Contents

• 1.0 Introduction....................................................4

• 2.0 Installation.....................................................6

Unpacking .........................................................6

Mounting ..........................................................6

High Voltage Installation ...............................................8

Low Voltage Installation ..............................................12

• 3.0 Operation ................................................................ 17

Power Indicator.....................................................17

24VDC Power Switch ................................................17

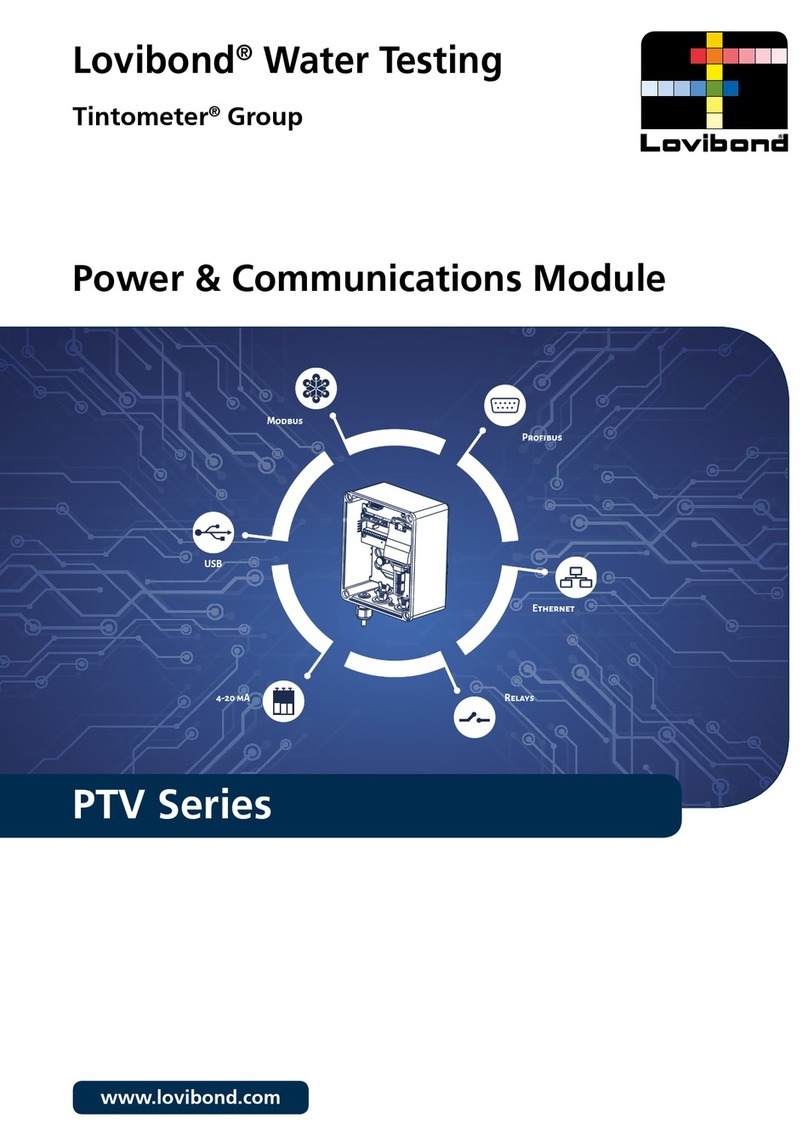

Analog Outputs ....................................................17

Relay Outputs ......................................................17

USB..............................................................17

Optional RS-485 MODBUS ............................................17

• 4.0 Maintenance ............................................................. 18

Fuse Replacement ...................................................18

Cleaning ..........................................................19

• 5.0 Replacement Parts........................................................ 20

• 6.0 Specifications............................................................. 20

• 7.0 Certification .............................................................. 21

FCC Class A Notice ..................................................21

DOC Class A Notice - Avis DOC, Classe A .................................21

• 8.0 Troubleshooting .......................................................... 22

To Preserve, Protect and Improve the Quality of the Environment

Disposal of Electrical Equipment in the European Union

Because of the European Directive 2002/96/EC your electrical instrument must not be disposed of with normal

household waste!

Tintometer GmbH will dispose of your electrical instrument in a professional and environmentally responsible manner.

This service, excluding the cost of transportation is free of charge. This service only applies to electrical instruments

purchased after 13th August 2005. Send your electrical Tintometer instruments for disposal freight prepaid to your

supplier