Copyright © Lojer Oy, 2014 | 05/2014

Contents

1 Lojer Scandia SC330 Operating table............................................................................................................ 4

1.1 Content of the package........................................................................................................................... 4

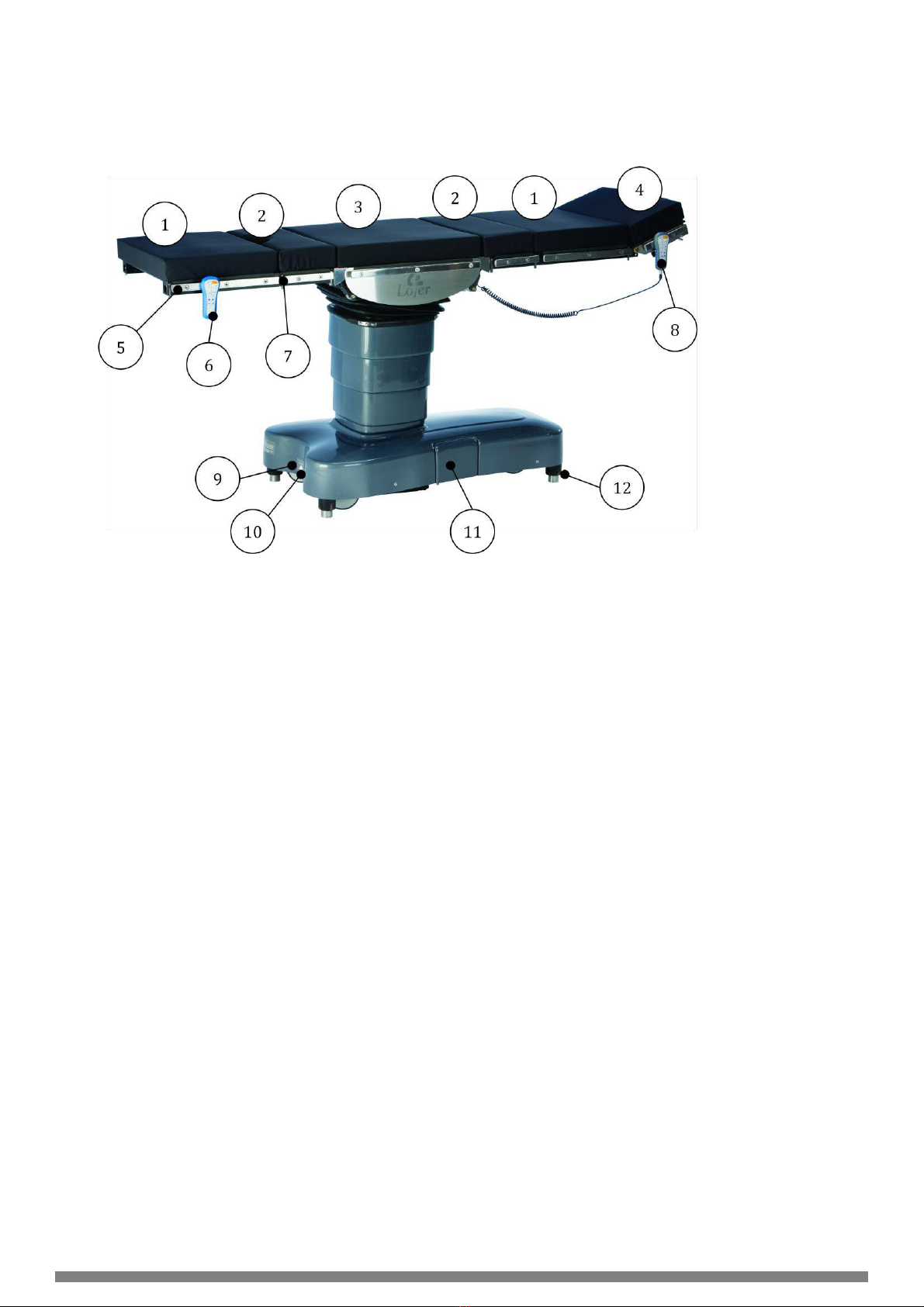

1.2 Description of parts ................................................................................................................................. 5

