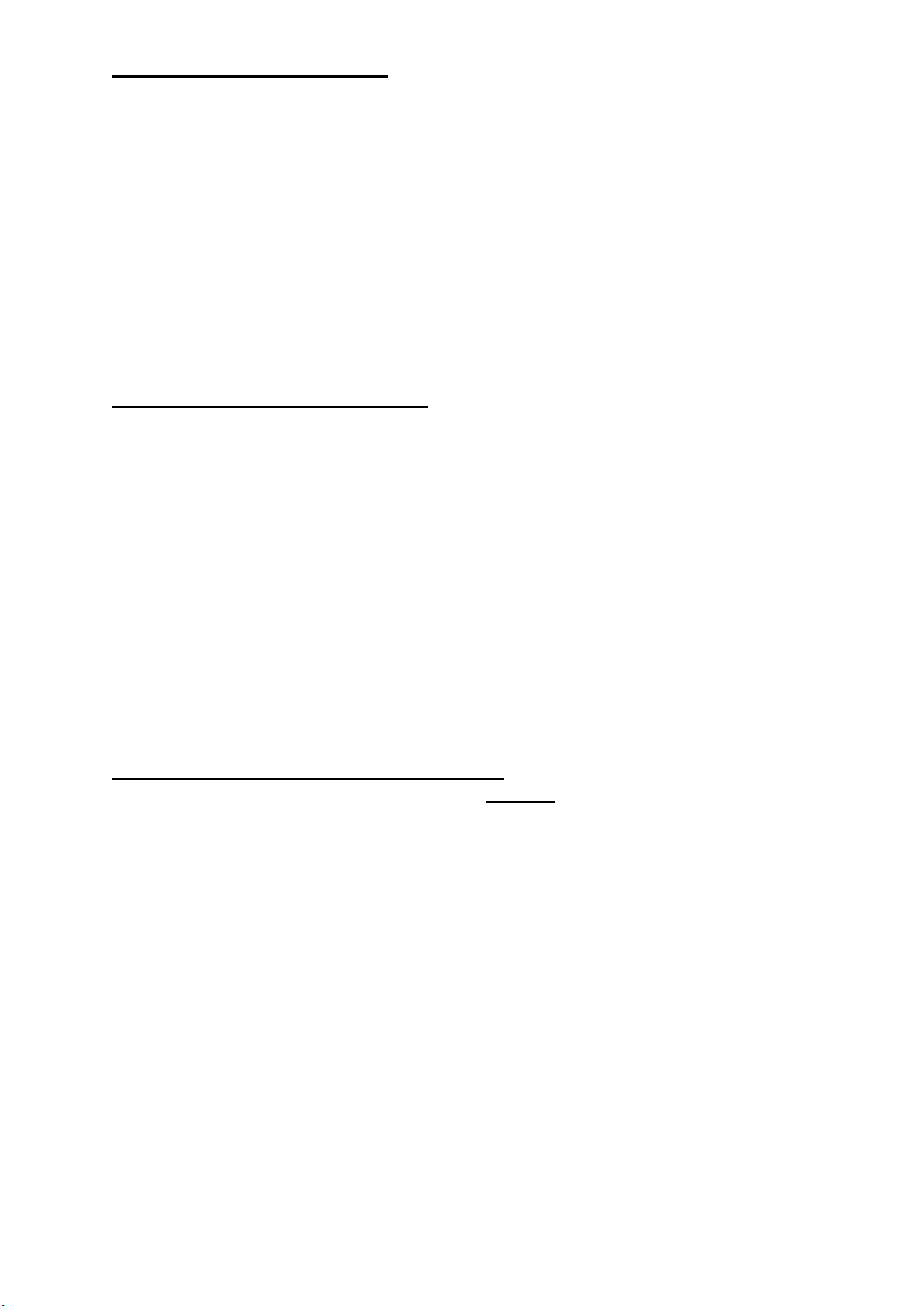

1.1 New Install-Winch not working:

“I have installed the winch and it is not firing up.”

Please ensure all steps below have been taken in order before calling for assistance:

•Ensure all battery cable connections are tight.

•Ensure battery cable has been crimped into motor leads with a swage or other device. If it

has not you will not have a good connection and performance will suffer, you may also have

sporadic issues.

•Ensure solenoid has not been mounted directly to aluminium. If the boat is aluminium,

mount the solenoid to Teflon or other non-conductive material, then mount that to the boat.

•Ensure solenoid is mounted with terminals facing up

•Ensure switching wire connections between rocker switch and solenoid are properly

crimped and tight.

•Ensure a jumper lead is connected from AUX post on the circuit breaker to the middle

spade pin on the left hand side, back of the rocker switch.

1.2 Previous Install-Winch not working:

“Was working fine last season, but now it will not function.”

•Is the solenoid engaging?

Is the solenoid clicking when the up or down switch is engaged?

If the solenoid is making a “brrrrrrr” sound of multiple partial clicks per second, this is a

power supply issue. It means your solenoid is not getting enough power through it to turn

the winch motor. 95% of the time this is due to:

-Bad connections either at the battery, circuit breaker, or solenoid.

-Low Battery Voltage.

-Corroded connections or cable inside the sheath.

Please check all connections, battery voltage, and ensure cable is not corroded inside the

sheath before calling for assistance.

If the solenoid is making a single click sound carry on to next step below.

•Solenoid appears to be engaging, a single click can be heard when the up or down button

is pressed. Note: this still does not guarantee the solenoid is functioning correctly continue

to instructions below.

1.3 Checking Motor, Circuit Breaker, & Solenoid

Note the steps below MUST be completed in order for a correct diagnosis.

•To Check the Winch Motor

-Grab a spare battery and take it to the area where the solenoid is mounted

-Disconnect the leads from the solenoid that go to the winch motor. Note these are on the

two rear posts on the solenoid.

-Touch them to the battery. The winch should fire up in one direction. When reversed it

should fire up in the other direction.

Note: If the motor works in both direction the issue will lie with the power supply, solenoid, or

circuit breaker.

•Checking the solenoid and circuit breaker

-Reconnect the motor leads to the solenoid

-On the back of your circuit breaker there is a battery pos coming in on the left-hand stud

(BAT), and a battery positive going out on the right-hand stud (AUX). Disconnect the lead

from the left-hand stud and add it to the right-hand stud. Ensure the nut is done up tight

connection the leads together.

-Engage the operating switch up and down. If the winch works your issue is with the circuit

breaker. Contact Lone Star for a replacement.

-If it does not work the issue is most likely within your solenoid. Contact Lone Star for

replacement.