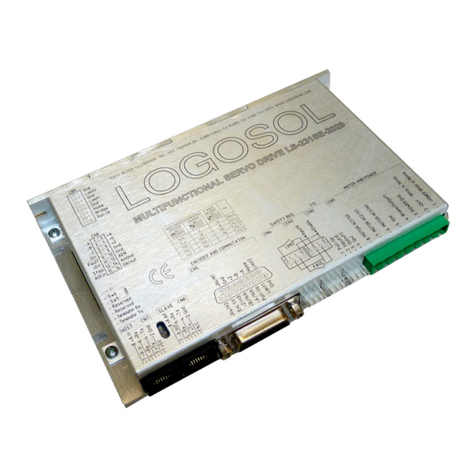

Logosol Absolute Positioning Servo Drive LS-173AP

Doc # 712173008 / Rev. 1.06, 05/09/2002

Logosol, Inc. •• 1155 Tasman Drive •• Sunnyvale, CA 94089 Tel: (408) 744-0974 •• www.logosolinc.com 9

B. Initial Connection to the Host

1. Turn on the power supply.

2. Run the Logosol Distributed Control Network Utility.

3. Choose the proper COM port

4. Click “SERVO” button.

5. Click on “A/D Target” edit box and write your absolute target position.

6. Click “GO” button. The motor should rotate slowly in the proper direction and will stop

when the “A/D Value” becomes equal to “A/D target”. More information about using LDCN

utility is available in LDCN Help.

2. Installation and using Logosol Motion Control Center

A. Installation

1. Insert the Logosol Motion Control Center installation disk into the floppy drive.

2. Select Run from the Windows 95/98/NT Start menu.

3. Type a:\mccsetup and then click OK (a: represents the drive letter).

4. The installation wizard will guide you through the setup process.

B. Initial Connection to the Host

1. Turn on the power supply.

2. Run the Logosol Motion Control Center software.

3. From the Connection menu select Terminal. This will open a terminal window. From the

Target pull-down list select either RS-485-COM1 or RS-485-COM2 corresponding to the

one used to communicate with LS-173AP. Press the Return key to verify that the

connection is established and the command prompt (>) appears on the terminal window.

4. Type INI at the command prompt followed by Return to initialize the controller. It may take

few seconds to complete the process.

5. Type KP A1=20 to set the proportional coefficient, then set the velocity, acceleration and

error limit by the following commands: VEL A1=100, ACC A1=1000 and

MAX A1=8000.

6. Type SER to close the servo loop, then MVP A1=20 to instruct the controller to go to

absolute position 20. Type GO A1 to initiate the motion. The motor should rotate slowly in

the proper direction and will stop when ADC value becomes 20. For more information,

refer to the following MCL*Terminal Interpreter Command Set for executing various motion

commands and parameters settings.

*The information about MCL Terminal Interpreter command set is also available in MCC Help Menu Index

(Advanced Features /Command set for Distributed Servo Drive maintenance).