Dear Customer,

thank you for your trust in this LRP product. By purchasing a LRP Quantum Reverse 2 digital series speed-con-

trol you have chosen a high-performance product full of new design features, such as:

WARNING NOTES

SPECIFICATION

• Affix the speed-control using the supplied doublesided adhesive tape.

• Make sure there are enough cooling slits in the body. This will increase the performance and life of all the

electronic components.

• Position the speed-control where it is protected in the event of a crash.

• Install the speed-control so that you have easy access to the plugs and the SET-button.

• Make sure there is enough clearance (about 3cm) between the speed-control, power cable and antenna

receiver. Avoid any direct contact between power components, the receiver or the antenna. This can cause

interference. If interference occurs, position the components at a different place in the model.

• The aerial should be run vertically up and away from the receiver. Avoid contact with any parts made of

carbon fibre or metal. If the aerial is too long, don’t coil up the excess length. It is better to cut it down to a

length of about 35 cm. See also the instructions supplied with your radio control system.

INSTALLATION TIPS

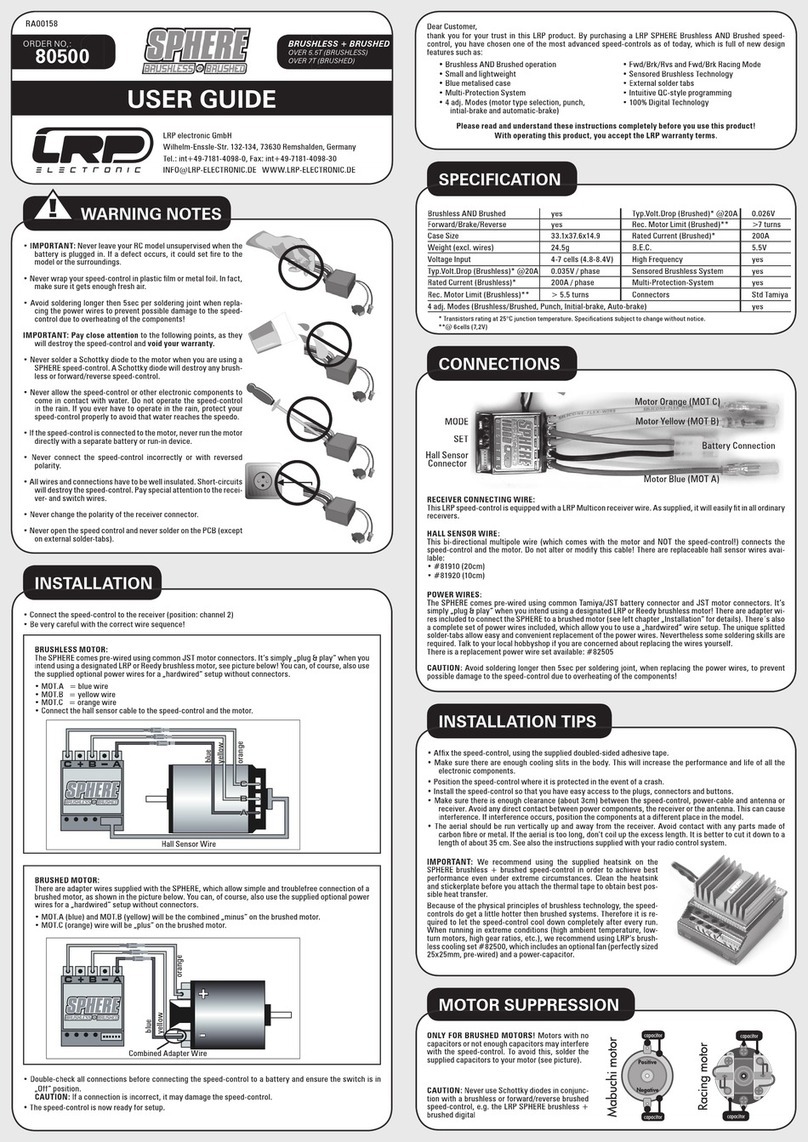

CONNECTIONS

POWER WIRES:

The QR2 series comes pre-wired using common „Tamiya/JST-

style“ battery and motor connectors. It‘s simply „plug & play“

when you intend using a designated motor!

The unique splitted solder-tabs allow easy and convenient re-

placement of the power wires, if you plan using a „hardwired“

wire setup with different connectors (use polarised connecting

systems only!). Nevertheless, some soldering skills are re-

quired. Talk to your local hobbyshop if you are concerned about

replacing the wires yourself.

RECEIVER CONNECTING WIRE:

This LRP speed-control is equipped with a LRP Multicon receiver

wire. As supplied, it will easily fit in all ordinary receivers.

Motors with no capacitors or not enough capacitors may interfere with the speed control. To avoid this, solder

the supplied capacitors to your motor (see picture).

INSTALLATION

• Solder the capacitors to the motor.

• Attach the speed-control to the model.

• Connect the speed-control to the receiver (position: channel 2).

• (QR2 Bullet ONLY!) > Connect the external fet lead, if you are using such a servo.

• Connect the speed-control to the motor. Yellow wire PLUS, Blue wire MINUS.

• Then check all the connections before connectiong the speed-control to a battery.

CAUTION: if a connection is incorrect, it will destroy the speed-control.

• The speed-control is now ready to be set-up (see back page).

• Ultra High Performance using SMD Mosfet‘s

• Small in size, super lightweight

• Real-Time-Braking

• Extended runtime

• Racing mode, reverse switch off

• Plug-in-and-Drive.

