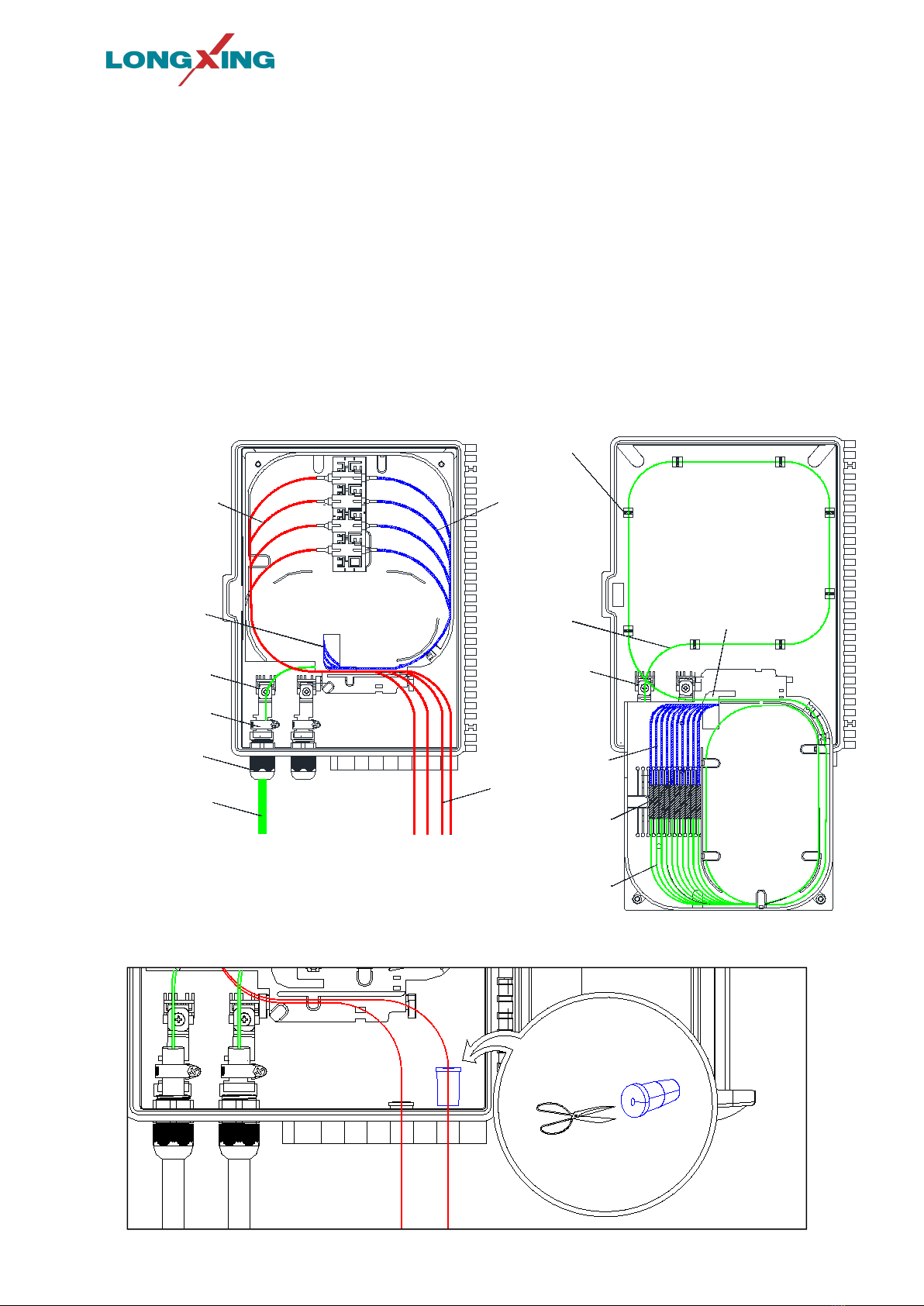

2、Cable fixing

Will stripping cable inserted into the hole good fiber optic cable, through the hose hoops and cable

strengthen core placed to strengthen the core press block press tightly, and then the cable fixed with stainless

steel hose hoops.

3、Optical fiber connection

According to the picture shows to pigtail or splitter (input) welding and welding after the

completion of the layout will be in accordance with pictures of optical fiber, pigtail,heat shrinkable protective

sleeve and splitter is put to the corresponding position and be fixed, take fiber with protective coat and pigtail

end with nylon tie fixed,the heat shrinkable protective sleeve useful rubber cover plate fixed, the splitter used

double-sided tape fixed, finally cover the transparent plate.

4、Pigtail/path cord

Flip in splice tray, with fixed screw will be fixed in the splice tray.

According to the picture shows will pigtail joint insert adapter, and will put the pigtail tray be fixed.

Will do the path cord or terminal box outlet joint through the fiber outlet hole, the path cord (outlet) joint

insert the adapter.

5、Fiber outlet holes sealing

Step1.Cut the Path cord(outlet) ring,will do the path cord (outlet) package closely;

Step2. Will do the path cord(outlet) sealing ring from the corresponding pressed into the slots, to the bottom;

Path cord (outlet)

Cable outlet ports

Strengthen the core

fixed press block

Stainless steel hose

hoops

Fiber

Rubber ring

Pigtail

Pigtail

Tie mounts

Strengthen the

core fixed press

block

Fiber with

protective coat Cable outlet ports

Heat shrinkable

protective sleeve

Fiber

Path cord(outlet)