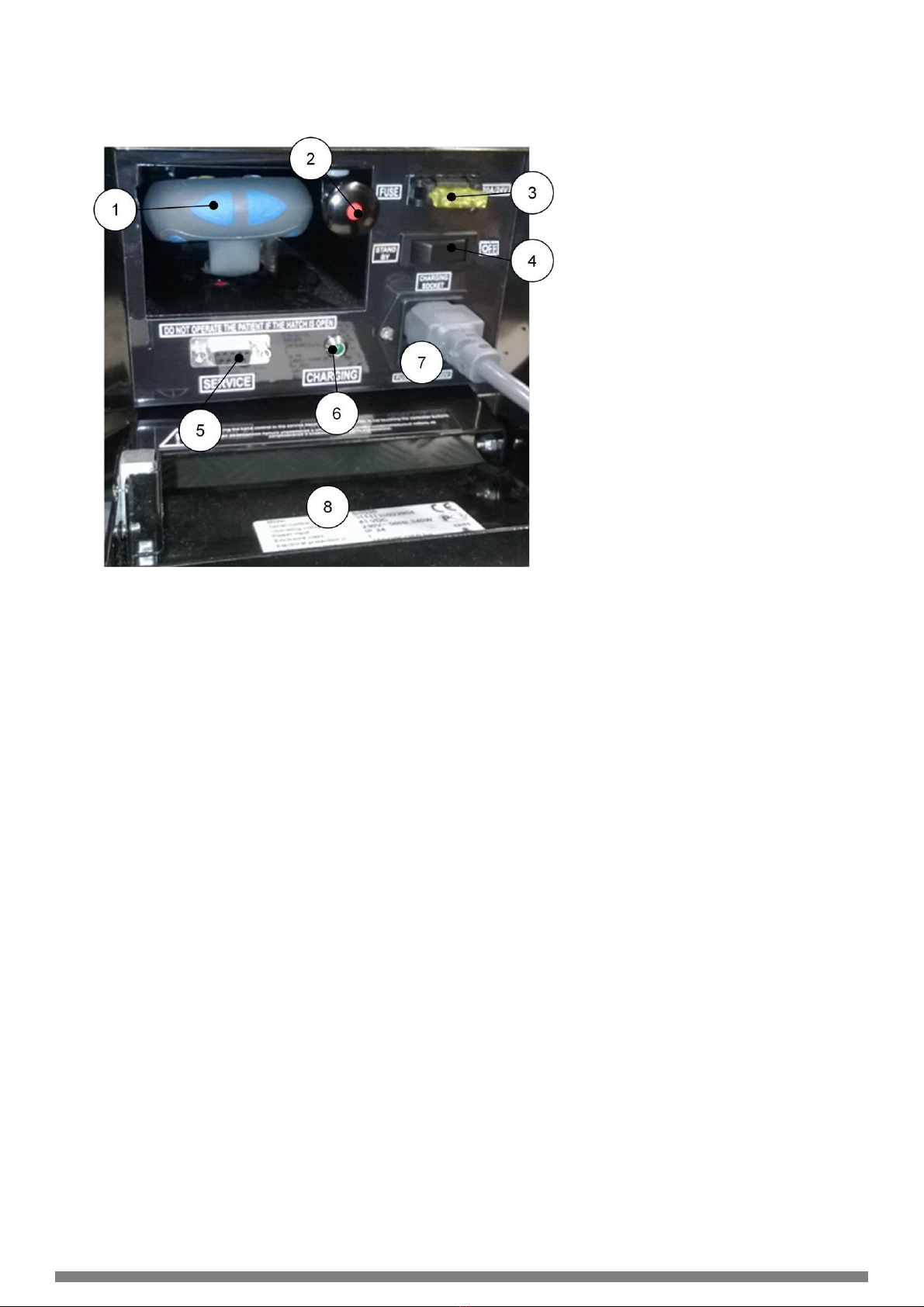

1.3 Controls................................................................................................................................................... 7

1.3.1 Hand control..................................................................................................................................... 7

1.3.2 Wireless (blue) Bluetooth hand control (Option).............................................................................. 8

1.3.3 Foot control (Accessory).................................................................................................................. 8

1.4 Options and accessories......................................................................................................................... 8

1.5 Markings and signs ................................................................................................................................. 9

2 Introduction................................................................................................................................................... 10

2.1 Inspection upon delivery........................................................................................................................ 10

2.2 Before use............................................................................................................................................. 10

3 Using the device ........................................................................................................................................... 12

3.1 Indicator LEDs (hand control) and audible signals ............................................................................... 13

3.2 ON/StandBy (Power ON/StandBy)........................................................................................................ 14

3.3 Working position (Floor locks down)/Transport position (floor locks up) .............................................. 14

3.4 Patient orientation ................................................................................................................................. 15

3.5 Adjustments........................................................................................................................................... 15

3.5.1 Height adjustment.......................................................................................................................... 15

3.5.2 Back section adjustment................................................................................................................ 15

3.5.3 Leg section adjustment.................................................................................................................. 15

3.5.4 Lateral tilt........................................................................................................................................ 15

3.5.5 Trendelenburg/Antitrendelenburg.................................................................................................. 15

3.5.6 Zero-position.................................................................................................................................. 16

3.5.7 Slide (Option)................................................................................................................................. 16

3.5.8 Memory slot.................................................................................................................................... 16

3.5.9 Transporting the operating table.................................................................................................... 16

3.5.10 Directional or Driving wheel (Option)........................................................................................... 17

3.6 Attaching/removing the table top sections ............................................................................................ 17

3.7 Head section adjustment....................................................................................................................... 18

3.8 Charging the batteries........................................................................................................................... 19

4 Table top configurations ............................................................................................................................... 20

4.1 Standard configuration.......................................................................................................................... 20

4.2 Safe working load (SWL) 350 kg........................................................................................................... 20

4.3 Lithotomy configuration, step 1 ............................................................................................................. 21

4.4 Lithotomy configuration, step 2 ............................................................................................................. 21

4.5 Cardiovascular configuration................................................................................................................. 21

4.6 TUR configuration ................................................................................................................................. 22

4.7 Prohibited configurations....................................................................................................................... 22

5 Movement limitations.................................................................................................................................... 23

6 Cleaning and disinfecting ............................................................................................................................. 24