* Transistors rating at 25°C junction temperature. Specifications subject to change without notice

** @ 6 cells (7,2V) with single motor.

MOTOR SUPPRESSION

CAUTION: Never use schottky dio-

des in conjunction with a forward/

reverse speed-control such as the

QR2 series speed-controls.

Please read and understand these instructions completely before you use this product!

With operating this product, you accept the LRP warranty terms..

ORDER NO.:

84110 FORWARD + REVERSE

OVER 14 TURNS

RA00123

USER GUIDE

ORDER NO.:

84210

ORDER NO.:

84310

FORWARD + REVERSE

OVER 11 TURNS

FORWARD + REVERSE

OVER 7 TURNS

SPECIAL FEATURES

RACING MODE, switch off reverse

You have the option of switching off reverse for racing. The speed-control then uses the full reverse range as

a brake only.

REVERSE OPERATION

An additional protective function is the 8sec time limit in reverse. If you run your model for longer than 8sec,

the speed-control switches to neutral. Move the throttle stick briefly to neutral, and you can then use reverse

for a further 8sec.

Extensive testing has shown that this limit never gets reached in normal use.

REAL-TIME-BRAKING

In contrast to conventional forward/reverse speed-controls, the QR2 series has a real-time-brake. It works

fully proportional in operation until your vehicle comes to a complete stop. The unit then switches to reverse

without any annoying delays.

MULTI-PROTECTION-SYSTEM, 3-way protection

This unique monitoring software is the perfect protection for the QR2 series speed-controls against short-cir-

cuits (motor), overload and overheating. If your speed-control is ever faced with overload, the motor function

is switched off for protection and the LED will flash red/green to indicate the overload, although the steering

function is maintained. Wait a few minutes to allow the speed-control to cool down.

If the speed-control switches off frequently, either the motor used is too strong, the motor pinion is too big or

you are using full brake too often.

IMPORTANT:

The supplied heatsink improves and safeguards the performance

capacity of your QR2 speed-control when used close to it‘s spe-

cified limits.

Use only the genuine QR2 series heatsink (#81123) and attach

it using the supplied heat-transfering double-sided tape (thin/

clear). Do not use any other tape to attach the heatsink!

• IMPORTANT: Never leave your RC model unsupervised when the

battery is plugged in. If a defect occurs, it could set fire to the model

or the surroundings.

• Never wrap your speed-control in plastic film or metal foil. In fact,

make sure it gets enough fresh air.

• Avoid soldering longer then 5sec per soldering joint when replacing

the power wires to prevent possible damage to the speed-control

due to overheating of the components!

IMPORTANT: Pay close attention to the following points, as they will

destroy the speed-control and void your warranty:

• Never solder a Schottky diode to the motor when you are using a

Quantum Reverse 2 speed-control. A Schottky diode will destroy

any forward/reverse speed-control.

• Never allow the speed-control or other electronic components to

come in contact with water. Do not operate the speed-control in

the rain. If you ever have to operate in the rain, protect your speed-

control properly to avoid that water reaches the speedo.

• Never cut off the original power plug.

• If the speed-control is connected to the motor, never run the motor

directly with a separate battery or run-in device.

• Never connect the speed-control incorrectly or with reversed pola-

rity.

• All wires and connections have to be well insulated. Short-circuits

will destroy the speed-control. Pay special attention to the receiver-

and switch wires.

• Never change the polarity of the receiver connector.

• Never open the speed control and never solder on the PCB (except on

external solder-tabs).

• If you use more than 6 cells in the drive battery, the motor limit rises

by 2 turns for each additional cell.

Product QR2 Super QR2 Pro QR2 Bullet

Order.No. 84110 84210 84310

Forward/Brake/Reverse yes yes yes

Case Size 26.0x26.0x15.7mm 26.0x26.0x15.7mm 26.0x26.0x15.7mm

Weight (excl.wires) 16.5g 17.0g 18.0g

Voltage Input 4-7 cells (4.8-8.4V) 4-7 cells (4.8-8.4V) 4-7 cells (4.8-8.4V)

Typical Voltage Drop@20A* 0.075V 0.060V 0.050V

Rated Current* 50A 65A 75A

Rec. Motor Limit** Over 14 Turns Over 11 Turns Over 7 Turns

B.E.C. 5.0V 5.0V 5.0V

PWM Frequency yes yes yes

Multi-Protection-System yes yes yes

Connectors Standard Tamiya Style Standard Tamiya Style Standard Tamiya Style

Setup Procedure Single button Single button Single button

Switching OFF • Switch speed-control Off

Reverse • Press and hold the SET-button

• Switch speed-control On while SET-button is pressed

Switching ON • Switch speed-control Off

Reverse • Press and hold the SET-button

• Switch speed-control On while SET-button is pressed

Receiver Lead

On/Off Switch

Motor Connectors

(yellow = plus)

(blue = minus)

Tamiya Connector

(Battery)

Fet-Servo lead

(blue), only for

QR2 Bullet

LRP electronic GmbH

Wilhelm-Enssle-Str. 132-134, 73630 Remshalden, Germany

Tel.: int+49-7181-4098-0, Fax: int+49-7181-4098-30

INFO@LRP-ELECTRONIC.DE WWW.LRP-ELECTRONIC.DE

RA00123_QR2_E_071207fv.indd 1RA00123_QR2_E_071207fv.indd 1 07.12.2007 10:08:5507.12.2007 10:08:55