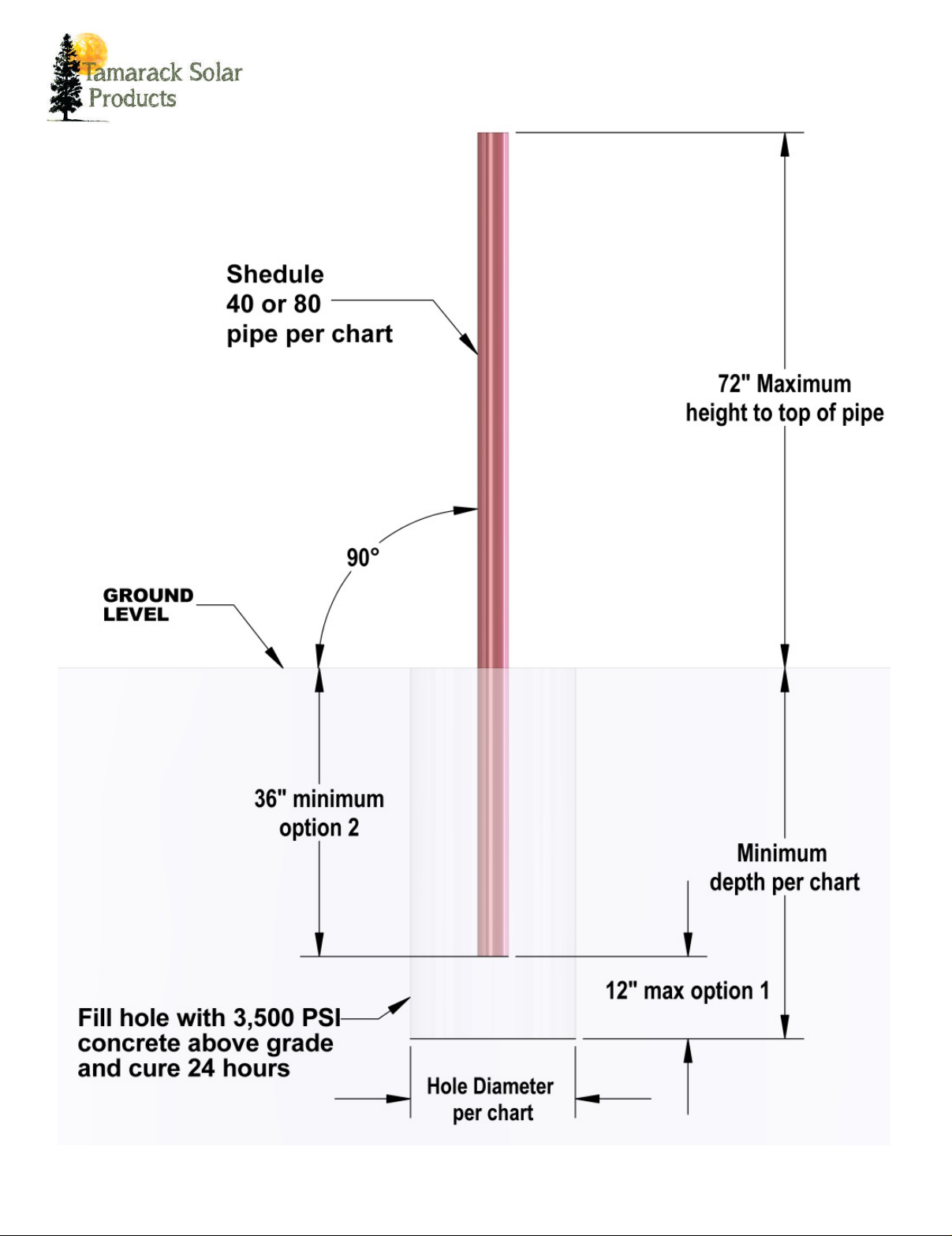

Foundation Hole Guidelines...........................................................................................Error! Bookmark not defined.

InstallerResponsibility

............................................................................................................................................... 9

Warranty Information .............................................................................................................................................. 11

Introduction

The Top of Pole Mount is an extremely sturdy, universal pole mounting solution for small area

solar

photovoltaic (PV) needs. With its user adjustable angle settings (0° to 60° in 10° increments), the Top

of Pole Mount can support installations in a wide

range of locations.

Customer Support

Tamarack Solar makes every effort to ensure your

m

ounting kit is easy to install. If you need

assistance at any point in your installation or have suggestions on how

we can improve your

experience, call customer

support at 1-800-819-7236 or email us at info@tamaracksolar.com

Tools Required

Tools that support the following size Hex heads: Torque values are “dry”, add 15% if using anti-seize lubricant on

Stainless hardware (Recommended). A deep socket or short extension needed for 3/8”, in one location.

1. 3/8”= 240\20 In\Ft Lbs

2. 5/16”= 144\12 In\Ft Lbs

3. 1/4"= 84\7 In\Ft Lbs

Components List

: